-

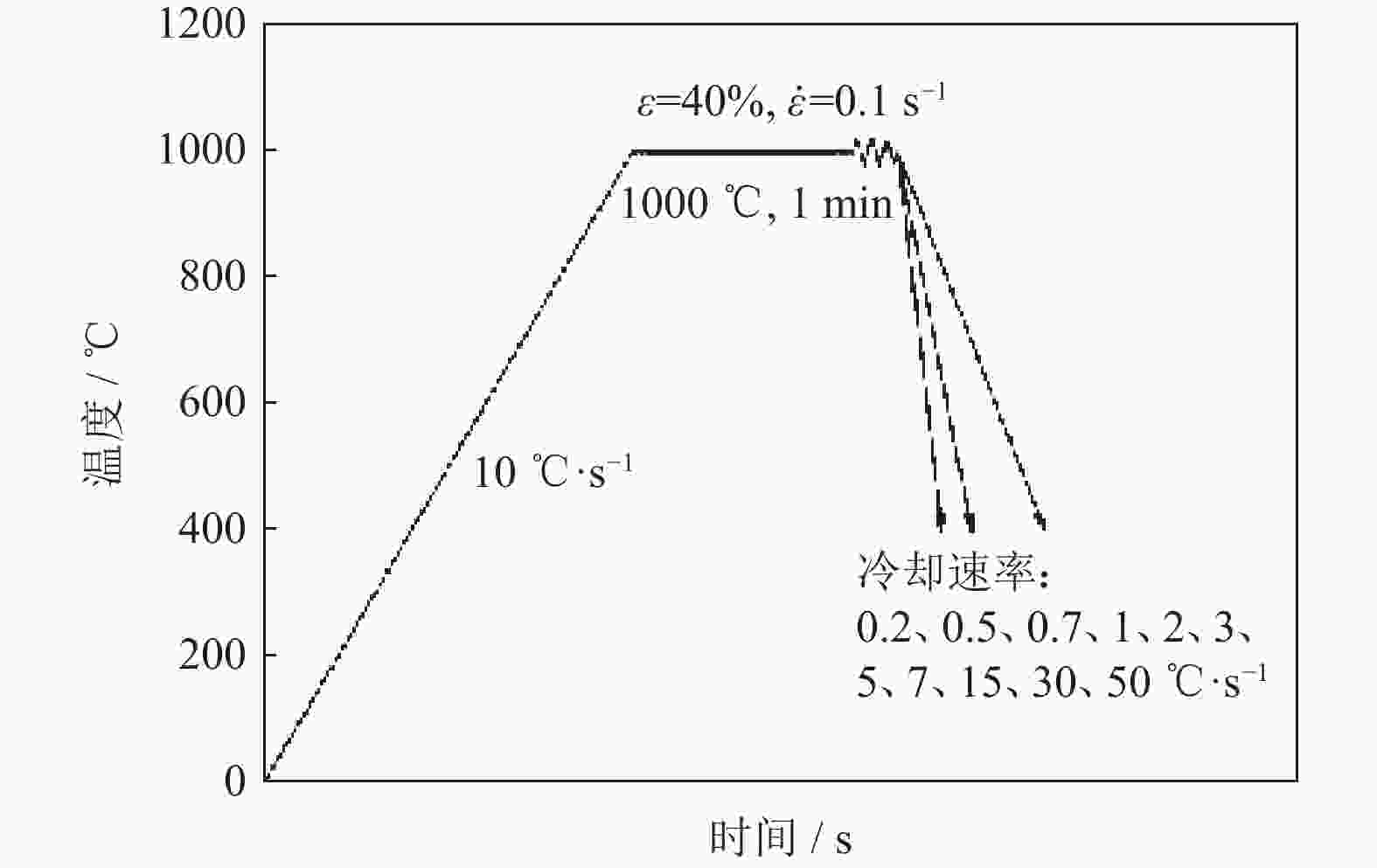

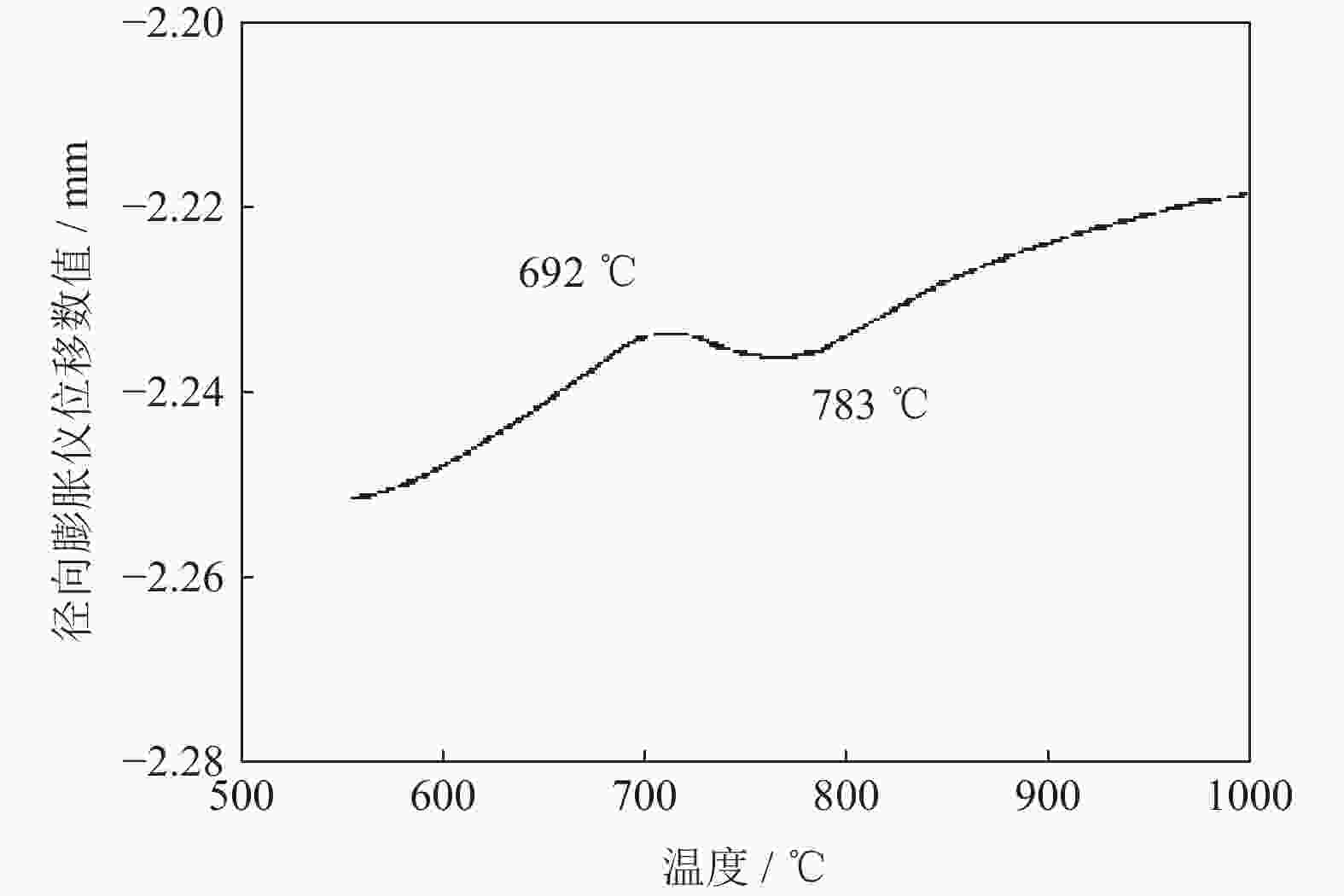

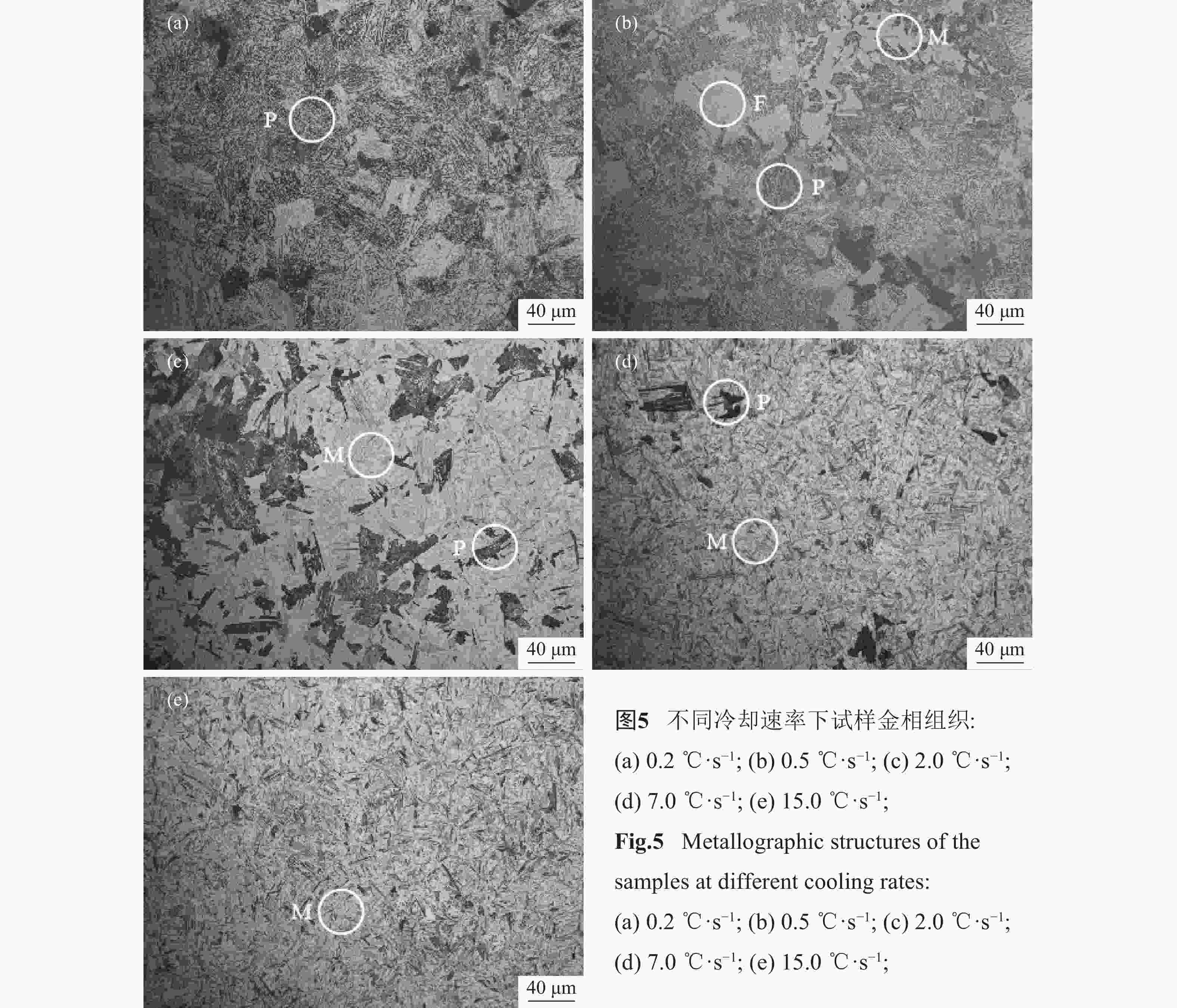

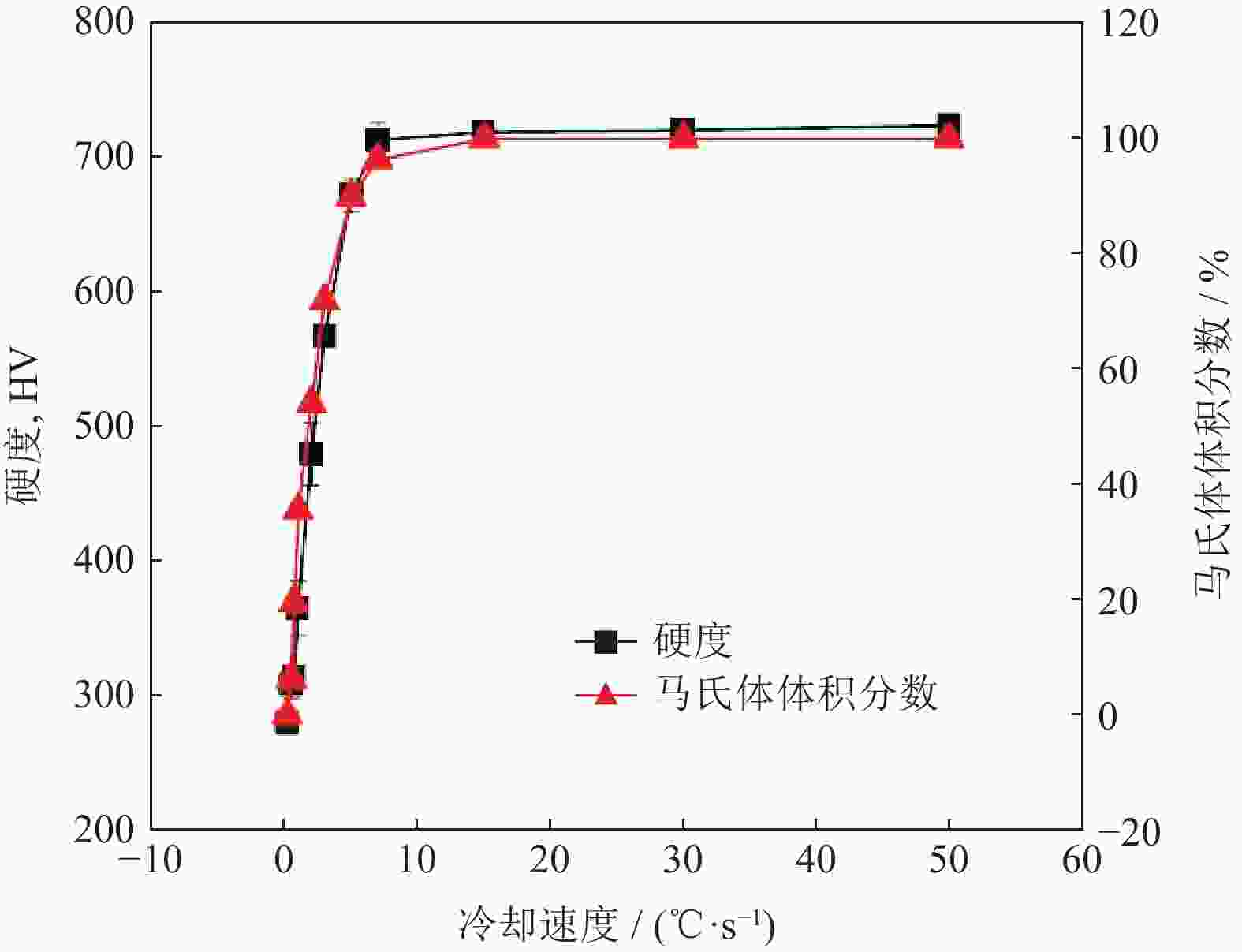

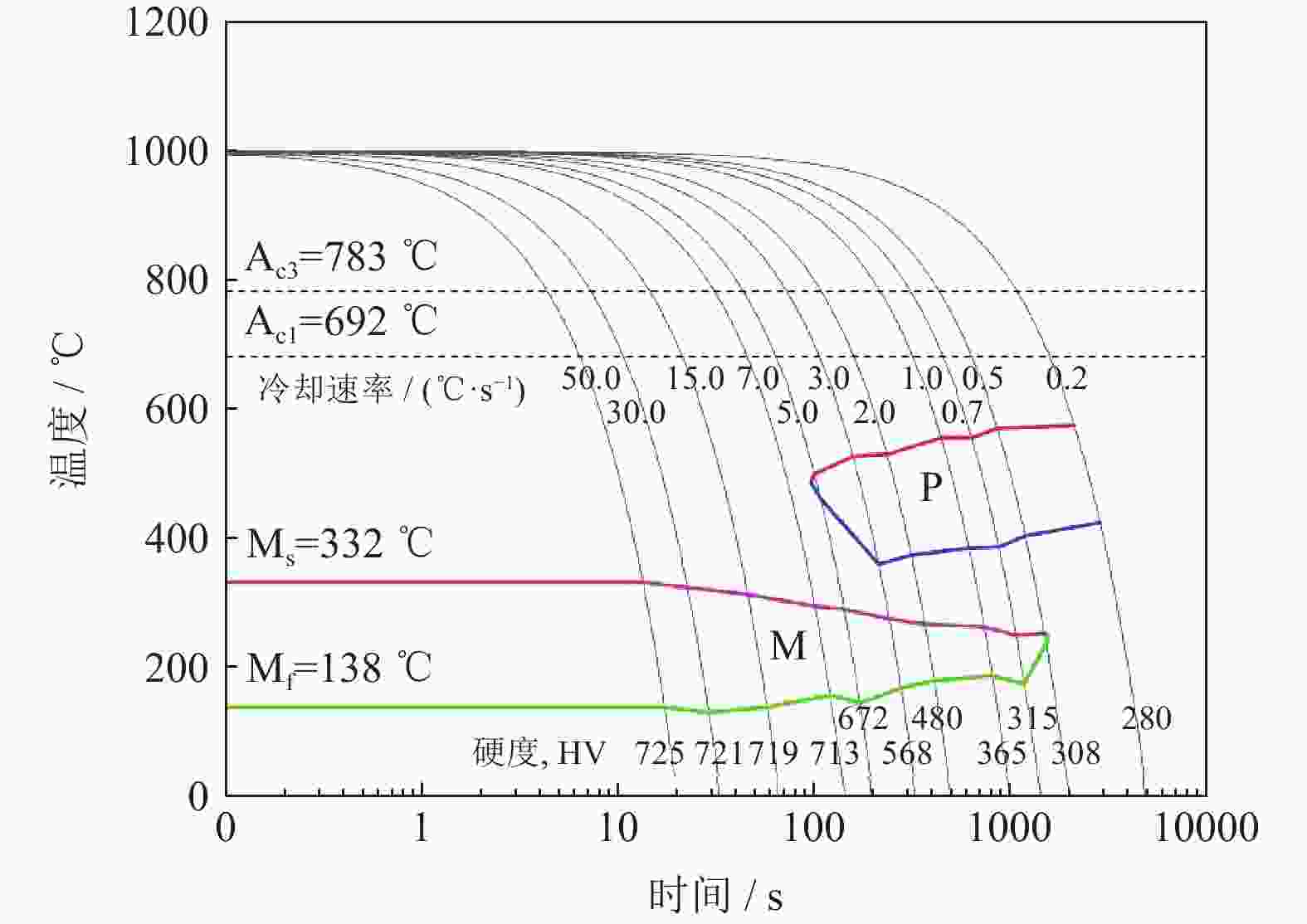

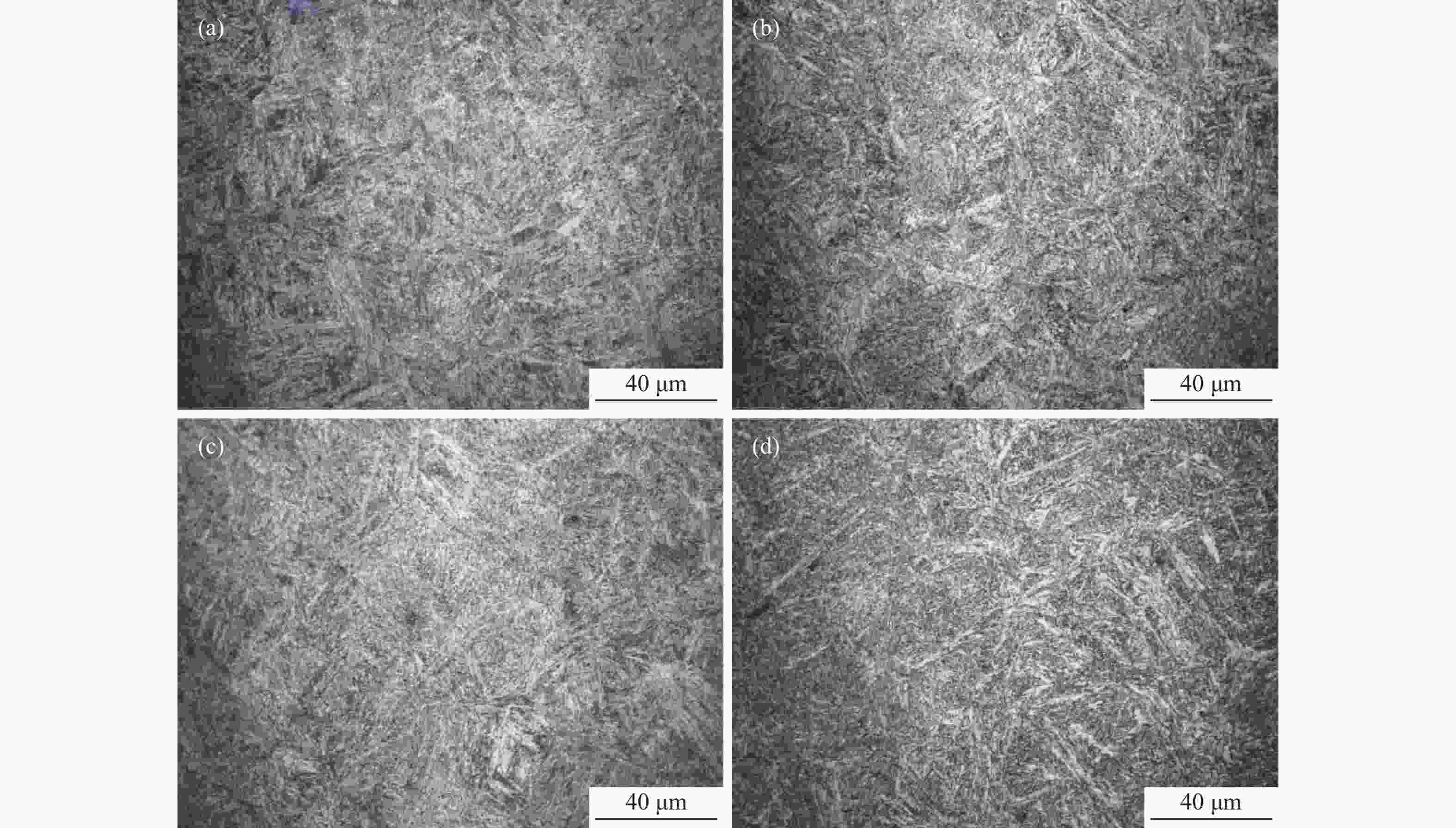

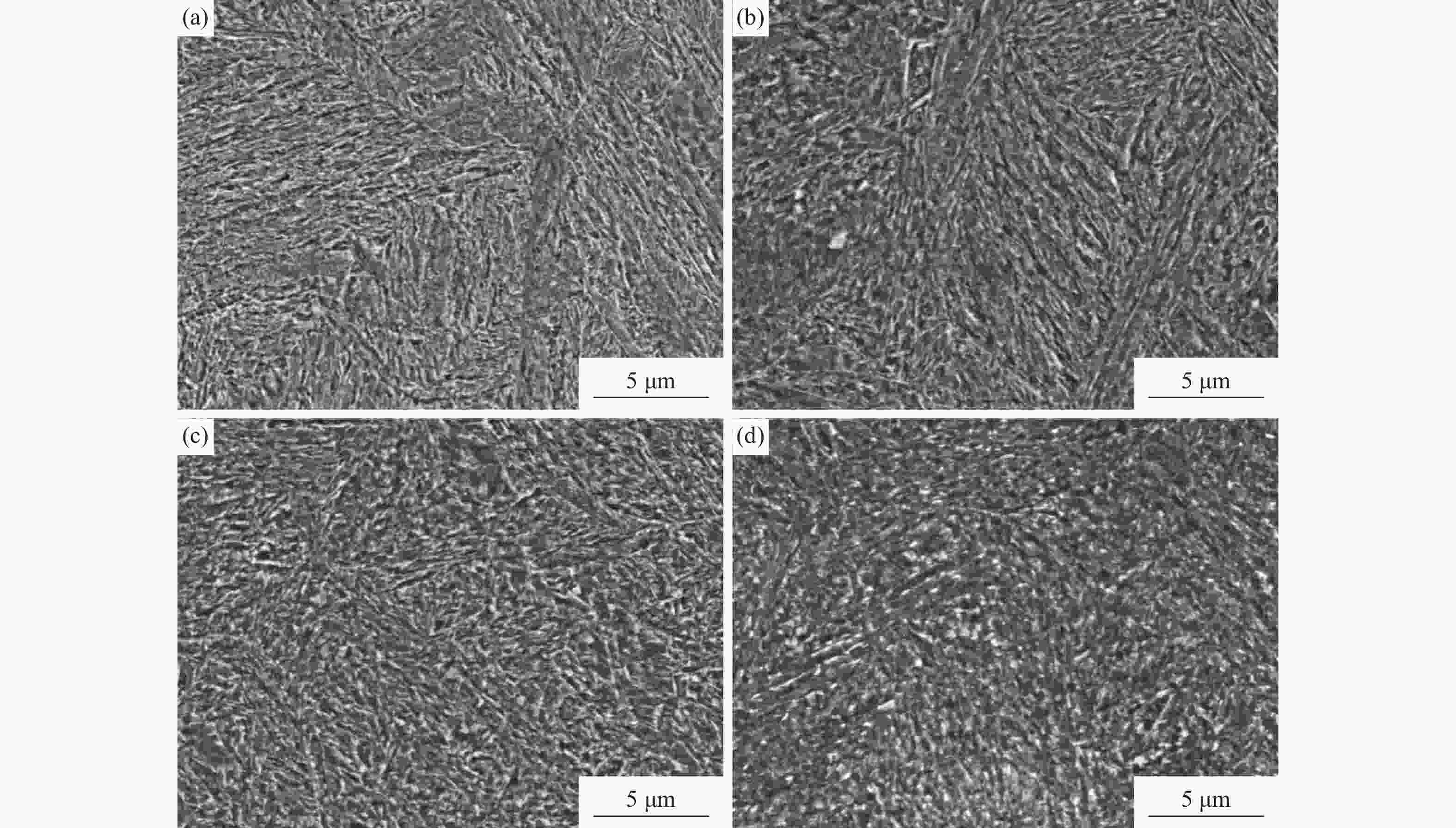

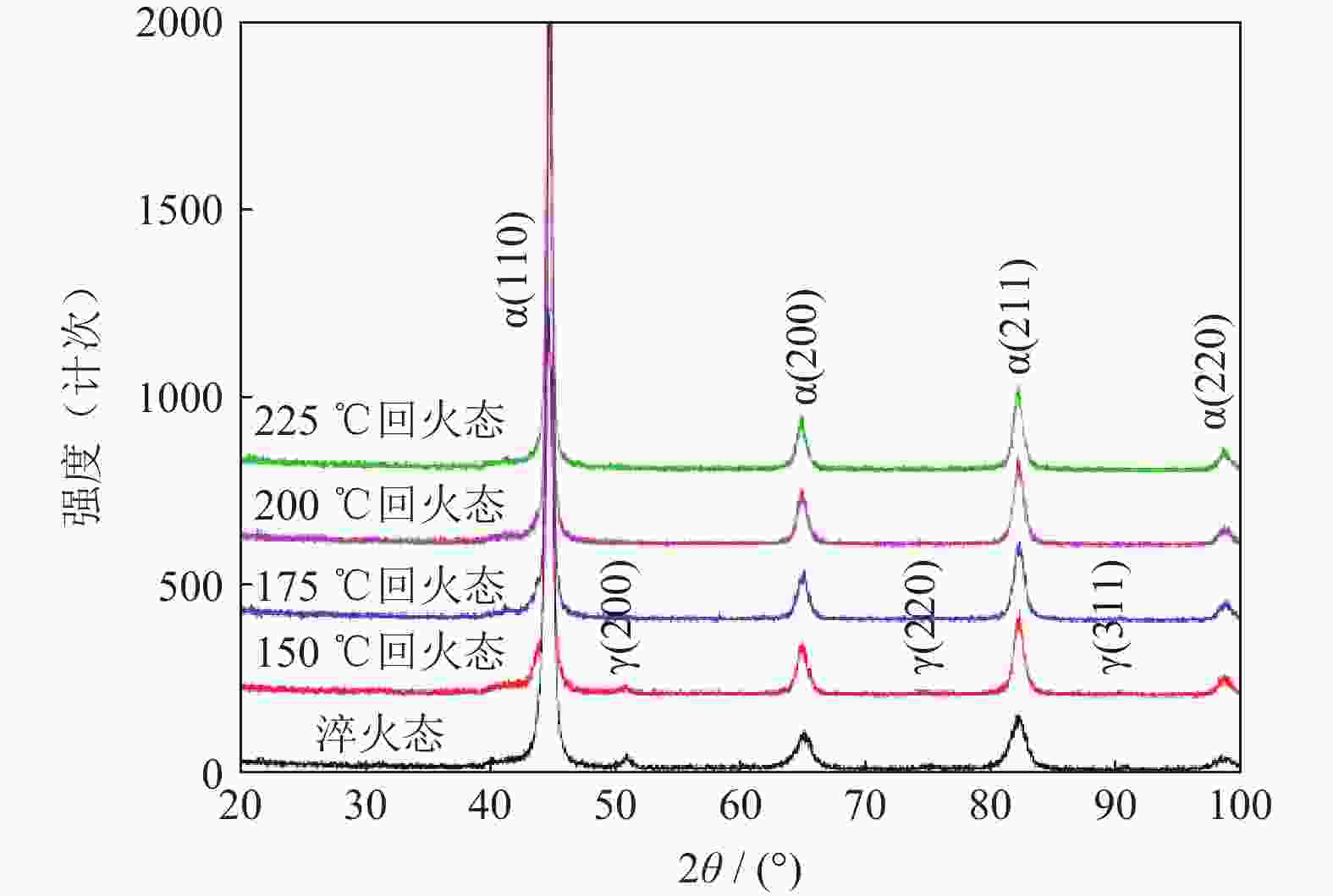

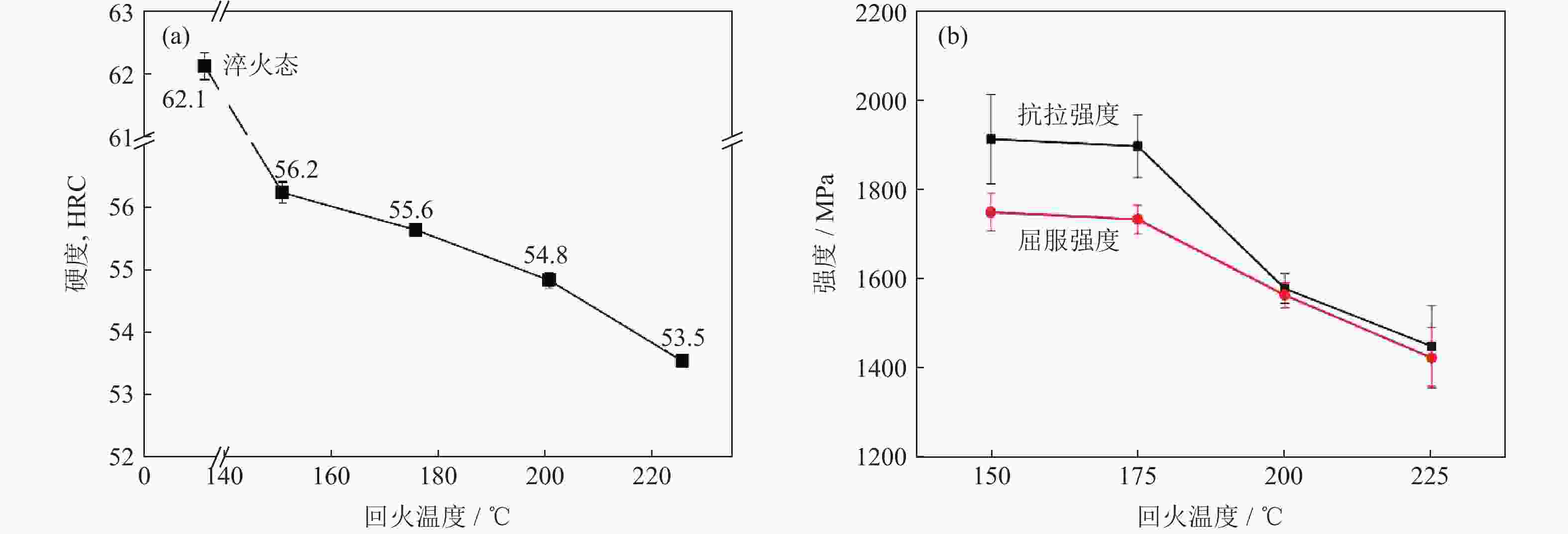

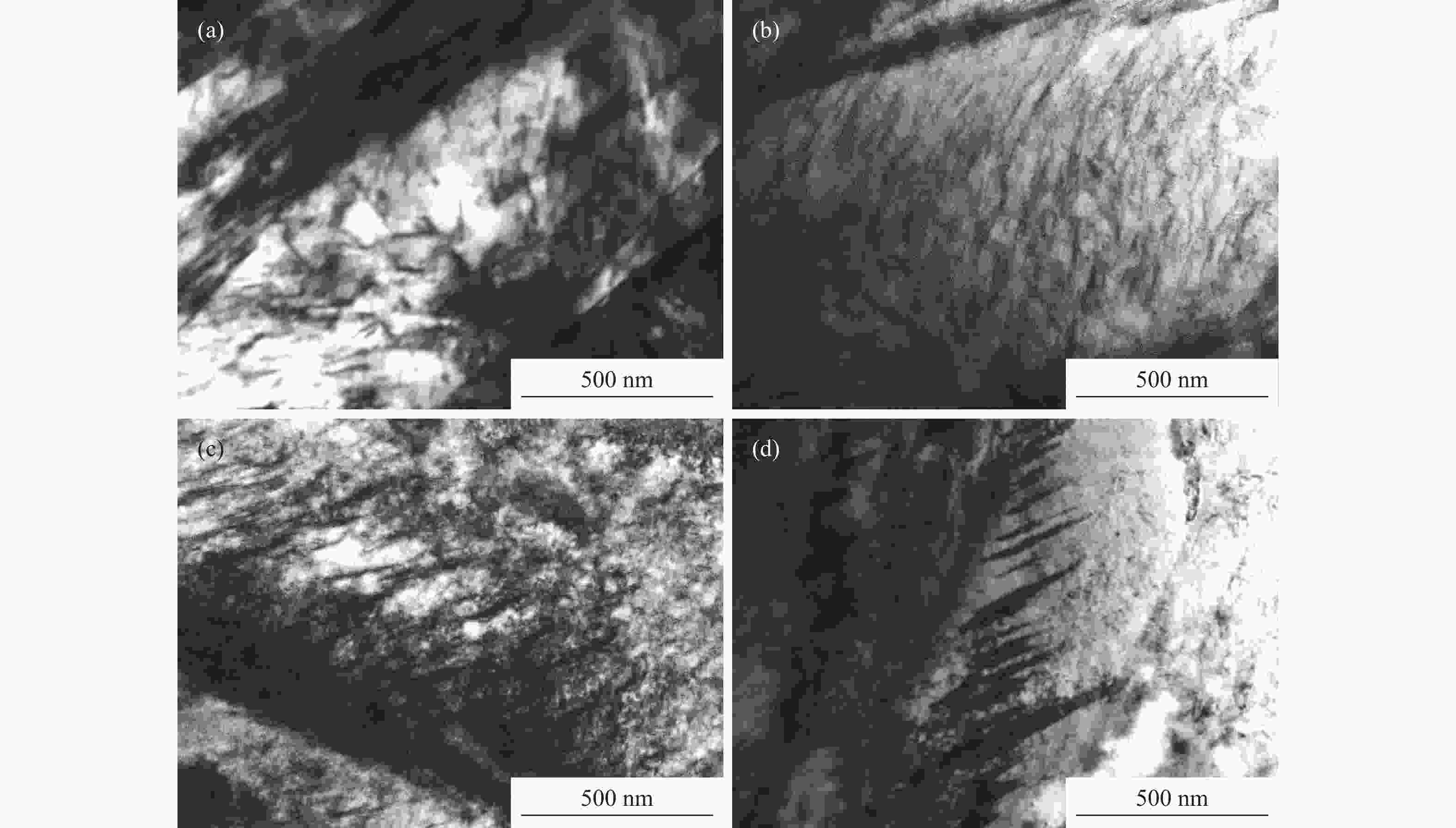

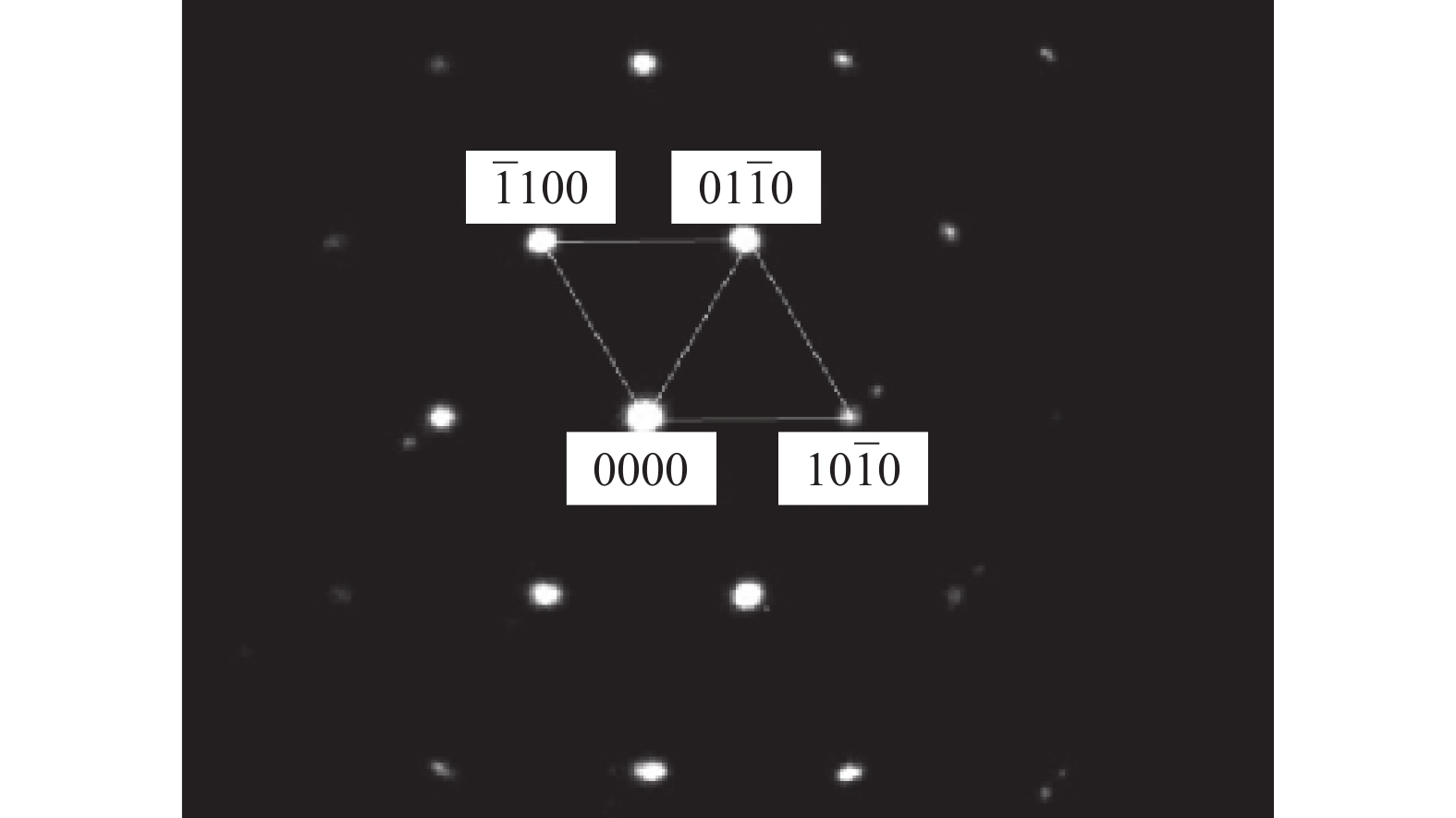

摘要: 对Fe–Ni–Cu–C–Mo粉末锻造材料的锻后热处理工艺进行了研究,通过动态连续冷却转变试验绘制出该材料的连续冷却转变(continuous cooling transformation,CCT)曲线,指导材料锻后冷却工艺的选取。对Fe–Ni–Cu–C–Mo淬火试样进行不同温度的低温回火试验,探究不同回火温度对该材料微观组织与力学性能的影响。结果表明,当锻后冷却速率大于7.0 ℃·s−1时,Fe–Ni–Cu–C–Mo粉锻材料组织全为马氏体,硬度趋于稳定;在150 ℃和175 ℃回火,碳化物均匀地分布在马氏体板条内部,起到析出强化的作用,材料表现出优异的抗拉性能。Abstract: The heat treatments of the powder forged Fe‒Ni‒Cu‒C‒Mo materials after forging were studied. The continuous cooling transformation diagram of the powder forged Fe‒Ni‒Cu‒C‒Mo alloys was constructed to guide the selection of cooling process after forging. The quenching Fe‒Ni‒Cu‒C‒Mo specimens were tempered at various temperatures in the low temperature tempering test, and the effects of tempering temperatures on the microstructure and mechanical properties of the Fe‒Ni‒Cu‒C‒Mo materials were investigated. The results show that, when the cooling rate of the Fe–Ni–Cu–C–Mo specimens after forging is more than 7.0 ℃·s−1, the microstructure is the martensite and the hardness tends to be stable. Tempering at 150 and 175 ℃, the carbide is evenly distributed inside the martensite lath, which acts as the precipitation strengthening, and the Fe–Ni–Cu–C–Mo specimens exhibit the excellent tensile properties.

-

Key words:

- powder forging /

- gear materials /

- low tempering /

- microstructure /

- mechanical properties

-

表 1 Q61合金粉末化学成分(质量分数)

Table 1. Chemical composition of the Q61 ally powders

% Ni Cu C Mo Fe 1.756 1.00 0.60 0.552 余量 表 2 粉锻Q61材料不同冷却速率对应的相变点温度

Table 2. Temperatures at the phase transition points of the powder forged Q61 materials at different cooling rates

冷却速率 / (℃·s−1) A→P开始温度 / ℃ A→P结束温度 / ℃ A→M开始温度 / ℃ A→M结束温度 / ℃ 0.2 575 425 — — 0.5 571 404 — — 0.7 556 387 250 175 1.0 556 385 263 188 2.0 530 374 267 180 3.0 527 360 275 168 5.0 500 462 290 145 7.0 — — 295 157 15.0 — — 313 138 30.0 — — 324 130 50.0 — — 332 138 -

[1] Huang P Y. Theory of Power Metallurgy. 2nd Ed. Beijing: Metallurgical Industry Press, 2004黄培云. 粉末冶金原理. 2版. 北京: 冶金工业出版社, 2004 [2] Guo B, Ge C C, Zhang S C, et al. Powder forging technology and its application process. Powder Metall Ind, 2011, 21(3): 45 doi: 10.3969/j.issn.1006-6543.2011.03.010郭彪, 葛昌纯, 张随财, 等. 粉末锻造技术与应用进展. 粉末冶金工业, 2011, 21(3): 45 doi: 10.3969/j.issn.1006-6543.2011.03.010 [3] Guo B. Study on Powder Forging and Densification Forming Technology of Ferrous Alloy [Dissertation]. Chengdu: Southwest Jiaotong University, 2012郭彪. 铁基材料粉末锻造及致密化成形技术研究[学位论文]. 成都: 西南交通大学, 2012 [4] Kuhn H A, Ferguson B L. Powder Forging. Princeton: Metal Powder Industries Federation, 1990 [5] Boreczky E, Han F L. North America's PM industry: The challenges of an evolving automotive market. Powder Metall Technol, 2015, 33(3): 232 doi: 10.3969/j.issn.1001-3784.2015.03.014Boreczky Eric, 韩凤麟. 北美粉末冶金汽车零件产业的发展与前景. 粉末冶金技术, 2015, 33(3): 232 doi: 10.3969/j.issn.1001-3784.2015.03.014 [6] MPIF. Plenary sessions highlight continued growth for global Powder Metallurg // World PM2018: Metal Powder Report. Beijing, 2017: 79 [7] Wang Y K, Peng M G. The generalization of powder forging process and technology. Met Mater Metall Eng, 2007, 35(5): 57 doi: 10.3969/j.issn.1005-6084.2007.05.014王云坤, 彭茂公. 粉末锻造工艺技术的发展概况. 金属材料与冶金工程, 2007, 35(5): 57 doi: 10.3969/j.issn.1005-6084.2007.05.014 [8] Yang S, Xiao Z Y, Guan H J, et al. Microstructure and mechanical properties of sintered and forged Fe–2Cu–0.5C–0.11S materials. Powder Metall Technol, 2017, 35(1): 23 doi: 10.3969/j.issn.1001-3784.2017.01.004杨硕, 肖志瑜, 关航健, 等. 烧结和锻造态Fe–2Cu–0.5C–0.11S材料的组织与力学性能研究. 粉末冶金技术, 2017, 35(1): 23 doi: 10.3969/j.issn.1001-3784.2017.01.004 [9] Wang S, Wang Q, Wang H L, et al. Effects of copper content on microstructure and mechanical properties of powder-forged rod Fe–C–Cu alloys manufactured at elevated temperature. Mater Sci Eng A, 2019, 743: 197 [10] Bai L N, Liu F P, Wang S, et al. Microstructure and mechanical properties of Fe–C–Cu powder-forged connecting rod. Acta Metall Sin, 2016, 52(1): 41 doi: 10.11900/0412.1961.2015.00486柏琳娜, 刘福平, 王邃, 等. Fe–C–Cu粉末锻造汽车发动机连杆的组织与力学性能. 金属学报, 2016, 52(1): 41 doi: 10.11900/0412.1961.2015.00486 [11] Sun L, Zhou C F, Wang H Y, et al. Microstructure and mechanical properties of powder metallurgy forging bilayer cam. Powder Metall Technol, 2017, 35(6): 403孙露, 周春芳, 王惠亚, 等. 粉末热锻双层材料凸轮的显微组织与力学性能. 粉末冶金技术, 2017, 35(6): 403 [12] Zhang B Q, Wang Q, Wang S, et al. Study on the microstructure and properties of powder-forged gear materials. Powder Metall Technol, 2020, 38(2): 113张冰清, 王琪, 王邃, 等. 粉末锻造齿轮材料的组织与性能研究. 粉末冶金技术, 2020, 38(2): 113 [13] Han F L. Introduction of US MPIF Standard 35 “P/F steel parts material standard” . Powder Metall Technol, 2000, 18(4): 292 doi: 10.3321/j.issn:1001-3784.2000.04.010韩风麟. 美国MPIF标准35“P/F钢零件材料标准”简介. 粉末冶金技术, 2000, 18(4): 292 doi: 10.3321/j.issn:1001-3784.2000.04.010 [14] Ulf E, Han F L. Copper in P/M steels. Powder Metall Technol, 2012, 30(6): 460 doi: 10.3969/j.issn.1001-3784.2012.06.011Ulf Engström, 韩凤麟. 粉末冶金钢中的Cu. 粉末冶金技术, 2012, 30(6): 460 doi: 10.3969/j.issn.1001-3784.2012.06.011 [15] Liu D J. Technological study of Fe–Cu–C sintered products. Powder Metall Ind, 2005, 15(3): 27 doi: 10.3969/j.issn.1006-6543.2005.03.007刘多俊. Fe–Cu–C烧结制品的工艺试验. 粉末冶金工业, 2005, 15(3): 27 doi: 10.3969/j.issn.1006-6543.2005.03.007 [16] Kandavel T K, Chandramouli R, Ravichandran M. Experimental study on the plastic deformation and densification characteristics of some sintered and heat treated low alloy powder metallurgy steels. Mater Des, 2010, 31(1): 485 [17] Ministry of Metallurgical Industry, People’ s Republic of China. YB/T 5128—1993 Steel—Determination of Continuous Cooling Transformation Diagram—Dilatometric Method. Beijing: Standards Press of China, 1994中华人民共和国冶金工业部. YB/T5128—1993钢的连续冷却转变曲线图的测定方法(膨胀法). 北京: 中国标准出版社, 1994 -

下载:

下载: