Effect of ultrafine SiC particles on microstructure and property of milled nanocrystalline AZ91 magnesium alloys

-

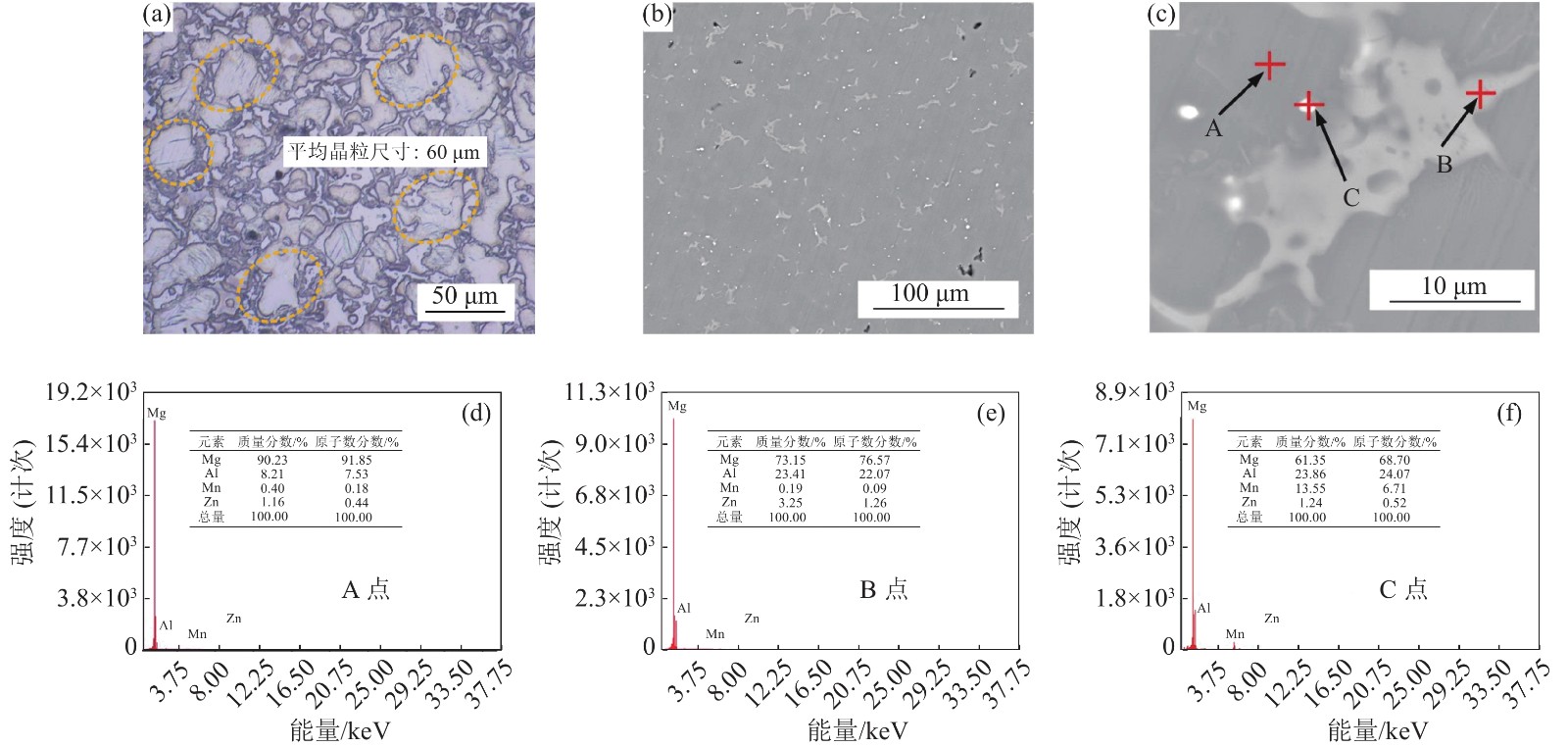

摘要: 通过机械球磨制备了SiC颗粒(SiCp)增强镁基复合材料粉末(AZ91‒xSiCp,x=5%、10%、15%,体积分数),实现了镁基体纳米化及亚微米级SiCp在镁基体中的均匀弥散分布,研究了SiCp对球磨后粉末微观组织的影响规律。结果表明,SiCp第二相的引入能够促进机械球磨过程中镁基体晶粒的细化,晶粒细化程度随SiCp体积分数的增加有所加强,同时SiCp含量的提高对Al元素在镁基体中的固溶及其自身颗粒的细化起到抑制作用。球磨后AZ91‒xSiCp(x=5%、10%、15%)复合粉末的硬度分别为HV 166、HV 175和HV 185,强化机制为细晶强化、弥散强化、固溶强化和承载强化,计算得到AZ91‒5%SiCp复合粉末不同强化机制所引起的强化效果占比分别为86.9%、7.4%、1.8%和3.8%。Abstract: The SiC particle (SiCp) reinforced magnesium matrix composite powders (AZ91‒xSiCp, x=5%, 10%, 15%, volume fraction) were synthesized by mechanical milling. After the mechanical milling, the grain size of the magnesium matrix was refined to nanoscale, and the ultrafine SiC particles were dispersed into the magnesium matrix uniformly. The effect of SiCp on the microstructure of the milled nanocrystalline AZ91 magnesium alloys was analyzed. In the results, SiCp could accelerate the refining of magnesium matrix. Meanwhile, both the dissolving of Al element into the magnesium matrix and the refining of SiCp are inhibited due to the increasing of SiCp. The hardness of AZ91‒xSiCp composites (x=5%, 10%, 15%) is HV 166, HV 175, and HV 185, respectively. The contribution ratio of grain boundary strengthening, Orowan strengthening, solid solution strengthening, and load-bearing strengthening to the milled AZ91‒xSiCp composites is about 86.9%, 7.4%, 1.8% and 3.8%, respectively.

-

图 3 球磨后AZ91‒xSiCp(x=5%、10%、15%,体积分数)复合粉末显微形貌及SiCp尺寸分布:(a)AZ91‒5%SiCp复合粉末显微形貌;(b)AZ91‒5%SiCp复合粉末中SiCp尺寸分布;(c)AZ91‒10%SiCp复合粉末显微形貌;(d);AZ91‒10%SiCp复合粉末中SiCp尺寸分布;(e)AZ91‒15%SiCp复合粉末显微形貌;(e);AZ91‒15%SiCp复合粉末中SiCp尺寸分布

Figure 3. SEM image and SiC particle size distribution of the milled AZ91‒xSiCp (x=5%, 10%, 15%, volume fraction) composite powders: (a) SEM image of the milled AZ91‒5%SiCp composite powders; (b) SiC particle size distribution of the milled AZ91‒5%SiCp composite powders; (c) SEM image of the milled AZ91‒10%SiCp composite powders; (d) SiC particle size distribution of the milled AZ91‒10%SiCp composite powders; (e) SEM image of the milled AZ91‒15%SiCp composite powders; (f) SiC particle size distribution of the milled AZ91‒15%SiCp composite powders;

-

[1] Wu Z, Ahmad R, Yin B, et al. Mechanistic origin and prediction of enhanced ductility in magnesium alloys. Science, 2018, 359(6374): 447 doi: 10.1126/science.aap8716 [2] Zhang W, Mao J, Li S, et al. Phosphorus-based alloy materials for advanced potassium-ion battery anode. J Am Chem Soc, 2017, 139(9): 3316 doi: 10.1021/jacs.6b12185 [3] Pan H, Qin G, Huang Y, et al. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater, 2018, 149: 350 doi: 10.1016/j.actamat.2018.03.002 [4] Suh B, Shim M, Shin K S, et al. Current issues in magnesium sheet alloys: Where do we go from here? Scr Mater, 2014, 84-85: 1 [5] Mordike B L, Ebert T. Magnesium: properties-applications-potential. Mater Sci Eng A, 2001, 302(1): 37 doi: 10.1016/S0921-5093(00)01351-4 [6] Wang Y, Choo H. Influence of texture on Hall-Petch relationships in an Mg alloy. Acta Mater, 2014, 81: 83 doi: 10.1016/j.actamat.2014.08.023 [7] Liang J M, Wang L M, He W, et al. Effect of milling time on microstructures and hardness of nanocrystalline Al–7Si–0.3Mg alloy powders. Powder Metall Technol, 2019, 37(5): 373梁加淼, 王利民, 何卫, 等. 球磨时间对纳米晶Al‒7Si‒0.3Mg合金粉末微观组织及硬度的影响. 粉末冶金技术, 2019, 37(5): 373 [8] Sun W T, Qiao X G, Zheng M Y, et al. Altered ageing behaviour of a nanostructured Mg‒8.2Gd‒3.8Y‒1.0Zn‒0.4Zr alloy processed by high pressure torsion. Acta Mater, 2018, 151: 260 [9] Wang X, Wang H, Hu L X, et al. Nanocrystalline Mg and Mg alloy powders by hydriding-dehydriding processing. Trans Nonferrous Met Soc China, 2010, 20(7): 1326 doi: 10.1016/S1003-6326(09)60299-5 [10] Yu H, Sun Y, Hu L X, et al. Microstructure and properties of mechanically milled AZ61 powders dispersed with submicron/nanometer Ti particulates. Mater Charact, 2017, 127: 272 doi: 10.1016/j.matchar.2017.03.017 [11] Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci, 2001, 46(1-2): 1 doi: 10.1016/S0079-6425(99)00010-9 [12] Medina J, Pérez P, Garcés G, et al. High-strength Mg‒6Zn‒1Y‒1Ca (wt%) alloy containing quasicrystalline I-phase processed by a powder metallurgy route. Mater Sci Eng A, 2018, 715: 92 doi: 10.1016/j.msea.2017.12.111 [13] Chen Q, Meng Y, Yi Y, et al. Microstructure and mechanical properties of cup-shaped parts of 15% SiCp reinforced AZ91 magnesium matrix composite processed by thixoforging. J Alloys Compd, 2019, 774: 93 doi: 10.1016/j.jallcom.2018.09.345 [14] Penther D, Ghasemi A, Riedel R, et al. Effect of SiC nanoparticles on manufacturing process, microstructure and hardness of Mg‒SiC nanocomposites produced by mechanical milling and hot extrusion. Mater Sci Eng A, 2018, 738: 264 doi: 10.1016/j.msea.2018.09.106 [15] Chen L, Xu J, Choi H, et al. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature, 2015, 528(7583): 539 doi: 10.1038/nature16445 [16] Nikmardan S, Pouyafar V. Fabrication of AZ91D/SiCp composites by mechanical milling of magnesium alloy chips and spark plasma sintering in a semi-solid regime. J Asian Ceram Soc, 2019, 7(2): 154 doi: 10.1080/21870764.2019.1595928 [17] Farzami M, Farahani M, Akbari D, et al. Friction stir weld of AZ91 magnesium alloy with and without nano-SiC particle. JOM, 2019, 71(11): 4171 doi: 10.1007/s11837-019-03764-6 [18] Yi Y, Meng Y, Li D, et al. Partial melting behavior and thixoforming properties of extruded magnesium alloy AZ91 with and without addition of SiC particles with a volume fraction of 15%. J Mater Sci Technol, 2018, 34(7): 1149 doi: 10.1016/j.jmst.2017.11.044 [19] Zhang G Y, Zha W S, Chen X L, et al. Application of mechanical ball-milling technology in material preparation. Powder Metall Technol, 2018, 36(4): 315张桂银, 查五生, 陈秀丽, 等. 机械球磨技术在材料制备中的应用. 粉末冶金技术, 2018, 36(4): 315 [20] Wu C, Sun A Z, Liu Y S, et al. Preparation and properties of nano-SiC particle reinforced Al–Mg composite. Powder Metall Technol, 2017, 35(3): 182吴超, 孙爱芝, 刘永生, 等. 纳米SiC颗粒增强铝镁复合材料的制备与性能研究. 粉末冶金技术, 2017, 35(3): 182 [21] Ramkumar T, Selvakumar M, Vasanthsankar R, et al. Rietveld refinement of powder X-ray diffraction, microstructural and mechanical studies of magnesium matrix composites processed by high energy ball milling. J Magn Alloy, 2018, 6(4): 390 doi: 10.1016/j.jma.2018.08.002 [22] Kamrani S, Hübler D, Ghasemi A, et al. Enhanced strength and ductility in magnesium matrix composites reinforced by a high volume fraction of nano- and submicron-sized SiC particles produced by mechanical milling and hot extrusion. Materials, 2019, 12(20): 3445 doi: 10.3390/ma12203445 [23] Burton A W, Ong K, Rea T, et al. On the estimation of average crystallite size of zeolites from the Scherrer equation: A critical evaluation of its application to zeolites with one-dimensional pore systems. Microporous Mesoporous Mater, 2009, 117(1-2): 75 doi: 10.1016/j.micromeso.2008.06.010 [24] Uvarov V, Popov I. Metrological characterization of X-ray diffraction methods for determination of crystallite size in nano-scale materials. Mater Charact, 2007, 58(10): 883 doi: 10.1016/j.matchar.2006.09.002 [25] Williamson G K, Hall W H. X-ray line broadening from field aluminum and wolfram. Acta Metall, 1953, 1(1): 22 doi: 10.1016/0001-6160(53)90006-6 [26] Chen L, Peng J, Xu J, et al. Achieving uniform distribution and dispersion of a high percentage of nanoparticles in metal matrix nanocomposites by solidification processing. Scr Mater, 2013, 69(8): 634 doi: 10.1016/j.scriptamat.2013.07.016 [27] Hassan S F, Gupta M. Development of high performance magnesium nano-composites using nano-Al2O3 as reinforcement. Mater Sci Eng A, 2005, 392(1-2): 163 doi: 10.1016/j.msea.2004.09.047 [28] Feng J, Sun H, Li X, et al. Microstructures and mechanical properties of the ultrafine-grained Mg‒3Al‒Zn alloys fabricated by powder metallurgy. Adv Powder Technol, 2016, 27(2): 550 doi: 10.1016/j.apt.2016.02.008 [29] Zhang P, Li S X, Zhang Z F. General relationship between strength and hardness. Mater Sci Eng A, 2011, 529: 62 doi: 10.1016/j.msea.2011.08.061 -

下载:

下载: