Study on tool steels with ultrahigh carbon and ultrahigh chromium prepared by vacuum hot-pressing

-

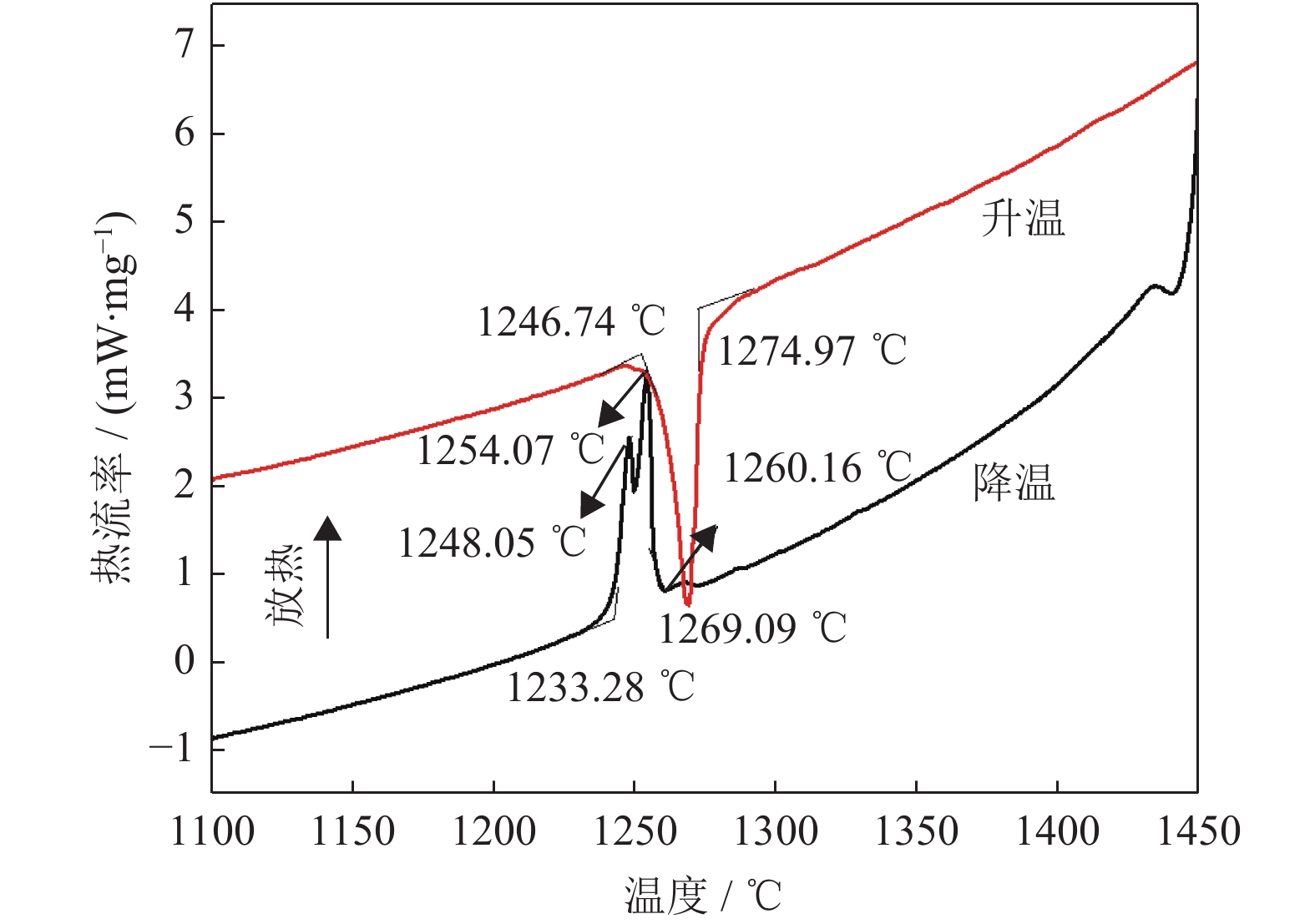

摘要: 采用真空热压技术制备了含有超高碳和铬(2.6%C,26%Cr,质量分数)的模具钢。基于差示扫描量热分析曲线,选取两个远低于熔点的温度(1100 ℃和1150 ℃)进行热压,分别制造出几乎完全致密、粉末之间冶金结合良好的块体钢,密度为7.45~7.47 g∙cm−3;对应热压温度1100 ℃ 和1150 ℃,热压态钢中平均碳化物尺寸分别为3.5 μm和5.5 μm,最大碳化物尺寸分别为6.0 μm和8.5 μm。经1150 ℃淬火、500 ℃回火,1100 ℃ 和1150 ℃热压钢的平均硬度分别为HRC 62.6和HRC 60.8,平均三点弯曲强度分别为2060 MPa和1850 MPa;经1150 ℃淬火、550 ℃回火,1100 ℃ 和1150 ℃热压钢硬度分别为HRC 55.2和HRC 53.6,平均三点弯曲强度分别为2490 MPa和2320 MPa。在相同淬火和回火条件下,1100 ℃热压钢的三点弯曲强度较高,原因是淬火回火后钢中碳化物尺寸较小。Abstract: Tool steels with the ultrahigh C and Cr (2.6% C and 26% Cr, mass fraction) were produced by the vacuum hot-pressing (VHP) in this study. Based on the differential scanning calorimetry analysis, two VHP temperatures (1100 ℃ and 1150 ℃) are selected which are much lower than the melting point. The bulk steels with the density of 7.45~7.47 g∙cm−3 are obtained by VHP at 1100 ℃ and 1150 ℃, respectively, exhibiting the full densification and good metallurgical bonding between powders. The average carbide sizes in the bulk steels obtained by VHP at 1100 ℃ and 1150 ℃ are 3.5 μm and 5.5 μm, and the maximum carbide sizes are 6.0 μm and 8.5 μm, respectively. After quenching at 1150 ℃ and tempering at 500 ℃, the average hardness values of the bulk steels obtained by VHP at 1100 ℃ and 1150 ℃ are approximately HRC 62.6 and HRC 60.8, and the average three-point bending strengths are 2060 MPa and 1850 MPa, respectively. After quenching at 1150 ℃ and tempering at 550 ℃, the average hardness values of the bulk steels obtained by VHP at 1100 ℃ and 1150 ℃ are approximately HRC 55.2 and HRC 53.6, and the average three-point bending strengths are 2490 MPa and 2320 MPa, respectively. At the same quenching and tempering conditions, the higher three-point bending strengths of the bulk steels obtained by VHP at 1100 ℃ can be attributed to the smaller carbide sizes.

-

Key words:

- vacuum hot-pressing /

- powder metallurgy /

- high carbon and high chromium /

- tool steels /

- carbides

-

图 7 淬火+回火态试样显微形貌:(a)1100 ℃热压,1150 ℃淬火,500 ℃回火;(b)1150 ℃ 热压,1150 ℃淬火,500 ℃回火;(c)1100 ℃热压,1150 ℃淬火,550 ℃回火;(d)1150 ℃热压,1150 ℃淬火,550 ℃回火

Figure 7. Microstructures of the as-VHP steels after quenching at 1150 ℃ and tempering: (a) VHP at 1100 ℃ and tempering at 500 ℃; (b) VHP at 1150 ℃ and tempering at 500 ℃; (c) VHP at 1100 ℃ and tempering at 550 ℃; (d) VHP at 1150 ℃ and tempering at 550 ℃

表 1 原料粉末化学成分(质量分数)

Table 1. Chemical composition of the raw powders

% C Cr V Mo Nb Fe 2.6 26.0 2.3 1.1 1.4 余量 -

[1] Ni X L, Zhang G Q, Zhang Y. Research progress of cold working die steel. Mater Sci Forum, 2013, 749: 145 doi: 10.4028/www.scientific.net/MSF.749.145 [2] Qiu L, Wu X C. Development of cold work die steel at home and abroad. Die Mould Manuf, 2017, 17(11): 89 doi: 10.3969/j.issn.1671-3508.2017.11.026邱凌, 吴晓春. 国内外冷作模具钢发展概述. 模具制造, 2017, 17(11): 89 doi: 10.3969/j.issn.1671-3508.2017.11.026 [3] Wang B. Development status of hot work die steel. Die Mould Manuf, 2017, 17(2): 79 doi: 10.3969/j.issn.1671-3508.2017.02.023王斌. 热作模具钢发展现状. 模具制造, 2017, 17(2): 79 doi: 10.3969/j.issn.1671-3508.2017.02.023 [4] Zhou Z C, Du J, Yan Y J, et al. The recent development of study on H13 hot-work die steel. Solid State Phenom, 2018, 279: 55 doi: 10.4028/www.scientific.net/SSP.279.55 [5] Zhang F C, Yang Z N. Development of and perspective on high-performance nanostructured bainitic bearing steel. Engineering, 2019, 5(2): 319 doi: 10.1016/j.eng.2018.11.024 [6] Zhang G H, Zhang Z C, Wu K M. Progress of research on composition design and heat treatment process of high carbon chromium bearing steel. Special Steel, 2015, 36(3): 9 doi: 10.3969/j.issn.1003-8620.2015.03.003张国宏, 张志成, 吴开明. 高碳铬轴承钢的成分设计和热处理工艺的研究进展. 特殊钢, 2015, 36(3): 9 doi: 10.3969/j.issn.1003-8620.2015.03.003 [7] Zhao X L, Wang B, Sun D J, et al. Effect of pre-existing VC carbides on nitriding and wear behavior of hot-work die steel. Appl Surf Sci, 2019, 498: 179 [8] Skela B, Sedlaček M, Kafexhiu F, et al. Wear behaviour and correlations to the microstructural characteristics of heat treated hot work tool steel. Wear, 2019, 426-427: 1118 doi: 10.1016/j.wear.2018.12.032 [9] Wu W H, Wu K Q, Xiao Y F, et al. Effect of atomization pressure on the properties of 316L stainless steel powders used in 3D printing. Powder Metall Technol, 2017, 35(2): 83 doi: 10.3969/j.issn.1001-3784.2017.02.001吴文恒, 吴凯琦, 肖逸凡, 等. 气雾化压力对3D打印用316L不锈钢粉末性能的影响. 粉末冶金技术, 2017, 35(2): 83 doi: 10.3969/j.issn.1001-3784.2017.02.001 [10] Zhang Q K, He Y H, Zhang H B, et al. The direct fabrication technology and mechanical properties of a new powder metallurgy high speed steel // China Heat Treatment Activity Week. Lanzhou, 2016: 322张乾坤, 贺跃辉, 张惠斌, 等. 新型近净成形粉末冶金高速钢的直接制备工艺及性能研究//中国热处理活动周.兰州, 2016: 322 [11] Herbert D, Calderon R, Gierl C. Powder Metallurgy and Sintered Materials. Hoboken: Wiley-VCH Verlag GmbH & Co. KGaA, 2017 [12] Micro-Melt WEAR 26 Datasheet. Metal Powders for Tool Steel Finished Products. Bridgeville: Carpenter Powder Products Inc, 2019 [13] General Administration of Quality Supervision, Inspection and Quarantine. GB/T232−2010 Metallic Materials-Bend Test. Beijing: Standards Press of China, 2010中华人民共和国国家质量监督检验检疫总局. GB/T232−2010金属材料弯曲试验方法. 北京: 中国标准出版社, 2010 [14] Zhang Q Y, Zhuang H S. Hand Book of Ternary Alloy Phase Diagrams. Beijing: China Machine Press, 2011张启运, 庄鸿寿. 三元合金相图手册. 北京: 机械工业出版社, 2011 [15] Zhou Q C, Wu X C, Shi N N, et al. Microstructure evolution and kinetic analysis of DM hot-work die steels during tempering. Mater Sci Eng A, 2011, 528(18): 5696 doi: 10.1016/j.msea.2011.04.024 [16] Ramesh G, Rahul R, Pradeep M, et al. Evolution of microstructure and mechanical properties of D2 tool steel during annealing heat treatment. Mater Today, 2018, 5(1): 2733 [17] Roberts G, Krauss G, Kennedy R. Tool Steels. 5th Ed. Beachwood: American Society for Metals, 1998 [18] Thelning, Erik K. Steel and its Heat Treatment. London: Butterworths, 1984 [19] Shim D S, Lee K Y, Park S H. Bending strength of tool steel preheated to various temperatures and layered by direct energy deposition. Mater Sci Eng A, 2019, 744: 548 doi: 10.1016/j.msea.2018.12.009 [20] Saastamoinen A, Kaijalainena A, Heikkala J, et al. The effect of tempering temperature on microstructure, mechanical properties and bendability of direct-quenched low-alloy strip steel. Mater Sci Eng A, 2018, 730: 284 doi: 10.1016/j.msea.2018.06.014 -

下载:

下载: