-

摘要: 采用粉末冶金技术制备WC-15%TiC-6%Co硬质合金(质量分数), 通过控制氮气压力、固相烧结温度和烧结时间对合金进行渗氮烧结, 得到表层富立方相WC-TiC-Co功能梯度硬质合金。利用扫描电子显微镜、X射线衍射仪和能谱仪研究硬质合金梯度区域的微观组织、物相组成及元素分布。结果表明: 制备的WC-TiC-Co硬质合金梯度层厚度大于20 μm, 并且表层富含Ti元素和N元素, 其组成形式为Ti(C0.7, N0.3)。Abstract: The WC-15%TiC-6%Co cemented carbides by mass were prepared by powder metallurgy, and the functionally graded cemented carbides of WC-TiC-Co with cubic rich surface were obtained by nitriding sintering in the control of nitrogen pressure, solid sintering temperature, and sintering time. The microstructures, phase constitution, and element distribution in graded zone of WC-TiC-Co alloys were investigated by scanning electron microscopy (SEM), X-ray diffraction (XRD), and energy dispersive spectroscopy (EDS), respectively. The results show that, the graded layer of WC-TiC-Co alloys with cubic rich surface has a thickness of more than 20 μm, which is rich in titanium and nitrogen as a form of cubic Ti(C0.7, N0.3) phase.

-

图 4 固相烧结温度对功能梯度硬质合金微观组织和成分的影响:(a)样品1显微形貌;(b)样品1能谱分析;(c)样品2显微形貌;(d)样品2能谱分析

Figure 4. Effect of solid sintering temperature on the microstructure and composition of the functionally graded cemented carbides: (a) SEM image of sample 1; (b) EDS of sample 1; (c) SEM image of sample 2; (d) EDS of sample 2

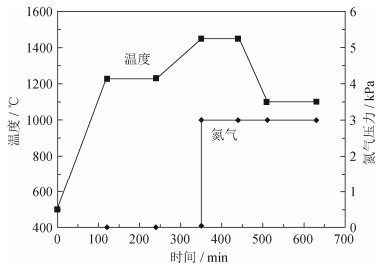

表 1 YT15硬质合金烧结参数

Table 1. Sintering parameters of YT15 cemented carbides

样品 固相烧结温度/℃ 固相烧结时间/h 氮气压力/kPa 1 1100 2.0 3 2 1200 2.0 3 3 1100 2.5 3 4 1100 2.0 1 -

[1] Shi L Y, Zhang S Q, Huang J H. Advances information of WC-Co functionally graded hard metals. Powder Metall Technol, 2010, 28(4): 305 http://pmt.ustb.edu.cn/article/id/fmyjjs201004015史留勇, 张守全, 黄继华. WC-Co功能梯度硬质合金研究进展. 粉末冶金技术, 2010, 28(4): 305 http://pmt.ustb.edu.cn/article/id/fmyjjs201004015 [2] Zhang W B, Sha C S, Du Y, et al. Computer simulations and verification of gradient zone formation in cemented carbides. Acta Metall Sinica, 2011, 47(10): 1307 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201110014.htm张伟彬, 沙春生, 杜勇, 等. 梯度硬质合金梯度层形成的计算机模拟及验证. 金属学报, 2011, 47(10): 1307 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201110014.htm [3] Li X F, Liu Y, Liu B, et al. Preparation of functionally graded cemented carbide with coarse grain by solid carburizing and its microstructure and properties. Cemented Carbide, 2017, 34(6): 398 https://www.cnki.com.cn/Article/CJFDTOTAL-YZHJ201706006.htm李晓峰, 刘咏, 刘彬, 等. 固体渗碳制备粗晶功能梯度硬质合金及其组织与性能研究. 硬质合金, 2017, 34(6): 398 https://www.cnki.com.cn/Article/CJFDTOTAL-YZHJ201706006.htm [4] Fischer Udo K R, Hartzell Erik T, Akerman Jan G H. Cemented Carbide Body Used Preperably for Rock Drilling and Mineral Cutting: US Patent, 4743515. 1988-10-05 [5] Guo Y, Li Z Y, Li Y. Preparation of η phase powder and the effect of sintering process on the plate-like WC grain. Powder Metall Technol, 2017, 35(1): 39 doi: 10.3969/j.issn.1001-3784.2017.01.007郭瑜, 李志友, 李烨. η相粉末的制备及烧结工艺对板状WC晶粒的影响. 粉末冶金技术, 2017, 35(1): 39 doi: 10.3969/j.issn.1001-3784.2017.01.007 [6] Suzuki H, Hayashi K, Taniguchi Y, et al. Beta-free layer formed near the surface of vacuum-sintered WC-beta-Co alloys containing nitrogen. Trans Jpn Inst Met, 1981, 22(11): 758 doi: 10.2320/matertrans1960.22.758 [7] Schwarzkopf M, Exner H E, Fischmeister H F, et al. Kinetics of compositional modification of (W, Ti) C-WC-Co alloy surfaces. Mater Sci Eng A, 1988, 105-106: 225 doi: 10.1016/0025-5416(88)90500-9 [8] Ekroth M, Frykholm R, Lindholm M, et al. Gradient zones in WC-Ti (C, N)-Co-based cemented carbides: Experimental study and computer simulations. Acta Mater, 2000, 48(9): 2177 doi: 10.1016/S1359-6454(00)00029-X [9] Shi L Y, Huang J H, Lin B, et al. Electron probe micro analysis on element distribution across surface layer of graded cemented carbide with cubic carbide free layer. Mater Sci Eng Powder Metall, 2014, 19(3): 349 doi: 10.3969/j.issn.1673-0224.2014.03.003史留勇, 黄继华, 林彬, 等. 脱β层梯度硬质合金表层元素分布的电子探针微区分析. 粉末冶金材料科学与工程, 2014, 19(3): 349 doi: 10.3969/j.issn.1673-0224.2014.03.003 [10] Barbatti C, Garcia J, Sket F, et al. Influence of nitridation on surface microstructure and properties of graded cemented carbides with Co and Ni binders. Surf Coat Technol, 2008, 202(24): 5962 doi: 10.1016/j.surfcoat.2008.06.179 [11] Lengaurer W, Dreyer K. Functionally graded hardmetals. J Alloys Compd, 2002, 338(1-2): 194 doi: 10.1016/S0925-8388(02)00232-3 [12] Chen Q W, Jiang X Q, Jiang A M. Microstructure of YT15 graded cemented carbides by nitriding sintering. Mater Sci Eng Powder Metall, 2011, 16(3): 437 doi: 10.3969/j.issn.1673-0224.2011.03.021陈巧旺, 蒋显全, 姜爱民. 渗氮烧结的YT15梯度硬质合金微观组织. 粉末冶金材料科学与工程, 2011, 16(3): 437 doi: 10.3969/j.issn.1673-0224.2011.03.021 [13] Chen Q W, Liu B, Jiang Z T, et al. Sintering process of functionally graded cemented carbides with cubic rich surface. J Mater Sci Eng, 2014, 32(1): 93 doi: 10.3969/j.issn.1673-2812.2014.01.019陈巧旺, 刘兵, 姜中涛, 等. 表层富立方相功能梯度硬质合金的烧结工艺. 材料科学与工程学报, 2014, 32(1): 93 doi: 10.3969/j.issn.1673-2812.2014.01.019 [14] Feng P, He Y H, Xiao Y F, et al. Advance in functionally graded cemented carbides with cubic carbide free layer. Chin J Nonferrous Met, 2007, 17(8): 1221 doi: 10.3321/j.issn:1004-0609.2007.08.001丰平, 贺跃辉, 肖逸峰, 等. 表面无立方相层功能梯度硬质合金的研究进展. 中国有色金属学报, 2007, 17(8): 1221 doi: 10.3321/j.issn:1004-0609.2007.08.001 [15] Chen L M, Lengauer W, Dreyer K. Advances in modern nitrogen-containing hardmetals and cermets. Int J Refract Met Hard Mater, 2000, 18(2-3): 153 doi: 10.1016/S0263-4368(00)00016-0 [16] Konyashin I Y. Activated nitriding of TiCN-based cermets. Surf Coat Technol, 1995, 73(1-2): 125 doi: 10.1016/0257-8972(94)02376-X [17] General Administration of Quality Supervision, Inspection and Quarantine. GB/T6394-2002 Metal-Methods for Estimating the Average Grain Size. Beijing: General Administration of Quality Supervision, Inspection and Quarantine, 2002国家质量监督检验检疫总局. GB/T6394-2002金属平均晶粒度测定方法. 北京: 国家质量监督检验检疫总局, 2002 [18] Yan Y Q, Xi S M. Comparison of two alloys in measuring nitrogen potential. Ordn Mater Sci Eng, 1999, 22(4): 32 -

下载:

下载: