Study on microstructure and gas sensitivity of Au-doped WO3-based composite coating used in gas sensor

-

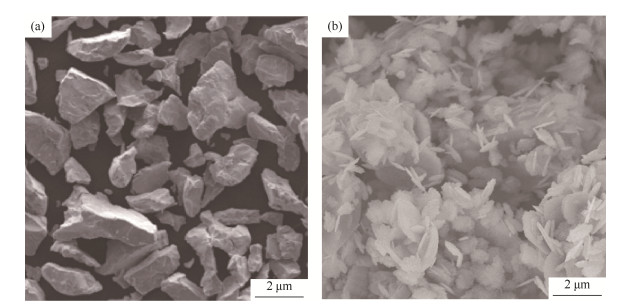

摘要: 为了提高气体传感器的测试精度, 选择等离子喷涂工艺来制备Au掺杂WO3基(WO3/Au)复合涂层, 并对复合涂层的组织和气敏性展开分析。结果表明: 在WO3/Au复合涂层的X射线衍射谱图上, 只观察到WO3与Au对应的两种衍射峰, 没有出现其他物相的衍射峰; 相对于纯WO3涂层, WO3/Au复合涂层没有发生颗粒尺寸、结晶度与微观结构的显著改变; WO3/Au复合涂层的吸脱附曲线发生了分离的现象, 出现了脱附滞后的情况。当温度上升, 气体传感器用纯WO3涂层和WO3/Au复合涂层都出现了响应值先升高到峰值又逐渐降低的现象, 其中最大值出现在300℃处; 不同于纯WO3涂层, 气体传感器用WO3/Au复合涂层可以实现对NO2的快速响应, 并获得更短的恢复时间, 说明WO3/Au复合涂层具备更优的气敏性。Abstract: To improve the accuracy of gas sensor, the Au-doped WO3-based (WO3/Au) composite coatings were prepared by the plasma spraying process, and the microstructure and gas sensitivity were analyzed. The results show that, only two diffraction peaks, corresponding to Au and WO3, are formed in the X-ray diffraction patterns of the WO3/Au composite coatings, and no other phase diffraction peaks are generated. Compared with the pure WO3 coatings, the WO3/Au composite coatings do not significantly change in the particle size, crystallinity, and microstructure. The separation phenomenon occurs in the desorption curve of the WO3/Au coatings, which results in the desorption lag. When the temperature rises, the response values of the pure WO3 coatings and the WO3/Au composite coatings used in gas sensors rise to the peak and then gradually decrease, and the maximum value appears at 300℃. Compared with the pure WO3 coatings, the WO3/Au composite coatings used in gas sensors can achieve the rapid response to NO2 and obtain the shorter recovery time, showing the better gas sensitivity of WO3/Au composite coatings.

-

Key words:

- plasma spraying /

- WO3 coatings /

- doping /

- microstructure /

- gas sensitivity

-

表 1 试验用化学试剂

Table 1. Chemical reagents used in experiment

试剂 制造商 WC16, NH3H2O, Au 永华化学股份有限公司 C2H5O, C3H5O, HO(C2H4O)nH 天津市恒兴化学试剂制造有限公司 表 2 等离子体喷涂参数

Table 2. Plasma spraying parameters

编号 电流/A 电压/V 喷涂速度/(mL·min-1) 喷涂距/mm 1 550 60 15 150 2 550 60 15 175 3 550 60 15 200 表 3 WO3/Au复合涂层能谱分析

Table 3. EDS analysis of WO3/Au composite coatings

元素 质量分数/% 摩尔分数/% O 46.86 68.62 Al 4.46 3.51 W 41.56 23.61 Au 7.12 4.26 -

[1] Zhang Y, Lu W W. Optical electrode construction and photoelectric conversion performance of WO3/BiVO4 thin film. J Henan Univ Sci Technol Nat Sci, 2019, 40(4): 94 https://www.cnki.com.cn/Article/CJFDTOTAL-LYGX201904017.htm张源, 卢伟伟. WO3/BiVO4薄膜光电极构建及光电转化性能. 河南科技大学学报(自然科学版), 2019, 40(4): 94 https://www.cnki.com.cn/Article/CJFDTOTAL-LYGX201904017.htm [2] Wei F J, Zhang H J, Nguyen M, et al. Template-free synthesis of flower-like SnO2 hierarchical nanostructures with improved gas sensing performance. Sens Actuators B, 2015, 215(11): 15 http://smartsearch.nstl.gov.cn/paper_detail.html?id=756ae0c4c621a7caec1570bed3ab5b41 [3] Sun P, Cao Y, Liu J, et al. Dispersive SnO2 nanosheets: Hydrothermal synthesis and gas-sensing properties. Sens Actuators B, 2011, 156(2): 779 doi: 10.1016/j.snb.2011.02.038 [4] Zhang J J, Zhang C, Li X J, et al. Effect of firing temperature on sensing performance of 8YSZ-WO3 ammonia sensor. J Technol, 2019, 19(1): 35 doi: 10.3969/j.issn.2096-3424.2019.01.004张晶晶, 张骋, 李学娇, 等. 煅烧温度对8YSZ-WO3氨传感器性能的影响. 应用技术学报, 2019, 19(1): 35 doi: 10.3969/j.issn.2096-3424.2019.01.004 [5] Sheng S X, Wu C M, Feng J T, et al. Study on catalytic destruction of PCDD/Fs in sintering flue gas. China Resour Compr Util, 2019, 37(3): 14 https://www.cnki.com.cn/Article/CJFDTOTAL-ZWZS201903005.htm盛守祥, 吴昌敏, 冯俊亭, 等. 催化降解烧结烟气中二噁英的研究. 中国资源综合利用, 2019, 37(3): 14 https://www.cnki.com.cn/Article/CJFDTOTAL-ZWZS201903005.htm [6] Espid E, Taghipour F. Development of highly sensitive ZnO/In2O3 composite gas sensor activated by UV-LED. Sens Actuators B, 2016, 241(22): 828 [7] Baranov A, Spirjakin D, Akbari S, et al. Optimization of power consumption for gas sensor nodes: A survey. Sens Actuators A, 2015, 233(8): 279 [8] Yang Z J, Yang N L, Pileni M P. Nano kirkendall effect related to nanocrystallinity of metal nanocrystals: Influence of the outward and inward atomic diffusion on the final nanoparticle structure. J Phys Chem C, 2015, 119(13): 22249 doi: 10.1021/acs.jpcc.5b06000 [9] Niu F X, Chen Y, Zhang J H, et al. Preparation of tungsten trioxide/zinc oxide and its photocatalytic degradation of dye wastewater. Special Petrochem, 2019, 36(2): 22 https://www.cnki.com.cn/Article/CJFDTOTAL-JXSY201902007.htm牛凤兴, 陈钰, 张嘉豪, 等. WO3/ZnO的制备及其光催化降解染料废水研究. 精细石油化工, 2019, 36(2): 22 https://www.cnki.com.cn/Article/CJFDTOTAL-JXSY201902007.htm [10] Li T T, Shen Y B, Zhao S K, et al. Kinetics of sodium hydroxide-phosphate leaching scheelite concentrate. Trans Nonferrous Met Soc China, 2019, 29(3): 634 doi: 10.1016/S1003-6326(19)64973-3 [11] Chen Z Q, Zhan Z L, Wang L L, et al. Study on surface gas sensor of WO3 by mixing La2O3 for VOCs. New Chem Mater, 2019, 47(3): 189 https://www.cnki.com.cn/Article/CJFDTOTAL-HGXC201903043.htm陈志强, 詹自力, 王利利, 等. La2O2/WO3平面VOCs传感器的研究. 化工新型材料, 2019, 47(3): 189 https://www.cnki.com.cn/Article/CJFDTOTAL-HGXC201903043.htm [12] Li Z, Wang X, Zhang J F, et al. Preparation of Z-scheme WO3(H2O)0.303/Ag3PO4 composites with enhanced photocatalytic activity and durability. Chin J Catal, 2019, 40(3): 326 doi: 10.1016/S1872-2067(18)63165-1 [13] Hu M, Qin Y, Zhao B S, et al. Study on fabrication and NO2 sensing properties of porous silicon modified with WO3 nanowires. Chin J Sens Actuators, 2019, 32(2): 167 https://www.cnki.com.cn/Article/CJFDTOTAL-CGJS201902002.htm胡明, 秦岳, 赵博硕, 等. 氧化钨纳米线修饰多孔硅结构的制备及NO2气敏性能研究. 传感技术学报, 2019, 32(2): 167 https://www.cnki.com.cn/Article/CJFDTOTAL-CGJS201902002.htm [14] Liu A Q, Zhu H B, Yuan J P, et al. Microstructure and performance of WC-12Co coating prepared by APS. Powder Metall Ind, 2015, 25(6): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201506019.htm刘安强, 祝弘滨, 袁建鹏, 等. 大气等离子喷涂WC-12Co涂层的组织结构与性能研究. 粉末冶金工业, 2015, 25(6): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201506019.htm [15] Ni X J, Bo X H, Zhao X B, et al. Microstructure and electromagnetic shielding performance of plasma-sprayed Fe-Co-based amorphous alloy coatings. Powder Metall Ind, 2018, 28(5): 50 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201805014.htm倪晓俊, 薄希辉, 赵新彬, 等. 等离子喷涂Fe-Co基非晶合金涂层的结构与电磁屏蔽性能. 粉末冶金工业, 2018, 28(5): 50 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201805014.htm [16] Zhang G G, Ni H Z, Zhang X C, et al. Electrochromic properties of WO3 film by spin-coating. Chin J Lumin, 2019, 40(2): 183 https://www.cnki.com.cn/Article/CJFDTOTAL-FGXB201902008.htm张观广, 倪浩智, 张啸尘, 等. 旋涂法制备WO3薄膜电致变色性能. 发光学报, 2019, 40(2): 183 https://www.cnki.com.cn/Article/CJFDTOTAL-FGXB201902008.htm [17] Diao J L, Li Z Y, Zheng T, et al. Research on low-melting point sealing glass in P2O5-SnF2-WO3 system. J Changchun Univ Sci Technol Nat Sci, 2019, 42(1): 128 https://www.cnki.com.cn/Article/CJFDTOTAL-CGJM201901027.htm刁金龙, 李正宇, 郑涛, 等. P2O5-SnF2-WO3系统低熔点封接玻璃的研究. 长春理工大学学报(自然科学版), 2019, 42(1): 128 https://www.cnki.com.cn/Article/CJFDTOTAL-CGJM201901027.htm [18] Hu W, Huang Z. Microstructure and photothermal effect of photothermal agent nanocrystalline WO(3-x) prepared by hydrothermal method. Mater Sci Eng Powder Metall, 2019, 24(1): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201901006.htm胡伟, 黄智. 水热法制备光热治疗剂纳米WO(3-x)的组织结构与光热效应. 粉末冶金材料科学与工程, 2019, 24(1): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201901006.htm [19] Zhao M M, Chen M Y, Zhang P J, et al. Catalytic effect of Ni components on supported V2O5-WO3/NiO-TiO2 denitrification catalyst. Powder Metall Ind, 2019, 29(1): 42 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201901013.htm赵梦梦, 陈梦寅, 张鹏举, 等. 负载型V2O5-WO3/NiO-TiO2脱硝催化剂上Ni组分的催化作用. 粉末冶金工业, 2019, 29(1): 42 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201901013.htm -

下载:

下载: