Study on particle characteristics and microstructure of La2Ce2O7 coating by atmospheric plasma spraying based on the response surface method

-

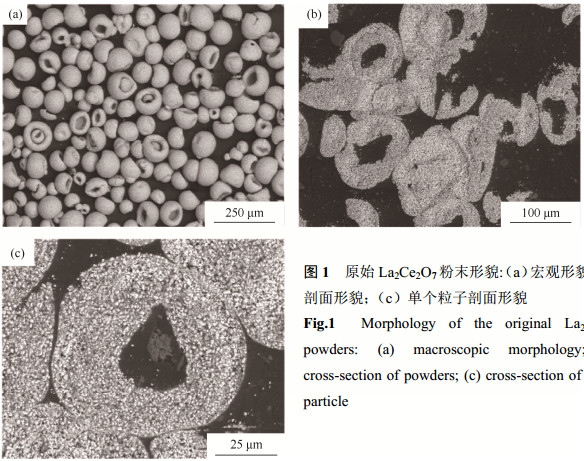

摘要: 根据Box-Behnken曲面响应法,利用Design Expert软件设计了大气等离子喷涂三个工艺参数(电流I、氩气流量、氢气流量)的三水平回归分析试验,通过SprayWatch-2i系统在线测试La2Ce2O7粒子飞行速度及表面温度,经统计分析得到粒子温度和速度的回归模型。采用扫描电镜表征涂层微观结构,并利用Image-Pro-Plus图像分析软件计算未熔颗粒面积分数和孔隙率。结果表明,La2Ce2O7粒子速度符合线性模型,电流、氩气流量是影响粒子速度的主要因素,而氢气流量对粒子速度的影响不显著。粒子速度随氩气流量和电流增大而线性增长。当氩气流量为120 L·min–1,电流为600 A,氢气流量为10 L·min–1时,粒子速度达到最大。粒子温度符合二次模型,氩气流量、电流以及两者之间的相互作用是影响粒子温度的最主要因素。当氩气流量为74.22 L·min–1,电流为543.96 A,氢气流量为10 L·min–1时,粒子温度达到最大。粒子熔化状态提高,涂层未熔颗粒下降。Abstract: Based on the Box-Behnken response surface method, the regression experiments for the three factors of atmospheric plasma spraying (arc current, argon flow rate, and hydrogen flow rate) were designed by Design Expert software. The velocity and temperature of La2Ce2O7 particles were monitored by SprayWatch-2i on-line diagnosis system. By the statistic analysis, the regression models of particle temperature and velocity were established. Scanning electron microscope (SEM) was used to characterize the coating microstructure. The area fraction of non-molten particles and porosity were calculated by Image-Pro-Plus software. The results show that, the La2Ce2O7 particle velocity is well fitted by the linearity regression model. The current and argon flow rate are the main parameters influencing the particle velocity. The particle velocity increases linearly with the increase of argon flow rate and current. The maximum velocity of particles can be obtained at the argon flow rate of 120 L·min-1, the current of 600 A, and the hydrogen flow rate of 10 L·min-1. However, the particle temperature conforms to the quadratic regression model, which is strongly influenced by the argon flow rate, the current, and the interaction between the current and argon flow rate. The maximum velocity of particles can be reached at the argon flow rate of 74.22 L·min-1, the current of 543.96 A, and the hydrogen flow rate of 10 L·min-1. The melting state of the particles increases and the non-molten particles decrease in the La2Ce2O7 coating.

-

图 2 电流、氩气流量和氢气流量对粒子速度的影响:(a)电流-氩气流量等高线图(b)电流-氩气流量响应曲面图;(c)电流-氢气流量等高线图;(d)电流-氢气流量响应曲面图;(e)氢气流量-氩气流量等高线图;(f)氢气流量-氩气流量响应曲面图

Figure 2. Effects of I, QAr, and ${Q_{{{\rm{H}}_2}}}$ on the particle velocity: (a) contour plot of I-QAr; (b) response surface plot of I-QAr; (c) contour plot of I-${Q_{{{\rm{H}}_2}}}$; (d) response surface plot of I-${Q_{{{\rm{H}}_2}}}$; (e) contour plot of QAr-${Q_{{{\rm{H}}_2}}}$; (f) response surface plot of QAr-${Q_{{{\rm{H}}_2}}}$

图 4 电流、氩气流量和氢气流量对粒子温度的影响:(a)电流-氩气流量等高线图(b)电流-氩气流量响应曲面图;(c)电流-氢气流量等高线图;(d)电流-氢气流量响应曲面图;(e)氢气流量-氩气流量等高线图;(f)氢气流量-氩气流量响应曲面图

Figure 4. Effects of I, QAr, and ${Q_{{{\rm{H}}_2}}}$ on the particle temperature: (a) contour plot of I-QAr; (b) response surface plot of I-QAr; (c) contour plot of I-${Q_{{{\rm{H}}_2}}}$; (d) response surface plot of I-${Q_{{{\rm{H}}_2}}}$; (e) contour plot of QAr-${Q_{{{\rm{H}}_2}}}$; (f) response surface plot of QAr-${Q_{{{\rm{H}}_2}}}$

表 1 La2Ce2O7粉末化学成分(质量分数)

Table 1. Chemical composition of La2Ce2O7 powders

% La Ce O 39.05 49.99 10.98 表 2 试验影响因子及取值水平

Table 2. Experimental factors and the numeric values

因素 水平 低 中 高 电弧电流/ A 400 500 600 Ar流量/ (L·min–1) 74 97 120 H2流量/ (L·min–1) 10 15 20 表 3 试验矩阵及粒子温度与速度的实验值

Table 3. Design matrix along with the experimental values of the particle velocity and the particle temperature

编号 电弧电流/ A Ar流量/ (L·min–1) H2流量/ (L·min–1) 粒子温度/ ℃ 粒子速度/ (m·s–1) 1 400 97 10 2771.49 118.75 2 500 74 20 2893.07 125.28 3 600 97 20 2777.20 136.78 4 400 97 20 2799.37 120.68 5 500 97 15 2802.27 131.83 6 400 120 15 2747.11 127.15 7 500 74 10 2955.72 133.60 8 500 97 15 2805.85 131.18 9 500 97 15 2802.61 129.49 10 400 74 15 2864.87 118.91 11 500 120 20 2730.80 131.77 12 500 97 15 2787.62 132.69 13 500 97 15 2805.77 127.46 14 600 74 15 2928.42 138.20 15 500 120 10 2753.64 131.45 16 600 120 15 2705.90 146.55 17 600 97 10 2804.77 139.19 表 4 粒子速度方差分析

Table 4. ANOVA of the particle velocity in the response surface linear model

来源 平方和 自由度 均方 F值 P值 模型 771.19 3 257.06 34.45 < 0.0001 I 707.44 1 707.44 94.80 < 0.0001 QAr 54.76 1 54.76 7.34 0.0179 ${Q_{{{\rm{H}}_{\rm{2}}}}}$ 8.99 1 8.99 1.20 0.2923 残差 97.01 13 7.46 — — 失拟项 79.72 9 8.86 2.05 0.2549 纯误差 17.28 4 4.32 — — 表 5 粒子温度方差分析

Table 5. ANOVA of the particle temperature in the response surface quadratic model

来源 平方和 自由度 均方 F值 P值 模型 71457.81 9 7939.76 44.91 < 0.0001 I 139.83 1 139.83 0.79 0.4030 QAr 62064.69 1 62064.69 351.04 < 0.0001 ${Q_{{{\rm{H}}_{\rm{2}}}}}$ 907.04 1 907.04 5.13 0.0579 I·QAr 2744.08 1 2744.08 15.52 0.0056 I·${Q_{{{\rm{H}}_{\rm{2}}}}}$ 768.66 1 768.66 4.35 0.0755 QAr·${Q_{{{\rm{H}}_{\rm{2}}}}}$ 396.42 1 396.42 2.24 0.1780 I2 1241.84 1 1241.84 7.02 0.0329 $Q_{{\rm{Ar}}}^2$ 3283.12 1 3283.12 18.57 0.0035 $Q_{{{\rm{H}}_{\rm{2}}}}^2$ 87.58 1 87.58 0.50 0.5043 残差 1237.61 7 176.80 — — 失拟项 1008.31 3 336.10 5.86 0.0602 纯误差 229.30 4 57.33 — — 表 6 La2Ce2O7物理性能参数

Table 6. Physical property parameters of La2Ce2O7

k/(W·m–1·K–1) r2/m r1/m L/(J·kg–1) ρ/(kg·m–3) Tm/K 1.5 40 × 10–6 15 × 10–6 1.65 × 105 6.82 × 103 2673 -

[1] Padture N P, Gell M, Jordan E H. Thermal barrier coatings for gas-turbine engine applications. Science, 2002, 296(5566): 280 doi: 10.1126/science.1068609 [2] Lü Y H, Zhang Q F. Current research status and development trend of advanced thermal barrier coatings. Powder Metall Ind. 2015, 25(1): 8 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201501003.htm吕艳红, 张启富. 新型热障涂层研究现状及发展趋势. 粉末冶金工业, 2015, 25(1): 8 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201501003.htm [3] Ji Z, Wang C Y, Xia Y, et al. The research of YSZ ceramic coating's preparation techniques on the surface of etching machine process chamber. Powder Metall Technol, 2015, 33(6): 460 doi: 10.3969/j.issn.1001-3784.2015.06.011纪箴, 王聪瑜, 夏洋, 等. 氧化钇稳定氧化锆耐刻蚀涂层的研究现状. 粉末冶金技术, 2015, 33(6): 460 doi: 10.3969/j.issn.1001-3784.2015.06.011 [4] Zhou C G, Wang N, Wang Z B, et al. Thermal cycling life and thermal diffusivity of a plasma-sprayed nanostructured thermal barrier coating. Scr Mater, 2004, 51(10): 945 doi: 10.1016/j.scriptamat.2004.07.024 [5] He M T, Meng H M, Wang Y C, et al. Research and development of advanced thermal barrier coating materials and preparation technology. Powder Metall Technol, 2019, 37(1): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201901014.htm何明涛, 孟惠民, 王宇超, 等. 新型热障涂层材料及其制备技术的研究与发展. 粉末冶金技术, 2019, 37(1): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201901014.htm [6] Rangaraj S, Kokini K. Fracture in single-layer zirconia (YSZ)-bond coat alloy (NiCoCrAlY) composite coatings under thermal shock. Acta Mater, 2004, 52(2): 455 doi: 10.1016/j.actamat.2003.09.029 [7] Cao X Q, Vassen R, Stoever D. Ceramic materials for thermal barrier coatings. J Eur Ceram Soc, 2004, 24(1): 1 doi: 10.1016/S0955-2219(03)00129-8 [8] Wang Y, Guo H B, Gong S K. Thermal shock resistance and mechanical properties of La2Ce2O7 thermal barrier coatings with segmented structure. Ceram Int, 2009, 35(7): 2639 doi: 10.1016/j.ceramint.2009.02.025 [9] Ma W, Gong S K, Li H F, et al. Novel thermal barrier coatings based on La2Ce2O7/8YSZ double-ceramic-layer systems deposited by electron beam physical vapor deposition. Surf Coat Technol, 2008, 202(12): 2704 doi: 10.1016/j.surfcoat.2007.09.047 [10] Dong H Y, Wang D X, Pei Y L, et al. Optimization and thermal cycling behavior of La2Ce2O7 thermal barrier coatings. Ceram Int, 2013, 39(2): 1863 doi: 10.1016/j.ceramint.2012.08.034 [11] Srinivasan V, Friis M, Vaidya A, et al. Particle injection in direct current air plasma spray: salient observations and optimization strategies. Plasma Chem Plasma Process, 2007, 27(5): 609 doi: 10.1007/s11090-007-9089-8 [12] Guessasma S, Montavon G, Coddet C. Velocity and temperature distributions of alumina–titania in-flight particles in the atmospheric plasma spray process. Surf Coat Technol, 2005, 192(1): 70 doi: 10.1016/j.surfcoat.2004.03.020 [13] Friis M, Persson C, Nylén P, et al. Investigation of particle in-flight characteristics during atmospheric plasma spraying of yttria-stabilized ZrO2: Part 1. Experimental. J Therm Spray Technol, 2001, 10(2): 301 doi: 10.1361/105996301770349394 [14] Mao J, Deng C M, Deng C G, et al. Application of response surface methodology to the process study of atmospheric plasma spraying. Surf Technol, 2013, 42(4): 65 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201304017.htm毛杰, 邓春明, 邓畅光, 等. 响应曲面法在大气等离子喷涂工艺研究中的应用. 表面技术, 2013, 42(4): 65 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201304017.htm [15] Box G E P, Behnken D W. Some new three level designs for the study of quantitative variables. Technometrics, 1960, 2(4): 455 doi: 10.1080/00401706.1960.10489912 [16] Cao X Q, Vassen R, Schwartz S, et al. Spray-drying of ceramics for plasma-spray coating. J Eur Ceram Soc, 2000, 20(14): 2433 http://www.sciencedirect.com/science/article/pii/S0955221900001126 [17] Xiong H B, Zheng L L, Li L, et al. Melting and oxidation behavior of in-flight particles in plasma spray process. Int J Heat Mass Transfer, 2005, 48(25-26): 5121 doi: 10.1016/j.ijheatmasstransfer.2005.07.019 [18] Wang L S, Zhang S L, Liu T, et al. Dominant effect of particle size on the CeO2 preferential evaporation during plasma spraying of La2Ce2O7. J Eur Ceram Soc, 2017, 37(4): 1577 doi: 10.1016/j.jeurceramsoc.2016.11.020 -

下载:

下载: