Research on 18Ni300 alloy powders prepared by close-coupled gas atomization technology used for selective laser melting

-

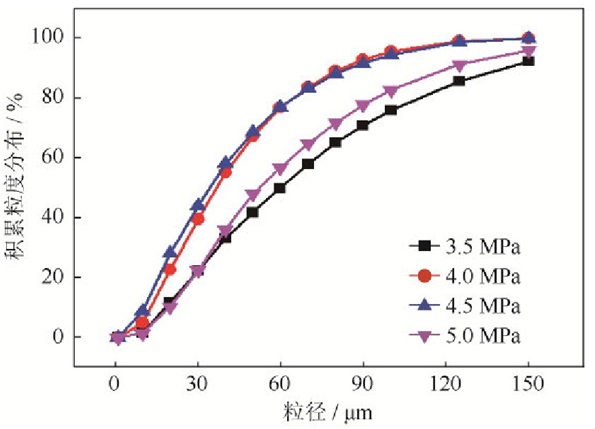

摘要: 基于紧耦合气雾化技术制备符合选区激光熔化用18Ni300合金粉末, 重点研究了雾化压力对粉末粒度(中值粒径, D50)、粒度分布、球形度、氧含量、流动性和松装密度等特性的影响。结果表明: 雾化压力对上述粉末特性影响显著, 当雾化压力在3.5 MPa到4.5 MPa范围时, 随着压力的提高, 粉末粒度降低、表面形貌改善、流动性变好、松装密度增加。当雾化压力为4.5 MPa时, 所制备的粉末综合特性最优, 粉末粒度(D50)为34 μm, 球形度为0.77, 氧含量为0.02%(质量分数), 流动性为17.4[s·(50g)-1], 松装密度为4.32g·cm-3, 15~53 μm粒径范围粉末收得率为38.1%, 满足选区激光熔化技术对金属粉末性能的要求。Abstract: The 18Ni300 alloy powders used for selective laser melting were prepared by close-coupled gas atomization, the effects of gas pressure on the particle size (median particle diameter, D50), particle size distribution, particle shape, oxygen content by mass, flowability, and apparent density of 18Ni300 alloy powders were investigated in this paper. The results show that, the gas pressure has the significant effect on these characteristics. With the increase of gas pressure from 3.5 MPa to 4.5 MPa, the particle size decreases, the surface morphology improves, the flowability gets better, and the apparent density increases. When the gas pressure is 4.5 MPa, the 18Ni300 alloy powders show the optimal comprehensive characteristics, the particle size (D50) is 34 μm, the sphericity is 0.77, the oxygen content by mass is 0.02%, the flowability is 17.4[s·(50 g)-1], the apparent density is 4.32 g·cm-3, and the powder yield in the size of 15~53 μm is 38.1%, meeting the requirements of selective laser melting for the metal powders.

-

表 1 18Ni300合金化学成分(质量分数)

Table 1. Chemical composition of the 18Ni300 alloy

% Ni Mo Co Ti Mn C S P O N H 18.01 4.94 9.01 0.74 0.012 0.001 0.001 0.005 0.0005 0.001 0.00004 表 2 气雾化工艺参数

Table 2. Process parameters of the gas atomization

工艺 金属熔体温度/℃ 雾化压力/MPa 1 1650 ± 20 3.5 2 1650 ± 20 4.0 3 1650 ± 20 4.5 4 1650 ± 20 5.0 表 3 不同工艺制备的粉末粒径(D50) 与收得率(η)

Table 3. Particle size (D50) and yield (η) of the powders prepared by the different processes

工艺 D50/μm η/% 1 60.0 28.5 2 36.5 32.5 3 34.0 38.1 4 40.0 35.9 表 4 不同工艺制备粉末的球形度、流动性与松装密度

Table 4. Spherical, flowability, and apparent density of the powders prepared by the different processes

工艺 球形度 流动性/[s·(50 g) -1] 松装密度/(g·cm-3) 1 0.65 22.3 4.08 2 0.70 19.5 4.21 3 0.77 17.4 4.32 4 0.72 18.6 4.30 -

[1] Shi Y S. The industrial application and industrialization development of 3D printing technology. Mach Des Manuf Eng, 2016, 45(2): 11 doi: 10.3969/j.issn.2095-509X.2016.02.002史玉升. 3D打印技术的工业应用及产业化发展. 机械设计与制造工程, 2016, 45(2): 11 doi: 10.3969/j.issn.2095-509X.2016.02.002 [2] Yang E Q. The influence of 3D printing to the development of aviation manufacturing. Aeronaut Sci Technol, 2013(1): 13 doi: 10.3969/j.issn.1007-5453.2013.01.005杨恩泉. 3D打印技术对航空制造业发展的影响. 航空科学技术, 2013(1): 13 doi: 10.3969/j.issn.1007-5453.2013.01.005 [3] Gu D D, Meiners W, Wissenbach K, et al. Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int Mater Rev, 2012, 57(3): 133 doi: 10.1179/1743280411Y.0000000014 [4] Lu B H, Li D C. Development of the additive manufacturing (3D printing) technology. Mach Build Autom, 2013, 42(4): 1 doi: 10.3969/j.issn.1671-5276.2013.04.001卢秉恒, 李涤尘. 增材制造(3D打印)技术发展. 机械制造与自动化, 2013, 42(4): 1 doi: 10.3969/j.issn.1671-5276.2013.04.001 [5] Ouyang H W, Chen X, Yu W T, et al. Progress and prospect on the gas atomization. Powder Metall Technol, 2007, 25(1): 53 doi: 10.3321/j.issn:1001-3784.2007.01.013欧阳鸿武, 陈欣, 余文焘, 等. 气雾化制粉技术发展历程及展望. 粉末冶金技术, 2007, 25(1): 53 doi: 10.3321/j.issn:1001-3784.2007.01.013 [6] Liu W S, Peng F, Ma Y Z, et al. Research progress in metal powder production by gas atomization. Mater Rev, 2009, 23(3): 53 doi: 10.3321/j.issn:1005-023X.2009.03.012刘文胜, 彭芬, 马运柱, 等. 气雾化法制备金属粉末的研究进展. 材料导报, 2009, 23(3): 53 doi: 10.3321/j.issn:1005-023X.2009.03.012 [7] Zheng Z, Wang L F, Yan B. Research progress of metal materials for 3D printing. Shanghai Nonferrous Met, 2016, 37(1): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-SHHA201601012.htm郑增, 王联凤, 严彪. 3D打印金属材料研究进展. 上海有色金属, 2016, 37(1): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-SHHA201601012.htm [8] Wang H J, Cui Z W, Sun F, et al. Superalloy GH4169 complicated components prepared by selective laser melting forming technique. Powder Metall Technol, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009王会杰, 崔照雯, 孙峰, 等. 激光选区熔化成形技术制备高温合金GH4169复杂构件. 粉末冶金技术, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009 [9] Wu W H, Wu K Q, Xiao Y F, et al. Effect of atomization pressure on the properties of 316L stainless steel powders used in 3D printing. Powder Metall Technol, 2017, 35(2): 83 doi: 10.3969/j.issn.1001-3784.2017.02.001吴文恒, 吴凯琦, 肖逸凡, 等. 气雾化压力对3D打印用316L不锈钢粉末性能的影响. 粉末冶金技术, 2017, 35(2): 83 doi: 10.3969/j.issn.1001-3784.2017.02.001 [10] National Technical Committee for Standardization of Nonferrous Metals. GB/T 5314-2011 Powders for Powder Metallurgical Purpose: Sample. Beijing: China Standard Press, 2012全国有色金属标准化技术委员会. GB/T 5314-2011粉末冶金用粉末: 取样方法. 北京: 中国标准出版社, 2012 [11] Bouwman A M, Bosma J C, Vonk P, et al. Which shape factor (s) best describe granules?Powder Technol, 2004, 146(1-2): 66 doi: 10.1016/j.powtec.2004.04.044 [12] National Technical Committee for Standardization of Nonferrous Metals. GB/T 1482-2010 Metallic Powders-Determination of Flow Time by Means of a Calibrated Funnel (Hall Flowmeter). Beijing: China Standard Press, 2011全国有色金属标准化技术委员会. GB/T 1482-2010金属粉末流动性的测定标准漏斗法(霍尔流速计). 北京: 中国标准出版社, 2011 [13] National Technical Committee for Standardization of Nonferrous Metals. GB/T 149.1-2010 Metallic Powders-Determination of Apparent Density: Part 1. Funnal Method. Beijing: China Standard Press, 2012全国有色金属标准化技术委员会. GB/T 1479.1-2011金属粉末松装密度的测定第1部分: 漏斗法. 北京: 中国标准出版社, 2012 [14] Li Q Q. The principle of powder production by the close-coupled gas atomization. Powder Metall Ind, 1999, 9(5): 3 doi: 10.3969/j.issn.1006-6543.1999.05.001李清泉. 紧密耦合气体雾化制粉原理. 粉末冶金工业, 1999, 9(5): 3 doi: 10.3969/j.issn.1006-6543.1999.05.001 [15] Ouyang H W, Huang B Y, Chen X, et al. Filming mechanism of high-pressure gas atomization in state of 'opened' wake. Chin J Nonferrous Met, 2005, 15(7): 1000 doi: 10.3321/j.issn:1004-0609.2005.07.003欧阳鸿武, 黄伯云, 陈欣, 等. 开涡状况下紧耦合气雾化的成膜机理. 中国有色金属学报, 2005, 15(7): 1000 doi: 10.3321/j.issn:1004-0609.2005.07.003 [16] See J B, Johnson G H. Interactions between nitrogen jets and liquid lead and tin streams. Powder Technol, 1978, 21(1): 119 doi: 10.1016/0032-5910(78)80115-6 -

下载:

下载: