-

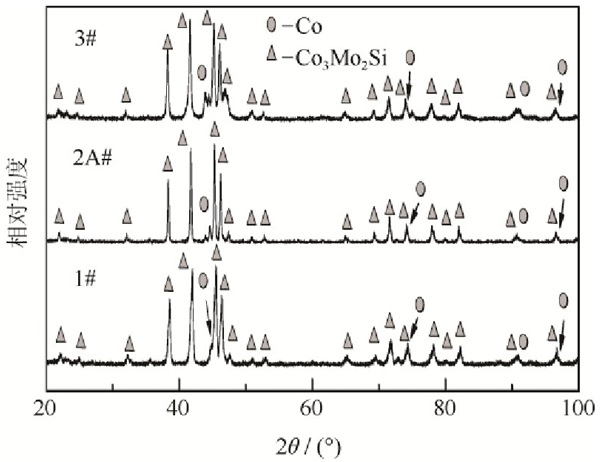

摘要: 为优化过渡金属硅化物的中低温脆性, 以金属粉末为原料通过热压烧结制备了Co3Mo2Si增强、Co基固溶体(Coss)增韧Coss/Co3Mo2Si复合材料, 并对其微观组织结构及力学性能进行了研究。结果表明: Coss/Co3Mo2Si复合材料主要由Co3Mo2Si三元金属硅化物相和Coss相组成, 两相均匀分布; Co3Mo2Si三元金属硅化物相质量分数增加材料的硬度升高, 但抗弯强度降低, Coss相质量分数增加材料的相对密度和抗弯强度均升高; 抗弯强度的最大值可由单一Co3Mo2Si相的335.7MPa提高到Coss/Co3Mo2Si复相的756.2MPa。Abstract: To optimize the brittleness of transition metal silicides at low and medium temperature, the Co3Mo2Si reinforced and Co-based solid solution (Coss) toughened Coss/Co3Mo2Si composites were in-situ synthetised by hot pressing sintering, using metal powders as raw materials, and the microstructure and mechanical properties of Coss/Co3Mo2Si composites were studied. The results show that the Coss/Co3Mo2Si composites mainly consist of Co3Mo2Si ternary metal silicide phase and Coss phase in uniform distribution. With the increase of Co3Mo2Si ternary metal silicide phase weight fraction, the hardness increases but the bending strength decreases; with the increase of Coss phase weight fraction, the relative density and bending strength increase. The maximum bending strength can be increased from 335.7 MPa of Co3Mo2Si single phase to 756.2 MPa of Coss/Co3Mo2Si dual phases.

-

Key words:

- transition metal silicides /

- hot-pressing sintering /

- in-situ synthesis /

- hardness /

- bending strength

-

表 1 Coss/Co3Mo2Si复合材料试样化学成分和烧结参数

Table 1. Chemical compositions and sintering parameters of the Coss/Co3Mo2Si composite samples

试样编号 元素质量分数/% 元素原子数比 球磨时间/h 烧结温度/ ℃ 烧结时间/h 烧结压力/MPa Co Mo Si Co: Mo: Si Co3Mo2Si 44.56 48.36 7.08 3:2:1 5 1250 1 30 1# 46.92 46.30 6.78 3.3:2:1 5 2A# 52.95 41.05 6.00 4.2:2:1 5 2B# 52.95 41.05 6.00 4.2:2:1 10 2C# 52.95 41.05 6.00 4.2:2:1 20 3# 59.13 35.65 5.22 5.4:2:1 5 表 2 烧结试样的力学性能

Table 2. Mechanical properties of the sintered Coss/Co3Mo2Si composite samples

试样编号 Co3Mo2Si质量分数/% Coss质量分数/% 测试密度/(g·cm-3) 相对密度/% 抗弯强度/MPa 硬度, HV Co3Mo2Si 100 0 6.97 77.6 335.7 1140 1# 95.73 4.27 7.04 78.6 364.5 1060 2A# 84.87 15.13 8.31 93.0 489.6 910 2B# 84.87 15.13 7.57 84.7 528.8 904 2C# 84.87 15.13 7.04 78.7 701.3 918 3# 73.72 26.28 8.75 98.0 756.2 810 -

[1] Guo J T. Materials Science and Engineering for Superalloys. Beijing: Science Press, 2008郭建亭. 高温合金材料学. 北京: 科学出版社, 2008 [2] Liang J K, Hou X Y, Cui Y, et al. Effect of sintering temperature on microstructures and mechanical properties of Co-based wear-resistant alloy. Powder Metall Technol, 2017, 35(3): 188 doi: 10.19591/j.cnki.cn11-1974/tf.2017.03.005梁锦奎, 侯星宇, 崔宇, 等. 烧结温度对钴基耐磨合金微观组织和性能的影响. 粉末冶金技术, 2017, 35(3): 188 doi: 10.19591/j.cnki.cn11-1974/tf.2017.03.005 [3] Zou X W, Ma Q, Jia J G. Research developments of Laves phase high temperature structural silicides. Mater Rev, 2008, 22(5): 85 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200805023.htm邹欣伟, 马勤, 贾建刚. Laves相高温结构硅化物的研究进展. 材料导报, 2008, 22(5): 85 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200805023.htm [4] Young K, Ouchi T, Fetcenko M A. Pressure-compositiontemperature hysteresis in C14 Laves phase alloys: Part 1. Simple ternary alloys. J Alloys Compd, 2009, 480(2): 428 doi: 10.1016/j.jallcom.2008.12.113 [5] Lu X D, Wang H M. High-temperature phase stability and tribological properties of laser clad Mo2Ni3Si/NiSi metal silicide coatings. Acta Mater, 2004, 52(18): 5419 doi: 10.1016/j.actamat.2004.08.006 [6] Zhao G, Zhou X J, Zhang J, et al. Preparation and antioxidation mechanism of Nb-Ti-Al based alloy protective coatings. Powder Metall Technol, 2017, 35(5): 347 doi: 10.19591/j.cnki.cn11-1974/tf.2017.05.005赵刚, 周小军, 张静, 等. Nb-Ti-Al基合金防护涂层制备及其抗氧化机理研究. 粉末冶金技术, 2017, 35(5): 347 doi: 10.19591/j.cnki.cn11-1974/tf.2017.05.005 [7] Liu Y, Wang H M. Elevated temperature wear behaviors of a Co-Mo-Si ternary metal silicide alloy. Scr Mater, 2005, 52: 1235 doi: 10.1016/j.scriptamat.2005.03.002 [8] Liu Y X, Chen X, Yin F C, et al. Microstructure and corrosion resistance in liquid Al bath of Co-Mo-Cr-Si alloys. Chin J Nonferrous Met, 2018, 28(10): 2033 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201810010.htm刘永雄, 陈欣, 尹付成, 等. Co-Mo-Cr-Si合金组织及其耐铝液腐蚀性能. 中国有色金属学报, 2018, 28(10): 2033 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201810010.htm [9] Xu Y W, Wang H M. Microstructure and wear properties of laser melted γ-Ni/Mo2Ni3Si metal silicide "in situ" composite. Mater Lett, 2007, 61: 412 doi: 10.1016/j.matlet.2006.04.072 [10] Yan X L, Chen X Q, Grytsiv A, et al. On the ternary Laves phase{Sc, Ti}2M3Si (M=Cr, Mn, Fe, Co, Ni) with MgZn2-type. J Alloys Compd, 2007, 429: 10 doi: 10.1016/j.jallcom.2006.03.086 [11] Zou X W, Ma Q, Jia J G. In situ preparation of (Cu-Mo)/Mo5Si3 composites by hot-press sintering. Powder Metall Technol, 2008, 26(6): 426 http://pmt.ustb.edu.cn/article/id/fmyjjs200806006邹欣伟, 马勤, 贾建刚. 热压原位合成(Cu-Mo)/Mo5Si3复合材料. 粉末冶金技术, 2008, 26(6): 426 http://pmt.ustb.edu.cn/article/id/fmyjjs200806006 [12] Shi H F, Bao Y N, Liu Y. Effect of scanning speed on microstructure and property of Co-Mo-Si alloy coating prepared by argon arc cladding. Mater Prot, 2018, 51(8): 100 https://www.cnki.com.cn/Article/CJFDTOTAL-CLBH201808023.htm时海芳, 鲍亚楠, 刘忆. 熔覆速度对氩弧熔覆Co-Mo-Si合金涂层组织及性能的影响. 材料保护, 2018, 51(8): 100 https://www.cnki.com.cn/Article/CJFDTOTAL-CLBH201808023.htm [13] Kumar K S, Hazzledine P M. Polytypic transformations in Laves phases. Intermetallics, 2004, 12: 763 doi: 10.1016/j.intermet.2004.02.017 [14] Brady M P, Liu C T, Zhu J H. Effects of Fe additions on the mechanical properties and oxidation behavior of Cr2Ta Laves phase reinforced Cr. Scr Mater, 2005, 52: 815 doi: 10.1016/j.scriptamat.2005.01.016 [15] Zhang X H. Study of Stirring Ball Milling of TiH2/SiC Mixed Powders and their Sintering Behavior[Dissertation]. Changsha: Hunan University, 2012张小虎. TiH2/SiC复合粉末的搅拌球磨及其烧结行为研究[学位论文]. 长沙: 湖南大学, 2012 [16] Green D J. An Introduction to the Mechanical Properties of Ceramics. Beijing: Tsinghua University Press, 2003: 238Green D J. 陶瓷材料力学性能导论. 北京: 清华大学出版社, 2003: 238 [17] Liu Y, Wang H M. Microstructure and high-temperature sliding wear property of Coss/Co3Mo2Si metal silicide alloys. Mater Sci Eng A, 2005, 396: 240 doi: 10.1016/j.msea.2005.01.020 -

下载:

下载: