Microstructure and properties of carbon fiber reinforced Fe-Cu based friction materials prepared by powder metallurgy

-

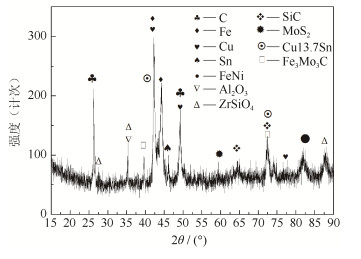

摘要: 以铁-铜为主组元, 以石墨和MoS2为润滑组元, 以Al2O3、SiC、锆英砂为摩擦组元, 并添加不同质量分数的碳纤维, 将原料混合均匀后经600 MPa冷压成形, 然后在氢气气氛下热压烧结2 h (980℃, 2~3 MPa), 制备得到碳纤维增强铁-铜基摩擦材料, 并对其硬度、相对密度、显微组织、摩擦磨损性能进行研究。结果表明: 铁-铜基体上均匀分布着耐磨的陶瓷相及润滑组元, 铁-铜基体有部分固溶, 碳纤维掩埋在基体和摩擦组元间。当碳纤维质量分数为2%~4%时, 所制备的摩擦材料硬度为HV 102.2~118.6, 相对密度为90.4%~92.6%, 摩擦系数为0.56~0.60, 磨损失重量最小。该摩擦材料的磨损主要为磨粒磨损, 伴随少量粘着磨损。碳纤维可以强化基体, 钉扎摩擦组元, 在摩擦磨损过程中隔断犁沟, 降低材料磨损。Abstract: The carbon fiber reinforced Fe-Cu based friction materials were prepared by cold press molding at 600 MPa and hot pressed sintering at 980 and 2℃~3 MPa for 2 h in hydrogen atmosphere, using Fe-Cu as the main component, graphite and MoS2 as the lubrication component, and Al2O3, SiC, and zirconium sand as the friction component with adding carbon fiber in different mass fraction. The hardness, relative density, microstructure, and friction and wear properties of the friction materials were investigated in the paper. The results show that the wear-resisting ceramic phase and the lubricating component are uniformly distributed on the Fe-Cu matrix, and the Fe-Cu matrix is partially solid-dissolved, and the carbon fiber is buried between the matrix and the friction component. When the mass fraction of carbon fiber is 2%~4%, the hardness of the prepared friction material is HV 102.2~118.6, the relative density is 90.4%~92.6%, the friction coefficient is 0.56~0.60, respectively, and the accumulated wear loss weight is the smallest. The wear mechanism of friction materials is mainly abrasive wear, accompanied by a small amount of adhesive wear. The carbon fiber can strengthen the matrix, nail the friction components, separate the furrow, and reduce the wear during the friction process.

-

Key words:

- Fe-Cu based allys /

- friction materials /

- carbon fiber /

- powder metallurgy /

- microsturcture /

- properties

-

图 2 含不同质量分数碳纤维的铁‒铜基摩擦材料显微组织及能谱分析:(a)0%;(b)2%;(c)4%;(d)6%;(e)A区域能谱图;(f)B区域能谱图;(g)C区域能谱图;(h)D区域能谱图

Figure 2. SEM images and EDS analysis of Fe-Cu based friction materials with different carbon fiber content by mass: (a) 0%; (b) 2%; (c) 4%; (d) 6%; (e) EDS of area A; (f) EDS of area B; (g) EDS of area C; (h) EDS of area D

表 1 铁‒铜基摩擦材料各组分质量分数及粉末粒度

Table 1. Mass fraction and particle size of each component in Fe-Cu based friction materials

原材料 Fe Cu Mo Ni 石墨 MoS2 Al2O3 SiC 锆英砂 Sn 质量分数/ % 50 20 4 4 8 3 3 4 2 2 粒度/ 目 200 200 200 200 80 150 200 200 150 200 表 2 实验用碳纤维性能参数

Table 2. Performance parameters of carbon fiber used in experiment

单丝数/ K 抗拉强度/ GPa 弹性模量/ GPa 密度/ (g·cm-3) 单丝直径/ μm 6 4 240 1.75 7 表 3 含不同质量分数碳纤维的铁‒铜基摩擦材料的相对密度及硬度

Table 3. Relative density and hardness of Fe-Cu based friction materials with different carbon fiber content by mass

碳纤维质量分数/ % 实际密度/ (g·cm-3) 理论密度/ (g·cm-3) 相对密度/ % 孔隙率/ % 硬度,HV 0 5.08 6.11 83.2 16.8 80.3 2 5.37 5.80 92.6 7.4 118.6 4 5.03 5.56 90.4 9.6 102.2 6 4.60 5.32 86.5 13.5 90.5 -

[1] Wang D, Liu Y C. Present situation of friction materials. Adv Ceram, 2007, 28(3): 15 https://www.cnki.com.cn/Article/CJFDTOTAL-XDTC200703009.htm王东, 刘英才. 摩擦材料研究进展. 现代技术陶瓷, 2007, 28(3): 15 https://www.cnki.com.cn/Article/CJFDTOTAL-XDTC200703009.htm [2] Yang J S. Development of semimetal brake materials. Powder Metall Technol, 2001, 19(3): 158 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200103009.htm杨金生. 半金属制动材料的研制. 粉末冶金技术, 2001, 19(3): 158 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200103009.htm [3] Zhang Q J, Bao J S, Yin Y, et al. Research and development of brake friction materials. Surf Technol, 2016, 45(11): 32 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201611005.htm张庆金, 鲍久圣, 阴妍, 等. 制动摩擦材料的研究与发展现状. 表面技术, 2016, 45(11): 32 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201611005.htm [4] Liu L J, Li L, Wu Q J, et al. Effects of braking velocity on friction properties of Cu-based powder metallurgy friction material. Powder Metall Technol, 2018, 36(2): 83 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201802001.htm刘联军, 李利, 吴其俊, 等. 刹车速度对铜基粉末冶金摩擦材料性能的影响. 粉末冶金技术, 2018, 36(2): 83 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201802001.htm [5] Chen W G, Luo Q W, Zhang J, et al. Study of Fe and Cu-based P/M friction materials for automotive brake pads. Powder Metall Technol, 2012, 30(3): 192 doi: 10.3969/j.issn.1001-3784.2012.03.007陈文革, 罗启文, 张剑, 等. 汽车刹车片用铁-铜基摩擦材料的研究. 粉末冶金技术, 2012, 30(3): 192 doi: 10.3969/j.issn.1001-3784.2012.03.007 [6] Dyachkova L N, Feldshtein E E. Microstructures, strength characteristics and wear behavior of the Fe-based P/M composites after sintering or infiltration with Cu-Sn alloy. J Mater Sci Technol, 2015, 31(12): 1226 doi: 10.1016/j.jmst.2015.10.007 [7] Ferrer C, Pascual M, Busquets D, et al. Tribological study of Fe-Cu-Cr-graphite alloy and cast iron railway brake shoes by pin-on-disc technique. Wear, 2010, 268(5-6): 784 http://www.sciencedirect.com/science/article/pii/S004316480900636X [8] Yu X, Guo Z M, Yang J, et al. Effect of Fe content and friction components on properties of copper-based powder metallurgy friction material. Powder Metall Technol, 2014, 32(1): 43于潇, 郭志猛, 杨剑, 等. Fe含量及摩擦组元对铜基粉末冶金摩擦材料性能的影响. 粉末冶金技术, 2014, 32(1): 43 [9] Donnet J B, Bansal R C, Wang M J. Carbon Fibers. 3rd Ed. NewYork: Marcel Dekker, 1990 [10] Chung D D L. Comparison of submicron-diameter carbon filaments and conventional carbon fibers as fillers in composite materials. Carbon, 2001, 39(8): 1119 http://www.sciencedirect.com/science/article/pii/S0008622300003146 [11] Fei J, Li H J, Fu Y W, et al. Effect of reinforced fiber on the performance of paper-based friction material. Lubr Eng, 2010, 35(10): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-RHMF201010004.htm费杰, 李贺军, 付业伟, 等. 增强纤维对纸基摩擦材料性能的影响. 润滑与密封, 2010, 35(10): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-RHMF201010004.htm [12] Chen L, Zhang Y D, Fu J. Study on preparation and wear resistance of carbon fiber reinforced iron matrix composite. Hot Working Technol, 2016, 45(20): 133 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201620039.htm陈莉, 张永丹, 富佳. 碳纤维增强铁基复合材料的制备及其耐磨性能研究. 热加工工艺, 2016, 45(20): 133 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201620039.htm [13] Shen L N, Ruan H L, Ouyang Z Y, et al. Study on iron-based matrix performance of short carbon fiber reinforced diamond bit. Explor Eng Rock Soil Drill Tunnel, 2014, 41(3): 77沈立娜, 阮海龙, 欧阳志勇, 等. 短碳纤维增强金刚石钻头铁基胎体性能的研究. 探矿工程(岩土钻掘工程), 2014, 41(3): 77 [14] Zhang Y D. Study on the Preparation and Properties of Ti/Fe Matrix Composites Reinforced by Carbon Fiber[Dissertation]. Changchun: Changchun University of Technology, 2016张永丹. 碳纤维-钛/铁基复合材料的制备及性能研究[学位论文]. 长春: 长春工业大学, 2016 [15] Zhao Y, Liu R H, Ran X, et al. Preparation and characterization of copper matrix composite reinforced by carbon fiber. Hot Working Technol, 2015, 44(10): 145 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201510044.htm赵宇, 刘润红, 冉旭, 等. 碳纤维增强铜基复合材料的制备与表征. 热加工工艺, 2015, 44(10): 145 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201510044.htm [16] Li B Q, Zhang F Q, Yang Z, et al. Frictional wear properties of carbon-fiber-reinforced copper-based self-lubricating composites. Min Metall Eng, 2016, 36(5): 107 https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201605031.htm黎炳前, 张福勤, 杨昭, 等. 碳纤维增强铜基自润滑复合材料的摩擦磨损性能研究. 矿冶工程, 2016, 36(5): 107 https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201605031.htm [17] Zhou H B, Yao P P, Xiao Y L, et al. Interface formation and wear mechanism between characteristic friction components and base components of Cu-based powder metallurgy friction materials. Chin J Nonferrous Met, 2016, 26(2): 328周海滨, 姚萍屏, 肖叶龙, 等. 铜基粉末冶金摩擦材料特征摩擦组元与基体的界面形成及磨损机理. 中国有色金属学报, 2016, 26(2): 328 [18] Yang M. Effect of Al, Zr on Properties and Microstructure of Fe-18Cu Matrix PM Friction Material[Dissertation]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2011杨明. Al、Zr对Fe-18Cu基粉末冶金摩擦材料组织和性能的影响[学位论文]. 南京: 南京航空航天大学, 2011 [19] Song B B, Liu Y D, Fu C Q, et al. Effects of MoS2 on tribological wear properties of Fe-20wt% Cu-based friction materials. Hot Working Technol, 2016, 45(24): 52 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201624013.htm宋贝贝, 刘玉德, 付传起, 等. MoS2对Fe-20wt% Cu基摩擦材料摩擦磨损性能的影响. 热加工工艺, 2016, 45(24): 52 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201624013.htm [20] Zhang X L, Chen Y, Du S M, et al. Effect of mass fraction ratio of Al2O3 to SiO2 on friction and wear properties of Cu-based powder metallurgy brake material. J Henan Univ Sci Technol Nat Sci, 2017, 38(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-LYGX201704001.htm张学良, 陈跃, 杜三明, 等. Al2O3和SiO2质量分数配比对铜基粉末冶金制动材料摩擦磨损性能的影响. 河南科技大学学报(自然科学版), 2017, 38(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-LYGX201704001.htm [21] Chen B J, Yang Z, Liu J X. Impacts of carbon fibers on performance of copper-based friction materials in powder metallurgy. Foundry Technol, 2017, 38(6): 1304陈帮军, 杨茁, 刘建秀. 碳纤维对铜基粉末冶金摩擦材料性能的影响. 铸造技术, 2017, 38(6): 1304 [22] Ma X L, Ao Y H, Xiao L H, et al. Effect of surface modification of carbon fiber on friction properties of carbon fiber/phenolic resin matrix composite. Chin J Mater Res, 2015, 29(2): 101 https://www.cnki.com.cn/Article/CJFDTOTAL-CYJB201502004.htm马小龙, 敖玉辉, 肖凌寒, 等. 表面改性对碳纤维/酚醛树脂基复合材料摩擦性能的影响. 材料研究学报, 2015, 29(2): 101 https://www.cnki.com.cn/Article/CJFDTOTAL-CYJB201502004.htm -

下载:

下载: