-

摘要: 通过改变MoS2(质量分数1.0%~2.0%)和石墨(质量分数0~1.0%)的成分比例,在一定滑动线速度下,测量青铜基含油轴承承受压强的极限值,研究MoS2和石墨含量对青铜基含油轴承的力学性能和摩擦性能的影响。结果表明:在不加入石墨的情况下,随着MoS2含量的增加,含油轴承的负荷×线速度(pv)极限值降低,其中青铜-1MoS2(MoS2质量分数1.0%)含油轴承极限pv值最高,达到2.940 MPa·m·s-1;在同时加入石墨和MoS2的情况下,随着石墨含量的增加,含油轴承的摩擦因数降低,其中青铜-1MoS2/-1石墨(MoS2质量分数1.0%,石墨质量分数1.0%)含油轴承摩擦因数最低,为0.038;石墨能够改善含油轴承的摩擦性能,但是会大幅度降低其力学性能。Abstract: By changing the contents of MoS2 (mass fraction 1.0%~2.0%) and graphite (mass fraction 0~1.0%), the bearing pressure limit value of bronze oil bearing at the certain sliding linear velocity was measured, the effects of MoS2 and graphite contents on the mechanical and frictional properties of bronze oil bearing were studied. The results show that, the limit value of load×linear velocity (pv) for the oil bearings decreases with the increase of MoS2 content without graphite addition, and the bronze-1MoS2 (1.0%MoS2, mass fraction) oil bearing has the highest pv value of 2.940 MPa·m·s-1. In the case of adding graphite and MoS2 at the same time, the friction coefficient of the oil bearing decreases with the increase of the graphite content, and the bronze-1MoS2-1graphite (1.0%MoS2 and 1.0%graphite, mass fraction) oil bearing has the lowest friction coefficient of 0.038. Graphite can improve the friction properties of oil bearings, but it may greatly reduce the mechanical properties of oil bearings.

-

Key words:

- bronze /

- oil bearing /

- friction /

- molybdenum disulfide /

- graphite

-

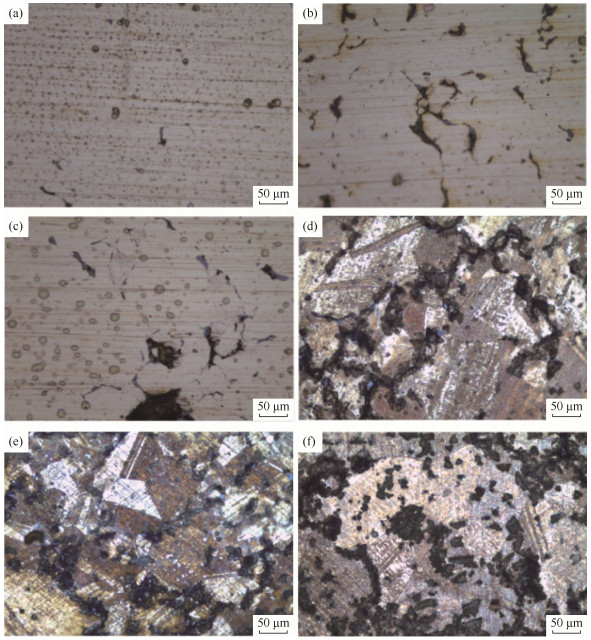

图 1 未添加石墨、添加不同质量分数MoS2的轴承试样腐蚀前后的显微组织形貌:(a)青铜-1MoS2(MoS2质量分数1.0%);(b)青铜-1.5MoS2(MoS2质量分数1.5%);(c)青铜-2MoS2(MoS2质量分数2.0%);(d)腐蚀后青铜-1MoS2;(e)腐蚀后青铜-1.5MoS2;(f)腐蚀后青铜-2MoS2

Figure 1. Microstructures of the bearing samples without graphite and with MoS2 in different mass fractions before and after corrosion: (a) bronze-1MoS2 (MoS2 mass fraction of 1.0%); (b) bronze-1.5MoS2 (MoS2 mass fraction of 1.5%); (c) bronze-2MoS2 (MoS2 mass fraction of 2.0%); (d) bronze-1MoS2 after corrosion; (e) bronze-1.5MoS2 after corrosion; (f) bronze-2MoS2 after corrosion

图 2 含质量分数1.0%MoS2且添加不同质量分数石墨的轴承试样腐蚀前后显微组织形貌:(a)青铜-1MoS2(不含石墨);(b)青铜-1MoS2-0.5石墨(石墨质量分数0.5%);(c)青铜-1MoS2-1石墨(石墨质量分数1.0%);(d)腐蚀后青铜-1MoS2;(e)腐蚀后青铜-1MoS2-0.5石墨;(f)腐蚀后青铜–1MoS2-1石墨

Figure 2. Microstructures of the bearing samples with 1.0% MoS2 and graphite in different mass fractions before and after corrosion: (a) bronze-1MoS2 (without graphite); (b) bronze-1MoS2-0.5graphite (graphite mass fraction of 0.5%); (c) bronze-1MoS2-1graphite (graphite mass fraction of 1.0%); (d) bronze-1MoS2 after corrosion; (e) bronze-1MoS2-0.5graphite after corrosion; (f) bronze-1MoS2- 1graphite after corrosion

表 1 铜基含油轴承主要成分含量(质量分数)

Table 1. Main composition of the bronze oil bearing

% 序号 Cu–10Sn MoS2 石墨 硬脂酸锌 1# 余量 1.0 0 0.6 2# 余量 1.5 0 0.6 3# 余量 2.0 0 0.6 4# 余量 1.0 0.5 0.6 5# 余量 1.5 0.5 0.6 6# 余量 2.0 0.5 0.6 7# 余量 1.0 1.0 0.6 8# 余量 1.5 1.0 0.6 9# 余量 2.0 1.0 0.6 -

[1] Han F L. Powder metallurgy machinery parts. Powder Metall Technol, 2016, 34(2): 155 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ802.008.htm韩凤麟. 粉末冶金机械零件. 粉末冶金技术, 2016, 34(2): 155 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ802.008.htm [2] Shen X P. Powder Metallurgy Manufacturing Engineering. Beijing: National Defense Industry Press, 2015申小平. 粉末冶金制造工程. 北京: 国防工业出版社, 2015 [3] Teruhisa W, Han F L. Porous sintered bearings. Powder Metall Technol, 2002, 20(3): 121 doi: 10.3321/j.issn:1001-3784.2002.03.001渡边侊尚, 韩凤麟. 烧结含油轴承. 粉末冶金技术, 2002, 20(3): 121 doi: 10.3321/j.issn:1001-3784.2002.03.001 [4] Duan J H. Development of powder metallurgy materials and metallurgical technology. World Nonferrous Met, 2018(15): 16 doi: 10.3969/j.issn.1002-5065.2018.15.010段家欢. 浅析粉末冶金材料及冶金技术发展. 世界有色金属, 2018(15): 16 doi: 10.3969/j.issn.1002-5065.2018.15.010 [5] Lu N G. The present state and tendency of sintered friction materials in the world. Powder Metall Technol, 2002, 20(5): 294 doi: 10.3321/j.issn:1001-3784.2002.05.008鲁乃光. 烧结金属摩擦材料现状与发展动态. 粉末冶金技术, 2002, 20(5): 294 doi: 10.3321/j.issn:1001-3784.2002.05.008 [6] Du M. Study on Tribological Properties of Graphite and Copper Coated Graphite-Copper Composites Materials [Dissertation]. Changchun: Changchun University of Technology, 2018杜明. 石墨及镀铜石墨–铜基复合材料摩擦学性能研究[学位论文]. 长春: 长春工业大学, 2018 [7] Sun Y A, Zhang L, Li X H, et al. Study about high-speed self-lubricating oil-containing bearing. Powder Metall Technol, 2002, 20(2): 90 doi: 10.3321/j.issn:1001-3784.2002.02.007孙永安, 张玲, 李县辉, 等. 高速自润滑含油轴承的研究. 粉末冶金技术, 2002, 20(2): 90 doi: 10.3321/j.issn:1001-3784.2002.02.007 [8] Zhou Q W. The Preparation and Property Study of Nanomaterials Based on Molybdenum Disulfide [Dissertation]. Nanjing: Nanjing University, 2019周青伟. 二硫化钼及其复合材料的制备与性能研究[学位论文]. 南京: 南京大学, 2019 [9] Shi M S. Solid Lubricating Materials. Beijing: Chemical Industry Press, 2000石淼森. 固体润滑材料. 北京: 化学工业出版社, 2000 [10] Yan H Y. Principle and application of solid lubrication technology. Technol Market, 2016, 23(11): 133 doi: 10.3969/j.issn.1006-8554.2016.11.099晏浩洋. 固体润滑技术的原理与应用. 技术与市场, 2016, 23(11): 133 doi: 10.3969/j.issn.1006-8554.2016.11.099 [11] Yang Q T. Study on Friction and Wear Properties of Ag–G–MoS2 [Dissertation]. Hefei: Hefei University of Technology, 2010杨茜婷. 银–石墨–二硫化钼复合材料的摩擦磨损性能研究[学位论文]. 合肥: 合肥工业大学, 2010 [12] Cui Z T. Tribological Properties of Graphite–MoS2 Coating and Its Application in Deep Groove Ball Bearings[Dissertation]. Chongqing: Chongqing University, 2018崔中涛. 石墨–二硫化钼涂层摩擦学性能及其在深沟球轴承上的应用研究[学位论文]. 重庆: 重庆大学, 2018 [13] Yang C Z. Tribological Properties of MoS2 Coating and Its Application in TBA Bearing[Dissertation]. Chongqing: Chongqing University, 2018杨承璋. 二硫化钼涂层摩擦学性能及其在TBA轴承上的应用[学位论文]. 重庆: 重庆大学, 2018 [14] Chen S X. The Study of Preparation, Microstructure and Properties of Cu–MoS2 Composites [Dissertation]. Hefei: Hefei University of Technology, 2009陈淑娴. 铜–二硫化钼复合材料的制备及其组织与性能研究[学位论文]. 合肥: 合肥工业大学, 2009 [15] Zhang Y D. Preparation and Properties of Cu/Cu–MoS2 Self-lubricating Composite [Dissertation]. Luoyang: Henan University of Science and Technology, 2014张银娣. 自润滑Cu/Cu–MoS2复合材料的制备及性能研究[学位论文]. 洛阳: 河南科技大学, 2014 [16] Niu S Q, Ruan H S, Zhu J P, et al. The study and application of bronze-graphite oil-containing self-lubricating composites. Tribology, 1992, 12(4): 335 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX199204005.htm牛淑琴, 阮虎生, 朱家佩, 等. 青铜–石墨系含油自润滑复合材料的研究与应用. 摩擦学学报, 1992, 12(4): 335 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX199204005.htm [17] Chen R. Graphite-material and graphite-bearing. Carbon, 2001(4): 32 doi: 10.3969/j.issn.1001-8948.2001.04.005陈锐. 石墨材料与石墨轴承. 炭素, 2001(4): 32 doi: 10.3969/j.issn.1001-8948.2001.04.005 [18] Zhang M J, Zhu S W, Yu J F, et al. Development of graphite/copper matrix composites. Foundry Technol, 2017, 38(11): 2565 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201711002.htm张铭君, 朱世伟, 于俊凤, 等. 石墨/铜基复合材料研究进展. 铸造技术, 2017, 38(11): 2565 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201711002.htm [19] Zhang M M, Xie F, Li B, et al. Introduction of metallic sulfide solid lubricants in brief. Synth Lubric, 2015, 42(3): 27 doi: 10.3969/j.issn.1672-4364.2015.03.010张蒙蒙, 谢凤, 李斌, 等. 金属硫化物固体润滑剂简介. 合成润滑材料, 2015, 42(3): 27 doi: 10.3969/j.issn.1672-4364.2015.03.010 -

下载:

下载: