| [1] |

Li C, Li N, Liu X Q, et al. Effect of WC mass fraction on the microstructure and properties of Ti(C0.7N0.3)-based cermets. Powder Metall Technol, 2018, 36(2): 100李朝, 李楠, 柳学全, 等. WC质量分数对Ti(C0.7N0.3)基金属陶瓷组织和性能的影响. 粉末冶金技术, 2018, 36(2): 100

|

| [2] |

Ghanaraja S, Ravikumar K S, Raju H P, et al. Studies on dry sliding wear behaviour of Al2O3 reinforced Al based metal matrix composites. Mater Today, 2017, 4(9): 10043

|

| [3] |

Liu B, Zhang Q, Chen H, et al. Study on the effect of sub-micro SiC particle on the properties and microstructure of Ti(C,N)-based cermet. Powder Metall Technol, 2015, 33(3): 170 doi: 10.3969/j.issn.1001-3784.2015.03.003刘兵, 张茜, 陈慧, 等. 亚微米级SiC颗粒对Ti(C,N)基金属陶瓷材料性能和结构的影响研究. 粉末冶金技术, 2015, 33(3): 170 doi: 10.3969/j.issn.1001-3784.2015.03.003

|

| [4] |

Singh S, Singh R. Effect of process parameters on micro hardness of Al–Al2O3 composite prepared using an alternative reinforced pattern in fused deposition modelling assisted investment casting. Rob Comput Integr Manuf, 2016, 37: 162 doi: 10.1016/j.rcim.2015.09.009

|

| [5] |

Nie L, Ma W M, Zhang Y, et al. Preparation and properties of Al2O3–ZrO2/Co–Ni–BN cermets. J Chin Ceram Soc, 2017, 45(6): 829聂力, 马伟民, 张勇, 等. Al2O3–ZrO2/Co–Ni–BN金属陶瓷的制备与性能. 硅酸盐学报, 2017, 45(6): 829

|

| [6] |

Song J G, Chen L, Guo X S, et al. Effect of raw material formulation on the properties of Al2O3–Al cermet materials. China Ceram, 2018, 54(7): 13宋杰光, 陈林, 郭新爽, 等. 原料配方对氧化铝/铝金属陶瓷材料性能的影响. 中国陶瓷, 2018, 54(7): 13

|

| [7] |

Qiao H X, Xiao H Y, Huang Y. SiO2 loading into polydopamine-functionalized TiO2 nanotubes for biomedical applications. Surf Coat Technol, 2019, 364: 170 doi: 10.1016/j.surfcoat.2019.02.089

|

| [8] |

Tao Z X, Cong S H, Peng J J, et al. Study on the microstructure and properties of multi-component hard phase reinforced Mo2FeB2 based cermets. Powder Metall Ind, 2018, 28(3): 44陶则旭, 从善海, 彭家健, 等. 多组元硬质相增强Mo2FeB2基金属陶瓷的组织和性能研究. 粉末冶金工业, 2018, 28(3): 44

|

| [9] |

Peng C Z, Xiong W, Yang J L, et al. Synthesis and application of silicon dioxide coated aluminum powders. Mater Prot, 2016, 49(10): 68彭成章, 熊伟, 杨佳霖, 等. SiO2包覆铝粉的合成及其应用. 材料保护, 2016, 49(10): 68

|

| [10] |

Pattnayak A, Madhu N, Panda A S. A Comparative study on mechanical properties of Al–SiO2 composites fabricated using rice husk silica in crystalline and amorphous form as reinforcement. Mater Today, 2018, 5(2): 8184

|

| [11] |

Song J G, Wang X Q, Chen L, et al. Preparation and properties of Al–Al2O3 metal ceramics via powder metallurgy methods. J Ceram Process Res, 2018, 19(1): 50

|

| [12] |

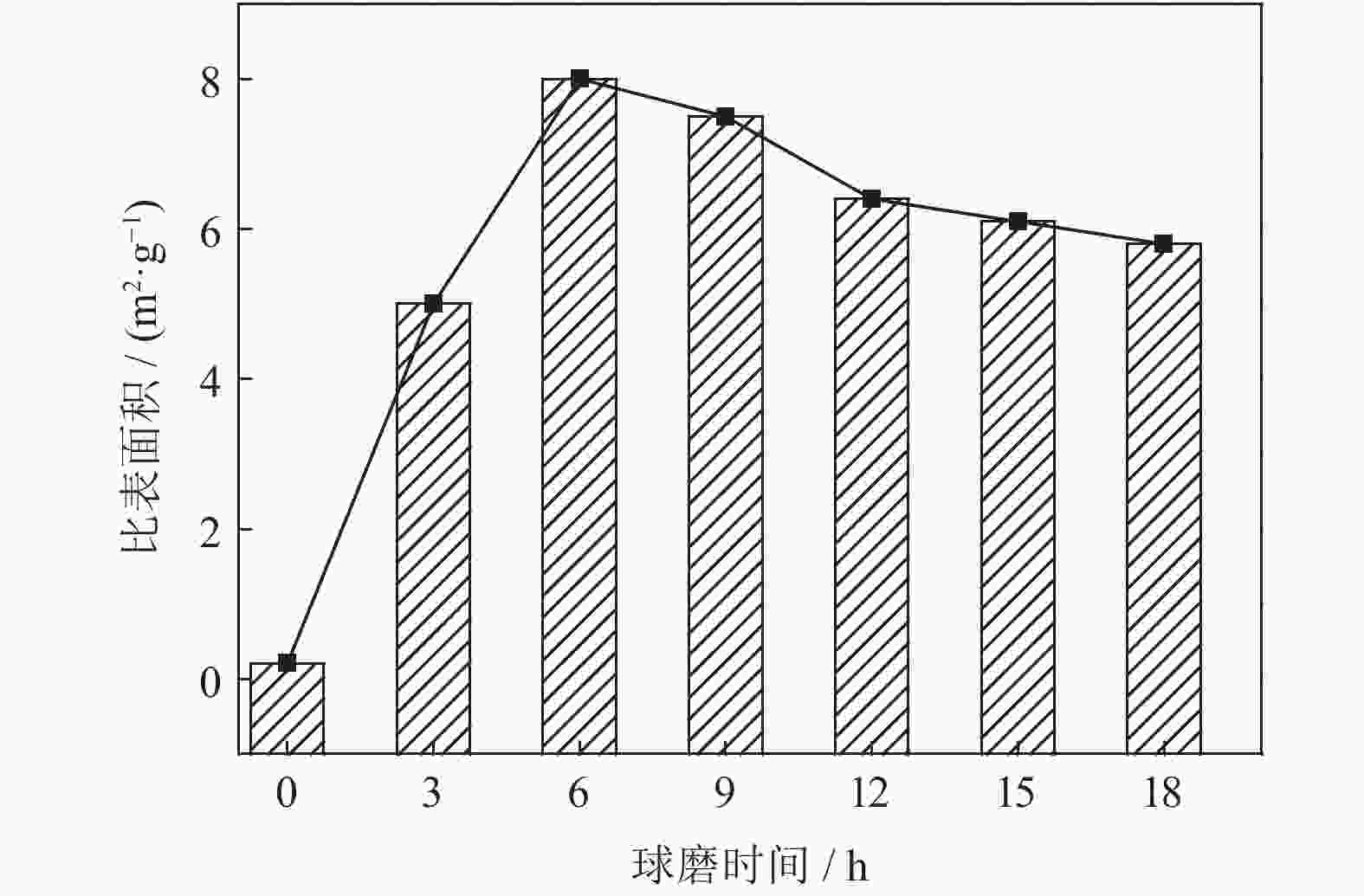

Yang C Y, Liu Y Z, Yu K B. Effects of ball milling time on microstructures and properties of graphene/ODS copper composite materials. Mater Sci Eng Powder Metall, 2018, 23(3): 281 doi: 10.3969/j.issn.1673-0224.2018.03.008杨长毅, 刘允中, 余开斌. 球磨时间对石墨烯/ODS铜基复合材料组织与性能的影响. 粉末冶金材料科学与工程, 2018, 23(3): 281 doi: 10.3969/j.issn.1673-0224.2018.03.008

|

| [13] |

Wu L M, Wu Y, Zhang Z Z, et al. Preparation process of h–BN nanosheets by ball milling enhanced liquid phase exfoliation methods. J Synth Cryst, 2018, 47(11): 2248 doi: 10.3969/j.issn.1000-985X.2018.11.003武黎明, 武杨, 张振忠, 等. 球磨增强液相剥离法制备h–BN纳米片的工艺研究. 人工晶体学报, 2018, 47(11): 2248 doi: 10.3969/j.issn.1000-985X.2018.11.003

|

| [14] |

Fan T, Shen X, Wang H, et al. Effects of ball milling technology on microstructure and properties of SiCp/Cu composites prepared by in situ synthesis. Powder Metall Technol, 2016, 34(4): 264 doi: 10.3969/j.issn.1001-3784.2016.04.005范涛, 申珣, 王虎, 等. 球磨工艺对原位合成SiCp增强铜复合材料组织及性能的影响. 粉末冶金技术, 2016, 34(4): 264 doi: 10.3969/j.issn.1001-3784.2016.04.005

|

| [15] |

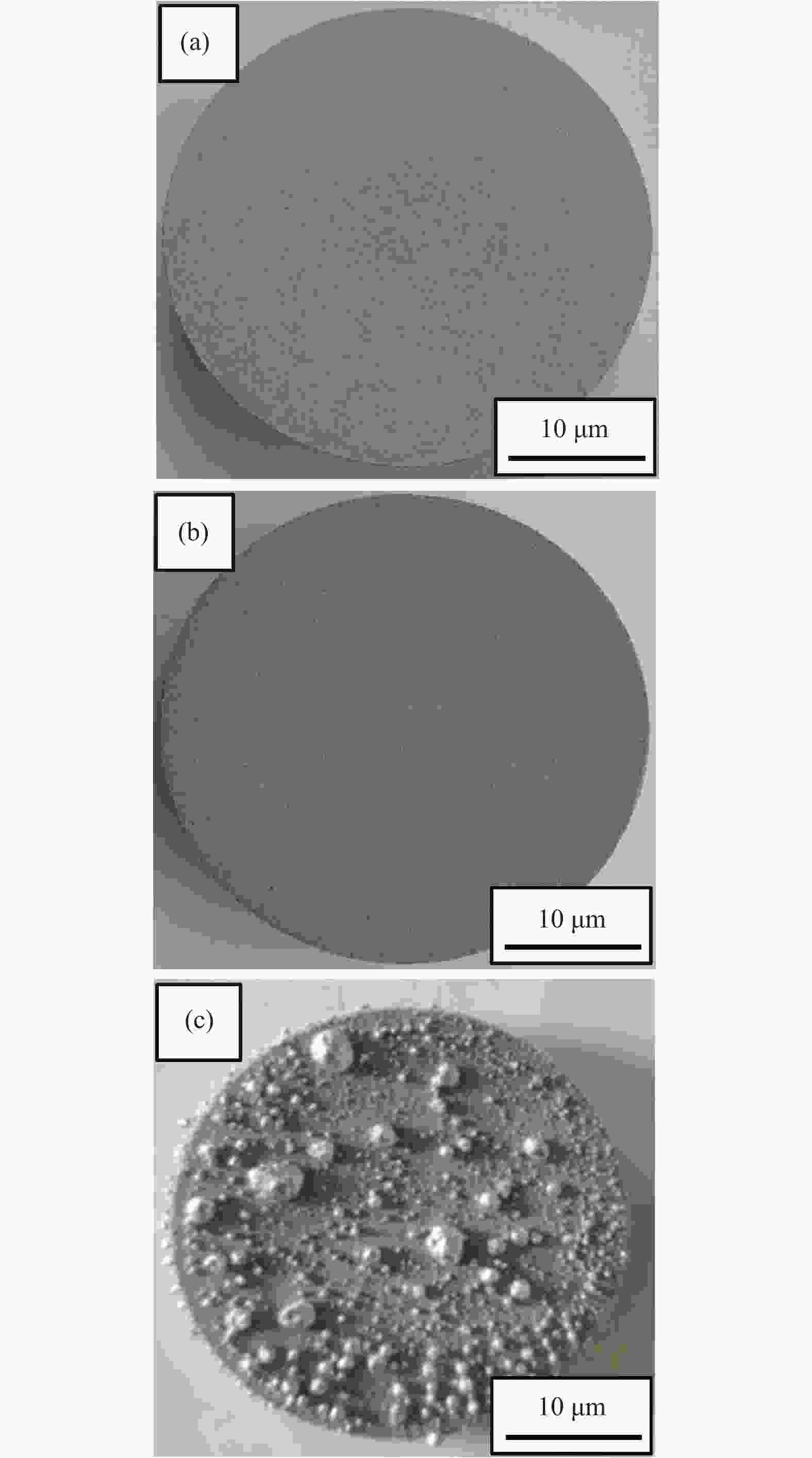

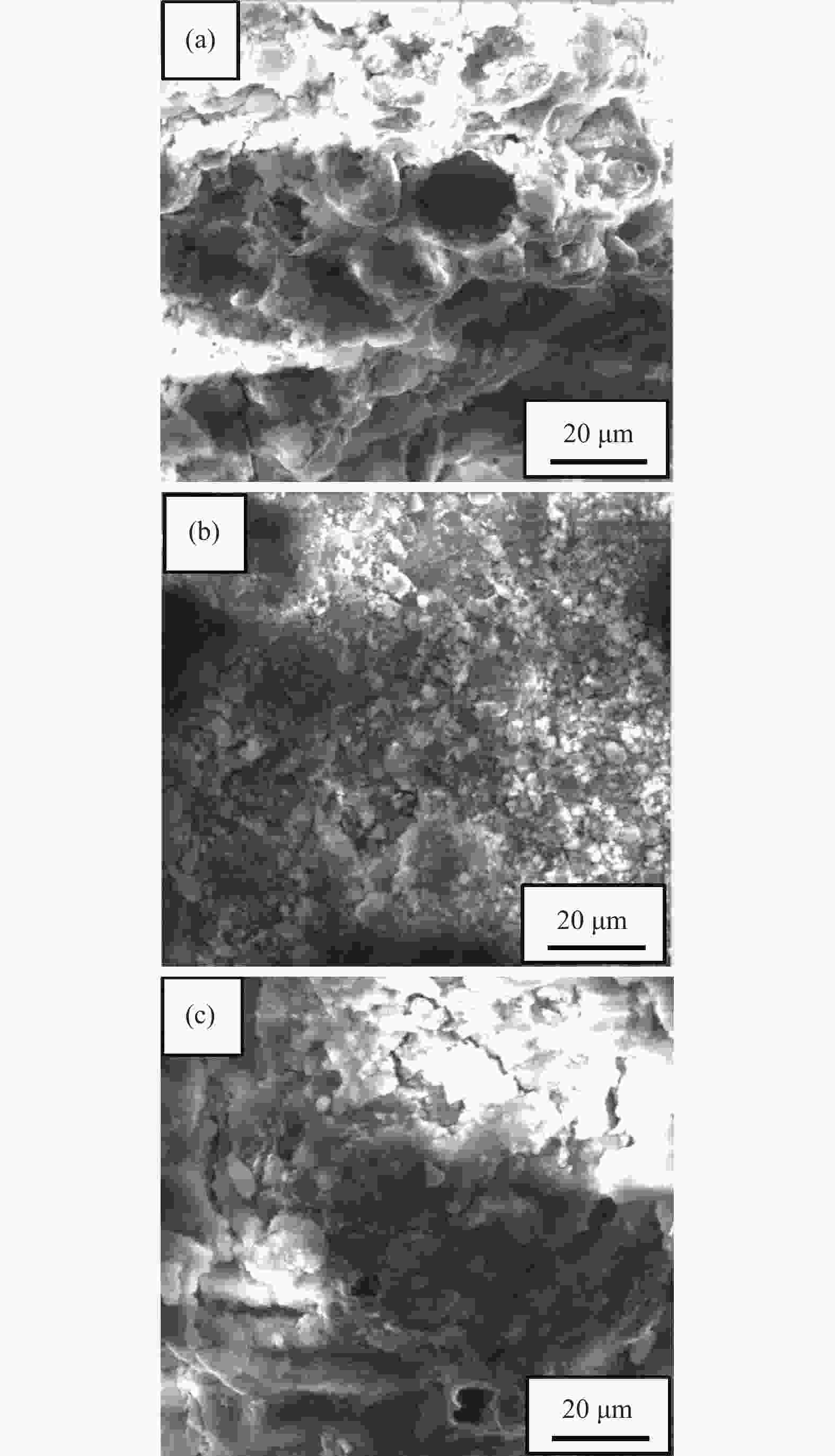

Song J G, Liu Y, He L, et al. Influence of ball milling process on the pinned effect of Al2O3/Al cermet composite powder. Key Eng Mater, 2018, 777: 80 doi: 10.4028/www.scientific.net/KEM.777.80

|

| [16] |

Beata L M, Dariusz G, Marcin M. Effect of sintering temperature on microstructure and selected properties of spark plasma sintered Al–SiC composites. Vacuum, 2019, 164: 250 doi: 10.1016/j.vacuum.2019.03.033

|

| [17] |

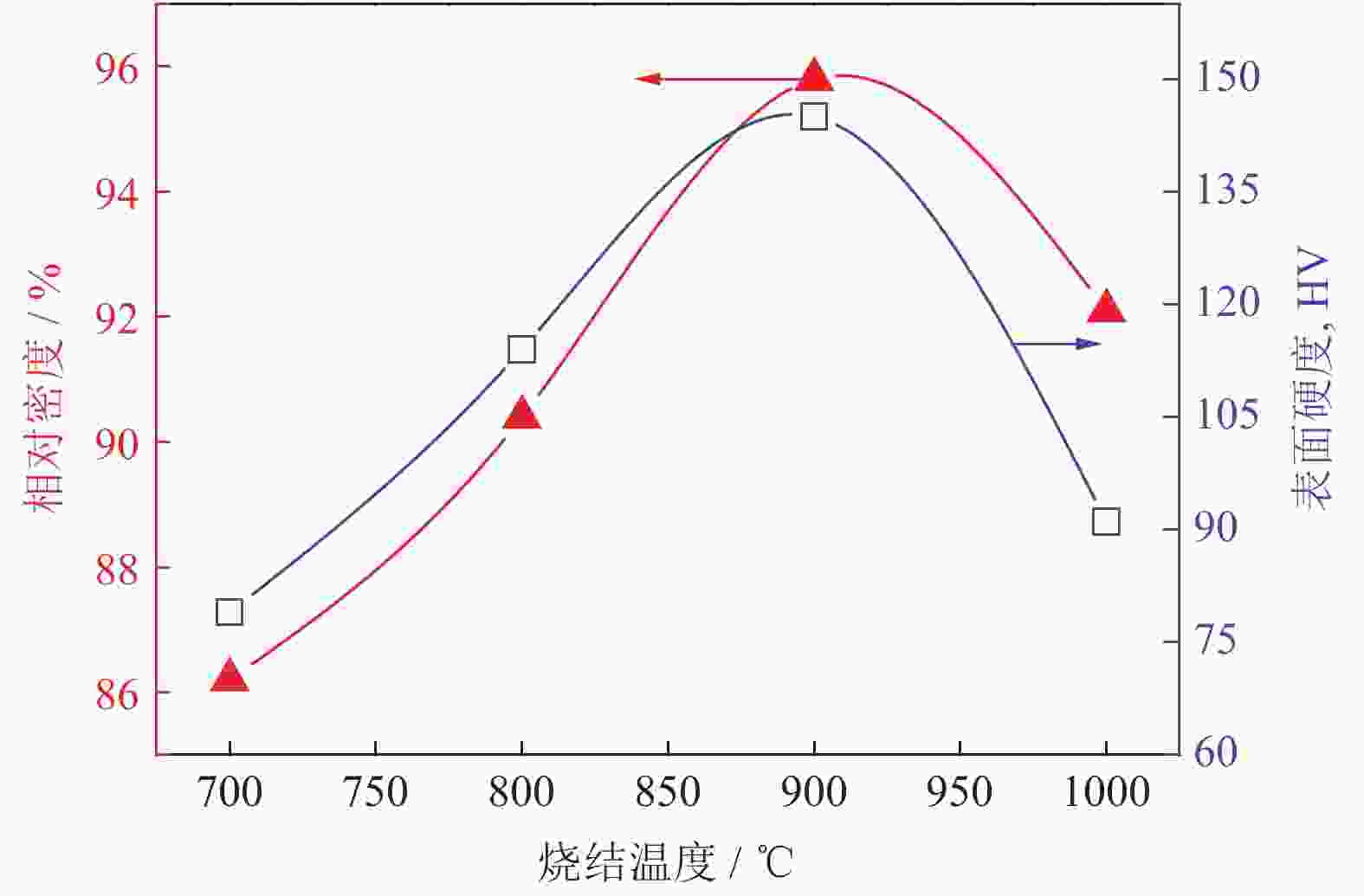

Ge Y X, Yang Z H, Sun L M, et al. Effect of sintering temperature on properties of copper-graphite composite materials. Trans Mater Heat Treat, 2019, 40(2): 8葛月鑫, 杨正海, 孙乐民, 等. 烧结温度对铜–石墨复合材料性能的影响. 材料热处理学报, 2019, 40(2): 8

|

| [18] |

Song J G, Liu Y, Pang C L, et al. Sintering densification and properties of Al2O3/Al cermet materials via powder metallurgy method. J Ceram Process Res, 2018, 19(2): 142

|

下载:

下载: