Research progress in the preparation of particle-reinforced magnesium matrix composites by powder metallurgy

-

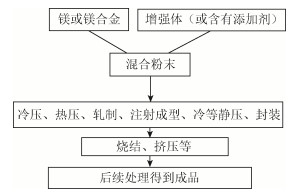

摘要: 概述了粉末冶金法制备颗粒增强镁基复合材料的研究进展, 介绍了颗粒增强镁基复合材料的常用基体和微米级、纳米级增强体。重点阐述了粉末冶金法制备颗粒增强镁基复合材料的工艺, 包括增强体预处理工艺、混合粉体成形工艺及烧结工艺。总结了粉末冶金制备工艺对复合材料组织与力学性能的影响规律, 包括增强体-基体界面结合情况的研究和颗粒增强体强化机制的探究。最后, 对粉末冶金法制备颗粒增强镁基复合材料的发展前景进行了展望, 并提出改进措施。Abstract: The research and development of particle-reinforced magnesium matrix composites prepared by powder metallurgy were summarized in this paper, the substrate and the micron-scale/nanoscale reinforcements commonly used for the particle-reinforced magnesium matrix composites were introduced. The powder metallurgy process was systematically described, including the pretreatment process of reinforcements, the molding process of mixed powders, and sintering process. The influence of powder metallurgy technology on the microstructure and mechanical properties of the composite was investigated, including the interface bonding between reinforcement and matrix and the particle reinforcement strengthening mechanism. Finally, the development prospect for the preparation of the particle-reinforced magnesium matrix composites by powder metallurgy was expected, and the improvement measures were proposed.

-

表 1 几种常用镁合金和其他材料的力学性能[9]

Table 1. Mechanical properties of the common magnesium alloys and other materials[9]

材料名称 抗拉强度/MPa 延伸率/% 弹性模量/GPa 比强度 铸态镁合金AZ31 251 13.8 45 141 铸态镁合金AZ91 280 8.0 45 187 铸态镁合金AM60 270 15.0 45 180 塑料ABS 35 40.0 21 41 聚碳酸酯(PC) 104 3.0 67 102 铸态铝合金A380 315 3.0 71 106 铸态45钢 517 22.0 200 80 -

[1] Yang Z R, Wang S Q, Ju X Q, et al. Reaction sintering of Al3Ti particulate reinforced Mg matrix composite. Powder Metall Technol, 2009, 27(6): 451 http://pmt.ustb.edu.cn/article/id/fmyjjs200906012杨子润, 王树奇, 鞠新庆, 等. Al3Ti颗粒增强镁基复合材料的反应烧结. 粉末冶金技术, 2009, 27(6): 451 http://pmt.ustb.edu.cn/article/id/fmyjjs200906012 [2] Wu Q, Jia C C, Nie J H. The mechanical and electrical properties of magnesium matrix composites reinforced by tungsten-coated carbon nanotubes. Powder Metall Technol, 2012, 30(3): 171 doi: 10.3969/j.issn.1001-3784.2012.03.003吴琼, 贾成厂, 聂俊辉. 镀W碳纳米管增强Mg基复合材料的力学和电学性能. 粉末冶金技术, 2012, 30(3): 171 doi: 10.3969/j.issn.1001-3784.2012.03.003 [3] Tian Y, Wu P P, Xiao L, et al. Technological advances in fabrication of magnesium matrix composites. Mater Rev, 2016, 30(10): 32 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201619005.htm田莹, 吴萍萍, 肖旅, 等. 镁基复合材料的制备技术进展. 材料导报, 2016, 30(10): 32 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201619005.htm [4] Yu H H, Guo Z M, Luo J, et al. Effect of sintering temperature on the microstructure and properties of SiO2 particles strengthening AZ91 magnesium alloy. Powder Metall Technol, 2014, 32(5): 338 http://pmt.ustb.edu.cn/article/id/fmyjjs201405004于海华, 郭志猛, 罗骥, 等. 烧结温度对SiO2颗粒强化AZ91镁合金组织与性能的影响. 粉末冶金技术, 2014, 32(5): 338 http://pmt.ustb.edu.cn/article/id/fmyjjs201405004 [5] Wu C, Sun A Z, Liu Y S, et al. Preparation and properties of nano-SiC particle reinforced Al-Mg composite. Powder Metall Technol, 2017, 35(3): 182 doi: 10.19591/j.cnki.cn11-1974/tf.2017.03.004吴超, 孙爱芝, 刘永生, 等. 纳米SiC颗粒增强铝镁复合材料的制备与性能研究. 粉末冶金技术, 2017, 35(3): 182 doi: 10.19591/j.cnki.cn11-1974/tf.2017.03.004 [6] Ghasali E, Alizadeh M, Niazmand M, et al. Fabrication of magnesium-boron carbide metal matrix composite by powder metallurgy route: Comparison between microwave and spark plasma sintering. J Alloys Compd, 2017, 697: 200 doi: 10.1016/j.jallcom.2016.12.146 [7] Wu Z, Kang P C, Wu G H, et al. The effect of interface modification on fracture behavior of tungsten fiber reinforced copper matrix composites. Mater Sci Eng A, 2012, 536: 45 doi: 10.1016/j.msea.2011.11.088 [8] Wu R, Yan Y, Wang G, et al. Recent progress in magnesium-lithium alloys. Int Mater Rev, 2015, 60(2): 65 doi: 10.1179/1743280414Y.0000000044 [9] Shi R R, Li M Y, Li X X, et al. Review of magnesium alloys forming performance and processing technology. Foundry Technol, 2013, 34(7): 889 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201307034.htm石然然, 李名尧, 李晓霞, 等. 镁合金成形性能和加工技术综述. 铸造技术, 2013, 34(7): 889 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201307034.htm [10] Jiang X D, Chen T J, Ma Y, et al. Effects of SiC on the grain refinement in AZ91D magnesium alloy. Spec Cast Nonferrous Alloys, 2009, 29(8): 763 doi: 10.3870/tzzz.2009.08.024姜向东, 陈体军, 马颖, 等. SiC对AZ91D镁合金晶粒细化效果的影响. 特种铸造及有色合金, 2009, 29(8): 763 doi: 10.3870/tzzz.2009.08.024 [11] Shen M J, Wang X J, Li C D, et al. Effect of bimodal size SiC particulates on microstructure and mechanical properties of AZ31B magnesium matrix composites. Mater Des, 2013, 52: 1011 doi: 10.1016/j.matdes.2013.05.067 [12] Long Q S, Wang W W, Ren G X, et al. Process optimization of SiC nanoparticle reinforced magnesium matrix composites prepared by semi-solid mechanical stirring. Foundry Technol, 2016, 37(5): 848 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201605002.htm龙前生, 王伟伟, 任广笑, 等. 纳米SiC颗粒增强镁基复合材料半固态搅拌法制备工艺优化. 铸造技术, 2016, 37(5): 848 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201605002.htm [13] Lu N N, Xu L, Li C Y, et al. Research progress on preparation technology of aluminum matrix composites reinforced by graphene. Powder Metall Technol, 2017, 35(4): 310 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.012鲁宁宁, 许磊, 历长云, 等. 石墨烯增强铝基复合材料制备技术研究进展. 粉末冶金技术, 2017, 35(4): 310 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.012 [14] Zhao L Z, Liu W, Zhang J, et al. Electroless plating Ni/Ni3P of carbon nanotubes. Bull Chin Ceram Soc, 2016, 35(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201601001.htm赵龙志, 刘武, 张坚, 等. 碳纳米管化学镀Ni/Ni3P的表面改性研究. 硅酸盐通报, 2016, 35(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201601001.htm [15] Xi X B, Miao H, Jin Y F, et al. Mechanical properties and hot-corrosion resistance of composite coatings with Ni-P chemical deposition and Ni-Co-Mn electroplating. Rare Met Mater Eng, 2017, 46(3): 790 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201703037.htm奚小波, 缪宏, 金亦富, 等. 化学镀Ni-P电镀Ni-Co-Mn复合层力学及耐热腐蚀性能. 稀有金属材料与工程, 2017, 46(3): 790 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201703037.htm [16] Yang J L, Long L W, Li Y J, et al. Effects of surface modification of SiCp on the wear-resistance of aluminium-silicon-based composites. Spec Cast Nonferrous Alloys, 2016, 36(3): 287 https://www.cnki.com.cn/Article/CJFDTOTAL-TZZZ201603025.htm杨建林, 龙律位, 李永靖, 等. SiCp表面改性对Al-Si基复合材料耐磨性的影响. 特种铸造及有色合金, 2016, 36(3): 287 https://www.cnki.com.cn/Article/CJFDTOTAL-TZZZ201603025.htm [17] Zhang Y H, Li G, Miao M H, et al. Microstructure and mechanical properties of carbon nanotube reinforced magnesium matrix composites by powder metallurgy. Acta Mater Compos Sinica, 2013, 30(Suppl 1): 102 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE2013S1021.htm张云鹤, 李庚, 苗孟河, 等. 粉末冶金法碳纳米管增强镁基复合材料的微观组织及力学性能. 复合材料学报, 2013, 30(增刊1): 102 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE2013S1021.htm [18] Yang J L, Long L W, Li Y J, et al. Effect of SiCp pretreatment on wear-resistance of Al-Si based composites. Heat Treat Met, 2016, 41(5): 98 https://www.cnki.com.cn/Article/CJFDTOTAL-JSRC201605025.htm杨建林, 龙律位, 李永靖, 等. SiCp预处理对Al-Si基复合材料耐磨性的影响. 金属热处理, 2016, 41(5): 98 https://www.cnki.com.cn/Article/CJFDTOTAL-JSRC201605025.htm [19] Zhang Q Q, Wu G Q, Sha W, et al. Preparation and surface modification of submicron YAl2 particles by mixed milling with magnesium for fabricating YAl2p/MgLiAl composites. Powder Technol, 2014, 262: 209 doi: 10.1016/j.powtec.2014.04.081 [20] Zakaulla M, Anwar Khan A R, Mukunda P G. Evaluation of the taguchi method for wear behavior of Al6061/Cu-SiC/Cu-Gr hybrid composite. Mater Today Proceed, 2015, 2(4-5): 2951 doi: 10.1016/j.matpr.2015.07.262 [21] Suryanarayana C, Al-Aqeeli N. Mechanically alloyed nanocomposites. Prog Mater Sci, 2013, 58(4): 383 doi: 10.1016/j.pmatsci.2012.10.001 [22] Salleh E M, Ramakrishan S, Hussain Z. Characterization of binary Mg-Mn alloy synthesized through mechanical alloying: effects of milling speed. Adv Mater Res, 2015, 1087: 479 doi: 10.4028/www.scientific.net/AMR.1087.479 [23] Zou Y B, Wang Y J, Yuan H T, et al. Preparation and electrochemical characteristics of Mg-based composite materials for hydrogen storage. Rare Met Mater Eng, 2006, 35(2): 320 doi: 10.3321/j.issn:1002-185X.2006.02.035邹雅冰, 王一菁, 袁华堂, 等. 镁基复合贮氢合金的合成及其电化学性能. 稀有金属材料与工程, 2006, 35(2): 320 doi: 10.3321/j.issn:1002-185X.2006.02.035 [24] Tan Z Z, Qi X Q, Zhao Y H, et al. Mg-based amorphous powder with high biocompatibility prepared by mechanical alloying. Nonferrous Met Mater Eng, 2017, 38(6): 317 https://www.cnki.com.cn/Article/CJFDTOTAL-SHHA201706003.htm谈正中, 戚孝群, 赵一鹤, 等. 机械合金法制备高生物相容性镁基非晶合金粉末. 有色金属材料与工程, 2017, 38(6): 317 https://www.cnki.com.cn/Article/CJFDTOTAL-SHHA201706003.htm [25] Yang C, Huang H F, de los Reyes M, et al. Microstructures and tensile properties of ultrafine-grained Ni-(1-3.5)wt% SiCNP composites prepared by a powder metallurgy route. Acta Metall Sinica, 2015, 28(7): 809 doi: 10.1007/s40195-015-0261-5 [26] Fang C F, Wen Z H, Hao H, et al. Microstructures and properties of Mg2Sn nanoparticle-reinforced Mg matrix composites. Rare Met Mater Eng, 2017, 46(6): 1719 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201706046.htm房灿峰, 闻志恒, 郝海, 等. 纳米Mg2Sn增强镁基复合材料的组织与性能. 稀有金属材料与工程, 2017, 46(6): 1719 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201706046.htm [27] Sheng S D, Chen D, Chen Z H, et al. Phase composition and interface of rapidly solidified/powder metallurgy AZ91/SiCp Mg-based composite material. Chin J Nonferrous Met, 2008, 18(7): 1185 doi: 10.3321/j.issn:1004-0609.2008.07.003盛绍顶, 陈鼎, 陈振华, 等. 快速凝固/粉末冶金AZ91/SiCp镁基复合材料的相组成及界面. 中国有色金属学报, 2008, 18(7): 1185 doi: 10.3321/j.issn:1004-0609.2008.07.003 [28] Wu J B. Research on Fabrication and Properties of CNTs/SiCp Magnesium Matrix Composites [Dissertation]. Nanchang: Nanchang University, 2015吴俊斌. CNTs/SiCp镁基复合材料的制备及性能研究[学位论文]. 南昌: 南昌大学, 2015 [29] Ruan A J, Ma L Q, Pan A X, et al. Study on mechanical property and damping capacity of SiC particle reinforced magnesium matrix composite produced by powder metallurgy. Light Alloy Fabr Technol, 2012, 40(2): 50 doi: 10.3969/j.issn.1007-7235.2012.02.012阮爱杰, 马立群, 潘安霞, 等. 粉末冶金法SiCp/Mg基复合材料的力学性能和阻尼性能研究. 轻合金加工技术, 2012, 40(2): 50 doi: 10.3969/j.issn.1007-7235.2012.02.012 [30] Chen L Y, Xu J Q, Choi H, et al. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature, 2015, 528(7583): 539 doi: 10.1038/nature16445 [31] Kong Y R, Guo Q, Zhang D. Review on interfacial properties of particle-reinforced aluminum matrix composites. Mater Rev, 2015, 29(5): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201509005.htm孔亚茹, 郭强, 张荻. 颗粒增强铝基复合材料界面性能的研究. 材料导报, 2015, 29(5): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201509005.htm [32] Abdel Hamid Z, Abou El-khair M T, Hassan H B. Synthesis and protection of AM50 magnesium alloy and its composites using environmentally pretreatment electrolyte. Surf Coat Technol, 2011, 206(6): 1041 doi: 10.1016/j.surfcoat.2011.07.062 [33] Zhu J, Li W X, Dai J F, et al. Interface debonding properties of carbon nanotube-reinforced magnesium matrix composites. Chin J Nonferrous Met, 2011, 21(11): 2888 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201111026.htm祝杰, 李维学, 戴剑锋, 等. 碳纳米管增强镁基复合材料的界面分离特性. 中国有色金属学报, 2011, 21(11): 2888 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201111026.htm [34] Shen M J. Fabrication and Structure Properties of Different Sizes SiCp Reinforced AZ31B Magnesium Matrix Composites [Dissertation]. Harbin: Harbin Institute of Technology, 2014沈明杰. 不同尺寸SiCp增强AZ31B镁基复合材料的制备及组织性能[学位论文]. 哈尔滨: 哈尔滨工业大学, 2014 [35] Niu X F, Li G, Zhang Z Y, et al. Simultaneously improving the strength and ductility of extruded bimodal size SiCp/AZ61 composites: Synergistic effect of micron/nano SiCp and submicron Mg17Al12 precipitates. Mater Sci Eng A, 2019, 743: 207 doi: 10.1016/j.msea.2018.11.023 [36] He G J. Study on the Strengthening Mechanism of n-SiCp/AZ91D Composites [Dissertation]. Beijing: Tsinghua University, 2012何广进. 纳米SiC颗粒增强AZ91D镁基复合材料的强化机制研究[学位论文]. 北京: 清华大学, 2012 [37] Xiao P, Gao Y M, Yang C C, et al. Microstructure, mechanical properties and strengthening mechanisms of Mg matrix composites reinforced with in situ nanosized TiB2 particles. Mater Sci Eng A, 2018, 710: 251 doi: 10.1016/j.msea.2017.10.107 [38] Ferguson J B, Sheykh-Jaberi F, Kim C S, et al. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs). Mater Sci Eng A, 2012, 558: 193 doi: 10.1016/j.msea.2012.07.111 -

下载:

下载: