High velocity compaction simulation and dynamic mechanical analysis of particles based on discrete element method

-

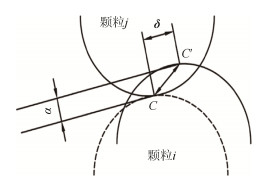

摘要: 采用三维离散单元法对高速压制条件下铝粉颗粒的动态响应进行了数值模拟,并与实验结果进行对比分析。结果表明,数值模拟与实验所测得的结果基本相同;在高速压制过程中,粉体的扰动呈不规则的弧形分布;在压制初期,会出现整体受力不均匀的现象,随着压制的进行,不均匀现象得到改善,粉体表现出较强的自组织性;在单次加载过程中,颗粒会发生多次碰撞;在致密化阶段,上层的部分颗粒会先发生变形并重排,中下层颗粒以重排为主;进入变形阶段后,所有颗粒的受力情况基本相同。Abstract: Three-dimensional discrete element method (DEM) was applied to simulate the dynamic response of aluminum powders under the high velocity compaction (HVC), and the results were compared with the experimental data. In the results, the numerical simulation is basically the same as the experiment results. The powder disturbance shows the irregular arc distribution during the high velocity compaction. There will be an uneven phenomenon of overall force in the initial stage of compaction; as the compaction keeps going, the uneven problem will be improved, and the powders exhibit the strong self-organization. In the single-pass loading process, the particle impact will occur repeatedly; in the densification stage, the upper particles will deform and rearrange, and the middle and lower layers will be dominated by the granular rearrangement; in the deformation stage, the force of all the particles is basically the same.

-

表 1 模拟中使用的主要参数

Table 1. Main parameters used in the simulation

材料密度/ (kg·m-3) 颗粒直径/ mm 颗粒间摩擦系数 模壁摩擦系数 刚度系数 冲击速度/ (m·s-1) 2700 0.15 0.3 0.1 108 10 -

[1] Yan Z Q, Cai Y X, Chen F. High velocity compaction in powder forming and the promising applications. Powder Metall Technol, 2009, 27(6): 455 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200906012.htm闫志巧, 蔡一湘, 陈峰. 粉末冶金高速压制技术及其应用. 粉末冶金技术, 2009, 27(6): 455 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200906012.htm [2] Chi Y, Guo S J, Meng F, et al. High velocity compaction in powder metallurgy. Powder Metall Ind, 2005, 15(6): 41 doi: 10.3969/j.issn.1006-6543.2005.06.009迟悦, 果世驹, 孟飞, 等. 粉末冶金高速压制成形技术. 粉末冶金工业, 2005, 15(6): 41 doi: 10.3969/j.issn.1006-6543.2005.06.009 [3] Chelluri B, Knoth E. Powder forming using dynamic magnetic compaction // 4th International Conference on High Speed Forming. Columbus, 2010: 26 [4] Skoglund P. HVC punches PM to new mass production limits. MPR, 2002, 57(9): 26 http://www.researchgate.net/publication/285009917_HVC_punches_PM_to_new_mass_production_limits [5] Jin L, Zeng Y W, Li H, et al. Numerical simulation of large-scale triaxial tests on soil-rock mixture based on DEM of irregularly shaped particles. Chin J Geotech Eng, 2015, 37(5): 829 https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201505010.htm金磊, 曾亚武, 李欢, 等. 基于不规则颗粒离散元的土石混合体大三轴数值模拟. 岩土工程学报, 2015, 37(5): 829 https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201505010.htm [6] Deng Y B, Yang Y C, Shi D D, et al. Refinement and application of variable particle-size methods in 3D discrete element modelling for large-scale problems. Chin J Geotech Eng, 2017, 39(1): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201701005.htm邓益兵, 杨彦骋, 史旦达, 等. 三维离散元大尺度模拟中变粒径方法的优化及其应用. 岩土工程学报, 2017, 39(1): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201701005.htm [7] Zhang C, Liu J, Luo X L, et al. Effect of loading speed on pressure distribution in metal powder pressing based on discrete element method. Powder Metall Technol, 2019, 37(2): 98 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201902003.htm张超, 刘军, 罗晓龙, 等. 基于离散元法的金属粉末压制加载速度对压力分布影响. 粉末冶金技术, 2019, 37(2): 98 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201902003.htm [8] Jerier J F, Hathong B, Richefeu V, et al. Study of cold powder compaction by using the discrete element method. Powder Technol, 2011, 208(2): 537 doi: 10.1016/j.powtec.2010.08.056 [9] Martin C L, Bouvard D. Study of the cold compaction of composite powders by the discrete element method. Acta Mater, 2003, 51(2): 373 doi: 10.1016/S1359-6454(02)00402-0 [10] Martin C L, Bouvard D, Shima S. Study of particle rearrangement during powder compaction by the discrete element method. J Mech Phys Solids, 2003, 51(4): 667 doi: 10.1016/S0022-5096(02)00101-1 [11] Yang X, Guo S J. Discrete element simulation of powder compaction process // China Powder Metallurgy New Technology and Nanrong Metal Powder Metallurgy Conference. Guangzhou, 2008: 165杨霞, 果世驹. 粉末压制致密化过程的离散元模拟// 中国粉末冶金新技术及南荣金属粉末冶金会议文集. 广州, 2008: 165 [12] Zheng Z S, Xu D, Lei X Y, et al. Numerical simulation and influential factors analysis of density distribution in high velocity compaction. J Mater Eng, 2012(7): 10 doi: 10.3969/j.issn.1001-4381.2012.07.003郑洲顺, 徐丹, 雷湘媛, 等. 粉末高速压制成形密度分布的数值模拟及影响因素分析. 材料工程, 2012(7): 10 doi: 10.3969/j.issn.1001-4381.2012.07.003 [13] Zheng Z S, Wang S, Zheng S, et al. Numerical simulation of particle flow for high velocity compaction based on discrete element method. Rare Met Mater Eng, 2010, 39(12): 2132 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201012014.htm郑洲顺, 王爽, 郑珊, 等. 基于离散单元法的粉末高速压制流动过程模拟. 稀有金属材料与工程, 2010, 39(12): 2132 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201012014.htm [14] Wang S, Zheng Z S, Zhou W. The pressure wave analysis in high velocity compaction process. Acta Phys Sin, 2011, 60(12): 590 https://www.cnki.com.cn/Article/CJFDTOTAL-WLXB201112085.htm王爽, 郑洲顺, 周文. 粉末高速压制成形过程中的应力波分析. 物理学报, 2011, 60(12): 590 https://www.cnki.com.cn/Article/CJFDTOTAL-WLXB201112085.htm [15] Hu X P, Liu J, Ma B B. Research on the influential factors of contact force between metal particles based on the discrete element method. Mach Des Res, 2015, 31(5): 101 https://www.cnki.com.cn/Article/CJFDTOTAL-JSYY201505032.htm胡仙平, 刘军, 马斌斌. 基于DEM的金属颗粒间接触力的影响因素. 机械设计与研究, 2015, 31(5): 101 https://www.cnki.com.cn/Article/CJFDTOTAL-JSYY201505032.htm [16] Yi M J, Yin H Q, Qu X H, et al. Influence of force and stress wave on the quality of green compacts in high velocity compaction. Powder Metall Technol, 2009, 27(3): 207 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200903011.htm易明军, 尹海清, 曲选辉, 等. 力与应力波对高速压制压坯质量的影响. 粉末冶金技术, 2009, 27(3): 207 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200903011.htm [17] Cundall P A, Strack O D L. A discrete numerical model for granular assemblies. Géotechnique, 1979, 29(1): 47 doi: 10.1680/geot.1979.29.1.47 [18] Sun Q C, Wang G Q. Review on granular flow dynamics and its discrete element method. Adv Mech, 2008, 38(1): 87 doi: 10.3321/j.issn:1000-0992.2008.01.006孙其诚, 王光谦. 颗粒流动力学及其离散模型评述. 力学进展, 2008, 38(1): 87 doi: 10.3321/j.issn:1000-0992.2008.01.006 [19] Cheng Y F, Guo S J, Lai H Y. Computer simulation of random packing of spherical particles. J Univ Sic Technol Beijing, 1999, 21(4): 387 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD199904019.htm程远方, 果世驹, 赖和怡. 球形颗粒随机排列过程的计算机模拟. 北京科技大大学学报, 1999, 21(4): 387 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD199904019.htm [20] Luo X L, Liu J, Tian S J, et al. 3D Numerical simulation of aluminum powders under impact loading based on discrete element method. China Mech Eng, 2018, 29(20): 2515 doi: 10.3969/j.issn.1004-132X.2018.20.019罗晓龙, 刘军, 田始军, 等. 基于离散单元法的铝粉冲击加载过程三维数值模拟. 中国机械工程, 2018, 29(20): 2515 doi: 10.3969/j.issn.1004-132X.2018.20.019 -

下载:

下载: