Study on low temperature creep properties of Al8030 composites added by directional distribution of graphene nanoplatelets

-

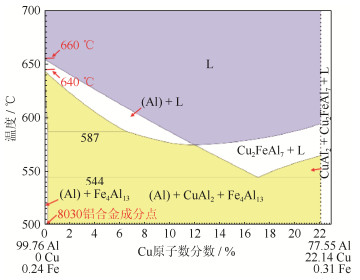

摘要: 采用粉末改性和半固态挤压工艺制备了石墨烯纳米片/Al8030复合材料, 其中石墨烯纳米片质量分数为0.5%, 研究了石墨烯纳米片对铝基复合材料显微组织和低温蠕变性能的影响。结果表明: 石墨烯纳米片主要分布于晶界处, 并且具有与挤压方向平行的定向分布特征。复合材料样品在服役条件下的稳态蠕变速率与铝合金基体相比下降超过50%。在90 ℃和50~90MPa实验条件下, 基体的蠕变机制以位错攀移机制为主, 而复合材料的蠕变则由位错滑移和位错攀移机制共同影响; 在120~150 ℃和50~90MPa实验条件下, 基体和复合材料的蠕变均由位错攀移机制和第二相增强机制协同控制, 但石墨烯纳米片的添加使得第二相增强机制对蠕变的控制更明显。Abstract: The Al8030 composites added by graphene nanoplatelets (GNPs) with the mass fraction of 0.5% were prepared by powder modification and semi-solid extrusion process, and the effects of GNPs on the microstructure and low temperature creep properties of aluminum matrix composites were investigated. The results show that, the GNPs are mainly distributed on the grain boundary of composites and show the directional distribution characteristics as parallel to the extrusion direction. The steady-state creep rate of the composite samples in the service conditions decreases by more than 50% compared to that of the matrix. In the experimental conditions of 90 ℃ and 50~90 MPa, the creep mechanism of the matrix is dominated by the dislocation climbing mechanism, while the creep of the composites is affected by the dislocation slip and dislocation climbing. In the experimental conditions of 120~150 ℃ and 50~90 MPa, the creep mechanism of the matrix and composites are controlled by the dislocation climbing and the second phase enhancement, but the addition of GNPs makes the control effect of the second phase enhancement on creep more obvious.

-

图 4 对比样和0.5%GNPs/Al8030复合材料样品场发射扫描电子显微形貌:(a) 对比样横截面;(b) 对比样纵截面;(c) 0.5%GNPs/8030复合材料样横截面;(d) 0.5%GNPs/8030复合材料样纵截面

Figure 4. FESEM images of the comparison samples and 0.5%GNPs/Al8030 samples: (a) the cross section of comparison samples; (b) the longitudinal section of comparison samples; (c) the cross section of 0.5%GNPs/Al8030 samples; (d) the longitudinal section of0.5%GNPs/Al8030 samples

表 1 8030铝合金的化学成分(质量分数)

Table 1. Chemical composition of 8030 aluminum alloy

% 材料 Fe Cu Si Mg Zn B Al 标准8030铝合金 0.30~0.80 0.15~0.30 0.100 0.050 0.050 0.001~0.040 余量 实验用8030铝合金粉末 0.67 0.25 0.047 0.001 0.001 0.001 余量 表 2 两组试样在不同应力和不同温度条件下的稳态蠕变速率

Table 2. Steady-state creep rate of the two group samples in different stresses at different temperatures

应力/MPa 温度/ ℃ 稳态蠕变速率/s‒1 稳态蠕变下降/% 对比试样 0.5%GNPs/8030复合材料样品 50 90 4.08×10-10 1.47×10-10 64 120 1.20×10-9 4.26×10-10 65 150 4.76×10-9 2.30×10-9 52 70 90 1.38×10-9 6.61×10-10 52 120 8.51×10-9 3.56×10-9 58 150 4.22×10-8 2.13×10-8 50 90 90 5.06×10-9 1.12×10-9 78 120 7.62×10-8 2.15×10-8 72 150 3.72×10-6(断) 9.60×10-7 74 -

[1] Lu N N, Xu L, Li C Y, et al. Research progress on preparation technology of aluminum matrix composites reinforced by graphene. Powder Metall Technol, 2017, 35(4): 310 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.012鲁宁宁, 许磊, 历长云, 等. 石墨烯增强铝基复合材料制备技术研究进展. 粉末冶金技术, 2017, 35(4): 310 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.012 [2] Gao H X, Wang H L, Yang D. Study on single nanoparticles and nano/micro SiC particles reinforced aluminum composites. Powder Metall Technol, 2016, 34(1): 11 doi: 10.3969/j.issn.1001-3784.2016.01.002高红霞, 王华丽, 杨东. 单一纳米及纳/微米SiC混合颗粒增强铝基复合材料研究. 粉末冶金技术, 2016, 34(1): 11 doi: 10.3969/j.issn.1001-3784.2016.01.002 [3] Yang B, Du G X, Cheng F L, et al. Preparation and mechanical properties of graphene reinforced-Al7075 composite by semi-solid sintering. Powder Metall Technol, 2018, 36(4): 303 doi: 10.19591/j.cnki.cn11-1974/tf.2018.04.011杨斌, 杜更新, 程福来, 等. 半固态烧结制备石墨烯/7075铝基复合材料与性能研究. 粉末冶金技术, 2018, 36(4): 303 doi: 10.19591/j.cnki.cn11-1974/tf.2018.04.011 [4] Deng X B, Jiang X Y, Wang B. Effect of Fe and Cu content on microstructure and properties of Al-Fe-Cu alloy for cable. Light Alloy Fabricat Technol, 2016, 44(12): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-QHJJ201612006.htm邓显波, 江新洋, 王斌. 铁、铜含量对电缆用Al-Fe-Cu合金组织和性能的影响. 轻合金加工技术, 2016, 44(12): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-QHJJ201612006.htm [5] Yan S J, Yang C, Hong Q H, et al. Research of graphene-reinforced aluminum matrix nanocomposites. J Mater Eng, 2014(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC201404002.htm燕绍九, 杨程, 洪起虎, 等. 石墨烯增强铝基纳米复合材料的研究. 材料工程, 2014(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC201404002.htm [6] Wang J Y, Li Z Q, Fan G L, et al. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr Mater, 2012, 66(8): 594 doi: 10.1016/j.scriptamat.2012.01.012 [7] Li J L, Xiong Y C, Wang X D, et al. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater Sci Eng A, 2015, 626: 400 doi: 10.1016/j.msea.2014.12.102 [8] Zhou W W, Fan Y C, Feng X P, et al. Creation of individual few-layer graphene incorporated in an aluminum matrix. Composites Part A, 2018, 112: 168 doi: 10.1016/j.compositesa.2018.06.008 [9] Li M, Gao H Y, Liang J M, et al. Microstructure evolution and properties of graphene nanoplatelets reinforced aluminum matrix composites. Mater Charact, 2018, 140: 172 doi: 10.1016/j.matchar.2018.04.007 [10] Meng L L, Hu X S, Wang X J, et al. Graphene nanoplatelets reinforced Mg matrix composite with enhanced mechanical properties by structure construction. Mater Sci Eng A, 2018, 733: 414 doi: 10.1016/j.msea.2018.07.056 [11] Chu K, Wang F, Wang X H, et al. Anisotropic mechanical properties of graphene/copper composites with aligned graphene. Mater Sci Eng A, 2018, 713: 269 doi: 10.1016/j.msea.2017.12.080 [12] Du X, Du W B, Wang Z H, et al. Ultra-high strengthening efficiency of graphene nanoplatelets reinforced magnesium matrix composites. Mater Sci Eng A, 2018, 711: 633 doi: 10.1016/j.msea.2017.11.040 [13] Jiang X Y, Zhang Y, Yi D Q, et al. Low-temperature creep behavior and microstructural evolution of 8030 aluminum cables. Mater Charact, 2017, 130: 181 doi: 10.1016/j.matchar.2017.05.040 [14] Arshad A, Jabbal M, Yan Y Y, et al. A review on graphene based nanofluids: Preparation, characterization and applications. J Mol Liq, 2019, 279: 444 doi: 10.1016/j.molliq.2019.01.153 [15] Tian J. Study on Creep Behavior of AZ91D Composites Reinforced by Aluminum Silicate Short Fibers[Dissertation]. Guangzhou: South China University of Technology, 2011田君. 硅酸铝短纤维增强AZ91D复合材料蠕变行为的研究[学位论文]. 广州: 华南理工大学, 2011 [16] Yue S, Deng X B, Zhang J Y, et al. Effect of low temperature Sc micro-alloying on creep behavior of 8xxx series aluminum alloy wires. Trans Mater Heat Treat, 2017, 38(9): 36 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201709006.htm岳嵩, 邓显波, 张嘉艺, 等. 低温下Sc微合金化对8xxx系铝合金导线蠕变性能的影响. 材料热处理学报, 2017, 38(9): 36 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201709006.htm [17] Yuan G Y, Lü Y Z, Zeng X Q, et al. Influence of Sb microaddition on creep resistance and microstructure of Mg-9Al-0.8Zn alloy. Acta Metall Sinica, 2001, 37(1): 23 doi: 10.3321/j.issn:0412-1961.2001.01.005袁广银, 吕宜振, 曾小勤, 等. 添加微量Sb对Mg-9Al-0.8Zn合金蠕变抗力及微观组织的影响. 金属学报, 2001, 37(1): 23 doi: 10.3321/j.issn:0412-1961.2001.01.005 [18] Khorshidi R, Mahmudi R, Honarbakhsh-Raouf A. Compressive creep behavior of a cast Al-15Mg2Si in situ composite. Mater Sci Eng A, 2016, 668: 112 doi: 10.1016/j.msea.2016.05.058 -

下载:

下载: