Research progress on particle-reinforced titanium matrix composites prepared by powder metallurgy method

-

摘要: 颗粒增强钛基复合材料因具有高强度、轻量化、耐蚀性和高温力学性能优良等特点被广泛应用于航空航天、汽车工业、医用工程领域。本文介绍了钛基复合材料在国内外的发展概况与研究成果, 阐述了钛基复合材料基体组成、增强体形貌及物理性质、增强体引入方式、制备工艺及力学性能等方面, 重点讨论了利用不同粉末冶金法制备颗粒增强钛基复合材料的工艺特点及材料特性, 并对其进一步研究提出展望。Abstract: Particle-reinforced titanium-based composites are widely used in aerospace, automotive, and medical engineering due to their high strength, light weight, corrosion resistance, and excellent high temperature mechanical properties. The development overview and research results of titanium-based composites in domestic and international were introduced in this paper. The matrix composition of titanium-based composites, the morphology and physical properties of particle reinforcement materials, the introduction method of reinforcement, the preparation process, and the mechanical properties of the composites were described. Especially, the process characteristics and material properties of the particle-reinforced titanium-based composites prepared by the different powder metallurgy methods were discussed, and the propose prospects for the further research on titanium-based composites were expected.

-

表 1 纯钛、钛合金与了解有关增强材料的更多信息" 增强体材料的性能[10]

Table 1. Properties of pure titanium, titanium alloy, and reinforcements[10]

材料 抗拉强度/ MPa 弹性模量/ GPa 热膨胀系数/ (10-6K-1) Ti 345~685 105 8.80 Ti‒6Al‒4V 902 110 8.80 SiC 35~140 420 4.30 TiB 280 550 8.60 TiC 120 460 6.25~0.15 TiN — 250 9.30 TiB2 129 500 4.60~8.10 Si3N4 170 320 3.20 Al2O3 223 402 13.30 B4C 158 445 4.78 表 2 钛基复合材料室温力学性能

Table 2. Mechanical properties of titanium matrix composites at room temperature

-

[1] Shi C, Lei J B, Zhou S F, et al. Research progress on continuous fiber-reinforced metal matrix composites and their laser cladding. Laser Optoelectron Prog, 2017, 54(6): 060003-1 https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ201706003.htm石川, 雷剑波, 周圣丰, 等. 连续纤维增强金属基复合材料研究进展及其激光熔覆. 激光与光电子学进展, 2017, 54(6): 060003-1 https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ201706003.htm [2] Hu Y B, Ning F D, Wang X L, et al. Laser deposition-additive manufacturing of in situ TiB reinforced titanium matrix composites: TiB growth and part performance. Int J Adv Manuf Technol, 2017, 93(6): 3409 [3] Tang H P, Huang B Y, Liu Y, et al. Progress in powder metallurgy particle reinforced Ti matrix composite. Powder Metall Technol, 2004, 22(5): 293 doi: 10.3321/j.issn:1001-3784.2004.05.008汤慧萍, 黄伯云, 刘咏, 等. 粉末冶金颗粒增强钛基复合材料研究进展. 粉末冶金技术, 2004, 22(5): 293 doi: 10.3321/j.issn:1001-3784.2004.05.008 [4] Yu L L, Mao X N, Zhao Y Q, et al. Advanced progress on research of particulate reinforced titanium composites. Rare Met Lett, 2006, 25(4): 1 doi: 10.3969/j.issn.1674-3962.2006.04.001于兰兰, 毛小南, 赵永庆, 等. 颗粒增强钛基复合材料研究新进展. 稀有金属快报, 2006, 25(4): 1 doi: 10.3969/j.issn.1674-3962.2006.04.001 [5] Zeng L Y. Preparation of titanium matrix composites by combustion synthesis and sintering. Rare Met Lett, 2004, 23(2): 38 doi: 10.3969/j.issn.1674-3962.2004.02.010曾立英. 燃烧合成加烧结法制备钛基复合材料. 稀有金属快报, 2004, 23(2): 38 doi: 10.3969/j.issn.1674-3962.2004.02.010 [6] Zhang Z H. Discharge Plasma Sintering Technology and its Application in the Preparation of Titanium Matrix Composites. 1st Ed. Beijing: National Defense Industry Press, 2018张朝晖. 放电等离子体烧结技术及其在钛基复合材料制备中的应用. 1版. 北京: 国防工业出版社, 2018 [7] Peng D L, Zhao L H, Du L M. The progress in research on ceramic particulate-reinforced titanium matrix composites. Titanium Ind Prog, 2010, 27(2): 1 doi: 10.3969/j.issn.1009-9964.2010.02.001彭德林, 赵璐华, 杜立明. 陶瓷颗粒增强钛基复合材料的研究进展. 钛工业进展, 2010, 27(2): 1 doi: 10.3969/j.issn.1009-9964.2010.02.001 [8] Zhang L C, Attar H. Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: A review. Adv Eng Mater, 2016, 18(4): 463 doi: 10.1002/adem.201500419 [9] Liu B, Zhang Q, Chen H, et al. Study on the effect of sub-micro SiC particle on the properties and microstructure of Ti (C, N)-based cermet. Powder Metall Technol, 2015, 33(3): 170 doi: 10.3969/j.issn.1001-3784.2015.03.003刘兵, 张茜, 陈慧, 等. 亚微米级SiC颗粒对Ti (C, N)基金属陶瓷材料性能和结构的影响研究. 粉末冶金技术, 2015, 33(3): 170 doi: 10.3969/j.issn.1001-3784.2015.03.003 [10] Lei L M, Huang G F, Wang F Q, et al. Influence of matrix microstructure on fracture toughness of TiC/Ti-6Al-4V composit. Heat Treat Met, 2014, 39(9): 100 https://www.cnki.com.cn/Article/CJFDTOTAL-JSRC201409033.htm雷力明, 黄光法, 王方秋, 等. 基体组织对TiC/Ti-6Al-4V复合材料断裂韧性的影响. 金属热处理, 2014, 39(9): 100 https://www.cnki.com.cn/Article/CJFDTOTAL-JSRC201409033.htm [11] Gofrey T M T, Goodwin P S, Ward-Close C M. Titanium particulate metal matrix composites-reinforcement, production methods, and mechanical properties. Adv Eng Mater, 2000, 2(3): 85 doi: 10.1002/(SICI)1527-2648(200003)2:3<85::AID-ADEM85>3.0.CO;2-U [12] Hooyar A, Shima E H, Damon K, et al. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: a review. Int J Mach Tools Manuf, 2018, 133: 85 doi: 10.1016/j.ijmachtools.2018.06.003 [13] Zhang C, Yang F, Guo Z M, et al. Oxygen scavenging, grain refinement and mechanical properties improvement in powder metallurgy titanium and titanium alloys with CaB6. Powder Technol, 2018, 340: 362 doi: 10.1016/j.powtec.2018.09.054 [14] Lin X J, Dong F Y, Zhang S X, et al. Effects of different (TiC+TiB) content on microstructure and mechanical properties of TC4 alloy. Hot Working Technol, 2019, 48(6): 133 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201906033.htm林雪健, 董福宇, 张世鑫, 等. 不同含量(TiC+TiB)对TC4合金组织和力学性能的影响. 热加工工艺, 2019, 48(6): 133 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201906033.htm [15] Zhang M S. Research on the Microstructure and Properties of High Temperature Titanium Alloy Matrix Composites Enhanced by TiC and TiB[Dissertation]. Harbin: Harbin Institute of Technology, 2010张茂盛. TiC+TiB增强高温钛合金基复合材料的组织和性能研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2010 [16] Zhao Y T, Dai Q X, Chen G. Metal Matrix Composite. 2nd Ed. Beijing: Mechanical Industry Press, 2007赵玉涛, 戴起勋, 陈刚. 金属基复合材料. 2版. 北京: 机械工业出版社, 2007 [17] Tjong S C, Mai Y W. Processing-structure-property aspects of particulate-and whisker-reinforced titanium matrix composites. Compos Sci Technol, 2008, 68(3-4): 583 doi: 10.1016/j.compscitech.2007.07.016 [18] Liu C X, Sun J L. Effect of in-situ formed TiB2 on mechanical properties and microstructure of B4C/TiB2 ceramic composites. Trans Mater Heat Treat, 2010, 31(7): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201007008.htm刘长霞, 孙军龙. 原位反应生成TiB2对B4C/TiB2复合陶瓷力学性能和结构的影响. 材料热处理学报, 2010, 7(31): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201007008.htm [19] Ma F C, Zheng B, Liu P, et al. Modeling of effects of thermomechanical processing on elevated-temperature mechanical properties of in situ (TiB+TiC)/Ti-1100 composite. J Mater Sci, 2016, 51(16): 7502 doi: 10.1007/s10853-016-0029-y [20] Wei W H, Shao Z N, Shen J, et al. Microstructure and mechanical properties of in situ formed TiC-reinforced Ti-6Al-4V matrix composites. Mater Sci Technol, 2017, 34(2): 191 http://smartsearch.nstl.gov.cn/paper_detail.html?id=ddf55d9befb17a20b4a3e66342242210 [21] Qin Q, Wang T G, Fan H X. Progress in Ti matrix composites fabricated by powder metallurgy in situ method. Powder Metall Ind, 2010, 20(5): 42 doi: 10.3969/j.issn.1006-6543.2010.05.009覃群, 王天国, 范宏训. 粉末冶金原位合成法制备钛基复合材料的研究进展. 粉末冶金工业, 2010, 20(5): 42 doi: 10.3969/j.issn.1006-6543.2010.05.009 [22] Lü W J, Zhang X N, Zhang D, et al. The Progress in research on particulate-reinforced titanium matrix composites. Mater Rev, 1999, 13(6): 15 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB199906006.htm吕维洁, 张小农, 张荻, 等. 颗粒增强钛基复合材料研究进展. 材料导报, 1999, 13(6): 15 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB199906006.htm [23] Koch C C. Intermetallic matrix composites prepared by mechanical alloying-a review. Mater Sci Eng A, 1998, 244(1): 39 doi: 10.1016/S0921-5093(97)00824-1 [24] Fu B G, Li C Z, Liu J H, et al. Application and outlook of in situ synthesis in discontinuously reinforced titanium matrix composites. Foundry, 2018, 67(4): 312 doi: 10.3969/j.issn.1001-4977.2018.04.005付彬国, 李朝志, 刘金海, 等. 原位合成技术在非连续增强钛基复合材料中的应用及展望. 铸造, 2018, 67(4): 312 doi: 10.3969/j.issn.1001-4977.2018.04.005 [25] Li Y Y, Zhu F W, Qiao Z L. Study on mechanical alloying of TiB2 particulate reinforced titanium matrix composites. Appl Mech Mater, 2018, 875: 41 doi: 10.4028/www.scientific.net/AMM.875.41 [26] Fang C, Yao Z J, Zhang S S, et al. Effect of electron beam remelting on microstructure and tribological properties of TiC/Ti composite coating prepared by mechanical alloying. Acta Mater Compos Sinica, 2019, 36(1): 167 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201901020.htm方超, 姚正军, 张莎莎, 等. 电子束重熔对机械合金化法制备TiC/Ti复合涂层组织及摩擦性能的影响. 复合材料学报, 2019, 36(1): 167 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201901020.htm [27] Bai L, Ge C C, Shen W P. Spark plasma sintering technology. Powder Metall Technol, 2007, 25(3): 217 doi: 10.3321/j.issn:1001-3784.2007.03.013白玲, 葛昌纯, 沈卫平. 放电等离子烧结技术. 粉末冶金技术, 2007, 25(3): 217 doi: 10.3321/j.issn:1001-3784.2007.03.013 [28] Lee W H, Seong J G, Yoon Y H, et al. Synthesis of TiC reinforced Ti matrix composites by spark plasma sintering and electric discharge sintering: A comparative assessment of microstructural and mechanical properties. Ceram Int, 2019, 45(7): 8108 doi: 10.1016/j.ceramint.2019.01.062 [29] Falodun O E, Obadele B A, Oke S R, et al. Effect of sintering parameters on densification and microstructural evolution of nano sized titanium nitride reinforced titanium alloys. J Alloys Compd, 2017, 736: 202 http://www.sciencedirect.com/science/article/pii/S0925838817338975 [30] Nishimotoa A, Nishib C. Carbide layer coating on titanium by spark plasma sintering technique. Surf Coat Technol, 2018, 353: 324 doi: 10.1016/j.surfcoat.2018.08.092 [31] Merzhanov A G. History and recent developments in SHS. Ceram Int, 1995, 21(5): 371 doi: 10.1016/0272-8842(95)96211-7 [32] Levashov E A, Mukasyan A S, Rogachev A S, et al. Self-propagating high-temperature synthesis of advanced materials and coatings. Int Mater Rev, 2017, 62(4): 203 doi: 10.1080/09506608.2016.1243291 [33] Lagos M A, Agote I, Atxaga G, et al. Fabrication and characterisation of titanium matrix composites obtained using a combination of self propagating high temperature synthesis and spark plasma sintering. Mater Sci Eng A, 2016, 655: 44 doi: 10.1016/j.msea.2015.12.050 [34] Zhou X, Mohanty P. Electrochemical behavior of cold sprayed hydroxyapatite/titanium composite in Hanks'solution. Electrochim Acta, 2012, 65: 134 doi: 10.1016/j.electacta.2012.01.018 [35] Wang J D, Li L Q, Lin P P, et al. Effect of TiC particle size on the microstructure and tensile properties of TiCp/Ti6Al4V composites fabricated by laser melting deposition. Opt Laser Technol, 2018, 105: 195 doi: 10.1016/j.optlastec.2018.03.009 [36] Ogunlana M O, Akinlabi E T, Erinosho M F, et al. Integrated experimental approach for alloying of surface layer Ti6Al4V+B4C metal matrix composites using laser treatment. Mater Res, 2019, 22(2): 1 http://www.scielo.br/scielo.php?script=sci_abstract&pid=S1516-14392019000200210&lng=en&nrm=iso [37] Chen J M, Zhang C Y. Progress in the application of digital 3D printing technology in oral implants. Adv Mater Ind, 2017(11): 29 doi: 10.3969/j.issn.1008-892X.2017.11.008陈继民, 张成宇. 数字化3D打印技术在口腔种植中的应用进展. 新材料产业, 2017(11): 29 doi: 10.3969/j.issn.1008-892X.2017.11.008 [38] Hu Y B, Ning F D, Wang X L, et al. Laser deposition-additive manufacturing of in situ TiB reinforced titanium matrix composites: TiB growth and part performance. Int J Adv Manuf Technol, 2017, 93(6): 3409 [39] Gu D D, Wang H Q, Zhang G Q. Selective laser melting additive manufacturing of Ti-based nanocomposites: the role of nanopowder. Metall Mater Trans A, 2014, 45: 464 http://smartsearch.nstl.gov.cn/paper_detail.html?id=15b695d578d59a991bd97dbe3db040a0 [40] Wang L L, Long W, Zhou X P. Reasearch progress on preparation of pure matrix composites by powder metallurgy processing. Hot Working Technol, 2018, 47(18): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201818004.htm王莲莲, 龙威, 周小平. 粉末冶金制备纯铝基复合材料的研究进展. 热加工工艺, 2018, 47(18): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201818004.htm [41] Duan H Q, Han Y F, Lü W J, et al. Microstructure and mechanical properties of in-situ fabricated laminated Ti-(TiB+TiC)/Ti composites. Mater Mech Eng, 2017, 41(5): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201705004.htm段宏强, 韩远飞, 吕维洁, 等. 原位合成层状Ti-(TiB+TiC)/Ti复合材料的组织与力学性能. 机械工程材料, 2017, 41(5): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201705004.htm [42] Zhou P, Qin J N, Lü W J, et al. Microstructure and mechanical properties of in-situ synthesized titanium matrix composites prepared by powder metallurgy. Powder Metall Ind, 2009, 19(3): 11 doi: 10.3969/j.issn.1006-6543.2009.03.003周鹏, 覃继宁, 吕维洁, 等. 粉末冶金制备原位自生钛基复合材料的显微组织和力学性能研究. 粉末冶金工业, 2009, 19(3): 11 doi: 10.3969/j.issn.1006-6543.2009.03.003 [43] Huang G F, Guo X L, Han Y F, et al. Effect of extrusion dies angle on the microstructure and properties of (TiB+TiC)/Ti6Al4V in situ titanium matrix composite. Mater Sci Eng A, 2016, 667: 317 doi: 10.1016/j.msea.2016.05.021 -

下载:

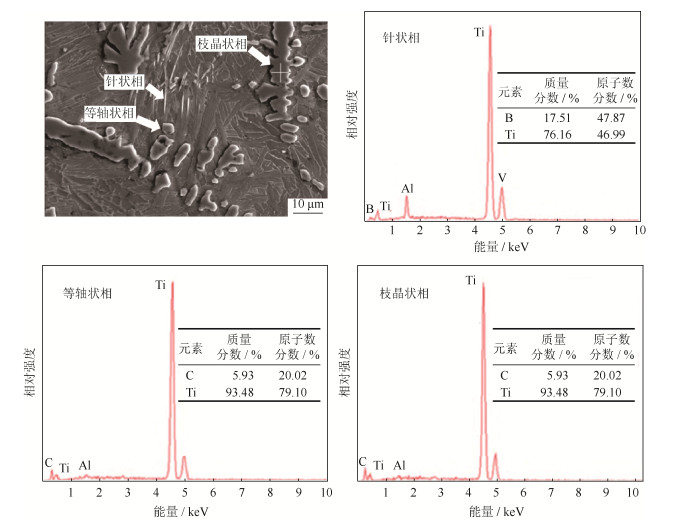

下载: