Study of the spherical HoCu powders prepared by supreme-speed plasma rotating electrode process

-

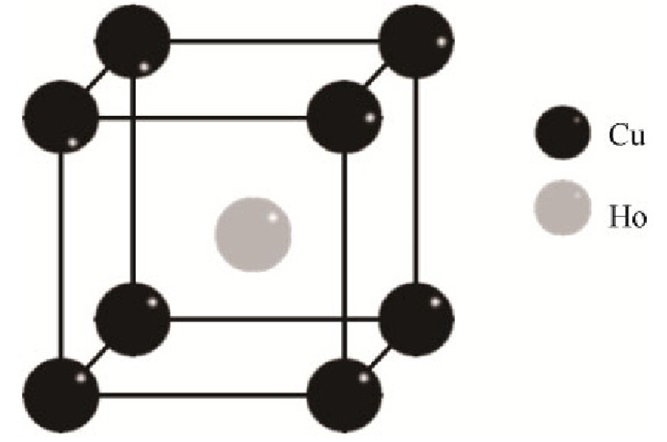

摘要: 采用超高转速等离子旋转电极工艺(supreme-speed plasma rotating electrode process, SS-PREP)制备韧性金属间化合物钬铜(HoCu)球形粉末, 粉末粒度在15~106μm之间。利用X射线衍射仪、扫描电子显微镜、能谱分析及光学显微镜分析了SS-PREP钬铜球形粉末的粒度分布、松装密度、振实密度及霍尔流速等粉末特性, 比较了不同试验方法对粒度分布的表征。结果表明, SS-PREP钬铜粉末主要由CsCl结构的RM型B2相构成, 不同粒度的HoCu球形颗粒化学成分基本一致, 随着粉末粒度增大, HoCu球形粉末的非球形颗粒比例呈现下降趋势。Abstract: The spherical HoCu powders as the ductile intermetallic compounds were prepared by the supreme-speed plasma rotating electrode process (SS-PREP) with the particle sizes of 15~106 μm without sieving. The particle size distribution, apparent density, tap density, and Hall flowability of the SS-PREP HoCu powders were investigated by X-ray diffraction (XRD), scanning electron microscope (SEM), energy disperse spectroscope (EDS), and optical microscope (OM). The particle size distribution characterized by the different test methods were compared and analyzed. The results show that, all of the SS-PREP HoCu powders consist of B2 phase in RM style with CsCl structure; the chemical compositions of HoCu powders in different particle sizes remain nearly constant; with the increase of powder sizes, the proportion of non-spherical HoCu particles decrease.

-

表 1 HoCu电极棒与粉末化学成分(质量分数)

Table 1. Chemical composition of the HoCu bars and powders by mass

% 元素 Ho Al Fe Si O Cu HoCu电极棒 72.3 < 0.002 < 0.015 < 0.01 0.09 余量 SS-PREP制备的HoCu球形粉末 72.0 < 0.002 < 0.015 < 0.01 0.12 余量 表 2 SS-PREP HoCu粉末性能

Table 2. Properties of the SS-PREP HoCu powders

粉末粒度/μm 霍尔流速/[(50 g)·s-1] 松装密度/(g·cm-3) 振实密度/(g·cm-3) 安息角 0~150 11.1 5.51 5.79 — 表 3 不同筛分方法得到的HoCu粉末粒度分布(0~150 μm)

Table 3. Particle size distribution of the HoCu powders in0~150 μm characterized by the different test methods

粒度/μm 干筛法粒度分布(质量分数)/% 激光衍射法粒度分布(体积分数)/% 中航工业540厂 美国泰勒 德国莱驰 丹东百特 0~45 12.01 11.47 9.47 6.96 45~53 6.75 7.47 6.75 13.90 53~63 13.41 12.39 12.37 16.83 63~75 12.24 18.25 13.71 16.82 75~90 42.46 36.50 40.38 19.67 90~106 11.50 13.45 16.58 13.10 106~150 0.20 0.47 0.74 12.18 -

[1] Cao G H, Oertel C G, Schaarschuch R, et al. TEM study of the martensitic phases in the ductile DyCu and YCu intermetallic compounds. Acta Mater, 2017, 132: 345 doi: 10.1016/j.actamat.2017.05.005 [2] Gschneidner Jr K A, Ji M, Wang C Z, et al. Influence of the electronic structure on the ductile behavior of B2 CsCl-type AB intermetallics. Acta Mater, 2009, 57(19): 5876 doi: 10.1016/j.actamat.2009.08.012 [3] Petit L, Szotek Z, Jackson J, et al. Magnetic properties of Gd intermetallics. J Magn Magn Mater, 2018, 448: 9 doi: 10.1016/j.jmmm.2017.04.005 [4] Mudryk Y, Paudyal D, Pathak A K, et al. Balancing structural distortions via competing 4f and itinerant interactions: A case of polymorphism in magnetocaloric HoCo2. J Mater Chem C, 2016, 4(20): 4521 doi: 10.1039/C6TC00867D [5] Morris J R, Ye Y Y, Lee Y B, et al. Ab initio calculation of bulk and defect properties of ductile rare-earth intermetallic compounds. Acta Mater, 2004, 52(16): 4849 doi: 10.1016/j.actamat.2004.06.050 [6] Gschneidner Jr K, Russell A, Pecharsky A, et al. A family of ductile intermetallic compounds. Nat Mater, 2003, 2(9): 587 doi: 10.1038/nmat958 [7] Wu Y R, Hu W Y, Han S C. First-principles calculation of the elastic constants, the electronic density of states and the ductility mechanism of the intermetallic compounds: YAg, YCu and YRh. Phys B: Condens Matter, 2008, 403(19-20): 3792 doi: 10.1016/j.physb.2008.07.009 [8] Blanco J A, Espeso J I, García Soldevilla J, et al. Magnetic structure of GdCu through the martensitic structural transformation: A neutron-diffraction study. Phys Rev B, 1999, 59(1): 512 doi: 10.1103/PhysRevB.59.512 [9] Ozols A, Sirkin H R, Vicente E E. Segregation in stellite powders produced by the plasma rotating electrode process. Mater Sci Eng A, 1999, 262(1-2): 64 doi: 10.1016/S0921-5093(98)01021-1 [10] Wosch E, Feldhaus S, El Gammal T. Rapid solidification of steel droplets in plasma rotating electrode process. ISIJ Int, 1995, 35(6): 764 doi: 10.2355/isijinternational.35.764 [11] Yin J G, Chen G, Zhao S Y, et al. Titanium-tantalum alloy powder produced by the plasma rotating electrode process (PREP). Key Eng Mater, 2018, 770: 18 doi: 10.4028/www.scientific.net/KEM.770.18 [12] Kaplanskii Y Y, Zaitsev A A, Sentyurina Z A, et al. The structure and properties of pre-alloyed NiAl-Cr (Co, Hf) spherical powders produced by plasma rotating electrode processing for additive manufacturing. J Mater Res Technol, 2018, 7(4): 461 doi: 10.1016/j.jmrt.2018.01.003 -

下载:

下载: