-

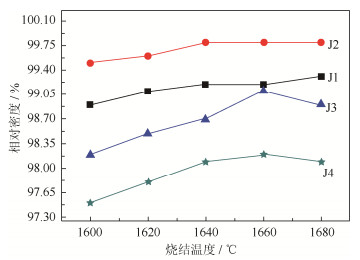

摘要: 以微米Al2O3为主要原料,微米金属Cr和W为主要添加物,采用热压烧结工艺改性制备了机器人覆盖件用氧化铝挤压金属陶瓷模具材料,研究了该金属陶瓷模具材料的强度、断裂韧性、硬度及耐磨性等力学性能,并分析了该材料磨损试样表面的微观结构。结果表明:当微米Al2O3添加量(质量分数)为65%,金属Cr和W添加量均为12.5%,烧结温度为1640 ℃时,所制备的试样综合性能最佳,其中相对密度为99.8%,抗弯强度为805.6 MPa,断裂韧性为14.5 MPa·m1/2,硬度为11.2 GPa;金属W和Cr形成的金属第二相在摩擦磨损过程中能产生机械冷焊作用,大大提高了模具材料的耐磨性能。Abstract: The alumina extruded metal-ceramic die materials used for the robot cover were prepared by the hot-pressing sintering, using the micro-size Al2O3 as the main material and the micro-size Cr and W as the main additives. The strength, fracture toughness, hardness, and wear resistance of the metal-ceramic die materials were studied, and the wear surface microstructure of the materials was analyzed. The results show that, when the mass fraction of the micro-size Al2O3 is 65%, the mass fractions of the micro-size W and Cr are both 12.5%, and the sintering temperature are 1640 ℃, the prepared samples can achieve the best combination properties, as the relative density, bending strength, fracture toughness, and hardness is 99.8%, 805.6 MPa, 14.5 MPa·m1/2, and 11.2 GPa respectively. At the same time, the second phases formed by metal W and Cr can produce the mechanical cold welding in the process of friction and wear, which greatly improves the wear resistance of the die materials.

-

Key words:

- metal ceramic /

- hot-pressing sintering /

- mechanical properties /

- friction and wear

-

表 1 实验用金属陶瓷模具材料化学组成(质量分数)

Table 1. Chemical composition of the experimental metal-ceramic die materials

% 试样编号 Al2O3 W Cr Mo Y2O3 合计 J1 70 10.0 10.0 9 1 100 J2 65 12.5 12.5 9 1 100 J3 60 15.0 15.0 9 1 100 J4 55 17.5 17.5 9 1 100 -

[1] Liu K Q, Xu Q, Zhang H J. Preparation and Application of Cermet. Beijing: Metallurgical Industry Press, 2008: 1刘开琪, 徐强, 张会军. 金属陶瓷的制备与应用. 北京: 冶金工业出版社, 2008: 1 [2] Zhang Y F, Ji Z, Liu G M, et al. Manufacturing process and properties of Al2O3 dispersion strengthened copper-based composite with high electrical conductivity. Powder Metall Technol, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005张一帆, 纪箴, 刘贵民, 等. Al2O3弥散增强Cu基高导电率复合材料的制备及性能研究. 粉末冶金技术. 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005 [3] Wang F, Chang Y H, Jia C C, et al. Preparation of Al2O3/Cu composite with high softening temperature by mechanical alloying and spark plasma sintering. Powder Metall Technol, 2016, 34(4): 285 doi: 10.3969/j.issn.1001-3784.2016.04.010王峰, 常宇宏, 贾成厂, 等. 机械合金化结合放电等离子烧结制备高软化温度Al2O3/Cu复合材料. 粉末冶金技术, 2016, 34(4): 285 doi: 10.3969/j.issn.1001-3784.2016.04.010 [4] Yao S Q, Xing S M, Deng J X. Behaviors of friction and wear and finite element analysis of three ceramic tool materials. Tribology, 2006, 26(6): 566 doi: 10.3321/j.issn:1004-0595.2006.06.013姚淑卿, 邢书明, 邓建新. A12O3基陶瓷刀具材料摩擦磨损特性及其有限元分析. 摩擦学学报, 2006, 26(6): 566 doi: 10.3321/j.issn:1004-0595.2006.06.013 [5] Bai Z H, Luo B H, Lin L, et al. Effects of sintering temperature on the mechanical and microstructure of two kinds of cermet. Cemented Carb, 2008, 25(3): 148 doi: 10.3969/j.issn.1003-7292.2008.03.005柏振海, 罗兵辉, 林莉, 等. 热压烧结温度对两种金属陶瓷组织性能的影响. 硬质合金, 2008, 25(3): 148 doi: 10.3969/j.issn.1003-7292.2008.03.005 [6] Sun D M, Liu L H, Liu Y T, et al. Study on A12O3/Cr3C2/(W, Ti)C ceramic die materials. Powder Metall Technol, 2005, 23(5): 343 doi: 10.3321/j.issn:1001-3784.2005.05.006孙德明, 刘立红, 刘玉婷, 等. A12O3/Cr3C2/(W, Ti)C陶瓷模具材料研究. 粉末冶金技术, 2005, 23(5): 343 doi: 10.3321/j.issn:1001-3784.2005.05.006 [7] Liu J, Zhou F. Properties and applications of ceramic materials for hot extrusion dies. Rare Met Mater Eng, 2003, 32(3): 232 http://en.cnki.com.cn/Article_en/CJFDTOTAL-COSE200303022.htm [8] Chen J. Preparation and Properties of Al2O3–W–Cr Metal Ceramic Extrusion Dies [Dissertation]. Changsha: Central South University, 2010陈娇. A12O3–W–Cr金属陶瓷挤压模具的制备与性能研究[学位论文]. 长沙: 中南大学, 2010 [9] Yu H J, Zheng Y, Bu H J, et al. Effect of HIP on the microstructure and mechanical properties of Ti(C, N)-based ceramet. Cemented Carb, 2006, 23(3): 134 doi: 10.3969/j.issn.1003-7292.2006.03.002于海军, 郑勇, 卜海建, 等. 热等静压处理对Ti(C, N)基金属陶瓷组织和性能的影响. 硬质合金, 2006, 23(3): 134 doi: 10.3969/j.issn.1003-7292.2006.03.002 [10] Li S L, Song K X, Guo X H. Study of Al2O3/Cu composite prepared by SPS. Powder Metall Technol, 2013, 31(1): 43 doi: 10.3969/j.issn.1001-3784.2013.01.009李韶林, 宋克兴, 国秀花. SPS法制备Al2O3/Cu复合材料研究. 粉末冶金技术, 2013, 31(1): 43 doi: 10.3969/j.issn.1001-3784.2013.01.009 [11] Zhao N Q, Zhou F G, Chen M F, et al. The microstructure and sintering process of P/M WC reinforced copper composite. Powder Metall Technol, 2000, 18(4): 265 doi: 10.3321/j.issn:1001-3784.2000.04.006赵乃勤, 周复刚, 陈民芳, 等. WC/Cu复合材料组织及烧结过程研究. 粉末冶金技术, 2000, 18(4): 265 doi: 10.3321/j.issn:1001-3784.2000.04.006 [12] Zhao J N, Zhang N, Zhou B B, et al. Toughening research and prospect of development on alumina matrix ceramic material. Bull Chin Ceram Soc, 2016, 35(9): 2866 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201609029.htm赵介南, 张宁, 周彬彬, 等. Al2O3基陶瓷材料的增韧研究进展. 硅酸盐通报, 2016, 35(9): 2866 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201609029.htm [13] Liu G X, Li K Z, Li G B. Effects of ZrO2 additive amount on properties of Al2O3/ZrO2 composite ceramics. Ordn Mater Sci Eng, 2015, 38(4): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201504012.htm刘国玺, 李克智, 李国斌. ZrO2添加量对Al2O3/ZrO2复相陶瓷性能的影响. 兵器材料科学与工程, 2015, 38(4): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201504012.htm [14] Zhao R, Sun H W, Liu H J, et al. Effect of composite sintering additives on Al2O3–ZrO2 ceramics relative density. Bull Chin Ceram Soc, 2011, 30(2): 271 http://en.cnki.com.cn/Article_en/CJFDTOTAL-GSYT201102007.htm [15] Zhang H L. Preparation and Properties of Ni-Based High Temperature Composite Self-lubricating Materials[Dissertation]. Shenyang: Northeastern University, 2014张洪龙. 镍基高温复合自润滑材料的制备与性能研究[学位论文]. 沈阳: 东北大学, 2014 -

下载:

下载: