-

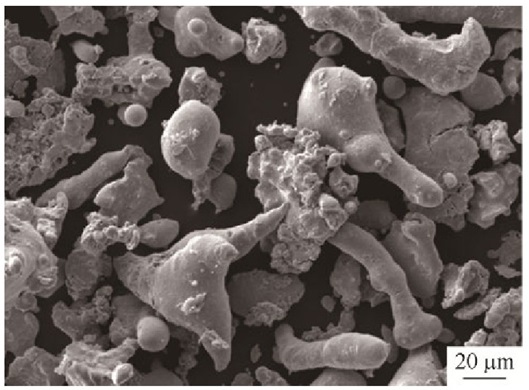

摘要: 采用气水耦合雾化法制备了含有质量分数0.4%稀土Ce的硅黄铜预合金粉末, 在680~720 ℃热压烧结预合金粉末, 获得了致密烧结体。通过洛氏硬度计测试烧结体硬度为HRB62~65, 使用万能力学实验机测试烧结体抗弯强度为530~550 MPa, 利用扫描电子显微镜观察烧结体基体微观组织为α相黄铜, 组织中还存在蠕虫状及花状的弥散银灰色(β'+γ)相。选择添加质量分数20%的硅黄铜预合金粉末配方(铁粉+铜粉+锌粉+预合金粉末)制备花岗岩切割用金刚石刀头, 与单质粉末混合配方(铁粉+铜粉+锌粉)制备的刀头相比, 添加硅黄铜预合金粉末的刀头硬度增加22%, 抗弯强度降低8%, 刀头锋利度和使用寿命整体提升, 胎体磨粒夹杂减少, 并出现大量排屑沟槽。Abstract: The silicon brass pre-alloyed powder with 0.4% Ce by mass was prepared by gas-water coupling atomization method. The dense sintered body were obtained by hot pressing sintering at 680~720 ℃. The hardness of the sintered body is HRB 62~65 tested by Rockwell hardness tester, and the bending strength is 530~550 MPa tested by the universal testing machine. The microstructure of the sintered body is consisted of the brass phase (α phase) and the vermicular and flower-like dispersed silver gray (β′ + γ) phases observed by scanning electron microscope. The diamond cutting segment for granites were prepared by the mixed powders of iron powder + copper powder + zinc powder + 20% silicon brass pre-alloyed powder by mass. Compared with the cutting segment prepared by the elemental powders (iron powder + copper powder + zinc powder), the hardness of the cutting segment prepared by the mixed powders with silicon brass pre-alloyed powder increases by 22% and the bending strength decreases by 8%. The sharpness and service life of the cutting segment with silicon brass pre-alloyed powder were improved, and the matrix was characterized by the reduction of abrasive inclusions and a large number of chip removal grooves.

-

Key words:

- pre-alloyed powder /

- sintering /

- diamond tool /

- sharpness /

- service life

-

表 1 实验用硅黄铜预合金粉末化学成分(质量分数)

Table 1. Chemical composition of the silicon brass pre-alloyed powders in experiment

% Cu Zn Si Ce 68 30 1.6 0.4 表 2 制备金刚石刀头用粉末配方(质量分数)

Table 2. Components of the powders used in the diamond cutting segment

% 成分 Fe Cu Zn 硅黄铜预合金粉末 配方一 60 30 10 — 配方二 60 18 2 20 表 3 硅黄铜预合金粉末烧结样块物理性能

Table 3. Physical properties of the sintered body using the silicon brass pre-alloyed powders

烧结温度/℃ 硬度,HRB 抗弯强度/MPa 680~720 62~65 530~550 位置 质量分数/% Cu Zn Sn Si Ce 1 69.47 27.86 1.27 0.74 0.66 2 55.84 22.68 1.82 13.35 6.31 3 51.37 30.38 2.09 9.36 6.44 表 5 两种配方混合粉末制备金刚石刀头的物理性能

Table 5. Physical properties of the diamond cutting segment prepared by two formulas of the mixture powders

材料 洛氏硬度,HRB 抗弯强度/MPa 配方一 45~48 860~900 配方二 55~58 800~820 -

[1] Sun Y C, Liu Y B, Wang Q S. Diamond Tools and Metallic Foundation. 1st Ed. Beijing: China Building Materials Industry Press, 1999孙毓超, 刘一波, 王秦生. 金刚石工具与金属学基础. 1版. 北京: 中国建材工业出版社, 1999 [2] Liu Y B, Xu Q, Xu L. Characteristics, status analysis and development tread of metal powders for diamond tools. Powder Metall Ind, 2017, 27(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704001.htm刘一波, 徐强, 徐良. 金刚石工具用金属粉末的特性、现状分析和发展趋势. 粉末冶金工业, 2017, 27(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704001.htm [3] Luo X Y, Ma H Q, Huang M, et al. Research and application of cobalt-substitute prealloy powder for diamond tools. Diamond Abras Eng, 2006(1): 18 doi: 10.3969/j.issn.1006-852X.2006.01.005罗锡裕, 麻洪秋, 黄漫, 等. 金刚石工具预合金代钴粉末的研究及应用. 金刚石与磨料磨具工程, 2006(1): 18 doi: 10.3969/j.issn.1006-852X.2006.01.005 [4] Meng W R, Xu K W, Yang J J, et al. Adaptability of brazing filling metal used for monolayer diamond tools with vacuum furnace brazing. Trans China Weld Inst, 2004, 25(1): 80 doi: 10.3321/j.issn:0253-360X.2004.01.021孟卫如, 徐可为, 杨吉军, 等. 金刚石工具真空钎焊钎料的适应性. 焊接学报, 2004, 25(1): 80 doi: 10.3321/j.issn:0253-360X.2004.01.021 [5] Yu Q, Ma J, Long W M, et al. Application of Cu-P per-alloyed powder in the carcass of diamond tools. Diamond Abras Eng, 2018, 38(4): 36 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201804007.htm于奇, 马佳, 龙伟民, 等. 铜磷预合金粉在金刚石工具中的应用. 金刚石与磨料磨具工程, 2018, 38(4): 36 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201804007.htm [6] Wang C, Zhang X F, Wang C F, et al. Current research situation and development of Cu-based diamonds tools made by powder metallurgy. Powder Metall Technol, 2012, 30(2): 140 doi: 10.3969/j.issn.1001-3784.2012.02.011王闯, 张效芬, 王长福, 等. 粉末冶金Cu基金刚石工具的研究现状及进展. 粉末冶金技术, 2012, 30(2): 140 doi: 10.3969/j.issn.1001-3784.2012.02.011 [7] Sui X, Song B Y, Li B, et al. Characteristic of microstructure and properties evolution of H65 brass alloy during continuous extrusion process. Chin J Nonferrous Met, 2009, 19(6): 1049 doi: 10.3321/j.issn:1004-0609.2009.06.012隋贤, 宋宝韫, 李冰, 等. H65黄铜合金连续挤压过程中的组织和性能演变特征. 中国有色金属学报, 2009, 19(6): 1049 doi: 10.3321/j.issn:1004-0609.2009.06.012 [8] Zhou S J. Wear resistance of silicon brass. Spec Cast Nonferrous Alloys, 2010, 30(4): 380 doi: 10.3870/tzzz.2010.04.030周世杰. 硅黄铜耐磨性能研究. 特种铸造及有色合金, 2010, 30(4): 380 doi: 10.3870/tzzz.2010.04.030 [9] Zhao D Z. Development and applications in brass powders containing rare-earth elements. Powder Metall Ind, 1999, 9(1): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG901.006.htm赵德志. 含稀土元素的黄铜粉末的研制及应用. 粉末冶金工业, 1999, 9(1): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG901.006.htm [10] Pang J S, Chao B, Chen M, et al. Effects of modification treatment on γ phase and cutting property of environmentfriendly silicon-brass. Mater Mech Eng, 2012, 36(5): 73 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201205020.htm庞晋山, 曹标, 陈明, 等. 变质处理对环境友好型硅黄铜γ相及切削性能的影响. 机械工程材料, 2012, 36(5): 73 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201205020.htm [11] State Administration for Market Regulation. GB/T 230.1-2018 Metallic Materials-Rockwell Hardness Test-Part 1: Test Methods. Beijing: China Quality Inspection Press, 2018国家市场监督管理总局. GB/T 230.1-2018金属材料洛氏硬度试验第1部分: 试验方法. 北京: 中国质检出版社, 2018 [12] Sun Y S, Huang H B. Structures and properties of two wear resistant brasses. Mater Mech Eng, 1991(1): 21 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC199101003.htm孙扬善, 黄海波. 两种耐磨黄铜的组织和性能. 机械工程材料, 1991(1): 21 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC199101003.htm [13] Zhong W J. Practical Manual of Copper Processing Technology. 2nd Ed. Beijing: Metallurgical Industry Press, 2007钟卫佳. 铜加工技术实用手册. 2版. 北京: 冶金工业出版社, 2007 [14] Taha M A, E-Mahallawy N A, Mousa T M, et al. Microstructure and castability of lead-free silicon brass alloys. Materialwiss Werkstofftech, 2012, 43(8): 699 doi: 10.1002/mawe.201200932 [15] Haruhiko A, Hisashi I, Li S F, et al. Microstructure and mechanical properties of high strength brass alloy with some elements. Mater Sci Forum, 2010, 654-656: 2552 http://www.scientific.net/MSF.654-656.2552 [16] Hu Y, Cheng J Q, Liu Z X. Influence of modification treatment and heat treatment on properties and microstructure of casting lead brass. Hot Working Technol, 2008, 37(5): 29 doi: 10.3969/j.issn.1001-3814.2008.05.009胡垚, 程巨强, 刘志学. 变质处理及热处理对铸造黄铜组织和性能的影响. 热加工工艺, 2008, 37(5): 29 doi: 10.3969/j.issn.1001-3814.2008.05.009 -

下载:

下载: