Study on preparation and photocatalytic properties of M/TiO2 composite film by two-step mechanical ball milling

-

摘要:

采用两步机械球磨法制备了M/TiO2(M = Al、Sn、Zn、Ti)双层复合薄膜,利用光学显微镜和X射线衍射仪分析了涂层的微观结构和相组成,测定了薄膜的光催化性能,研究了过渡层材质以及球磨时间对复合薄膜光催化性能的影响。研究表明,TiO2粉体在球磨过程中的晶体结构未发生显著变化,保持了良好的光催化活性。金属过渡层Al、Sn以及Zn将显著削弱复合薄膜的光催化活性,Ti是复合薄膜的理想金属过渡层,制备的Ti/TiO2复合薄膜具有优异的光催化性能。随着第二步球磨时间的延长,Ti/TiO2复合薄膜的光催化性能逐渐降低,这是由于第二层薄膜表面TiO2含量降低的原因所致。

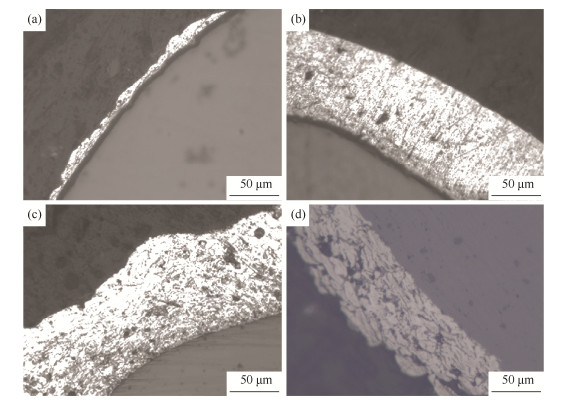

Abstract:The composite films of M/TiO2 (M = Al, Sn, Zn, Ti) were prepared by the two-step mechanical ball milling. The microstructure and phase composition of the composite coating were analyzed by the optical microscopy (OM) and X-ray diffraction (XRD), the photocatalytic properties of the composite films were determined, and the effects of the transition layer materials and milling time on the photocatalytic properties of the composite films were investigated. The results show that, the crystal structure of the TiO2 powders does not change significantly during the ball milling process, and the TiO2 powders still maintain the good photocatalytic activity. The metal transition layers of Al, Sn, and Zn will significantly weaken the photocatalytic activity of the composite films, while Ti is an ideal metal transition layer for the composite film, and the prepared Ti/TiO2 composite films have the excellent photocatalytic properties. With the prolongation of the second step milling time, the photocatalytic properties of the Ti/TiO2 composite films are gradually reduced, which is caused by the decrease of the TiO2 content on the surface of the second film.

-

Key words:

- mechanical ball milling /

- photocatalytic properties /

- milling time /

- composite film

-

-

[1] Chawla P, Sharma S K, Toor A P. Optimization and modeling of UV-TiO2 mediated photocatalytic degradation of golden yellow dye through response surface methodology. Chem Eng Commun, 2019, 206(9): 1123 doi: 10.1080/00986445.2018.1550392 [2] Tang X X, Zha W S, Zhang G Y, et al. The effects of oxidation temperature on the microstructure and photocatalytic activity of the TiO2 coating. Mater Sci, 2017, 23(2): 103 [3] Espíndola J C, Cristóvāo R O, Santos S G S, et al. Intensification of heterogeneous TiO2 photocatalysis using the NETmix mili-photoreactor under microscale illumination for oxytetracycline oxidation. Sci Total Environ, 2019, 681: 467 doi: 10.1016/j.scitotenv.2019.05.066 [4] Hao L, Lu Y, Sato H, et al. Fabrication of zinc coatings on alumina balls from zinc powder by mechanical coating technique and the process analysis. Powder Technol, 2012, 228: 337 http://www.sciencedirect.com/science/article/pii/S003259101200383X [5] Zhang G Y, Tang X X, Chen X L, et al. The effects of the content of NiO on the microstructure and photocatalytic activity of the NiO/TiO2 composite film. Mater Sci, 2018, 24(4): 372 http://www.onacademic.com/detail/journal_1000041712709299_f581.html [6] Hao L, Yoshida H, Itoi T, et al. Preparation of metal coatings on steel balls using mechanical coating technique and its process analysis. Coatings, 2017, 7(4): 53 doi: 10.3390/coatings7040053 [7] Chen L J, Zha W S, Wu K X, et al. Application of mechanical milling in fabrication of surface coatings. Powder Metall Technol, 2014, 32(1): 64 doi: 10.3969/j.issn.1001-3784.2014.01.012陈立甲, 查五生, 吴开霞, 等. 机械球磨方法在表面薄膜涂层制备中的应用. 粉末冶金技术, 2014, 32(1): 64 doi: 10.3969/j.issn.1001-3784.2014.01.012 [8] Lu Y, Yoshida H, Nakayama H, et al. Formation of TiO2/Ti composite photocatalyst film by 2-step mechanical coating technique. Mater Sci Forum, 2011, 675-677: 1229 doi: 10.4028/www.scientific.net/MSF.675-677.1229 [9] Tao J M, Huang S Z, Xu M C, et al. Study on the mechanical properties of pure bulk Al with nanocrystalline. J Mater Eng, 2009(6): 67 doi: 10.3969/j.issn.1001-4381.2009.06.016陶静梅, 黄素贞, 徐孟春, 等. 纯Al纳米晶体材料的力学性能研究. 材料工程, 2009(6): 67 doi: 10.3969/j.issn.1001-4381.2009.06.016 [10] Han B J, He Q, Yang M. Investigation of surface grain refinement of AZ91D magnesium alloys by surface mechanical attrition treatment. Surf Technol, 2014, 43(4): 32 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201404007.htm韩宝军, 何琼, 杨妙. 机械研磨处理AZ91D镁合金表面晶粒细化研究. 表面技术, 2014, 43(4): 32 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201404007.htm -

下载:

下载: