Mechanical behavior analysis on the compression molding process of NdFeB by different molding technology

-

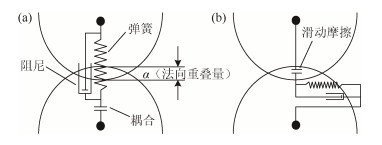

摘要: 为了优化钕铁硼粉末模压成型工艺, 通过离散元软件EDEM建立模压成型过程的离散元模型, 分析不同成型工艺条件(压制速度和摩擦系数)对压坯力学特征(压制力和压坯内应力)的影响, 为优化钕铁硼成型工艺提供理论参考。结果表明: 在成型过程中, 钕铁硼粉末位置状态基本保持与布粉时一致, 只有靠近模冲区域的粉末发生较大位移; 压坯成型时会出现应力松弛现象, 不同速度压制成型对压制力峰值影响不同, 但压制力最终均会收敛至相近的平衡值; 添加润滑剂能改善压坯内部受力状态, 减小压制力, 但是也会减小压坯相对密度; 对于大尺寸压坯成型宜采用双向压制方式。Abstract: The discrete element model of the compression molding process was established by the EDEM discrete element software to optimize the process of NdFeB powders compression molding. The effects of the different molding conditions (pressing speed and friction coefficient) on the mechanical characteristics of the green pressing (compression force and pressing internal stress) were analyzed to provide the reference for the optimizing of the molding parameters. The results show that, the position of NdFeB powders is the same as that at the time of powder distraction during the molding process, but the powders near the die-stamping area displace greatly. The stress relaxation phenomenon occurs at the molding of green pressing. It is worthy noticing that the pressing speed has the different effects on the peak force of compression, but eventually it will converge to a similar stable value. The addition of lubricant can improve the internal stress state of the green pressing, reduce the compression force, and decrease the relative density of the green pressing. For the large-scale green pressing, the two-directional pressing should be adopted.

-

Key words:

- NdFeB /

- compression molding /

- mechanical behavior /

- molding technology

-

表 1 EDEM软件中钕铁硼粉末颗粒参数

Table 1. NdFeB powder particle parameters in EDEM discrete element software

密度/(kg·m-3) 维氏硬度 泊松比,μ 弹性模量,E/MPa 抗压强度/MPa 7500 950 0.24 158 × 103 1100 表 2 304不锈钢材料参数

Table 2. Material parameters of 304 stainless steel

密度/ (kg·m-3) 维氏硬度 泊松比,μ 弹性模量,E/MPa 抗压强度/MPa 7930 — 0.3 194 × 103 — 表 3 材料间接触参数

Table 3. Contact parameters between the materials

接触材料 恢复系数 静摩擦系数 滚动摩擦系数 颗粒-颗粒 0.2 0.545 0.01 颗粒-模具 0.2 0.300 0.01 -

[1] Hu B P. Status and development tendency of rare-earth permanent magnet materials. J Magn Mater Devices, 2014(2): 66 doi: 10.3969/j.issn.1001-3830.2014.02.016胡伯平. 稀土永磁材料的现状与发展趋势. 磁性材料及器件, 2014(2): 66 doi: 10.3969/j.issn.1001-3830.2014.02.016 [2] Liu W Q, Zha S S, Yue M, et al. Research progress of sintered Nd-Fe-B permanent magnets with high coercivity. J Beijing Univ Technol, 2017, 43(10): 1569 doi: 10.11936/bjutxb2017010002刘卫强, 查善顺, 岳明, 等. 高矫顽力烧结钕铁硼永磁研究进展. 北京工业大学学报, 2017, 43(10): 1569 doi: 10.11936/bjutxb2017010002 [3] Zhong M L, Liu W P. Industrial technology situation and development trends of Nd-Fe-B permanent magnetic materials in China. Electron Compon Mater, 2013, 32(10): 6 doi: 10.3969/j.issn.1001-2028.2013.10.002钟明龙, 刘微平. 我国钕铁硼永磁材料产业技术现状与发展趋势. 电子元件与材料, 2013, 32(10): 6 doi: 10.3969/j.issn.1001-2028.2013.10.002 [4] Yan A R, Liu Z, Guo S, et al. Recent research development of rare-earth permanent magnetic materials. Met Funct Mater, 2017, 24(5): 5 https://www.cnki.com.cn/Article/CJFDTOTAL-JSGC201705003.htm闫阿儒, 刘壮, 郭帅, 等. 稀土永磁材料的最新研究进展. 金属功能材料, 2017, 24(5): 5 https://www.cnki.com.cn/Article/CJFDTOTAL-JSGC201705003.htm [5] Hu B P. Current status and prospects of rare earth permanent magnet industry. Rare Earth Inf, 2018, 416(11): 14 https://www.cnki.com.cn/Article/CJFDTOTAL-XTXX201811011.htm胡伯平. 稀土永磁产业现状及展望. 稀土信息, 2018, 416(11): 14 https://www.cnki.com.cn/Article/CJFDTOTAL-XTXX201811011.htm [6] Liu H Z. The latest development of preparation process of sintered Nd-Fe-B permanent magnet. Rare Met Cem Carb, 2012, 40(3): 44 https://www.cnki.com.cn/Article/CJFDTOTAL-XYJY201203012.htm刘海洲. 烧结钕铁硼永磁材料制备工艺的研究进展. 稀有金属与硬质合金, 2012, 40(3): 44 https://www.cnki.com.cn/Article/CJFDTOTAL-XYJY201203012.htm [7] Gan J Y, Wei S Q, Zeng Y Q, et al. Research progress of NdFeB magnetic powders pressing technology. Pop Sci Technol, 2018, 20(7): 46 doi: 10.3969/j.issn.1008-1151.2018.07.013甘家毅, 韦世强, 曾阳庆, 等. 钕铁硼磁性粉末压制工艺的研究进展. 大众科技, 2018, 20(7): 46 doi: 10.3969/j.issn.1008-1151.2018.07.013 [8] Li R S, Tang Y, Xu J Y, et al. Research progress of preparation process of sintered NdFeB permanent magnets. Hot Working Technol, 2019, 48(4): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201904003.htm利荣森, 唐焱, 徐晋勇, 等. 烧结钕铁硼永磁体制备工艺的研究进展. 热加工工艺, 2019, 48(4): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201904003.htm [9] Yan S W, Huang S Y, Hu J H, et al. Development and application of numerical simulation in powder metallurgy manufacturing. Powder Metall Technol, 2017, 35(1): 57 doi: 10.3969/j.issn.1001-3784.2017.01.010颜士伟, 黄尚宇, 胡建华, 等. 数值仿真技术在粉末冶金零件制造中的应用及研究进展. 粉末冶金技术, 2017, 35(1): 57 doi: 10.3969/j.issn.1001-3784.2017.01.010 [10] Wu B, Liu J, Yang Y. The influence of the mold wall friction coefficient on HVC powder based on the finite element simulation analysis. Powder Metall Technol, 2014, 32(6): 442 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201406009.htm吴斌, 刘军, 杨勇. 基于有限元仿真分析高速压实粉末时模壁摩擦因数对压制效果的影响. 粉末冶金技术, 2014, 32(6): 442 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201406009.htm [11] Zhang C, Liu J, Luo X L, et al. Effect of loading speed on pressure distribution in metal powder pressing based on discrete element method. Powder Metall Technol, 2019, 37(2): 98 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201902003.htm张超, 刘军, 罗晓龙, 等. 基于离散元法的金属粉末压制加载速度对压力分布影响. 粉末冶金技术, 2019, 37(2): 98 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201902003.htm [12] Wang D G, Jiao M H, Yu J W, et al. FE simulation of influence of height-diameter ratio on powder metallurgic product properties. China Mech Eng, 2007, 18(20): 2493 doi: 10.3321/j.issn:1004-132x.2007.20.024王德广, 焦明华, 俞建卫, 等. 压坯高径比对粉末冶金制品性能影响的有限元模拟. 中国机械工程, 2007, 18(20): 2493 doi: 10.3321/j.issn:1004-132x.2007.20.024 [13] Wang D G, Wu Y C, Jiao M H, et al. Finite element simulation of influence of different compacting processes on powder metallurgic products properties. China J Mech Eng, 2008, 44(1): 205 doi: 10.3321/j.issn:0577-6686.2008.01.036王德广, 吴玉程, 焦明华, 等. 不同压制工艺对粉末冶金制品性能影响的有限元模拟. 机械工程学报, 2008, 44(1): 205 doi: 10.3321/j.issn:0577-6686.2008.01.036 [14] Wang D G, Zhou R T, Xie T, et al. The mechanical behavior of powder warm compaction process. Mater Mech Eng, 2007, 31(5): 66 doi: 10.3969/j.issn.1000-3738.2007.05.019王德广, 周瑞庭, 解挺, 等. 粉末温压成形过程中的力学行为. 机械工程材料, 2007, 31(5): 66 doi: 10.3969/j.issn.1000-3738.2007.05.019 [15] Wang D G, Wu Y C, Jiao M H, et al. Research progress of friction behavior during powder forming. China J Mech Eng, 2009, 45(5): 12 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200905003.htm王德广, 吴玉程, 焦明华, 等. 粉末成形过程中摩擦行为研究进展. 机械工程学报, 2009, 45(5): 12 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200905003.htm [16] Jiang S Q, Tan Y Q, Zou X. Discrete element simulation on optimization of processing parameters in dry-pressing molding of ceramic powders. Mater Mech Eng, 2011, 35(9): 104 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201109030.htm姜胜强, 谭援强, 邹霞. 陶瓷材料干压成型工艺参数优化的离散元模拟. 机械工程材料, 2011, 35(9): 104 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201109030.htm [17] Wang W T. Numerical Simulation of Iron Powder Compression Forming Based on Discrete Element Method[Dissertation]. Taiyuan: North University of China, 2014王文涛. 基于离散元法的铁粉模压成形数值仿真研究[学位论文]. 太原: 中北大学, 2014 [18] Ouyang H. Forming Process Simulation Analysis and Research of Ceramic Tile Pressing Based on EDEM[Dissertation]. Guangzhou: Guangdong University of Technology, 2015欧阳虎. 基于EDEM的瓷砖粉料压制成型过程仿真分析与研究[学位论文]. 广州: 广东工业大学, 2015 [19] Liu B, Ma L, Liu Q Z, et al. Effect of vibration performance on packing density of NdFeB magnet powder based on EDEM. China Powder Sci Technol, 2017, 23(4): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS201704016.htm刘波, 马麟, 刘邱祖, 等. 基于EDEM的振动特性对钕铁硼永磁粉体填充密度的影响. 中国粉体技术, 2017, 23(4): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS201704016.htm [20] Hu B P, Rao X L, Wang Y Z. Rare Earth Permanent Magnet Materials. Beijing: Metallurgical Industry Press, 2017胡伯平, 饶晓雷, 王亦忠. 稀土永磁材料. 北京: 冶金工业出版社, 2017 -

下载:

下载: