Study on microstructure and crystallization kinetics of Zr46Cu46Al8 amorphous alloys prepared by copper mold absorption casting and high energy ball milling

-

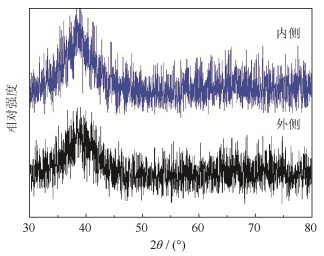

摘要: 采用铜模吸铸法制备出直径3 mm的Zr46Cu46Al8块体非晶合金, 利用高能球磨法获得了不同粒径的合金粉体, 通过X射线衍射仪、示差扫描量热仪、扫描电镜等测试手段及热力学计算方法, 研究了制备方法对非晶合金组织结构及晶化动力学的影响。结果表明, 块体合金和粉体合金均可获得完全非晶结构; 块体非晶合金玻璃转变和晶化过程具有明显的动力学效应; 单因素变量法制备非晶粉体的最佳参数为: 转速300 r·min-1, 球料比30:1, 球磨时间15 h; 相同条件下, 除过冷液相区外, 块体非晶合金热力学参数普遍高于非晶粉体, 且晶化放热更剧烈; 随着加热速率增大, 二者热力学参数均向高温区移动, 过冷液相区的宽度也逐渐增加; 块体非晶合金和非晶粉体的特征温度表观激活能数值相近, 块体非晶态合金的表观激活能较非晶粉体高, 热稳定性更优。Abstract: The Zr46Cu46Al8 bulk amorphous alloys in the diameter of 3 mm were prepared by copper mold absorption casting, and a series of alloy powders in different particle sizes were obtained by high-energy ball milling. The effects of preparation methods on the microstructure and crystallization kinetics of amorphous alloys were studied by X-ray diffraction, differential scanning calorimeter, scanning electron microscope, and typical thermodynamic calculation methods. The results show that, the complete amorphous structure can be obtained in bulk alloys and alloy powders. The glass transition and crystallization of bulk amorphous alloys show the obvious dynamic effects. The best parameters for the preparation of amorphous powders by single factor variable method are the milling speed as 300 r·min-1, the ball-to-powder weight ratio as 30:1, and the ball milling time as 15 h. In the same conditions, except for the supercooled liquid region, the thermodynamic parameters of bulk amorphous alloys are generally higher than those of the amorphous powders, and the crystallization heat in bulk amorphous alloys is more intense. With the increase of heating rate, the thermodynamic parameters of these two alloys move to the high temperature region, and at the same time, the width of supercooled liquid region increases gradually. The apparent activation energy values at the characteristic temperatures of these two alloys are similar, and the bulk alloys show the higher apparent activation energy values and the better thermal stability.

-

表 1 不同加热速率下Zr46Cu46Al8块体非晶的热力学参数值

Table 1. Thermodynamic parameters of Zr46Cu46Al8 bulk amorphous at different heating rates

V / (℃·min-1) Tg/K Tx/K Tp/K ∆Tx/K 10 700.2 764.2 772.1 63.9 20 707.9 772.9 782.5 64.9 30 711.1 781.1 788.7 69.9 40 721.4 786.5 794.9 65.1 50 724.1 788.4 794.1 64.2 表 2 不同加热速率下Zr46Cu46Al8非晶粉体的热力学参数值

Table 2. Thermodynamic parameters of Zr46Cu46Al8 amorphous powders at different heating rates

V / (℃·min-1) Tg/K Tx/K Tp/K ∆Tx/K 10 612.5 671.9 737.8 59.5 20 619.3 688.1 763.2 68.8 30 627.7 698.8 782.7 71.1 40 635.8 705.8 793.9 69.9 50 643.4 711.8 802.1 68.4 表 3 Kissinger方法和Ozawa方法计算所得合金各表观激活能

Table 3. Apparent activation energies of alloys calculated by Kissinger and Ozawa methods

方法 Eg/(kJ·mol-1) Ex/(kJ·mol-1) Ep/(kJ·mol-1) Kissinger1 254.92 300.99 290.27 Ozawa1 266.09 314.66 301.57 Kissinger2 151.24 143.08 105.92 Ozawa2 162.88 153.98 118.99 -

[1] Hao L, Chen X D, Yuan Z Z, et al. Recent development of bulk amorphous alloy. Mater Rev, 2004, 18(8): 22 doi: 10.3321/j.issn:1005-023X.2004.08.007郝雷, 陈学定, 袁子洲, 等. 大块非晶合金的研究进展. 材料导报, 2004, 18(8): 22 doi: 10.3321/j.issn:1005-023X.2004.08.007 [2] Wang L Q, Zhai S Q, Ding R, et al. Recent development of bulk amorphous alloys. Foundry Technol, 2017, 38(2): 274 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201702005.htm王立强, 翟慎秋, 丁锐, 等. 大块非晶合金研究进展. 铸造技术, 2017, 38(2): 274 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201702005.htm [3] Adachi N, Todaka Y, Yokoyama Y, et al. Cause of hardening and softening in the bulk glassy alloy Zr50Cu40Al10 after high-pressure torsion. Mater Sci Eng A, 2015, 627: 171 doi: 10.1016/j.msea.2014.12.101 [4] Inoue A, Takeuchi A. Recent progress in bulk glassy alloys. Mater Trans, 2002, 43(8): 1892 doi: 10.2320/matertrans.43.1892 [5] Inoue A, Shen B L. Formation and applications of bulk glassy alloys in late transition metal base system // Flow Dynamics: The Second International Conference on Flow Dynamics. Sendai, 2006: 11 [6] Ashley S. Metallic glass bulk up. Mech Eng, 1998, 120(6): 72 doi: 10.1115/1.1998-JUN-4 [7] Zhu Y T, Liu Y, Li F, et al. Preparation of Zr50Cu40Al10 amorphous powder by mechanical alloying and its crystallization behaviors. Mater Sci Eng Powder Metall, 2010, 15(1): 64 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201001016.htm朱艺添, 刘咏, 李飞, 等. 机械合金化制备Zr50Cu40Al10非晶合金粉末及其晶化研究. 粉体冶金材料科学与工程, 2010, 15(1): 64 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201001016.htm [8] Li B Q, Lu M, Wang Y N. A new probe for studying mechanical alloying of Cu–Zn mixed powder. Prog Nat Sci, 1994, 4(3): 361 doi: 10.3321/j.issn:1002-008X.1994.03.020李百秦, 鹿牧, 王业宁. 研究Cu–Zn混合粉末机械合金化过程的一种新探针. 自然科学进展, 1994, 4(3): 361 doi: 10.3321/j.issn:1002-008X.1994.03.020 [9] Guan G J. The Effect of Adulteration on the Fe Based Alloys Prepared by Mechanical Alloying and the Studies of Its Magnetic Properties [Dissertation]. Qingdao: China University of Petroleum, 2007关广金. 掺杂对机械合金化制备Fe基合金的影响及其磁性研究[学位论文]. 青岛: 中国石油大学, 2007 [10] Zhang X H. The Preparation of Fe–Co–C Amorphous Powders by Mechanical Alloying and the Studies of Its Magnetic Properties [Dissertation]. Qingdao: China University of Petroleum, 2005张晓花. 机械合金化制备Fe–Co–C系非晶合金粉末及磁性能研究[学位论文]. 青岛: 中国石油大学, 2005 [11] Xu C X, Pan F S, Wang J F, et al. Synthesis of Mg based amorphous alloy by ball milling and its thermal stability. Mater Rev, 2007, 21(5A): 189 https://cpfd.cnki.com.cn/Article/CPFDTOTAL-CLDB200705001068.htm许春霞, 潘复生, 王敬丰, 等. 球磨法制备Mg基非晶合金及其热稳定性. 材料导报, 2007, 21(5A): 189 https://cpfd.cnki.com.cn/Article/CPFDTOTAL-CLDB200705001068.htm [12] Kissinger H E. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand, 1956, 57(4): 217 doi: 10.6028/jres.057.026 [13] Starink M J. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta, 2003, 404(1): 163 http://www.sciencedirect.com/science/article/pii/S0040603103001448 [14] Ozawa T. Kinetic analysis of derivative curves in thermal analysis. J Thermal Anal, 1970, 2(3): 301 doi: 10.1007/BF01911411 [15] Flynn J H. The isoconversional method for determination of energy of activation at constant heating rates. J Thermal Anal, 1983, 27(1): 95 doi: 10.1007/BF01907325 -

下载:

下载: