Design of Cu-based powder alloys used for low speed and heavy bearing with inverse design methodology

-

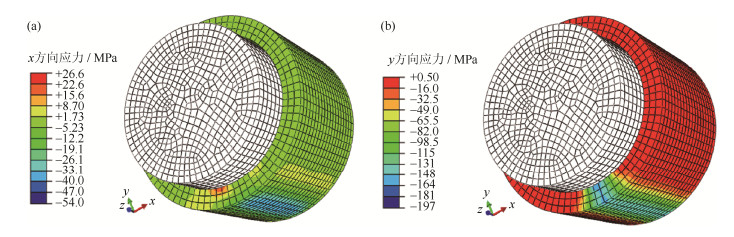

摘要: 基于需求导向, 采用逆向设计思想设计和开发了低速重载轴承用材料。首先, 利用有限元分析方法对低速重载滑动轴承服役条件进行分析, 获得了该服役条件下对材料性能的需求; 然后, 依据性能需求指标, 通过Ashby法绘制材料性能图, 并对各种可用材料进行比较和筛选, 确定Cu12Al6Ni5Fe铜基合金作为轴承材料; 最后, 采用粉末冶金法制备Cu12Al6Ni5Fe合金, 获得的合金强度为340MPa, 硬度HB 138, 达到了预期目标, 并通过对合金显微组织的分析, 提出了进一步改进思路。Abstract: Based on the demand oriented, the inverse design methodology was used to design the material used for low speed and heavy duty bearing in this paper. Firstly, the finite element analysis was performed to confirm the service condition of the low speed heavy duty sliding bearing, getting the properties of the material requirements under the service conditions. Then, the diagram of material properties was drawn by the Ashby approach, and the Cu12Al6Ni5Fe Cu-based alloys were selected as the bearing materials after comparison and screening. Finally, the Cu12Al6Ni5Fe alloy was prepared by powder metallurgy method, the alloy strength reached 340 MPa and the hardness was HB 138, which reached the expected target. According to the analysis of the alloy microstructure, the further improvement ideas were propose.

-

图 3 部分材料性能及价格图:(a)滑动摩擦系数与归一化磨损率常数;(b)线性膨胀系数与导热系数;(c)断裂韧性与强度;(d)材料与硬度;(e)材料与价格

Figure 3. Properties and price maps of some materials: (a) coefficient of sliding friction and normalized wear rate; (b) thermal diffusivity and thermal conductivity; (c) fracture toughness and strength; (d) material and hardness; (e) material and price

表 1 滑动轴承服役需求参数

Table 1. Demand parameters of bearing service

轴套尺寸/ mm 面压/ MPa 滑动速度/ (m·min-1) 试验时间/ h 磨损量/ mm 硬度,HB 外径50,内径40,长30 80 < 1 60 <0.05 125~175 表 2 常温下合金元素在铜中最大固溶度时晶格常数[20]

Table 2. Lattice constants at the maximum solid solubility of alloying elements in copper at room temperature

固溶元素 最大固溶度(原子数分数)/ % 晶格常数(最大固溶度)/ nm Sn 0 3.6074 Mg 3.13 3.6345 Mn 4.50 3.6200 Cr 0 3.6074 Al 19.00 3.6563 Zn 38.00 3.6930 Fe 0 3.6074 Si 8.30 3.6131 表 3 部分金属间化合物的硬度

Table 3. Hardness of some intermetallic compounds

表 4 合金元素对铝青铜组织和性能的影响[40]

Table 4. Effect of alloying elements on the microstructure and properties of aluminum bronze[40]

合金元素 组织 性能 Fe 减缓共析转变,形成Fe3Al作为结晶核心,细化晶粒 提高强度、硬度、疲劳极限和耐磨性,过量的Fe则降低耐蚀性 Mn 缩小α相区,稳定β相,含量高时共析转变温度降到室温以下 提高强度、韧性和耐蚀性 Ni 扩大α相转变温度,提高共析细化晶粒,形成强化相 提高强度、硬度、耐磨耐蚀性和热稳定性 Zn 溶入α固溶体,减少镍铝青铜中铁微粒的数量 降低耐磨性、耐蚀性和塑性 Sn 少量溶入固溶体,扩大β相区 提高硬度、耐蚀性和防污能力,降低塑性 Cr 形成化合物 提高硬度、降低塑性阻止退火时晶粒长大 Pb 以游离态存在 降低塑性和韧性 P 形成磷化物 降低塑性和韧性 表 5 Cu12Al6Ni5Fe合金中各相的能谱分析(质量分数)

Table 5. EDS analysis of each phase in Cu12Al6Ni5Fe alloy %

相组成 Cu Al Ni Fe α 82.47 10.82 4.74 1.97 KI 5.07 7.97 6.18 80.78 KII 46.39 12.77 5.37 35.47 NiAl 43.36 22.91 27.42 6.31 γ2 73.92 16.82 7.25 2.02 -

[1] Yan J, Zha W S, Zhang G Y. Research on the optimum sintering process of Al-based oil bearing in N2 atmosphere. Powder Metall Technol, 2018, 36(3): 211 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201803009.htm严峻, 査五生, 张桂银. 氮气保护下铝基烧结含油轴承烧结工艺优化研究. 粉末冶金技术, 2018, 36(3): 211 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201803009.htm [2] Wu W Y, Hu J H, Zhou T, et al. Experimental study on friction properties of sliding bearing under low speed and heavy load conditions. Bearing, 2016(4): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-CUCW201604009.htm吴汪洋, 胡军华, 周涛, 等. 低速重载滑动轴承摩擦性能试验研究. 轴承, 2016(4): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-CUCW201604009.htm [3] Cheng D X. Handbook of Mechanical Design: Separate Edition, Bearing. Beijing: Chemical Industry Press, 2017成大先. 机械设计手册: 单行本, 轴承. 北京: 化学工业出版社, 2017 [4] Kuang F M, Zhou X C, Huang J, et al. Tribological properties of nitrile rubber/UHMWPE/Nano-MoS2 water-lubricated bearing material under low speed and heavy duty. J Tribol, 2018, 140(6): 061301 doi: 10.1115/1.4039930 [5] Mitani H, Yokota M. Some mechanical properties of aluminium bronze sintered compacts. J Jpn Soc Powder Powder Metall, 1973, 20(4): 107 doi: 10.2497/jjspm.20.107 [6] Li Y Y, Xia W, Zhang W, et al. Strong and wear-resistant aluminum-bronze alloy and its tribological characteristics. Chin J Nonferrous Met, 1996, 6(3): 76 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ603.019.htm李元元, 夏伟, 张文, 等. 高强度耐磨铝青铜合金及其摩擦学特性. 中国有色金属学报, 1996, 6(3): 76 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ603.019.htm [7] Lu Y, Jin W X, Li W S, et al. Effect of Fe on wear-friction properties of high aluminum bronze. Mater Rev, 2008, 22(2): 135 doi: 10.3321/j.issn:1005-023X.2008.02.038路阳, 金硪馨, 李文生, 等. Fe对高铝青铜摩擦磨损性能的影响. 材料导报, 2008, 22(2): 135 doi: 10.3321/j.issn:1005-023X.2008.02.038 [8] Li Y W, Xiao L R, Zhang W, et al. Microstructure and mechanical properties of aluminum bronze with different Mn contents. Chin J Rare Met, 2017, 41(9): 985 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201709006.htm李雨蔚, 肖来荣, 章玮, 等. 不同Mn含量的铝青铜合金组织与性能. 稀有金属, 2017, 41(9): 985 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201709006.htm [9] Zhang Y Y, Gao W G, Chen S Y, et al. Inverse design of materials by multi-objective differential evolution. Comput Mater Sci, 2015, 98: 51 doi: 10.1016/j.commatsci.2014.10.054 [10] Segler M H S, Preuss M, Waller M P. Planning chemical syntheses with deep neural networks and symbolic AI. Nature, 2018, 555(7698): 604 doi: 10.1038/nature25978 [11] Johnson L, Arróyave R. An inverse design framework for prescribing precipitation heat treatments from a target microstructure. Mater Des, 2016, 107: 7 doi: 10.1016/j.matdes.2016.06.009 [12] Chang A M, Rudshteyn B, Warnke I, et al. Inverse design of a catalyst for aqueous CO/CO2 conversion informed by the NiII-iminothiolate complex. Inorg Chem, 2018, 57(24): 15474 doi: 10.1021/acs.inorgchem.8b02799 [13] Perkins J D, Paudel T R, Zakutayev A, et al. Inverse design approach to hole doping in ternary oxides: Enhancing p-type conductivity in cobalt oxide spinels. Phys Rev B, 2011, 84(20): 205207 doi: 10.1103/PhysRevB.84.205207 [14] Prashant Reddy G, Gupta N. Material selection for microelectronic heat sinks: An application of the Ashby approach. Mater Des, 2010, 31(1): 113 doi: 10.1016/j.matdes.2009.07.013 [15] Oliveira M C L D, Ett G, Antunes R A. Materials selection for bipolar plates for polymer electrolyte membrane fuel cells using the Ashby approach. J Power Sources, 2012, 206(1): 3 http://www.sciencedirect.com/science/article/pii/S0378775312002054 [16] Mehmood Z, Haneef I, Udrea F. Material selection for Micro-Electro-Mechanical-Systems (MEMS) using Ashby's approach. Mater Des, 2018, 157: 412 doi: 10.1016/j.matdes.2018.07.058 [17] Bonthu M K, Sharma A K. An investigation of dielectric material selection of RF-MEMS switches using Ashby's methodology for RF applications. Microsyst Technol, 2018, 24(4): 1803 doi: 10.1007/s00542-017-3539-x [18] Liu X Y, Bai X R, Jia J Y, et al. Materials selection of flexure accelerometer using Ashby chart. J Mech Eng, 2013, 49(21): 148 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201321018.htm刘小院, 白晓荣, 贾建援, 等. 基于Ashby图的挠性加速度计材料选择. 机械工程学报, 2013, 49(21): 148 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201321018.htm [19] Ashby M F. Materials Selection in Mechanical Design. Oxford: Butterworth-Heinemann, 2009 [20] Pearson W B. A Handbook of Lattice Spacings and Structures of Metals and Alloys. New York: Pergamon, 1958 [21] Wang B W, Wang T, Wang Z T. Copper Alloy and Its Processing Technology. Beijing: Chemical Industry Press, 2007王碧文, 王涛, 王祝堂. 铜合金及其加工技术. 北京: 化学工业出版社, 2007 [22] Liu P, Ren F Z, Jia S G. Copper Alloy and Its Application. Beijing: Chemical Industry Press, 2007刘平, 任凤章, 贾淑果. 铜合金及其应用. 北京: 化学工业出版社, 2007 [23] Wan H, Si N C, Liu G L, et al. Effect of rare earth on abrasion resistance of multi-aluminum bronze. Chin Rare Earth, 2015, 36(4): 81 https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ201504014.htm万浩, 司乃潮, 刘光磊, 等. 稀土对新型多元铝青铜磨损行为的影响. 稀土, 2015, 36(4): 81 https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ201504014.htm [24] Lahiri B B, Sarkar A, Subramainam B, et al. Studies on temperature evolution during fatigue cycling of Ni-Al-bronze (NAB) alloy using infrared thermography. Insight Nondestr Test Cond Monit, 2016, 58(2): 70 doi: 10.1784/insi.2016.58.2.70 [25] Thossatheppitak B, Suranuntchai S, Uthaisangsuk V, et al. Mechanical properties at high temperatures and microstructures of a nickel aluminum bronze alloy. Adv Mater Res, 2013, 683: 8 http://www.scientific.net/AMR.683.82 [26] Anantapong J, Uthaisangsuk V, Suranuntchai S, et al. Effect of hot working on microstructure evolution of as-cast nickel aluminum bronze alloy. Mater Des, 2014, 60(8): 233 http://www.sciencedirect.com/science/article/pii/S026130691400226X [27] Wang J H, Jiang X X, Li S Z. Microstructure and properties of boron-modified aluminum bronze. Acta Metall Sinica, 1996, 32(10): 1039 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB610.006.htm王吉会, 姜晓霞, 李诗卓. 加硼铝青铜的组织和性能. 金属学报, 1996, 32(10): 1039 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB610.006.htm [28] Yang F F, Kang H J, Guo E Y, et al. The role of nickel in mechanical performance and corrosion behaviour of nickel-aluminium bronze in 3.5 wt% NaCl solution. Corros Sci, 2018, 139: 333 doi: 10.1016/j.corsci.2018.05.012 [29] Dai A L, Yan G C, Zhu Z Y, et al. Wear-friction behavior of novel high aluminum bronzes alloy Cu-12Al-X in high temperature condition. Chin J Nonferrous Met, 2013, 23(11): 3083 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201311009.htm戴安伦, 严高闯, 朱治愿, 等. 新型高铝青铜合金Cu-12Al-X在高温下的摩擦磨损行为. 中国有色金属学报, 2013, 23(11): 3083 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201311009.htm [30] Li W S, Wang Z P, Lu Y, et al. Mechanical and tribological properties of a novel aluminum bronze material for drawing dies. Wear, 2006, 261(2): 155 doi: 10.1016/j.wear.2005.09.032 [31] Xu J L, Wang Z P, Chen C, et al. Research into a new high-strength aluminium bronze alloy. Int J Mater Prod Technol, 2004, 21(5): 443 doi: 10.1504/IJMPT.2004.005001 [32] Li Y Y, Ngai T L. Grain refinement and microstructural effects on mechanical and tribological behaviours of Ti and B modified aluminium bronze. J Mater Sci, 1996, 31(20): 5333 doi: 10.1007/BF01159301 [33] Ozdemir O, Zeytin S, Bindal C. Characterization of NiAl with cobalt produced by combustion synthesis. J Alloys Compd, 2010, 508(1): 216 doi: 10.1016/j.jallcom.2010.08.056 [34] Du S M, Liu G, Wang M J. Microstructure and properties of transient liquidphase diffusion bonded joint of AZ31B/Cu dissimilar metal. Chin J Nonferrous Met, 2013, 23(5): 1255 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201305011.htm杜双明, 刘刚, 王明静. AZ31B/Cu异种金属过渡液相扩散焊接头的显微组织及性能. 中国有色金属学报, 2013, 23(5): 1255 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201305011.htm [35] Yuan Q L, Chi C Z, Su Y A, et al. Investigation on the formation and properties of titanizing layer made by double glow discharge process on the surface of pure Cu. J Chin Electron Microsc Soc, 2004, 23(2): 163 https://www.cnki.com.cn/Article/CJFDTOTAL-DZXV200402015.htm袁庆龙, 池承忠, 苏永安, 等. 纯铜双层辉光离子渗钛组织形成机理及性能分析. 电子显微学报, 2004, 23(2): 163 https://www.cnki.com.cn/Article/CJFDTOTAL-DZXV200402015.htm [36] Yang P F, Lai Y S, Jian S R, et al. Nanoindentation identifications of mechanical properties of Cu6Sn5, Cu3Sn, and Ni3Sn4, intermetallic compounds derived by diffusion couples. Mater Sci Eng A, 2008, 485(1): 305 [37] Lu Y H. Fabrication and Properties of C/C-SiC-Cu5Si Composites[Dissertation]. Changsha: Central South University, 2013逯雨海. C/C-SiC-Cu5Si复合材料的制备及性能[学位论文]. 长沙: 中南大学, 2013 [38] Song K X, Zhang Y, Zhang Y M, et al. Research on fabrication of Cu/Zn compound materials by solid-liquid bonding method under the condition of pressure. Mater Rev, 2014, 28(10): 16 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201410006.htm宋克兴, 张亚, 张彦敏, 等. 压力条件下固-液复合法制备铜/锌复合材料的研究. 材料导报, 2014, 28(10): 16 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201410006.htm [39] Glimois J L, Forey P, Feron J L. Structural studies and physics of copper-rich alloys in the Cu-Zr system. J Less-Comm Met, 1985, 113(2): 213 doi: 10.1016/0022-5088(85)90279-6 [40] United editing group of Cast Nonferrous Alloys and Melting. Cast Nonferrous Alloys and Melting. Beijing: National Defense Industry Press, 1980《铸造有色合金及其熔炼》联合编写组编. 铸造有色合金及其熔炼. 北京: 国防工作工业出版社, 1980 [41] Brezina P. Heat treatment of complex aluminium bronzes. Int Met Rev, 1982, 27(1): 77 doi: 10.1179/imr.1982.27.1.77 [42] Lloyd D M, Lorimer G W, Ridley N. Characterization of phases in a nickel-aluminium bronze. Met Technol, 1980, 7(1): 114 doi: 10.1179/030716980803286577 [43] Han F L, Jia C C. Sintered Metal Oil Bearing: Principle, Design, Manufacture and Application. Beijing: Chemical Industry Press, 2004韩凤麟, 贾成厂. 烧结金属含油轴承: 原理、设计、制造与应用. 北京: 化学工业出版社, 2004 [44] Veloff N, Nadkarni A, Murphy T, et al. High performance bronze powders for self lubricated bearings. Powder Metall Technol, 2007, 25(5): 387 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200705016.htmVeloff N, Nadkarni A, Murphy T, 等. 制造烧结金属含油轴承的高性能青铜粉. 粉末冶金技术, 2007, 25(5): 387 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200705016.htm [45] An X G, Zha W S, Lei Y, et al. Effect of sintering temperature on crushing strength, oil content and microstructure of Al-Cu oil bearing. Powder Metall Technol, 2012, 30(2): 108 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201202007.htm安旭光, 查五生, 雷宇, 等. 烧结温度对Al-Cu系含油轴承压溃强度、含油率和微观形貌的影响. 粉末冶金技术, 2012, 30(2): 108 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201202007.htm [46] Deng Z H, Yin H Q, Jiang X, et al. Machine learning aided study of sintered density in Cu-Al alloy. Comput Mater Sci, 2018, 155: 48 doi: 10.1016/j.commatsci.2018.07.049 [47] Lü Y T, Wang L Q, Mao J W, et al. Recent advances of nickel-aluminum bronze (NAB). Rare Met Mater Eng, 2016, 45(3): 815 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201603050.htm吕玉廷, 王立强, 毛建伟, 等. 镍铝青铜合金(NAB)的研究进展. 稀有金属材料与工程, 2016, 45(3): 815 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201603050.htm -

下载:

下载: