Effect of two phase mass ratio on the microstructure and mechanical properties of duplex stainless steel fabricated by powder metallurgy

-

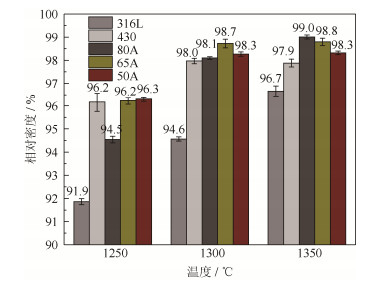

摘要: 将316L奥氏体不锈钢粉末与430铁素体不锈钢粉末分别按照80:20、65:35、50:50质量比混合, 采用冷等静压成型方法制备了双相不锈钢, 研究了奥氏体和铁素体起始粉末质量比对双相不锈钢组织结构和力学性能的影响。结果表明: 当奥氏体和铁素体起始粉末质量比为65:35, 烧结温度1350℃, 保温时间60min时, 双相不锈钢综合力学性能较好, 其中, 抗拉强度为847MPa, 屈服强度为281MPa, 硬度为HV207, 断后伸长率为37.5%。Abstract: Duplex stainless steels were fabricated by the cold isostatic pressing using the 316L austenite stainless steel powders and 430 ferrite stainless steel powders mixed by the mass ratio of 80:20, 65:35, and 50:50, respectively. The effect of the primary powder mass ratio of austenite to ferrite on the microstructure and mechanical properties of the duplex stainless steels were studied. The results show that, when the primary powder mass ratio of austenite to ferrite is 65:35, the sintering temperature is 1350℃, and the holding time is 60 min, the duplex stainless steels have the better comprehensive mechanical properties with the tensile strength of 847 MPa, the hardness of HV 207, the yield strength of 281 MPa, and the elongation of 37.5%.

-

Key words:

- cold isostatic pressing /

- duplex stainless steel /

- microstructure /

- mechanical properties

-

表 1 原料粉末及不同质量比混合粉末的化学成分(质量分数)

Table 1. Chemical compositions of the raw powders and the mixed powders by the different mass ratio

% 材料 Cr Ni Mo Mn Si Fe 316L 17.21 11.74 2.23 — 0.89 余量 430 17.24 — — 0.20 0.96 余量 80A 17.22 9.39 1.78 0.04 0.90 余量 65A 17.22 7.63 1.45 0.07 0.91 余量 50A 17.23 5.87 1.12 0.10 0.93 余量 注:80A代表该不锈钢粉末是由质量分数为80%316L不锈钢粉末和20%430不锈钢粉末组成,65A、50A同理。 表 2 烧结不锈钢的力学性能

Table 2. Mechanical properties of the sintered stainless steels

材料 抗拉强度/MPa 屈服强度/MPa 断后伸长率/% 硬度,HV 316L 582 240 48.5 132 430 499 333 30.7 163 80A 675 254 61.5 156 65A 847 281 37.5 207 50A 1008 426 12.3 292 -

[1] Chail G, Kangas P. Super and hyper duplex stainless steels: structures, properties and applications. Procedia Struct Integrity, 2016, 2: 1755 doi: 10.1016/j.prostr.2016.06.221 [2] Zheng C B, Shen X L, Tang Z J. Effect of solution treatment temperature on phase structure and corrosion resistance of 2507 duplex stainless steel. Heat Treat Met, 2015, 40(8): 124 https://www.cnki.com.cn/Article/CJFDTOTAL-JSRC201508029.htm郑传波, 申小兰, 唐祝君. 固溶温度对2507双相不锈钢组织与耐蚀性能的影响. 金属热处理, 2015, 40(8): 124 https://www.cnki.com.cn/Article/CJFDTOTAL-JSRC201508029.htm [3] Yuan S D. Effect of different welding processes on mechanical properties and corrosion resistance of duplex stainless steel. Weld Joining, 2017(3): 39 doi: 10.3969/j.issn.1001-1382.2017.03.010袁世东. 不同焊接工艺对双相不锈钢力学性能及耐腐蚀性能的影响. 焊接, 2017(3): 39 doi: 10.3969/j.issn.1001-1382.2017.03.010 [4] Zhang W Y, Hou S Z. Progress of the application of duplex stainless steel at home and abroad. Shanghai Mach Tool, 2015(3): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-ZBJX201503014.htm张文毓, 侯世忠. 国内外双相不锈钢的应用进展. 装备机械, 2015(3): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-ZBJX201503014.htm [5] Ryuichiro E. The influence of metallurgical factors on corrosion fatigue strength of stainless steels. Procedia Struct Integrity, 2016, 2: 517 doi: 10.1016/j.prostr.2016.06.067 [6] Wang L X. Discussion on the application of domestic super duplex stainless steel. Petrochem Equip Technol, 2017, 38(2): 54 doi: 10.3969/j.issn.1006-8805.2017.02.013王兰喜. 国产超级双相不锈钢应用浅析. 石油化工设备技术, 2017, 38(2): 54 doi: 10.3969/j.issn.1006-8805.2017.02.013 [7] Li D Y, Zhang Y M. Research on welding technology for duplex stainless steel. Petrochem Equip Technol, 2017, 38(1): 56 doi: 10.3969/j.issn.1006-8805.2017.01.056李冬毓, 张永明. 双相不锈钢焊接技术研究. 石油化工设备技术, 2017, 38(1): 56 doi: 10.3969/j.issn.1006-8805.2017.01.056 [8] Gu L L, Liu J R, Lei Z G, et al. Super duplex stainless steel SAF2507 of valve castings production development. China Foundry Mach Technol, 2016(5): 53 doi: 10.3969/j.issn.1006-9658.2016.05.015顾丽丽, 刘佳任, 雷志刚, 等. 超级双相不锈钢SAF2507阀门铸件的生产研制. 中国铸造装备与技术, 2016(5): 53 doi: 10.3969/j.issn.1006-9658.2016.05.015 [9] Cui L M, Zhang X J, Cai L J. Process practice of super duplex stainless steel. China Metall, 2017, 27(9): 44 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGYE201709010.htm崔利民, 张欣杰, 才丽娟. 超级双相不锈钢生产工艺实践. 中国冶金, 2017, 27(9): 44 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGYE201709010.htm [10] Tian B Q, Qian Z X, Ji X B. Influence of the Steckel mill rolling temperature on brittle zone length of 2507 super duplex stainless steel. Gansu Metall, 2018, 40(3): 26 doi: 10.3969/j.issn.1672-4461.2018.03.007田宝强, 钱张信, 纪显彬. 炉卷轧机轧制温度对2507超级双相不锈钢脆性区长度的影响. 甘肃冶金, 2018, 40(3): 26 doi: 10.3969/j.issn.1672-4461.2018.03.007 [11] Chen Y T, Zhong Y P, Guo X Z, et al. Casting process design and practice on diffuser with duplex stainless steel. Dev Appl Mater, 2019, 34(1): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-CLKY201901006.htm陈亚涛, 钟玉平, 郭绪镇, 等. 双相不锈钢导叶体铸造工艺设计及实践. 材料开发与应用, 2019, 34(1): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-CLKY201901006.htm [12] Brytan Z, Dobrzański L A, Grande M A, et al. The influence of sintering time on the properties of PM duplex stainless steel. J Ach Mater Manuf Eng, 2009, 37(2): 387 http://www.oalib.com/paper/2908856 [13] Davidson K, Singamneni S. Selective laser melting of duplex stainless steel powders: an investigation. Mater Manuf Processes, 2016, 31(12): 1543 doi: 10.1080/10426914.2015.1090605 [14] Chen X Q, Pang W J, Shang F, et al. Effects of solution treatment on microstructure and properties of SAF 2507 duplex stainless steel prepared by powder injection molding. Hot Working Technol, 2019, 48(6): 195 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201906047.htm陈晓秋, 庞午骥, 尚峰, 等. 固溶处理对粉末注射成形SAF 2507双相不锈钢组织和性能的影响. 热加工工艺, 2019, 48(6): 195 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201906047.htm [15] Qi M H, Ren S B, Zhang G Z, et al. Effects of solution treatment on microstructure and mechanical properties of hot isostatic pressing SAF3207. Powder Metall Technol, 2017, 35(5): 328 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201705002.htm齐美欢, 任淑彬, 张公桢, 等. 固溶处理对热等静压SAF 3207的组织与性能影响. 粉末冶金技术, 2017, 35(5): 328 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201705002.htm [16] Kazior J, Nykiel M, Pieczonka T, et al. Activated sintering of P/M duplex stainless steel powders. J Mater Process Technol, 2004, 157-158(51): 712 http://www.sciencedirect.com/science/article/pii/S0924013604011653 [17] Murali A P, Mahendran S, Ramajayam M, et al. Effect of sintering atmosphere and solution treatment on density, microstructure and tensile properties of duplex stainless steels developed from pre-alloyed powders. J Inst Eng, 2017, 98(2): 1 doi: 10.1007/s40033-016-0132-x [18] García C, Martín F, Blanco Y, et al. Corrosion behaviour of duplex stainless steels sintered in nitrogen. Corros Sci, 2009, 51(1): 76 doi: 10.1016/j.corsci.2008.10.003 [19] Puscas T M, Molinari A, Kazior J, et al. Sintering transformations in mixtures of austenitic and ferritic stainless steel powders. Powder Metall, 2001, 44(1): 48 doi: 10.1179/003258901666167 [20] Liou H Y, Tsai W T, Pan Y T, et al. Effects of alloying elements on the mechanical properties and corrosion behaviors of 2205 duplex stainless steels. J Mater Eng Perform, 2001, 10(2): 231 doi: 10.1361/105994901770345268 -

下载:

下载: