Analysis on vibration packing density of pure iron powders based on discrete element method

-

摘要: 为了提高粉末冶金制品的密度,采用振动的方法促进铁粉颗粒运动与重排,降低粉体的孔隙率,提高纯铁粉体的填充密度。利用离散元软件EDEM对模腔中纯铁粉体的振动填充过程进行数值模拟,研究了振动频率、振动幅度、振动时间对粉体填充密度的影响,确定出最佳工艺参数,并通过对比实验验证了仿真结果的可靠性。结果表明:振动频率和振动幅度对粉体填充密度的影响较大,随着频率和振幅的增大,填充密度先增加后减小;随着振动时间的增大,填充密度先增加后趋于稳定。Abstract: To increase the compaction density of the powder metallurgy products, the vibration was used to promote the movement and rearrangement of the iron powder particles, reduce the porosity of powders, and improve the packing density of powders. The vibration packing process of pure iron powders in the cavity was numerically simulated by the EDEM discrete element software. The influences of vibration frequency, vibration amplitude, and vibration time on the packing density of the powders were studied, the optimal technological parameters were determined, and the reliability of simulation was confirmed by the comparative experiment. The results show that, the packing density of powders is significantly influenced by the vibration frequency and amplitude. With the increase of the vibration frequency and amplitude, the packing density firstly increases, and then reduces; with the increase of the vibration time, the packing density firstly increases, and then tends to be stable.

-

Key words:

- packing density /

- vibration frequency /

- vibration amplitude /

- vibration time /

- discrete element method

-

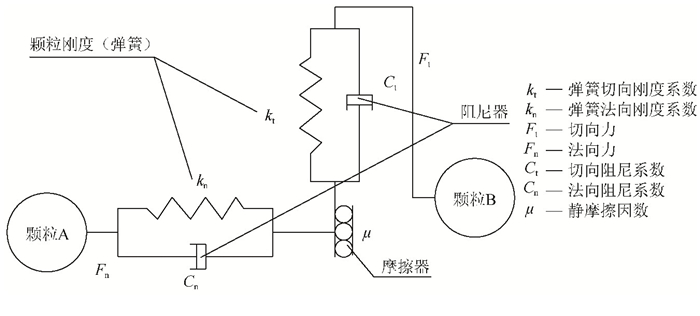

表 1 铁粉颗粒接触模型参数

Table 1. Contact model parameters of Fe powder particles

材料 恢复系数 静摩擦系数 滚动摩擦系数 颗粒-颗粒 0.15 0.30 0.01 颗粒-钢 0.13 0.25 0.01 -

[1] Chen M T, Shi J J, Chen G P. Development of powder metallurgy. Powder Metall Ind, 2017, 27(4): 66 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704018.htm陈梦婷, 石建军, 陈国平. 粉末冶金发展状况. 粉末冶金工业, 2017, 27(4): 66 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704018.htm [2] Gao Y, Xu Y F, Tian J P. Application and prospect of powder metallurgy in automobile. Powder Metall Ind, 2018, 28(6): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201806019.htm高阳, 徐岳锋, 田杰平. 粉末冶金在汽车上的应用与展望. 粉末冶金工业, 2018, 28(6): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201806019.htm [3] Li Y Y, Xiao Z Y, Chen W P, et al. Progress in high density powder metallurgy forming technology. Mater Sci Eng Powder Metall, 2005, 10(1): 1 doi: 10.3969/j.issn.1673-0224.2005.01.001李元元, 肖志瑜, 陈维平, 等. 粉末冶金高致密化成形技术的新进展. 粉末冶金材料科学与工程, 2005, 10(1): 1 doi: 10.3969/j.issn.1673-0224.2005.01.001 [4] Visscher W M, Bolsterli M. Random packing of equal and unequal spheres in two and three dimensions. Nature, 1972, 239: 504 doi: 10.1038/239504a0 [5] Knight J B, Ehrichs E E, Kuperman V Y, et al. Experimental study of granular convection. Phys Rev E, 1996, 54: 5726 doi: 10.1103/PhysRevE.54.5726 [6] Jiang Z H, Jing Y F, Zhao H F, et al. Effects of subharmonic motion on size segregation in vertically vibrated granular materials. Acta Phys Sin, 2009, 58(9): 5923 doi: 10.3321/j.issn:1000-3290.2009.09.006姜泽辉, 荆亚芳, 赵海发, 等. 振动颗粒物质中倍周期运动对尺寸分离的影响. 物理学报, 2009, 58(9): 5923 doi: 10.3321/j.issn:1000-3290.2009.09.006 [7] Vanel L, Rosato A D, Dave R N. Rise-time regimes of a large sphere in vibrated bulk solids. Phys Rev Lett, 1997, 78: 1255 doi: 10.1103/PhysRevLett.78.1255 [8] Majidi B, Melo J, Fafard M, et al. Packing density of irregular shape particles: DEM simulations applied to anode-grade coke aggregates. Adv Powder Technol, 2015, 26: 1256 doi: 10.1016/j.apt.2015.06.008 [9] Liu Y S, Ge M X, Chen Q D, et al. Experimental study of vibration packing density of molecular sieve. J Exp Mech, 2010, 25(3): 359 https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX201003022.htm刘应书, 葛铭霞, 陈启东, 等. 分子筛振动装填密度实验研究. 实验力学, 2010, 25(3): 359 https://www.cnki.com.cn/Article/CJFDTOTAL-SYLX201003022.htm [10] Liu B, Ma L, Liu Q Z, et al. Effect of vibration performance on packing density of NdFeB magnet powder based on EDEM. China Powder Sci Technol, 2017, 23(4): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS201704016.htm刘波, 马麟, 刘邱祖, 等. 基于EDEM的振动特性对钕铁硼永磁粉体填充密度的影响. 中国粉体技术, 2017, 23(4): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS201704016.htm [11] Chen S S, Tang X, Lü Y J, et al. Experimental study on the effect of vibrating filler auxiliary medium on micro powder filling process. Powder Metall Technol, 2019, 37(1): 3 doi: 10.19591/j.cnki.cn11-1974/tf.2019.01.001陈水胜, 唐鑫, 吕彦杰, 等. 振动填料辅助介质对微粉填充过程影响的实验研究. 粉末冶金技术, 2019, 37(1): 3 doi: 10.19591/j.cnki.cn11-1974/tf.2019.01.001 [12] Cundall P A. BALL-a Program to Model Granular Media Using the Distinct Element Method. London: Dames & Moore Advanced Technology Group, 1978 [13] Zhou Z Y, Li Y Y. Mechanical Modeling and Numerical Simulation of Metal Powder Forming Processes. Guangzhou: South China University of Technology Press, 2011周照耀, 李元元. 金属粉末成形力学建模与计算机模拟. 广州: 华南理工大学出版社, 2011 [14] Wang G Q, Hao W J, Wang J X. Discrete Element Method and Its Application on EDEM. Xi'an: Northwestern Polytechnical University Press, 2010王国强, 郝万军, 王继新. 离散单元法及其在EDEM上的实践. 西安: 西北工业大学出版社, 2010 [15] Wang D, Yang Y. Functional characteristics of large-scale discrete element software EDEM. Perspect Sci Technol Achiev, 2009(3): 75 https://www.cnki.com.cn/Article/CJFDTOTAL-KJCH200903036.htm王东, 杨溢. 大型离散元软件EDEM的功能特点. 科技成果纵横, 2009(3): 75 https://www.cnki.com.cn/Article/CJFDTOTAL-KJCH200903036.htm [16] Zhang H, Zhang Y Z. Brief introduction of particle mechanics simulation software EDEM. CAD/CAM Manufact Inform, 2008(12): 48 https://www.cnki.com.cn/Article/CJFDTOTAL-JSFY200812022.htm张辉, 张永震. 颗粒力学仿真软件EDEM简要介绍. CAD/CAM与制造业信息化, 2008(12): 48 https://www.cnki.com.cn/Article/CJFDTOTAL-JSFY200812022.htm [17] Bharadwaj R, Ketterhagen W R, Hancock B C. Discrete element simulation study of a freeman powder rheometer. Chem Eng Sci, 2010, 65(21): 5747 http://www.sciencedirect.com/science/article/pii/S0009250910002198 -

下载:

下载: