Study on microstructure and corrosion resistance of CoCrFeNiCuTix high-entropy alloy

-

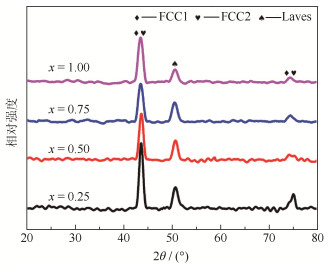

摘要: 采用真空热压烧结法制备了CoCrFeNiCuTix (x为摩尔比, x=0.25, 0.50, 0.75, 1.00)六元高熵合金, 研究了Ti含量对该高熵合金微观组织和耐腐蚀性的影响。利用金相显微镜、X射线衍射仪、扫描电子显微镜、HVS-1000B型数显显微硬度计和电化学工作站等设备测试和分析了CoCrFeNiCuTix高熵合金的组织结构和耐腐蚀性能。结果表明: 不同Ti含量(摩尔分数)的CoCrFeNiCuTix高熵合金, 物相都为面心立方结构, 组织主要为树枝晶; 随着Ti摩尔分数的增加, 高熵合金树枝晶组织减少, 硬度先增加后减小, x=0.50时, 合金的硬度值最大, 为HV 755;CoCrFeNiCuTix高熵合金的自腐蚀电位都正于45#钢, 耐腐蚀性先增强后减弱, x=0.50时, 其耐腐蚀性最优。Abstract: The CoCrFeNiCuTix(x = 0.25, , 0.50, 0.75, 1.00 by molar) high-entropy alloys (HEAs) were prepared by vacuum hot-pressing sintering in this paper. The effects of Ti contents on the microstructure and corrosion resistance of the CoCrFeNiCuTix HEAs were investigated and analyzed by optical microscope (OM), X-ray diffractometer (XRD), scanning electron microscope (SEM), HVS-1000B digital microhardness tester, and electrochemical workstation. The results show that the CoCrFeNiCuTix HEAs with different Ti contents by molar have the face-centeredcubic phase structure with the dendritic crystal microstructures. With the increase of Ti content, the dendritic structure declines in numbers, and the hardness of CoCrFeNiCuTix HEAs increases first and then decreases; the microhardness of the prepared HEAs reaches the maximum up to HV 755 at x=0.5. The self-corrosion potential of the prepared HEAs is positive to that of 45# steel; with the increase of Ti content by molar, the self-corrosion potential of the prepared HEAs increases first and then decrease, and the best corrosion resistance is obtained at x=0.5.

-

Key words:

- high-entropy alloys /

- vacuum hot-pressing sintering /

- microstructure /

- corrosion resistance /

- hardness

-

位置 Co Cr Cu Fe Ni Ti 1 18.39 20.74 17.52 20.75 18.97 3.63 2 14.48 29.36 13.84 23.64 12.16 6.52 3 20.18 17.53 15.35 18.46 22.34 6.14 4 18.10 19.13 13.79 20.21 19.27 9.50 5 17.86 21.43 11.19 18.45 18.87 12.25 6 14.65 20.23 18.43 14.84 16.27 15.58 7 22.10 21.53 6.57 13.40 19.13 17.27 8 23.07 18.34 11.19 17.06 17.51 12.83 表 2 CoCrFeNiCuTix高熵合金和45#钢的电化学参数

Table 2. Electrochemical parameters of CoCrFeNiCuTix high-entropy alloys and 45#steel

溶液 合金 Ecorr/V (vs SCE) Icorr/(A·cm−2) 1.0 mol·L−1H2SO4 CoCrFeNiCuTi0.25 -0.447 6.310 × 10-4 CoCrFeNiCuTi0.50 -0.240 3.162 × 10-5 CoCrFeNiCuTi0.75 -0.373 1.585 × 10-4 CoCrFeNiCuTi1.00 -0.336 5.012 × 10-5 45# -0.499 3.981 × 10-4 3.5% NaCl CoCrFeNiCuTi0.25 -0.249 1.585 × 10-4 CoCrFeNiCuTi0.50 -0.263 1.995 × 10-5 CoCrFeNiCuTi0.75 -0.243 3.162 × 10-5 CoCrFeNiCuTi1.00 -0.260 3.785 × 10-5 45# -0.373 3.981 × 10-3 -

[1] Liang X B, Wei M, Cheng J B, et al. Research progress in advanced materials of high-entropy alloys. J Mater Eng, 2009(12): 75 https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC200912020.htm梁秀兵, 魏敏, 程江波, 等. 高熵合金新材料的研究进展. 材料工程, 2009(12): 75 https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC200912020.htm [2] Yeh J W, Chen S K, Lin S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater, 2004, 6(5): 299 doi: 10.1002/adem.200300567 [3] Huang P K, Yeh J W, Shun T T, et al. Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Adv Eng Mater, 2004, 6(1-2): 74 doi: 10.1002/adem.200300507/abstract [4] Li Z L, Sun H F, Gao P, et al. Research and development of thenew multi-principal high elements entropy alloy. New Technol NewProcess, 2010(8): 62 doi: 10.3969/j.issn.1003-5311.2010.08.020李忠丽, 孙宏飞, 高鹏, 等. 新型多主元高熵合金的研究进展. 新技术新工艺, 2010(8): 62 doi: 10.3969/j.issn.1003-5311.2010.08.020 [5] Zhu H Y, Sun H F, Li Y C. Research status and development of multi-principal high-entropy alloys. Adv Mater Ind, 2008(9): 67 doi: 10.3969/j.issn.1008-892X.2008.09.015朱海云, 孙宏飞, 李业超. 多主元高熵合金的研究现状与发展. 新材料产业, 2008(9): 67 doi: 10.3969/j.issn.1008-892X.2008.09.015 [6] Zhang J J. The Microstructure and Performance of High-Entropy Alloys AlxCoCrFeNiTi0.5[Dissertation]. Dalian: Dalian University of Technology, 2013张峻嘉. AlxCoCrFeNiTi0.5系高熵合金的微观组织结构及性能[学位论文]. 大连: 大连理工大学, 2013 [7] Tsai K Y, Tsai M H, Yeh J W. Sluggish diffusion in Co-Cr-Fe-Mn-Nihigh-entropy alloys. Acta Mater, 2013, 61(13): 4887 doi: 10.1016/j.actamat.2013.04.058 [8] Zhang Y, Lu Z P, Ma S G, et al. Guidelines in predicting phase formation of high-entropyalloys. Mater Res Soc Commun, 2014, 4(2): 57 http://www.tandfonline.com/servlet/linkout?suffix=CIT0019&dbid=16&doi=10.1179%2F1743284715Y.0000000031&key=10.1557%2Fmrc.2014.11 [9] Zhang Y, Zuo T T, Cheng Y Q, et al. High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci Rep, 2013, 3: 1455 doi: 10.1038/srep01455 [10] Zhu J M, Fu H M, Zhang H F, et al. Microstructures and compressive properties of multicomponent AlCoCrFeNiMox alloys. Mater Sci Eng A, 2010, 527(26): 6975 doi: 10.1016/j.msea.2010.07.028 [11] Chou Y L, Wang Y C, Yeh J W, et al. Pitting corrosion of the high-entropy alloy Co1.5CrFeNi1.5Ti0.5Mo0.1 in chloride-containing sulphate solutions. Corros Sci, 2010, 52(10): 3481 doi: 10.1016/j.corsci.2010.06.025 [12] Chuang M H, Tsai M H, Wang W R, et al. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater, 2011, 59(16): 6308 doi: 10.1016/j.actamat.2011.06.041 [13] Tsai C W, Chen Y L, Tsai M H, et al. Deformation and annealing behaviors of high-entropy alloy Al0.5CoCrCuFeNi. J Alloys Compd, 2009, 486(1-2): 427 doi: 10.1016/j.jallcom.2009.06.182 [14] Wang X F, Zhang Y, Qiao Y, et al. Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys. Intermetallics, 2007, 15(3): 357 doi: 10.1016/j.intermet.2006.08.005 [15] Xie H B, Liu G Z, Guo J J, et al. Effect of Ti addition on the microstructure and wear properties of AlFeCrCoCu high-entropy alloy. Rare Met Mater Eng, 2016, 45(1): 145 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201601030.htm谢红波, 刘贵仲, 郭景杰, 等. Ti对AlFeCrCoCu高熵合金组织及耐磨性能的影响. 稀有金属材料与工程, 2016, 45(1): 145 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201601030.htm [16] Yu Y, Xie F Q, Zhang T B, et al. Microstructure control and corrosion properties of AlCoCrFeNiTi0.5 high-entropy alloy. Rare Met Mater Eng, 2012, 41(5): 862 doi: 10.3969/j.issn.1002-185X.2012.05.023于源, 谢发勤, 张铁邦, 等. AlCoCrFeNiTi0.5高熵合金的组织控制和腐蚀性能. 稀有金属材料与工程, 2012, 41(5): 862 doi: 10.3969/j.issn.1002-185X.2012.05.023 [17] Zhang Y, Zhou Y J, Hui X D, et al. Alloying of bulk metallic glass and high-entropy alloys. Sci China G, 2008, 38(4): 439 https://www.cnki.com.cn/Article/CJFDTOTAL-JGXK200804012.htm张勇, 周云军, 惠希东, 等. 大块金属玻璃及高熵合金的合金化作用. 中国科学(G辑), 2008, 38(4): 439 https://www.cnki.com.cn/Article/CJFDTOTAL-JGXK200804012.htm [18] Niu X L. Study of Steel Corrosion Protection by High-Entropy Alloy Coatings AlxFeCrCoNiCu[Dissertation]. Dalian: Dalian University of Technology, 2014牛雪莲. 钢基体腐蚀防护的高熵合金AlxFeCrCoNiCu涂层研究[学位论文]. 大连: 大连理工大学, 2014 [19] Sheng H F. Processing, Microstructure and Properties of Al xCoCrCuFeNi High Entropy Alloys and Their in-situ Composite[Dissertation]. Hefei: University of Science and Technology of China, 2014盛洪飞. AlxCoCrCuFeNi系高熵合金及其复合材料的制备、微结构与性能研究[学位论文]. 合肥: 中国科学技术大学, 2014 [20] Cantor B, Chang I T H, Knight P, et al. Microstructural development inequiatomic multicomponent alloys. Mater Sci Eng A, 2004, 375-377: 213 http://www.sciencedirect.com/science/article/pii/s0921509303009936 [21] Dong X T, Liu G Z, Ban Y F, et al. Effect of Ti element on microstructure and hardness of Al1.2FeCrCoNiTix high-entropy alloys. Hot Working Technol, 2018, 47(4): 75 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201804018.htm董鑫涛, 刘贵仲, 班煜峰, 等. Ti元素对Al1.2FeCrCoNiTix高熵合金微观组织及硬度的影响. 热加工工艺, 2018, 47(4): 75 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201804018.htm -

下载:

下载: