-

摘要: 石墨烯因其独特的二维结构和优异的导热、导电及力学性能,成为了最具潜力的增强体材料之一。本文综述了铝−石墨烯复合材料的制备工艺,着重介绍了影响铝−石墨烯复合材料力学性能和导电率的因素,总结了铝−石墨烯复合材料在高强高导材料领域的应用,讨论了产业化过程中在优质石墨烯粉制备、规模化混粉工艺、连续化加工等方面所面临的挑战,提出了铝−石墨烯复合材料可能的产业化工艺方案和研发方向。Abstract: Graphene has become one of the most potential reinforcing materials because of the unique two-dimensional structure and the excellent thermal, electrical, and mechanical properties. In this paper, the preparation of the aluminum−graphene composites was reviewed. The influence factors on the mechanical properties and conductivity performances of the aluminum−graphene composites were introduced. Subsequently, the applications of the aluminum−graphene composites in the field of high strength and high conductivity materials were investigated. Challenges on the preparation of high quality graphene powders, the scale production of mixing powders, and the continuously processing method in the industrialization were discussed. The possible technological methods for the industrialization of aluminum−graphene composites and the potential research directions were proposed.

-

Key words:

- composites /

- graphene /

- high-strength /

- high-conductivity /

- research progress

-

表 1 不同实验条件下的铝−石墨烯复合材料力学性能

Table 1. Mechanical properties of the aluminum-graphene composites under the different experimental conditions

石墨烯质量

分数 / %基体 力学性能 较基体材料增幅 延伸率 /

%参考文献 极限抗拉强度 / MPa 屈服强度 / MPa 抗拉强度增幅 / % 屈服强度增幅 / % 0.25 纯Al 164 112 56 38 15.0 [37] 0.50 152 104 45 28 13.0 1.00 138 92 31 13 12.0 0.50 纯Al 173 136 17 9 45.7 [27] 1.00 248 194 69 55 15.2 0.30 纯Al 280 195 11 14 — [29] 0.50 纯Al 105 — 20 — — [42] 0.50 纯Al 165 139 21 26 18.1 [24] 177 148 30 34 18.8 0.30 Al−Mg−Cu 455 322 25 58 11.8 [32] 0.15 Al−Mg−Cu 400 262 7 22 — [39] 0.50 467 319 25 49 — 材料 石墨烯质量分数 / % 加工工艺 抗拉强度 / MPa 电导率 / %IACS 薄层石墨烯增强铝基复合材料(FLG/Al) 0 SPS+热挤压 137 62.20 0.42 833 K温度下SPS+热挤压 165 60.00 0.42 883 K温度下SPS+热挤压 177 59.80 石墨烯增强铝基复合材料(Gr/Al) 0 铸造+冷轧+200 ℃时效0 h 67 58.27 0.50 铸造+冷轧+200 ℃时效0 h 92 57.41 0.50 铸造+冷轧+200 ℃时效1 h 180 63.45 0.50 铸造+冷轧+200 ℃时效2 h 177 63.10 0.50 铸造+冷轧+200 ℃时效4 h 148 62.93 0.50 铸造+冷轧+200 ℃时效6 h 145 63.27 表 3 常见架空导线的力学及导电性能[50]

Table 3. Mechanical and electrical conductivity performance of the common overhead conductors[50]

编号 类别 牌号 名义抗拉强度,σb / MPa 名义密度,σ / (g·cm−3) 20 ℃导电率,Y / %IACS 1 铝绞线 JL-400-37 160 2.755 59.8 2 钢芯铝绞线 JL/GIA-400/25 230 3.087 55.8 3 铝包钢芯铝绞线 JL/LBIA-395/25 232 3.013 56.9 4 铝合金绞线 JLHAI-400-37 315 2.755 51.4 5 钢芯铝合金绞线 JLHAI/GIA-400/25 380 3.087 48.0 6 铝包钢芯铝合金绞线 JLHAI/LBIA-455/30 372 3.010 49.3 7 铝合金芯铝绞线 JL/LHAI-415/95 186 2.757 58.0 -

[1] Novoselov K S, Geim A K, Morozov S V, et al. Electric field effect in atomically thin carbon flms. Science, 2004, 306(5696): 666 doi: 10.1126/science.1102896 [2] Lee C, Wei X, Kysar J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science, 2008, 321(5887): 385 doi: 10.1126/science.1157996 [3] Balandin A A, Ghosh S, Bao W, et al. Superior thermal conductivity of single-layer graphene. Nano Lett, 2008, 8(3): 902 doi: 10.1021/nl0731872 [4] Bolotin K I, Sikes K J, Jiang Z, et al. Ultrahigh electron mobility in suspended graphene. Solid State Commun, 2008, 146(9-10): 351 doi: 10.1016/j.ssc.2008.02.024 [5] Liu Y, Xu Z, Zhan J, et al. Superb electrically conductive graphene fibers via doping strategy. Adv Mater, 2016, 28(36): 7941 doi: 10.1002/adma.201602444 [6] Saboori A, Dadkhah M, Fino P, et al. An overview of metal matrix nanocomposites reinforced with graphene nanoplatelets; mechanical, electrical and thermophysical properties. Metals, 2018, 8(6): 423 doi: 10.3390/met8060423 [7] Zhu Y, Murali S, Stoller M D, et al. Carbon-based supercapacitors produced by activation of graphene. Science, 2011, 332(6037): 1537 doi: 10.1126/science.1200770 [8] Yan S J, Yang C, Hong Q H, et al. Research of graphene-reinforced aluminum matrix nanocomposites. J Mater Eng, 2014(4): 1 doi: 10.3969/j.issn.1001-4381.2014.04.001燕绍九, 杨程, 洪起虎, 等. 石墨烯增强铝基纳米复合材料的研究. 材料工程, 2014(4): 1 doi: 10.3969/j.issn.1001-4381.2014.04.001 [9] Wang J, Li Z, Fan G, et al. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr Mater, 2012, 66(8): 594 doi: 10.1016/j.scriptamat.2012.01.012 [10] Chen Y, Bi J, Yin C, et al. Microstructure and fracture toughness of graphene nanosheets/alumina composites. Ceram Int, 2014, 40(9): 13883 doi: 10.1016/j.ceramint.2014.05.107 [11] Liu J, Yan H, Jiang K. Mechanical properties of graphene platelet-reinforced alumina ceramic composites. Ceram Int, 2013, 39(6): 6215 doi: 10.1016/j.ceramint.2013.01.041 [12] Lin J, Zhang P, Zheng C, et al. Reduced silanized graphene oxide/epoxy-polyurethane composites with enhanced thermal and mechanical properties. Appl Surf Sci, 2014, 316: 114 doi: 10.1016/j.apsusc.2014.07.058 [13] Wang Y, Zhou J X, Cheng K M, et al. Progress on preparation, microstructure and property of graphene reinforced aluminum matrix composite. Mater Sci Forum, 2017, 898: 917 doi: 10.4028/www.scientific.net/MSF.898.917 [14] Zhang D D, Shen H L, Cao X, et al. Research progress in graphene reinforced aeronautical metal matrix composites. J Mater Eng, 2019, 47(1): 1 doi: 10.11868/j.issn.1001-4381.2018.000175张丹丹, 沈洪雷, 曹霞, 等. 石墨烯增强金属基航空复合材料研究进展. 材料工程, 2019, 47(1): 1 doi: 10.11868/j.issn.1001-4381.2018.000175 [15] Wang J Q, Lei W N, Xue Z M, et al. Research progress on synthesis and application of graphene reinforced metal matrix composites. J Mater Eng, 2018, 46(12): 18 doi: 10.11868/j.issn.1001-4381.2017.001534王剑桥, 雷卫宁, 薛子明, 等. 石墨烯增强金属基复合材料的制备及应用研究进展. 材料工程, 2018, 46(12): 18 doi: 10.11868/j.issn.1001-4381.2017.001534 [16] Li J, Yu X, Zhang J. Application progress of graphene composites for electric transmission and storage device. J New Ind, 2017, 7(2): 1李嘉, 于翔, 张静. 石墨烯复合材料在输电储电器件中的应用进展. 新型工业化, 2017, 7(2): 1 [17] Dong G X, Lü Y N, Han W D, et al. The progress of research on electrode materials of super-capacitors. Powder Metall Technol, 2016, 34(5): 384 doi: 10.3969/j.issn.1001-3784.2016.05.012董桂霞, 吕易楠, 韩伟丹, 等. 超级电容器电极材料的研究进展. 粉末冶金技术, 2016, 34(5): 384 doi: 10.3969/j.issn.1001-3784.2016.05.012 [18] Su Y, Li Z, Yu Y, et al. Composite structural modeling and tensile mechanical behavior of graphene reinforced metal matrix composites. Sci China Mater, 2018, 61(1): 112 doi: 10.1007/s40843-017-9142-2 [19] Buasri A, Prasanwon C, Boonsong B, et al. The fabrication of graphene-reinforced aluminum composites by powder metallurgy and uniaxial pressing. Key Eng Mater, 2018, 780: 10 doi: 10.4028/www.scientific.net/KEM.780.10 [20] Yang H, Tang Y, Yang P. Factors influencing thermal transport across graphene/metal interfaces with van der Waals interactions. Nanoscale, 2019, 11(30): 14155 doi: 10.1039/C9NR03538A [21] Kwon H, Mondal J, Alogab K A, et al. Graphene oxide-reinforced aluminum alloy matrix composite materials fabricated by powder metallurgy. J Alloys Compd, 2017, 698: 807 doi: 10.1016/j.jallcom.2016.12.179 [22] Zhu J, Yang Q, He X, et al. Micro-mechanism of interfacial separation and slippage of graphene/aluminum nanolaminated composites. Nanomaterials, 2018, 8(12): 1046 doi: 10.3390/nano8121046 [23] Saboori A, Pavese M, Badini C, et al. Microstructure and thermal conductivity of Al–graphene composites fabricated by powder metallurgy and hot rolling techniques. Acta Metall Sinica, 2017, 30(7): 675 doi: 10.1007/s40195-017-0579-2 [24] Zhou W, Mikulova P, Fan Y, et al. Interfacial reaction induced efficient load transfer in few-layer graphene reinforced Al matrix composites for high-performance conductor. Composites Part B, 2019, 167: 93 doi: 10.1016/j.compositesb.2018.12.018 [25] Saboori A, Moheimani S K, Dadkhah M, et al. An overview of key challenges in the fabrication of metal matrix nanocomposites reinforced by graphene nanoplatelets. Metals, 2018, 8(3): 172 doi: 10.3390/met8030172 [26] Li D S, Wu W Z, Qin Q H, et al. Microstructure and mechanical properties of graphene/Al composites. Chin J Nonferrous Met, 2015, 25(6): 1498李多生, 吴文政, QIN Qing-hua, 等. 石墨烯/Al复合材料的微观结构及力学性能. 中国有色金属学报, 2015, 25(6): 1498 [27] Li J L, Xiong Y C, Wang X D, et al. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater Sci Eng A, 2015, 626: 400 doi: 10.1016/j.msea.2014.12.102 [28] Zhao L, Lu H, Gao Z. Microstructure and mechanical properties of Al/Graphene composite produced by high-pressure torsion. Adv Eng Mater, 2015, 17(7): 976 doi: 10.1002/adem.201400375 [29] Rashad M, Pan F, Tang A, et al. Effect of graphene nanoplatelets addition on mechanical properties of pure aluminum using a semi-powder method. Prog Nat Sci, 2014, 24(2): 101 doi: 10.1016/j.pnsc.2014.03.012 [30] Yang B, Du G X, Cheng F L, et al. Preparation and mechanical properties of graphene reinforced-Al7075 composite by semi-solid sintering. Powder Metall Technol, 2018, 36(4): 303杨斌, 杜更新, 程福来, 等. 半固态烧结制备石墨烯/7075铝基复合材料与性能研究. 粉末冶金技术, 2018, 36(4): 303 [31] Jain V, Kumar A, Sivaiah B, et al. Synthesis of aluminum-graphene nanocomposite sintered using spark plasma sintering. Frontiers in Materials Processing, Applications, Research and Technology. Eds by Muruganant M, Chirazi A, Raj B, Springer, Singapore, 2018: 155 [32] Zhao S Z, Yan S J, Chen X, et al. Effect of SPS process on tensile properties of graphene nanosheet reinforced aluminum matrix composites. Rare Met Mater Eng, 2019, 48(2): 632赵双赞, 燕绍九, 陈翔, 等. SPS工艺对石墨烯增强铝基复合材料拉伸性能的影响. 稀有金属材料与工程, 2019, 48(2): 632 [33] Zou J Y. The Preparation and Properties of Graphene Reinforced Pure Aluminum Composites [Dissertation]. Harbin: Harbin Institute of Technology, 2015邹君玉. 石墨烯/纯铝复合材料的制备及其性能研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2015 [34] Guan R G, Lian C, Zhao Z Y, et al. Study on preparation of graphene and Al-graphene composite. Rare Met Mater Eng, 2012, 41(Suppl 2): 607管仁国, 连超, 赵占勇, 等. 石墨烯铝基复合材料的制备及其性能. 稀有金属材料与工程, 2012, 41(增刊 2): 607 [35] Chyada F A, Jabur A R, Alwan H A. Effect addition of graphene on electrical conductivity and tensile strength for recycled electric power transmission wires. Energy Procedia, 2017, 119: 121 doi: 10.1016/j.egypro.2017.07.055 [36] Yao H, Liao J, Cui X D, et al. Research progress of Al/C composite. Hot Working Technol, 2016, 45(22): 43姚辉, 廖晶, 崔晓东, 等. 铝碳复合材料的研究进展. 热加工工艺, 2016, 45(22): 43 [37] Li G, Xiong B. Effects of graphene content on microstructures and tensile property of graphene-nanosheets/aluminum composites. J Alloys Compd, 2017, 697: 31 doi: 10.1016/j.jallcom.2016.12.147 [38] Lu N N, Xu L, Li C Y, et al. Research progress on preparation technology of aluminum matrix composites reinforced by graphene. Powder Metall Technol, 2017, 35(4): 310鲁宁宁, 许磊, 历长云, 等. 石墨烯增强铝基复合材料制备技术研究进展. 粉末冶金技术, 2017, 35(4): 310 [39] Yan S J, Dai S L, Zhang X Y, et al. Investigating aluminum alloy reinforced by graphene nanoflakes. Mater Sci Eng A, 2014, 612: 440 doi: 10.1016/j.msea.2014.06.077 [40] Xiao R. Study of Preparation and Properties of Graphene and Graphene-Reinforced Al−20Si Composites [Dissertation]. Harbin: Harbin Institute of Technology, 2014肖瑞. 石墨烯及其Al−20Si基复合材料的制备与性能研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2014 [41] Li Z, Fan G, Tan Z, et al. Uniform dispersion of graphene oxide in aluminum powder by direct electrostatic adsorption for fabrication of graphene/aluminum composites. Nanotechnology, 2014, 25(32): 325601 doi: 10.1088/0957-4484/25/32/325601 [42] Qi T J, Yu Z M, Xu Z P, et al. Preparation and mechanical properties of graphene reinforced aluminum composites. J Harbin Univ Sci Technol, 2015, 20(3): 61齐天娇, 俞泽民, 许志鹏, 等. 石墨烯增强铝基复合材料制备及力学性能研究. 哈尔滨理工大学学报, 2015, 20(3): 61 [43] Bartolucci S F, Paras J, Rafiee M A, et al. Graphene–aluminum nanocomposites. Mater Sci Eng A, 2011, 528(27): 7933 doi: 10.1016/j.msea.2011.07.043 [44] Yu Z, Yang W, Zhou C, et al. Effect of ball milling time on graphene nanosheets reinforced Al6063 composite fabricated by pressure infiltration method. Carbon, 2019, 141: 25 doi: 10.1016/j.carbon.2018.09.041 [45] Zhou W, Bang S, Kurita H, et al. Interface and interfacial reactions in multi-walled carbon nanotube-reinforced aluminum matrix composites. Carbon, 2016, 96: 919 doi: 10.1016/j.carbon.2015.10.016 [46] Nam Y, Ki D K, Soler-Delgado D, et al. A family of finite-temperature electronic phase transitions in graphene multilayers. Science, 2018, 362(6412): 324 doi: 10.1126/science.aar6855 [47] Khan M, Din R U, Wadood A, et al. Effect of graphene nanoplatelets on the physical and mechanical properties of Al6061 in fabricated and T6 thermal conditions. J Alloys Compd, 2019, 790: 1076 doi: 10.1016/j.jallcom.2019.03.222 [48] Tokutomi J, Uemura T, Sugiyama S, et al. Hot extrusion to manufacture the metal matrix composite of carbon nanotube and aluminum with excellent electrical conductivities and mechanical properties. CIRP Annals, 2015, 64(1): 257 doi: 10.1016/j.cirp.2015.04.083 [49] Tian R Z. Aluminum Alloy and Its Processing Manual. 2nd Ed. Changsha: Central south university, 2005田荣璋. 铝合金及其加工手册. 2版. 长沙: 中南大学出版社, 2005 [50] Yang E N, Wu X M, Li C H, et al. Electromechanical properties, current situation and development of aluminum alloys for overhead conductors. Mater Rev, 2014, 28(17): 111杨恩娜, 吴细毛, 李春和, 等. 架空导线用铝合金的机电性能及现状与发展. 材料导报, 2014, 28(17): 111 -

下载:

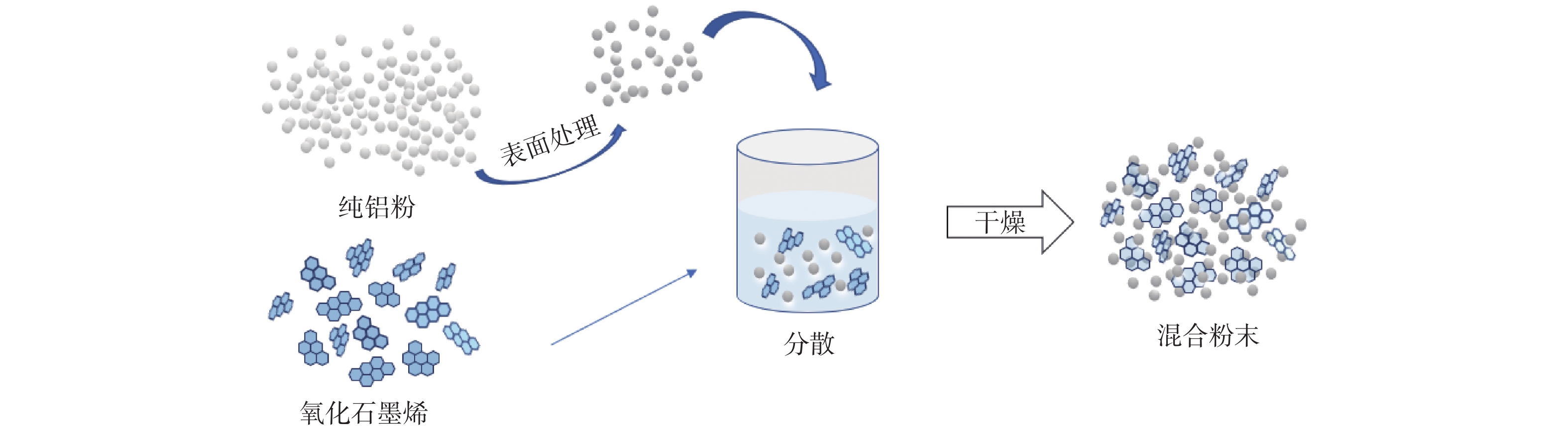

下载: