Effects of W content by mass on the microstructure and mechanical properties of Mo-W alloy

-

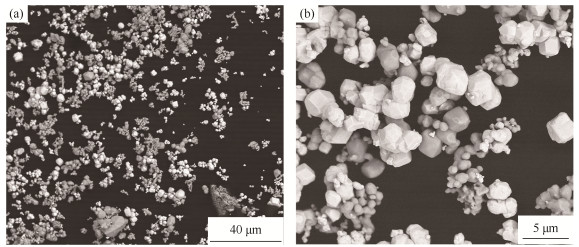

摘要: 采用粉末冶金法制备含不同质量分数W(20%~80%)的Mo-W合金, 研究W含量对Mo-W合金组织结构与力学性能的影响。结果表明: 烧结过程中Mo与W相互扩散形成单相固溶体。W质量分数的增加能显著降低Mo-W合金的晶粒尺寸, 经1990℃烧结的Mo-80W合金晶粒尺寸比Mo-20W合金下降了46.5%。随W质量分数的增加, Mo-W合金的维氏硬度呈“双驼峰”形变化趋势, 在W质量分数为40%与60%处出现峰值。Mo-W合金的相对密度和抗拉强度随W质量分数的增加而下降, 抗拉强度最大值出现在烧结温度为1990℃的Mo-20W合金, 达到514.83 MPa; 随烧结温度的升高, 低W含量的Mo-W合金(W质量分数20%~40%)抗拉强度呈先上升后下降趋势, 而高W含量的Mo-W合金(W质量分数60%~80%)抗拉强度逐渐升高。Mo-W合金断裂方式为沿晶断裂与穿晶断裂相结合的混合模式。Abstract: Mo-W alloys with the W content by mass of 20%~80% were produced by the conventional powder metallurgy technology, the effects of W content on the microstructure and mechanical properties of Mo-W alloy were studied in this paper. The results show that the single phase solid solution is formed by the interdiffusion of W and Mo during the sintering process. The grain size decreases significantly with the increase of W content by mass. The grain size of Mo-80W alloy decreases by 46.5% compared with that of Mo-20W alloy at the sintering temperatures of 1990. With the increase of W content by mass, a℃.double dump. trend of Vickers hardness can be observed, and the peak value appears at 40% W and 60% W. Relative densities and tensile strength generally decline with the W content rising, and the maximum tensile strength of Mo-20W alloy is 514.83 MPa at the sintering temperature of 1990. With the increase of sint℃ ering temperature, the tensile strength of low-tungsten-content alloy (W content by mass: 20%~40%) increases first and then decreases, while the high-tungsten-content alloy (W content by mass: 60%~80%) increases gradually. The failure mode of Mo-W alloy is the mixture of intergranular fracture and transgranular fracture.

-

Key words:

- Mo-W alloy /

- sintering temperature /

- microstructure /

- mechanical properties

-

图 3 W质量分数与烧结温度对Mo-W合金相对密度与晶粒尺寸的影响:(a)W质量分数与烧结温度对Mo-W合金相对密度的影响;(b)W质量分数对1990 ℃烧结Mo-W合金相对密度与晶粒尺寸的影响;(c)烧结温度对Mo-20W合金相对密度与晶粒尺寸的影响;(d)烧结温度对Mo-70W合金相对密度与晶粒尺寸的影响

Figure 3. Effects of W content by mass and sintering temperature on the relative density and grain size of Mo-W alloys: (a) the relationship of W content by mass, sintering temperature, and relative density of the Mo-W alloy; (b) the relationship of W content by mass, relative density, and grain size of Mo-W alloy sintered at 1990 ℃; (c) the relationship of sintering temperature, relative density, and grain size of the Mo-20W alloy; (d) the relationship of sintering temperature, relative density, and grain size of the Mo-70W alloy

表 1 原料粉与混合粉的氧含量(质量分数)与费氏粒度

Table 1. Fsss and oxygen content by mass of the raw powders and the mixed powders

原料粉与混合粉 W质量分数/% 费氏粒度/μm O质量分数/% Mo — 2.79 0.1800 Mo-20W 20 2.75 0.1938 Mo-30W 30 2.73 0.1747 Mo-40W 40 2.77 0.1734 Mo-50W 50 2.74 0.1486 Mo-60W 60 2.78 0.1593 Mo-70W 70 2.78 0.1407 Mo-80W 80 2.83 0.1475 W — 2.80 0.1100 -

[1] Dong D, Wang C Y. Research progress on preparation technology of molybdenum alloy. Powder Metall Technol, 2017, 35(4): 304 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.011董帝, 王承阳. 钼合金制备工艺的研究进展. 粉末冶金技术, 2017, 35(4): 304 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.011 [2] Chen J Y, Fan J L, Cheng H C. Effects of particle size and dispersion of TiC on the microstructure and tensile strength of Mo alloy. Mater Sci Eng Powder Metall, 2018, 23(6): 614 doi: 10.3969/j.issn.1673-0224.2018.06.010陈季勇, 范景莲, 成会朝. TiC粒度及分散性对Mo合金组织与抗拉强度的影响. 粉末冶金材料科学与工程, 2018, 23(6): 614 doi: 10.3969/j.issn.1673-0224.2018.06.010 [3] Ju Y C, Liu X Y, Wang Q, et al. Research progress of refractory metals and their applications in aerospace//Proceedings of The 2nd JCAP and 38th APTIS Technical Conference-Materials, Craft and Manufacturing. Dalian, 2017: 29琚印超, 刘小勇, 王琴, 等. 难熔金属研究进展及在航天领域的应用情况//中国航天第三专业信息网第三十八届技术交流会暨第二届空天动力联合会议论文集. 大连, 2017: 29 [4] Ju Y P, Wang A Q. Current research status of Mo alloys. Powder Metall Ind, 2015, 25(4): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201504020.htm居炎鹏, 王爱琴. 钼合金研究现状. 粉末冶金工业, 2015, 25(4): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201504020.htm [5] Zhou Y H, Hu P, Chang T, et al. Research progress of strengthening and toughening modes and mechanisms of molybdenum alloys. J Funct Mater, 2018, 49(1): 1026 https://www.cnki.com.cn/Article/CJFDTOTAL-GNCL201801006.htm周宇航, 胡平, 常恬, 等. 钼合金强韧化方式及机理研究进展. 功能材料, 2018, 49(1): 1026 https://www.cnki.com.cn/Article/CJFDTOTAL-GNCL201801006.htm [6] Sahoo P K, Srivastava S K, Kamal S S K, et al. Consolidation behavior of W-20-40wt% Mo nanoalloys synthesized by thermal decomposition method. Int J Refract Met Hard Mater, 2015, 51: 124 doi: 10.1016/j.ijrmhm.2015.03.008 [7] Waseem O A, Ryu H J. Toughening of a low-activation tungsten alloy using tungsten short fibers and particles reinforcement for fusion plasma-facing applications. Nucl Fusion, 2019, 59(2): 26007 doi: 10.1088/1741-4326/aaf43f [8] El-Genk M S, Tournier J M. A review of refractory metal alloys and mechanically alloyed-oxide dispersion strengthened steels for space nuclear power systems. J Nucl Mater, 2005, 340(1): 93 doi: 10.1016/j.jnucmat.2004.10.118 [9] Antusch S, Reiser J, Hoffmann J, et al. Refractory materials for energy applications. Energy Technol, 2017, 5(7): 1064 doi: 10.1002/ente.201600571 [10] Chakraborty S P, Banerjee S, Sanyal G, et al. Studies on the synthesis of a Mo-30wt% W alloy by non-conventional approaches. J Alloys Compd, 2010, 501(2): 211 doi: 10.1016/j.jallcom.2010.04.114 [11] Jeon K C, Kim B S, Kim Y D, et al. Porous Mo-30wt. % W alloys synthesized from camphene/MoO3-WO3 slurry by freeze drying and sintering process. Int J Refract Met Hard Mater, 2015, 53: 32 doi: 10.1016/j.ijrmhm.2015.04.021 [12] Ohser-Wiedemann R, Martin U, Müller A, et al. Spark plasma sintering of Mo-W powders prepared by mechanical alloying. J Alloys Compd, 2013, 560: 27 doi: 10.1016/j.jallcom.2013.01.142 [13] Huang P Y. Theory of Powder Metallurgical. 2nd Ed. Beijing: Metallurgical Industry Press, 2004黄培云. 粉末冶金原理. 2版. 北京: 冶金工业出版社, 2004 [14] Wesemann I, Hoffmann A, Mrotzek T, et al. Investigation of solid solution hardening in molybdenum alloys. Int J Refract Met Hard Mater, 2010, 28(6): 709 doi: 10.1016/j.ijrmhm.2010.05.010 [15] Jiang D Y, Zhou Q, Xue L, et al. First-principles study the phase stability and mechanical properties of binary W-Mo alloys. Fusion Eng Des, 2018, 130: 56 doi: 10.1016/j.fusengdes.2018.03.050 [16] Dhuban S B, Ramesh S, Tan C Y, et al. Sintering behaviour and properties of manganese-doped alumina. Ceram Int, 2019, 45(6): 7049 doi: 10.1016/j.ceramint.2018.12.207 [17] Su Y, Liu N, Tang Z Q, et al. Valence electron structure and property of W-Mo solid solution alloy. Heat Treat, 2015, 30(6): 13 doi: 10.3969/j.issn.1008-1690.2015.06.003苏宇, 刘宁, 汤振齐, 等. 钨钼固溶体合金的价电子结构及其性能研究. 热处理, 2015, 30(6): 13 doi: 10.3969/j.issn.1008-1690.2015.06.003 -

下载:

下载: