Method and mechanism analysis of improving the holding force between Ni-coated diamond and Cu-matrix bonding

-

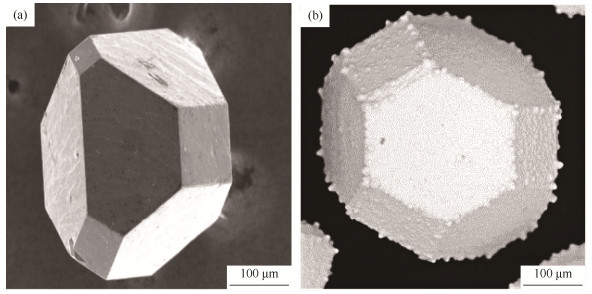

摘要: 为了提高金刚石与金属结合剂间的把持力, 将镀Ni金刚石在1050℃下处理1 h, 然后用浓硝酸清洗金刚石表面, 最后采用真空热压烧结制备铜基结合剂金刚石样条。用扫描电子显微镜观察高温处理前后金刚石镀层表面形貌, 通过铜基结合剂样条的抗弯强度来评价金刚石与铜基结合剂间的结合力。用X射线衍射仪分析高温处理后镀层与金刚石间的物相。结果表明: 镀Ni金刚石经1050℃处理1 h后, 镀层基本上保持完整, 金刚石表面变粗糙; 铜基结合剂金刚石样条的抗弯强度从未镀金刚石的759 MPa增加到镀Ni金刚石的791 MPa, 再增加到高温处理镀Ni金刚石的833 MPa, 说明金刚石与铜基结合剂间把持力得到有效提高。Abstract: To improve the holding force between the diamond and metal matrix bonding, the Ni-coated diamond was treated at 1050 for 1 h, th℃ en the diamond surface was cleaned by the concentrated nitric acid, finally, the Cu-matrix bonding diamond segments were prepared by vacuum hot-pressing sintering. The surface morphologies of diamond coatings before and after high temperature treatment were observed by scanning electron microscope. The flexural strength of Cu-matrix bonding diamond segments was measured to evaluate the holding force between diamond and Cu-matrix bonding. The phases between the coating and diamond after high temperature treatment were analyzed by X-ray diffraction. The results show that, the Ni coating treated at 1050 for 1 h mainly℃ maintains integral and the diamond surface was roughened. The flexural strength of Cu-matrix bonding diamond segments increases from 759 MPa for the uncoated diamond to 791 MPa for the Ni-coated diamond, and then to 833 MPa for the Ni-coated diamond after high temperature treatment, showing the effective improvement of the holding force between Ni-coated diamond and Cu-matrix bonding.

-

Key words:

- diamond /

- surface etching /

- Cu-matrix bonding /

- holding force /

- mechanism analysis

-

表 1 铜基结合剂化学组成(质量分数)

Table 1. Chemical composition of Cu-matrix bonding

% Cu Fe Co Sn Ni Cr 30 28~32 25 3~5 6~9 2 -

[1] Dai Q L, Xu X P, Wang Y C. Measures used to improve bonding of diamond to matrix and bonding mechanisms. Mater Sci Eng, 2002, 20(3): 465 doi: 10.3969/j.issn.1673-2812.2002.03.042戴秋莲, 徐西鹏, 王永初. 金属结合剂对金刚石把持力的增强措施及增强机制评述. 材料科学与工程, 2002, 20(3): 465 doi: 10.3969/j.issn.1673-2812.2002.03.042 [2] Chen C, Peng F, Zhang M, et al. Well-proportioned electrodeposition on diamond grains. Surf Technol, 2006, 35(1): 40 doi: 10.3969/j.issn.1001-3660.2006.01.014陈超, 彭放, 张美, 等. 金刚石颗粒表面均匀电镀工艺研究. 表面技术, 2006, 35(1): 40 doi: 10.3969/j.issn.1001-3660.2006.01.014 [3] Ma W Y, Zhao Y H, Mai X. Effect of Cr coating on the thermal properties of Ag/diamond composites. Powder Metall Technol, 2014, 32(1): 30 doi: 10.3969/j.issn.1001-3784.2014.01.006马文跃, 赵云辉, 麦鑫. Cr镀层对Ag/金刚石复合材料热学性能的影响. 粉末冶金技术, 2014, 32(1): 30 doi: 10.3969/j.issn.1001-3784.2014.01.006 [4] Huang X, Xu Y J, Yin X, et al. Effect of particle size, grade and coating thickness of diamond coated with chromium film on thermal properties of diamond/Cu composite. Powder Metall Ind, 2018, 28(3): 53 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201803017.htm黄霞, 徐燕军, 尹翔, 等. 镀铬金刚石粒度、品级和膜厚对金刚石/铜复合材料热物性能的影响. 粉末冶金工业, 2018, 28(3): 53 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201803017.htm [5] Huang S L, Zhang Y J, Yang D L. Study of electroless plating nickel on the diamond. Surf Technol, 2015, 44(6): 65 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201506013.htm黄世玲, 张迎九, 杨德林. 金刚石化学镀镍的研究. 表面技术, 2015, 44(6): 65 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201506013.htm [6] Gu Q C, Peng J H, Xu L, et al. Preparation of Ti-coated diamond particles by microwave heating. Appl Surf Sci, 2016, 390: 909 doi: 10.1016/j.apsusc.2016.08.168 [7] Das M K, Li R X, Qin J Q, et al. Effect of electrodeposition conditions on structure and mechanical properties of Ni-W/diamond composite coatings. Surf Coat Technol, 2017, 309: 337 doi: 10.1016/j.surfcoat.2016.11.074 [8] Mao A Q, He Y Z, Zheng C H, et al. Development of cladding on diamond. Mater Rev, 2005, 19(2): 31 doi: 10.3321/j.issn:1005-023X.2005.02.009冒爱琴, 何宜柱, 郑翠红, 等. 金刚石表面金属化的研究现状. 材料导报, 2005, 19(2): 31 doi: 10.3321/j.issn:1005-023X.2005.02.009 [9] Wang J S. Study on Etching of Synthetic Diamond Crystallites by Iron Group Metals and Iron-Group Metal Salts[Dissertation]. Changsha: Hunan University, 2016王俊沙. 铁族金属及其盐对人造金刚石单晶腐蚀研究[学位论文]. 长沙: 湖南大学, 2016 [10] Chen J, Wan L, Wang J S, et al. Effect of temperature on the catalytic etching behavior of synthetic diamond single crystals by iron powder. J Synth Cryst, 2015, 44(6): 1448 doi: 10.3969/j.issn.1000-985X.2015.06.005陈静, 万隆, 王俊沙, 等. 温度对铁粉催化腐蚀人造金刚石单晶的影响. 人工晶体学报, 2015, 44(6): 1448 doi: 10.3969/j.issn.1000-985X.2015.06.005 [11] Tokumitsu K. Synthesis of metastable Fe3C, Co3C and Ni3C by mechanical alloying method. Mater Sci Forum, 1996, 235: 127 http://www.scientific.net/MSF.235-238.127 [12] Zhu D Y, Guan X F, Dui W Z, et al. Preparation and structure property of high-temperature self-lubricating Ni-graphite alloy by melting method. Chin J Nonferrous Met, 2004, 14(5): 707 doi: 10.3321/j.issn:1004-0609.2004.05.001朱定一, 关翔锋, 兑卫真, 等. 镍-石墨高温自润滑材料的熔炼制备及其组织性能. 中国有色金属学报, 2004, 14(5): 707 doi: 10.3321/j.issn:1004-0609.2004.05.001 [13] Breval E, Cheng J P, Agrawal D K. Development of titanium coatings on particulate diamond. J Am Ceram Soc, 2000, 83(8): 2106 doi: 10.1111/j.1151-2916.2000.tb01524.x [14] Nakanishi K, Kuroshima H, Matsumoto T, et al. Atomically flat diamond (100) surface formation by anisotropic etching of solid-solution reaction of carbon into nickel. Diamond Relat Mater, 2016, 68: 127 doi: 10.1016/j.diamond.2016.06.011 [15] Xiao C J. Effect of nano-Si3N4/Ni composite coatings on the properties of diamond bits. Mater Sci Eng Powder Metall, 2015, 20(6): 900 doi: 10.3969/j.issn.1673-0224.2015.06.013肖长江. 纳米Si3N4/Ni复合镀层对金刚石节块性能的影响. 粉末冶金材料科学与工程, 2015, 20(6): 900 doi: 10.3969/j.issn.1673-0224.2015.06.013 -

下载:

下载: