Preparation and high temperature properties of new self-lubricating die materials

-

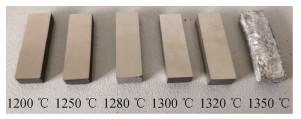

摘要: 以铁镍基合金为基体, 添加硬质相Cr2O3及固体润滑剂CaF2, 利用粉末冶金工艺制备了高温自润滑热锻模具材料。采用X射线衍射仪、扫描电子显微镜及显微硬度计, 研究了烧结工艺对铁镍基自润滑材料力学性能的影响, 分析了Cr2O3和CaF2对铁镍基自润滑材料烧结性能的影响, 并得到了最佳烧结工艺。结果表明: 当烧结工艺为1320℃、保温2 h时, 制备得到的铁镍基自润滑材料力学性能优越; 硬质相Cr2O3质量分数从0增加到30%, 试样相对密度下降4.0%, 硬度从HV 227.3增加到HV 342.8;固体润滑剂CaF2质量分数从0增加到10%, 试样相对密度和硬度均下降; 通过600℃摩擦磨损实验发现, 随CaF2质量分数的增加, 试样摩擦系数和磨损率先降低后升高; 当添加质量分数20% Cr2O3和8% CaF2时, 自润滑模具材料的综合性能最佳。Abstract: A new high-temperature self-lubricating die materials was prepared by powder metallurgy using Fe-Ni alloy as the base materials, Cr2O3 as the hard phase, and CaF2 as the solid lubricant. The effects of sintering process on the mechanical properties of Fe-Ni-based self-lubricating materials were investigated by X-ray diffractometer, scanning electron microscope, and microhardness tester, the influences of Cr2O3 and CaF2 on the sintering properties of the self-lubricating materials were studied, and the optimum sintering process was obtained. The results show that, the self-lubricating materials sintered at 1320℃ for 2 h exhibit the excellent mechanical properties. When the content of Cr2O3 by mass increases from 0 to 30%, the relative density of the sample decreases by 4.0%, and the hardness increases from HV 227.3 to HV 342.8. When the content of CaF2 by mass increases from 0 to 10%, the relative density and hardness of the sample gradually decrease. With the increase of CaF2 content by mass in the friction and wear test at 600℃, the friction coefficient and wear rate decrease first and then increase. The self-lubricating die materials show the best combination performances as the Cr2O3 content of 20% and the CaF2 content of 8% by mass.

-

Key words:

- powder metallurgy technology /

- self-lubricating materials /

- sintering process /

- friction /

- wear

-

表 1 铁镍基自润滑材料组元成分(质量分数)

Table 1. Component compositions of Ni-Fe-based self-lubricating materials

% 编号 基体,Fe-35Ni-15Cr-5Ti-4Mo-0.2C Cr2O3 CaF2 0# 100 0 0 1# 90 10 0 2# 80 20 0 3# 70 30 0 4# 60 40 0 5# 76 20 4 6# 74 20 6 7# 72 20 8 8# 70 20 10 -

[1] Kang J H, Park I W, Jae J S, et al. A study on die wear model of warm and hot forgings. Met Mater, 1998, 4(3): 477 doi: 10.1007/BF03187813 [2] Barrau O, Boher C, Gras R, et al. Analysis of the friction and wear behaviour of hot work tool steel for forging. Wear, 2003, 255(7): 1444 http://www.sciencedirect.com/science/article/pii/S0043164803002801 [3] Yan S S, Liu Z M. A cellular automaton model for friction process dynamic characteristics of gland self-lubricating composite. China Mech Eng, 2011, 22(10): 1222 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX201110021.htm燕松山, 刘佐民. 高温发汗自润滑材料摩擦过程动态特征的元胞自动机模型. 中国机械工程, 2011, 22(10): 1222 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX201110021.htm [4] Xu W, Xie T, Zhou H S, et al. Design for Fe/Cu based lead-free self-lubricating laminar composites. Powder Metall Technol, 2011, 29(2): 137 http://pmt.ustb.edu.cn/article/id/fmyjjs201102012徐伟, 解挺, 周海山, 等. 无铅自润滑铜/铁基层状复合材料设计与研究. 粉末冶金技术, 2011, 29(2): 137 http://pmt.ustb.edu.cn/article/id/fmyjjs201102012 [5] Dellacorte C, Edmonds B J. Preliminary Evaluation of PS300: A New Self-Lubricating High Temperature Composite Coating for Use to 800 ℃. Cleveland: NASA Lewis Research Center, 1995 [6] Dellacorte C, Fellenstein J A. The effect of compositional tailoring on the thermal expansion and tribological properties of PS300: A solid lubricant composite coating. Tribol Trans, 1997, 40(4): 639 doi: 10.1080/10402009708983703 [7] Dellacorte C, Sliney H E, Bogdanski M S. Tribological and mechanical comparison of sintered and HIPped PM212: High temperature self-lubricating composites // Annual Meeting of the Society of Tribologists and Lubrication Engineers. Philadelphia, 1992: 19920005910 [8] Wu Z, Deng J X, Qi T, et al. Study on cutting performance with macro-texturing self-lubricated tools. Tool Eng, 2011, 45(7): 18 doi: 10.3969/j.issn.1000-7008.2011.07.006吴泽, 邓建新, 亓婷, 等. 微织构自润滑刀具的切削性能研究. 工具技术, 2011, 45(7): 18 doi: 10.3969/j.issn.1000-7008.2011.07.006 [9] Guo J T, Zhou L Z, Yuan C, et al. Microstructure and properties of several originally invented and unique superalloys in China. Chin J Nonferrous Met, 2011, 21(2): 237 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201102002.htm郭建亭, 周兰章, 袁超, 等. 我国独创和独具特色的几种高温合金的组织和性能. 中国有色金属学报, 2011, 21(2): 237 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201102002.htm [10] Wang H J, Zhou C Y, Yao Z H, et al. Fe-Ni-Based High Temperature Self-Lubricating Hot Forging Die Material and Preparation Method: China Patent, 201810445936.3. 2018-9-25王华君, 周春杨, 姚振华, 等. 铁镍基高温自润滑热作模具材料及其制备方法: 中国专利, 201810445936.3. 2018-9-25 [11] Ding L, Xiang D P, Li Y Y, et al. Effects of sintering temperature on fine-grained tungsten heavy alloy produced by high-energy ball milling assisted spark plasma sintering. Int J Refract Met Hard Mater, 2012, 33(1): 65 http://www.sciencedirect.com/science/article/pii/S0263436812000388 [12] Gethin D T, Arimn A K, Tran D V, et al. Compaction and ejection of green powder compacts. Powder Metall, 1994, 37(1): 42 doi: 10.1179/pom.1994.37.1.42 [13] Ding H D, Fu S L, Zhu Y L, et al. Wear investigation of self-lubrication material slid friction. Chin J Nonferrous Met, 2001, 11(4): 616 doi: 10.3321/j.issn:1004-0609.2001.04.017丁华东, 傅苏黎, 朱有利, 等. 自润滑材料滑动摩擦磨损性能与机理. 中国有色金属学报, 2001, 11(4): 616 doi: 10.3321/j.issn:1004-0609.2001.04.017 [14] Soroka I, Sereda P J. Interrelation of hardness, modulus of elasticity, and porosity in various gypsum systems. J Am Ceram Soc, 2010, 51(6): 337 doi: 10.1111/j.1151-2916.1968.tb15949.x/abstract [15] Zhu S Y, Bi Q L, Yang J, et al. Effect of fluoride content on friction and wear performance of Ni3Al matrix high-temperature self-lubricating composites. Tribol Lett, 2011, 43(3): 341 doi: 10.1007/s11249-011-9812-8 [16] Peterson M B, Murray S F, Florek J J. Consideration of lubricants for temperatures above 1000 F. Tribol Trans, 1959, 2(2): 225 [17] Peterson M B, Calabrese S J, Li S Z, et al. Paper Ⅰ (ⅱ) Frictional properties of lubricating oxide coatings. Tribology, 1990, 17: 15 http://www.sciencedirect.com/science/article/pii/S0167892208702372 -

下载:

下载: