Superfast preparation of Al-Sc alloys with high Sc content by spark plasma sintering

-

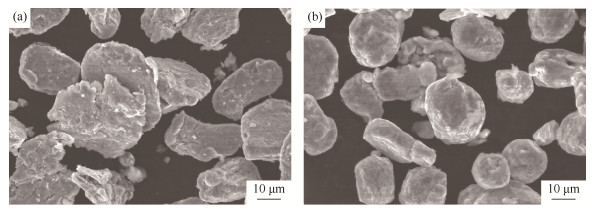

摘要: 采用放电等离子烧结技术制备高钪含量Al-Sc合金, 利用扫描电子显微镜、能谱仪和X射线衍射仪等设备对球磨前后Al-Sc合金粉末的形貌、相组成以及不同温度快速烧结样品的显微组织结构进行观察和分析, 研究烧结温度对Al-Sc合金显微组织的影响。结果表明: 球磨后粉末的形状较规则, 其颗粒尺寸为25~45 μm, 并初步实现了机械合金化, 除Al、Sc相以外, 有少量Al3Sc和AlSc2相生成。放电等离子烧结可实现高钪含量铝钪合金的快速致密化, 成功制备出钪含量30%(质量分数)的铝钪合金, 通过调整烧结工艺参数, 烧结样品的相对密度可达92.19%;当烧结温度高于500℃时, 所得样品致密, 无孔洞, 且无明显晶界; 随着烧结温度的提高, Sc相与第二相融合, 形成Al3Sc、AlSc2等第二相, 存在于合金中, 且Al3Sc相呈现逐渐增强的趋势。Abstract: Aluminum-scandium alloys with high scandium content by mass were prepared by spark plasma sintering (SPS). The morphology, the phase composition, and the microstructures after sintering at different temperatures of Al-Sc alloy powders were investigated by scanning electron microscope (SEM), energy dispersive spectrometry (EDS), and X-ray diffractometry (XRD). The effect of sintering temperature on the microstructure of Al-Sc alloys was studied in the paper. The results show that, the Al-Sc alloy powders after ball milling are regular with the particle size of 25~45 μm, and the mechanical alloying of Al-Sc alloy powders is realized initially. In addition to the Al and Sc phases, a small amount of Al3Sc and AlSc2 are generated. The spark plasma sintering can realize the rapid densification of Al-Sc alloy with high scandium content, the Al-Sc alloy with 30% Sc by mass is successfully produced by SPS method. By adjusting the SPS process parameters, the relative density of sintered sample can be improved to 92.19%. The samples with the higher density and non-obvious grain boundary are achieved at the sintered temperature above 500℃. The second phases of Al3Sc and AlSc2 are formed by the combination of Sc with the increase of sintering temperature, and the peak intensity of Al3Sc increases gradually.

-

Key words:

- spark plasma sintering /

- Al-Sc alloys /

- rapid densification /

- microstructure /

- sintering properties

-

表 1 球磨前后铝钪合金粉末氮氧含量(质量分数)

Table 1. Nitrogen and oxygen contents in Al-Sc powders by mass before and after mechanical milling %

序号 球磨状态 质量分数/ % O N 1 球磨前 0.084~0.240 0.016 2 球磨后 0.053~0.600 0.015 表 2 不同烧结温度和压力下Al-30Sc合金样品的密度

Table 2. Density of the Al-30Sc alloy samples sintered at different temperatures and presses

序号 外加压力/ MPa 烧结温度/ ℃ 密度/ (g∙cm-3) 相对密度/ % 1 30 450 2.351 75.84 2 30 550 2.788 89.94 3 30 600 2.829 91.26 4 40 600 2.858 92.19 表 3 不同温度烧结Al-30Sc合金样品在图 4中不同区域的能谱分析

Table 3. EDS analysis of different zones in Fig. 4 of the Al-30Sc alloy samples sintered at different temperatures

区域组成 450 ℃ 550 ℃ 600 ℃ A B A B A B Al 74.22 0.1 97.38 75.64 73.99 32.74 Sc 25.78 99.9 2.62 24.36 26.01 67.26 相 Al3Sc Sc-rich Sc-rich Al3Sc Al3Sc AlSc -

[1] Röyset J. Scandium in aluminium alloys overview: physical metallurgy, properties and applications. Metall Sci Technol, 2007, 25(2): 11 http://www.researchgate.net/publication/238798615_Scandium_in_Aluminium_Alloys_Overview_Physical_Metallurgy_Properties_and_Applications [2] Ahmad Z. The properties and application of scandium-reinforced aluminum. JOM, 2003, 55(2): 35 doi: 10.1007/s11837-003-0224-6 [3] Lin H C. Development and prospect of aluminum scandium alloy. Chin Rare Earth, 2010, 31(3): 97 doi: 10.3969/j.issn.1004-0277.2010.03.021林河成. 铝钪合金材料的发展现状及前景. 稀土, 2010, 31(3): 97 doi: 10.3969/j.issn.1004-0277.2010.03.021 [4] Yang S H, Qiu Z X, Zhang M J. Application and production of Al-Sc alloy. Light Met, 2006(4): 55 doi: 10.3969/j.issn.1002-1752.2006.04.015杨少华, 邱竹贤, 张明杰. 铝钪合金的应用及生产. 轻金属, 2006(4): 55 doi: 10.3969/j.issn.1002-1752.2006.04.015 [5] Barth S, Gloess D, Bartzsch H, et al. Sputter deposition of piezoelectric AlN and AlScN films for ultrasonic and energy harvesting applications//Energy Self-Sufficient Sensors, 2014, Gmm-Workshop-Proceedings of VDE. Magdeburg, 2014: 21 [6] Sumisaka M, Yamazak K, Fujii S, et al. Sputter deposition of ScAlN using large size alloy target with high Sc content and reduction of Sc content in deposited films. Jpn J Appl Phys, 2015, 54(7S1): 07HD06.1 [7] Takayanagi S, Matsukawa M, Yanagitani T. Effects of energetic negative ions generated from sputtering targets on ScAlN film growth//2016 IEEE International Ultrasonics Symposium. Tours, 2016: 16 [8] Sagal V, Thomass M E, Li J, et al. Fine Grain Size Material, Sputtering Target, Methods of Forming, and Micro-Arc Reduction Method: US Patent, 20030052000. 2004-06-22 [9] Žukauskaite A. Metastable ScAlN and YAlN Thin Films Grown by Reactive Magnetron Sputter Epitaxy[Dissertation]. Linköping: Linköping University, 2014 [10] Sun B L, Zhai Y C, Tian Y W. Preparation of Al-Sc alloy in fluoride molten salts with molten salt electrolysis. Chin J Rare Met, 1998, 2(3): 191 doi: 10.3969/j.issn.0258-7076.1998.03.008孙本良, 翟玉春, 田彦文. 氟盐体系中电解制取铝钪合金的研究. 稀有金属, 1998, 2(3): 191 doi: 10.3969/j.issn.0258-7076.1998.03.008 [11] Cheng T, Lü Z J, Zhai X J, et al. Preparation of Al-Sc alloys investigated in the systems of CaCl2-LiF. J Mater Metall, 2010, 9(1): 39 doi: 10.3969/j.issn.1671-6620.2010.01.010程涛, 吕子剑, 翟秀静, 等. CaCl2-LiF体系制备铝钪合金. 材料与冶金学报, 2010, 9(1): 39 doi: 10.3969/j.issn.1671-6620.2010.01.010 [12] Yang S, Gu S Q, Liu F Q. A Method for Electrolytic Production of Aluminum Scandium Alloy: China Patent, 1410599. 2003-04-16杨昇, 顾松青, 刘凤琴. 一种电解生产铝钪合金的方法: 中国专利, 1410599. 2003-04-16 [13] Guo R, Cao W L, Zhai X J, et al. Preparation of Al-Sc application alloys by molten salt electrolysis method. Chin J Rare Met, 2008, 32(5): 645 doi: 10.3969/j.issn.0258-7076.2008.05.021郭瑞, 曹文亮, 翟秀静, 等. 熔盐电解法制备Al-Sc应用合金的工艺研究. 稀有金属, 2008, 32(5): 645 doi: 10.3969/j.issn.0258-7076.2008.05.021 [14] Yang Q S, Chen J J, Chen W P. Preparation of Al-Sc intermediate alloy by alumino-thermic reduction of Sc2O3. Rare Met Cem Carb, 2007, 35(2): 5 doi: 10.3969/j.issn.1004-0536.2007.02.002杨庆山, 陈建军, 陈卫平. 铝热还原Sc2O3制备Al-Sc中间合金. 稀有金属与硬质合金, 2007, 35(2): 5 doi: 10.3969/j.issn.1004-0536.2007.02.002 [15] Tang C C, Chang H Q, Bao X G, et al. Preparation of Al-Sc intermediate alloy by alumino-strontiu-thermic reduction of Sc2O3. J Chin Rare Earth Soc, 2012, 30(6): 680 https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB201206005.htm唐冲冲, 常化强, 包晓刚, 等. 铝锶热还原Sc2O3制备铝钪中间合金. 中国稀土学报, 2012, 30(6): 680 https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB201206005.htm [16] Huang M S. Preparation of Al-Sc alloy. Jiangxi Nonferrous Met, 2005, 19(2): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS200502009.htm黄美松. 铝-钪(2%)合金的制备. 江西有色金属, 2005, 19(2): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS200502009.htm [17] Zhang K N, Jiang J S, Zhang X M, et al. Preparation of Al-Sc Alloy by Alumino-Thermic Reduction Method: China Patent, 1605641A. 2005-04-13张康宁, 将家顺, 张晓梅, 等. 铝热还原制备铝钪合金的方法: 中国专利, 1605641A. 2005-04-13 [18] Zhu C L, Shen M W, Ji C Q, et al. Preparation of Al-Sc Alloy by Calcium-Thermic Reduction Method: China Patent, 102220503A. 2011-10-19朱昌洛, 沈明伟, 冀成庆, 等. 钙热还原法制备铝钪中间合金的方法: 中国专利, 102220503A. 2011-10-19 [19] Zhang M J, Liang J X. Property and preparation of Al-Sc alloys. J Mater Metall, 2002, 1(2): 110 https://www.cnki.com.cn/Article/CJFDTOTAL-HUJI200202006.htm张明杰, 梁家骁. 铝钪合金的性质与生产. 材料与冶金学报, 2002, 1(2): 110 https://www.cnki.com.cn/Article/CJFDTOTAL-HUJI200202006.htm [20] Gschneidnerk K A, Calderwood F W. The Al-Sc (aluminum-scandium) system. Bull Alloy Phase Diagrams, 1989, 10(1): 34 doi: 10.1007/BF02882170 [21] Gao L, Miyamoto H. Spark plasma sintering technology. J Inorg Mater, 1997, 12(2): 129 https://www.cnki.com.cn/Article/CJFDTOTAL-WGCL199702000.htm高濂, 宫本大树. 放电等离子烧结技术. 无机材料学报, 1997, 12(2): 129 https://www.cnki.com.cn/Article/CJFDTOTAL-WGCL199702000.htm [22] Liu J S, Ji Z, Jia C C, et al. Preparation and properties of nano-AlN particle dispersion strengthened Cu-matrix composite. Powder Metall Technol, 2017, 35(5): 323 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201705001.htm刘佳思, 纪箴, 贾成厂, 等. 纳米AlN颗粒弥散增强铜基复合材料的制备及性能研究. 粉末冶金技术, 2017, 35(5): 323 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201705001.htm [23] Wang D P, Mu Y C, Cheng X Z, et al. Effects of raw material ratio on the properties of molybdenum carbide prepared by spark plasma sintering method. Powder Metall Technol, 2018, 36(1): 31王大鹏, 穆云超, 成晓哲, 等. 原料配比对放电等离子烧结钼碳化合物的影响. 粉末冶金技术, 2018, 36(1): 31 [24] Wang H Y, Chen Y H, Bai Z J, et al. Preparation of Ta-W-Si alloy by powder metallurgy method. Powder Metall Technol, 2018, 36(1): 67 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201801012.htm王鸿业, 陈宇红, 白掌军, 等. 粉末冶金法制备Ta-W-Si合金. 粉末冶金技术, 2018, 36(1): 67 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201801012.htm [25] Guo Z Z, Gan G Y, Yan J K, et al. Present status and future prospects for Al-Sc alloys. Yunnan Metall, 2005, 34(3): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-YNYJ200503010.htm郭中正, 甘国友, 严继康, 等. 铝钪合金的现状与展望. 云南冶金, 2005, 34(3): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-YNYJ200503010.htm -

下载:

下载: