Preparation and characterization of spherical tantalum powder by radio frequency plasma

-

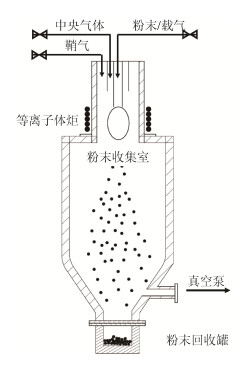

摘要: 采用射频等离子体对不规则状冶金级钽粉进行了球化处理, 研究了粉末供给速率对球化率的影响。结果表明, 当粉末供给速率为10 g·min-1时, 钽粉的球化率可到90%以上; 球化后的钽粉球形度良好、表面光洁, 内部无空心缺陷, 流动性为13.84[s·(50 g)-1], 松装密度从5.87 g/cm3增加到9.35 g/cm3, 达到了增材制造技术的要求; 球化后的粉末杂质元素含量和物相组成没有发生变化。Abstract: Spherical tantalum powders were fabricated by radio frequency (RF) plasma spheroidization process, the effect of powder feeding rate on the spheroidization efficiency was investigated. The results indicate that, the spheroidization efficiency can be above 90% as the powder feeding rate is 10 g·min-1; the obtained tantalum powders after spheroidization exhibit the good sphericity, smooth surface, and narrow size distribution without the internal hollow defects; the flowability of the obtained tantalum powders increases to 13.83[s·(50 g)-1], and the apparent density increases from 5.87 g/cm3 to 9.35 g/cm3, meeting the requirements of additive manufacturing technology; the impurity content and phase composition of tantalum powders after spheroidization remain unchanged.

-

Key words:

- additive manufacturing /

- tantalum powders /

- radio frequency plasma /

- spheroidization

-

表 1 射频等离子球化钽粉的工艺参数

Table 1. Processing parameters for RF plasma processing

中央气体流量(Argon) / (L·min-1) 载气流量(Helium) / (L·min-1) 鞘气流量(Argon) / (L·min-1) 等离子体功率/ kW 反应压力/ kPa 22 18 57 40 10~15 表 2 球化前后钽粉杂质元素质量分数

Table 2. Chemical compositions of impurity elements in tantalum powders before and after spheroidization

元素 C / ×10-6 O / ×10-6 N / ×10-6 H / ×10-6 球化前 12 620 49 27 球化后 13 680 48 28 -

[1] Levine B R, Sporer S, Poggie R A, et al. Experimental and clinical performance of porous tantalum in orthopedic surgery. Biomaterials, 2006, 27(27): 4671 doi: 10.1016/j.biomaterials.2006.04.041 [2] Ryan G, Pandit A, Apatsidis D P. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials, 2006, 27(13): 2651 doi: 10.1016/j.biomaterials.2005.12.002 [3] De Martino I, De Santis V, Sculco P K, et al. Long-term clinical and radiographic outcomes of porous tantalum monoblock acetabular component in primary hip arthroplasty: a minimum of 15-year follow-up. J Arthroplasty, 2016, 31(9): S110 doi: 10.1016/j.arth.2015.12.020 [4] Yang K, Tang H P, Wang J, et al. Research development of standardized and addtively manufactured custom-made porous tantalum implant. Hot Working Technol, 2017, 46(22): 5 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201722003.htm杨坤, 汤慧萍, 王建, 等. 标准化和增材制造个性化多孔钽植入体的研究进展. 热加工工艺, 2017, 46(22): 5 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201722003.htm [5] Zhang X Y, Fang G, Zhou J. Additively manufactured scaffolds for bone tissue engineering and the prediction of their mechanical behavior: A review. Materials, 2017, 10(1): E50 doi: 10.3390/ma10010050 [6] Tang H P, Qian M, Liu N, et al. Effect of powder reuse times on additive manufacturing of Ti-6Al-4V by selective electron beam melting. JOM, 2015, 67(3): 555 doi: 10.1007/s11837-015-1300-4 [7] He J L. The development of world tantalum powder technology. Eng Sci, 2001, 3(12): 85 doi: 10.3969/j.issn.1009-1742.2001.12.015何季麟. 世界钽粉生产工艺的发展. 中国工程科学, 2001, 3(12): 85 doi: 10.3969/j.issn.1009-1742.2001.12.015 [8] Jiang X L, Boulos M. Induction plasma spheroidization of tungsten and molybdenum powders. Trans Nonferrous Met Soc China, 2006, 16(1): 13 doi: 10.1016/S1003-6326(06)60003-4 [9] Hou Y B, Zeng K L, Yu Y G, et al. Plasma spheroidization of tungsten powder. Nonferrous Met, 2008, 60(1): 41 https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS200801010.htm侯玉柏, 曾克里, 于月光, 等. 等离子球化钨粉. 有色金属, 2008, 60(1): 41 https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS200801010.htm [10] Harbec D, Gitzhofer F, Tagnit-Hamou A. Induction plasma synthesis of nanometric spheroidized glass powder for use in cementitious materials. Powder Technol, 2011, 214(3): 356 doi: 10.1016/j.powtec.2011.08.031 [11] Gu Y W, Yap A U J, Cheang P, et al. Spheroidization of glass powders for glass ionomer cements. Biomaterials, 2004, 25(18): 4029 doi: 10.1016/j.biomaterials.2003.10.096 [12] Wang J J, Hao J J, Guo Z M, et al. Preparation of spherical niobium powder by RF induction plasma. Mater Sci Eng Powder Metall, 2014, 19(3): 361 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201403005.htm王建军, 郝俊杰, 郭志猛, 等. 射频等离子体制备球形铌粉. 粉末冶金材料科学与工程, 2014, 19(3): 361 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201403005.htm [13] Wang L Z, Liu Y, Chang S. Fabrication of spherical AlSi10Mg powders by radio frequency plasma spheroidization. Metall Mater Trans A, 2016, 47(5): 2444 doi: 10.1007/s11661-016-3384-z [14] Yu F C, Zhou X, Wang D Z, et al. Study on the RF inductively coupled plasma spheroidization of refractory W and W-Ta alloy powders. Plasma Sci Technol, 2018, 20(1): 014019 doi: 10.1088/2058-6272/aa8e94 [15] Tong J B, Lu X, Liu C C, et al. Numerical simulation and prediction of radio frequency inductively coupled plasma spheroidization. Appl Therm Eng, 2016, 100: 1198 doi: 10.1016/j.applthermaleng.2016.02.108 -

下载:

下载: