Effects of Al powders addition on microstructure and properties of automobile Al2O3 powders prepared by hot-pressing molding

-

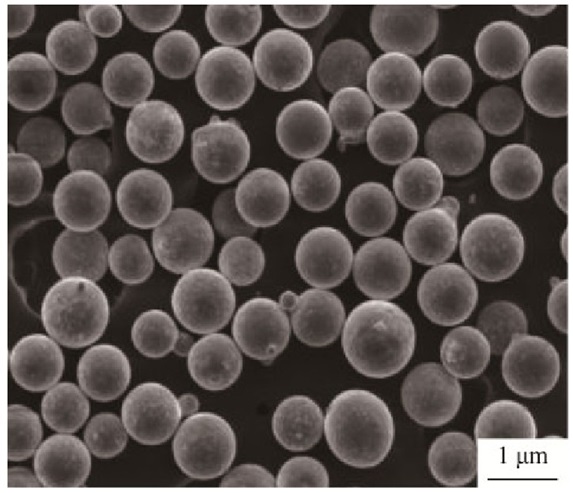

摘要: 选择Al粉作为Al2O3粉末材料的改性剂, 采用热压注工艺制备汽车用Al2O3粉末材料试样, 研究不同Al粉添加量(质量分数)对Al2O3粉末材料组织结构和力学性能的影响。结果表明: Al2O3粉末热压注试样最大收缩率出现在长度方向, 最小收缩率出现于高度方向。随着Al粉质量分数的增加, Al2O3粉末热压注试样收缩率表现出先减小, 后稳定增加, 最后再减小的变化规律, 弯曲强度和体积密度降低, 气孔率显著升高, 试样挠度增高, 浇注得到更大孔径的结构, 同时试样中大尺寸孔径数量也显著增多。随着Al粉质量分数的增加, 试样中Al2O3衍射峰不断上升, 玻璃相的变化不大。加入质量分数8%的Al粉后, 试样断口区域生成了明显的颗粒结构, 说明试样主要发生沿晶断裂。Abstract: The automobile Al2O3 powder samples were prepared by hot-pressing molding, using Al powders as the modifying agents, the effects of Al powder content by mass on the microstructure and mechanical properties of Al2O3 powder samples were studied. The results show that, the maximum shrinkage rate appears in the length direction of Al2O3 powder samples and the minimum one appears in the height direction. With the increase of Al powders content by mass, the shrinkage rate of Al2O3 powder samples decreases first and then increases steadily, and finally decreases. With the increase of Al powders content by mass, the bending strength and volume density of Al2O3 powder samples decrease, while the porosity increase significantly. In addition, the Al2O3 powder samples show a larger deflection, the structure with larger pore diameter can be obtained by hot-pressing molding, and the number of larger pore in Al2O3 powder samples also increases significantly. With the increase of Al powders content by mass, the diffraction peak of Al2O3 increases continuously, but the glass phase changes finitely. When the mass fraction of Al powders is 8%, the obvious grain structure is formed in the fracture area of Al2O3 powder samples and the intergranular fracture is mainly occurred.

-

Key words:

- Al2O3 powders /

- Al powders /

- hot-pressing molding /

- shrinkage rate /

- mechanical properties

-

表 1 实验用原材料纯度及粒度特征

Table 1. Purity and particle size distribution of the raw materials used in experiment

原料 纯度/% 粒度分布/% D10 D50 D90 增塑剂 ≥99.95 7.5 34.4 104.0 Al2O3 ≥99.5 3.2 15.9 40.5 Al粉 ≥99.5 — 1.0~3.0 — 表 2 添加不同质量分数Al粉的Al2O3粉末热压注试样物理性能

Table 2. Physical properties of the Al2O3 powder samples added by Al powders in the different mass fractions

Al粉质量分数/% 气孔率/% 体积密度/(g·cm-3) 抗弯强度/MPa 0 25.12 1.75 28.26 1 28.25 1.71 16.42 3 29.12 1.68 15.16 5 29.74 1.65 14.38 8 30.08 1.61 11.06 -

[1] Liu J Q, Peng L H, Qin S. Effect of Si3N4 on crystallinity of fused silica crucibles during casting. Refractories, 2016, 50(4): 248 doi: 10.3969/j.issn.1001-1935.2016.04.003刘金秋, 彭立华, 秦善. Si3N4添加量对熔融石英坩埚在铸锭过程中析晶的影响. 耐火材料, 2016, 50(4): 248 doi: 10.3969/j.issn.1001-1935.2016.04.003 [2] Kang H F, Li F, Zhao Y J, et al. Research status on ceramic cores and shells for superalloy hollow blades investment casting. J Mater Eng, 2013(8): 85 doi: 10.3969/j.issn.1001-4381.2013.08.014康海峰, 李飞, 赵彦杰, 等. 高温合金空心叶片精密铸造用陶瓷型芯与型壳的研究现状. 材料工程, 2013(8): 85 doi: 10.3969/j.issn.1001-4381.2013.08.014 [3] Ni F, Fu L H, Deng P, et al. Effects of SiO2-B2O3-Al2O3 scaling powder on microstructures and properties of Cu-C-SnO2 porous materials sintered by powders. Powder Metall Technol, 2018, 36(5): 335 doi: 10.19591/j.cnki.cn11-1974/tf.2018.05.003倪锋, 傅丽华, 邓攀, 等. SiO2-B2O3-Al2O3助焊剂对粉末烧结Cu-C-SnO2多孔材料组织与性能的影响. 粉末冶金技术, 2018, 36(5): 335 doi: 10.19591/j.cnki.cn11-1974/tf.2018.05.003 [4] Mao J W, Ding S Y, Li Y J, et al. Preparation of plasma sprayed Al2O3/TiO2 composite powder by sol-gel method. China Surf Eng, 2018, 31(3): 143 https://www.cnki.com.cn/Article/CJFDTOTAL-BMGC201803025.htm毛家玮, 丁思宇, 李永甲, 等. 等离子喷涂Al2O3/TiO2复合粉末的Sol-Gel法制备. 中国表面工程, 2018, 31(3): 143 https://www.cnki.com.cn/Article/CJFDTOTAL-BMGC201803025.htm [5] Wang Y M, Xiong X, Shi Q L, et al. Preparation and application of partial noncrystallization ZrO2-based powders for cold spraying by high energy ball milling. Mater Sci Eng Powder Metall, 2017, 22(5): 622 doi: 10.3969/j.issn.1673-0224.2017.05.005王跃明, 熊翔, 时启龙, 等. 部分非晶化ZrO2/Y2O3基冷喷涂粉末的制备及应用. 粉末冶金材料科学与工程, 2017, 22(5): 622 doi: 10.3969/j.issn.1673-0224.2017.05.005 [6] Shi Y L, Lin T, Qi C F, et al. Influence of co-precipitation reaction parameters and dispersant on performance of Cu-Al2O3 powders. Powder Metall Ind, 2017, 27(1): 16 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201701005.htm石永亮, 林涛, 戚翠芬, 等. 共沉淀反应条件与分散剂对Cu-Al2O3粉末性能的影响. 粉末冶金工业, 2017, 27(1): 16 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201701005.htm [7] Fu J, Shang F, Li H Q, et al. Research on rheology of feedstock for Ni-Al2O3 powder injection molding. Powder Metall Ind, 2016, 26(1): 20 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201601005.htm付杰, 尚峰, 李化强, 等. Ni-Al2O3粉末注射成形喂料的流变学研究. 粉末冶金工业, 2016, 26(1): 20 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201601005.htm [8] Feng W, Wang W H, Wang X Z, et al. Size calculation method of ceramic core locators for hollow turbine blade investment casting wax patterns. Acta Aeronaut Astronaut Sin, 2013, 34(1): 181 https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201301020.htm冯炜, 汪文虎, 王孝忠, 等. 空心涡轮叶片精铸蜡型陶芯定位元件尺寸计算方法. 航空学报, 2013, 34(1): 181 https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201301020.htm [9] Li B, Sun C B, Liu Y, et al. Effect of ceramic core powder particle size on inner cavity dimensions of casting. Foundry, 2015, 64(10): 1025 doi: 10.3969/j.issn.1001-4977.2015.10.019李波, 孙长波, 刘艳, 等. 陶瓷型芯粉料粒度对铸件内腔尺寸的影响. 铸造, 2015, 64(10): 1025 doi: 10.3969/j.issn.1001-4977.2015.10.019 [10] Liu X G, Li X, Tang D Z, et al. Effect of bimodal granularity distribution on the properties of silica-based ceramic cores. Mater Sci Forum, 2017, 898: 1724 doi: 10.4028/www.scientific.net/MSF.898.1724 [11] Li X, Yao J S, Liu X G, et al. Microstructure and performance of fused silica-based ceramic core reinforced by mullite fiber. Mater Sci Forum, 2016, 848: 228 doi: 10.4028/www.scientific.net/MSF.848.228 [12] Lu Z L, Fan Y X, Yang D S, et al. The effect of SiC whisker on the performances of Al2O3 matrixceramics mould for hollow turbine blade//2013 IEEE International Symposium on Assembly and Manufacturing. Xi'an, 2013: 85 -

下载:

下载: