-

摘要: 针对粉尘云最小着火能量(minimum ignition energy, MIE)、粉尘云最低着火温度(minimum ignition temperature of dust cloud, MITC)和粉尘层最低着火温度(minimum ignition temperature of dust layer, MITL)等参数, 开展了针对增材制造用金属粉末爆炸敏感性及影响因素的研究。结果表明, 镍合金粉末和不锈钢粉末爆炸敏感性较低, 而钛合金粉末的敏感程度略高于铝合金粉末, 八种粉末的爆炸敏感程度排序为: TA15>TC4>AlSi10Mg>316L>GH4169>GH3536>GH3625/304L。镍合金粉末和不锈钢粉末均不能被点燃; 钛合金、铝合金粉末的MIE和MITC均随粉尘浓度的升高呈先降低后升高的趋势, 而随喷尘压力的升高呈先降低后升高的趋势。Abstract: Based on the parameters of minimum ignition energy (MIE), minimum ignition temperature of dust cloud (MITC), and minimum ignition temperature of dust layer (MITL), the explosion sensitivity and influence factors of the typical metal powders used in additive manufacturing were investigated. The experimental results show that, the explosive sensitivity of nickel alloy powders and stainless steel powders is lower, while the explosive sensitivity of the titanium alloy powders is slightly higher than that of the aluminum alloy powders. The order of powder explosive sensitivity is as TA15>TC4>AlSi10Mg>316L>GH4169>GH3536>GH3625/304L. The results also show that, both nickel alloy powders and stainless steel powders could not be ignited. The MIE and MITC of titanium alloy powders and aluminum alloy powders decrease first and then increase with the increase of dust concentration, while decrease first and then increase with the increase of dust spraying pressure.

-

Key words:

- additive manufacturing /

- metal powders /

- explosion sensitivity

-

表 1 试验用粉末化学成分及粒度

Table 1. Chemical composition and particle size of powders used in the experiment

粉末类别 粉末牌号 化学成分(质量分数) 中位径/μm 钛合金 TC4 铁≤0.30%,碳≤0.10%,氮≤0.05%,氢≤0.015%,氧≤0.20%,铝5.5%~6.8%,钒3.5%~4.5%,钛余量 38.66 TA15 钒≤2.3%,铝≤6.9%,锆≤2%,锰≤1.7%,钛余量 32.52 铝合金 AlSi10Mg 硅9.0%~11%,锌≤0.10%,铁≤0.55%,镍≤0.05%,锰≤0.45%,钛≤0.15%,镁0.2%~0.45%,铝余量 33.41 镍合金 GH4169 镍50%~55%,铬17%~21%,钴≤1%,碳≤0.08%,锰≤0.35%,硅≤0.35%,硫≤0.015%,铜≤0.35%,铝0.2%~0.8%,钛≤0.65%,铁余量 31.80 GH3536 碳≤0.03%,硅≤0.08%,锰≤0.50%,磷≤0.04%,硫≤0.02%,铬22%~24%,钼15%~17%,铁≤3.0%,铝≤0.50%,铜1.3%~1.9%,镍余量 30.80 GH3625 铬20%~30%,铁≤5%,铌3.15%~4.15%,钼8%~10%,钴≤1%,碳≤0.1%,锰≤0.5%,硅≤0.5%,硫≤0.015%,磷≤0.015%,铜≤0.07%,铝≤0.4%,钛≤0.4%,镍余量 27.42 不锈钢 316L 碳≤0.03%,硅≤1%,锰≤2.00%,硫≤0.030%,磷≤0.045%,铬16.00%~18.00%,镍10.00%~14.00%,钼2.00%~3.00%,铁余量 38.91 304L 碳≤0.03%,硅≤1.0%,锰≤2.0%,铬18.0%~20.0%,镍9.0%~12.0%,硫≤0.03%,磷≤0.045%,铁余量 36.76 表 2 GH4169、GH3536和316L粉末MITC实验数据

Table 2. MITC experiment data of the GH4169, GH3536, and316L powders

粉末牌号 粉末质量浓度/ (kg·m-3) 喷尘压力/MPa 粉尘云最低着火温度/℃ GH4169 4.444 0.04 900 GH3536 4.444 0.04 950 316L 3.333 0.03 860 表 3 试验用金属粉末MITL数据

Table 3. MITL data of the metal powders used in experiment

粉末牌号 粉尘层厚度/mm 热表面温度/℃ 粉尘层温度/℃ 实验结果 TC4 5 380 476 着火 TA15 5 380 458 着火 AlSi10Mg 5 420 462 着火 GH4169 5 450 408 未着火 GH3536 5 450 386 未着火 GH3625 5 450 403 未着火 316L 5 450 383 未着火 304L 5 450 391 未着火 表 4 TC4、TA15和AlSi10Mg粉末的MITC与MITL对比

Table 4. MITC and MITL comparison of the TC4, TA15, and Al Si10Mg powders

粉末牌号 MITC/℃ MITL/℃ MITL下的粉尘层温度/℃ 粉尘层温度能否可作为点火源 TC4 460 380 476 是 TA15 430 380 458 是 AlSi10Mg 680 420 462 否 表 5 TC4、TA15和AlSi10Mg粉末MIE的最敏感条件

Table 5. Most sensitive conditions for the MIE of TC4, TA15, and AlSi10Mg powders

粉末牌号 质量浓度/(kg·m-3) 喷尘压力/MPa 最小着火能量/mJ TC4 1.667 0.3 80 TA15 1.667 0.3 20 AlSi10Mg 1.667 0.2 80 表 6 TC4、TA15和Al Si10Mg粉末粉尘MITC的最敏感条件

Table 6. Most sensitive conditions for the MITC of TC4, TA15, and AlSi10Mg powders

粉末牌号 质量浓度/(kg·m-3) 喷尘压力/MPa 粉尘云最低着火温度/℃ TC4 5.556 0.04 460 TA15 5.556 0.04 430 AlSi10Mg 4.444 0.03 680 -

[1] Zhang G X, Liu S F, Yang X, et al. Research progress on preparation of biological implant materials by additive manufacturing. Powder Metall Technol, 2019, 37(4): 312 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201904012.htm张光曦, 刘世锋, 杨鑫, 等. 增材制造技术制备生物植入材料的研究进展. 粉末冶金技术, 2019, 37(4): 312 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201904012.htm [2] Hu T P, Gao L M, Yang H N. Application of nondestructive testing techniques on additive manufacturing in aerospace fields. Aeronaut Manuf Technol, 2019, 62(8): 70 https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201908020.htm胡婷萍, 高丽敏, 杨海楠. 航空航天用增材制造金属结构件的无损检测研究进展. 航空制造技术, 2019, 62(8): 70 https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201908020.htm [3] Fang X, Dong J F. Application of additive manufacturing technology in bone defects. Chin J Tissue Eng Res, 2019, 23(18): 2915 doi: 10.3969/j.issn.2095-4344.1706方旭, 董军峰. 增材制造技术在骨缺损修复治疗中的应用. 中国组织工程研究, 2019, 23(18): 2915 doi: 10.3969/j.issn.2095-4344.1706 [4] Javaid M, Haleem A. Current status and applications of additive manufacturing in dentistry: A literature-based review. J Oral Biol Craniofac Res, 2019, 9(3): 179 doi: 10.1016/j.jobcr.2019.04.004 [5] Moses Oyesola, Khumbulani Mpofu, Ntombi Mathe. A techno-economic analytical approach of laser-based additive manufacturing processes for aerospace application. Procedia Manuf, 2019, 35: 155 doi: 10.1016/j.promfg.2019.05.019 [6] Ngo T D, Kashani A, Imbalzano G, et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B, 2018, 143: 172 doi: 10.1016/j.compositesb.2018.02.012 [7] Cheng Y W, Guan H J, Li B, et al. Characteristics and applications of metal powders for 3D printing. Mater Rev, 2017, 31(Suppl 1): 98 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2017S1022.htm程玉婉, 关航健, 李博, 等. 金属3D打印技术及其专用粉末特征与应用. 材料导报, 2017, 31(增刊1): 98 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2017S1022.htm [8] Zhang Y J, Chen Y. Research on the application of metal additive manufacturing technology. Powder Metall Ind, 2018, 28(1): 63 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201801019.htm张阳军, 陈英. 金属材料增材制造技术的应用研究进展. 粉末冶金工业, 2018, 28(1): 63 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201801019.htm [9] Zong G S, Zhao H. Technology and application of metal 3D printing. Powder Metall Ind, 2019, 29(5): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201905001.htm宗贵升, 赵浩. 金属增材制造技术工艺及应用. 粉末冶金工业, 2019, 29(5): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201905001.htm [10] Chen J J, Hu L S, Hu S Q, et al. Study on the minimum ignition energy and inhibition technology of titanium dust cloud. Fire Sci Technol, 2015, 34(5): 566 doi: 10.3969/j.issn.1009-0029.2015.05.004陈金健, 胡立双, 胡双启, 等. 钛粉尘云最小点火能及抑制技术研究. 消防科学与技术, 2015, 34(5): 566 doi: 10.3969/j.issn.1009-0029.2015.05.004 [11] Dong H P. The Explosion Parameters and Explosion Risk Evaluation of Titanuium Powder[Dissertation]. Nanning: Guangxi University, 2018董海佩. 钛粉的爆炸参数及爆炸危险性评价[学位论文]. 南宁: 广西大学, 2018 [12] Nifuku M, Koyanaka S, Ohya H, et al. Ignitability characteristics of aluminum and magnesium dusts that are generated during the shredding of post-consumer wastes. J Loss Prev Process Ind, 2007, 20(4): 322 http://www.sciencedirect.com/science/article/pii/S0950423007000587 [13] Wang Y G. Discussion on the explosion characteristics of aluminum dust and explosion prevention countermeasure of aluminum powder site. Fire Sci Technol, 2017, 36(6): 850 doi: 10.3969/j.issn.1009-0029.2017.06.043王以革. 铝粉爆炸特性与涉铝粉场所防爆对策探讨. 消防科学与技术, 2017, 36(6): 850 doi: 10.3969/j.issn.1009-0029.2017.06.043 [14] Zhong Y P, Xu D, Li G, et al. Measurement of minimum ignition temperature for magnesium dust cloud. Explos Shock Waves, 2009, 29(4): 429 doi: 10.3321/j.issn:1001-1455.2009.04.017钟英鹏, 徐冬, 李刚, 等. 镁粉尘云最低着火温度的实验测试. 爆炸与冲击, 2009, 29(4): 429 doi: 10.3321/j.issn:1001-1455.2009.04.017 [15] Ye Y M, Liang J, Jiang H Y J, et al. Research progress on Mg dust combustion explosion. Fire Sci Technol, 2019, 38(7): 921 doi: 10.3969/j.issn.1009-0029.2019.07.005叶亚明, 梁峻, 江湖一佳, 等. 镁粉尘燃烧爆炸研究进展. 消防科学与技术, 2019, 38(7): 921 doi: 10.3969/j.issn.1009-0029.2019.07.005 [16] Wang X F. Research of Monlinear Forecast on Minimum Ignition Energy and Minimum Ignition Temperature of Mg-Al Alloy Dust[Dissertation]. Taiyuan: North University of China, 2016王霞飞. 镁铝合金粉最低着火温度及最小点火能的非线性预测[学位论文]. 太原: 中北大学, 2016 [17] Wang Q H, Sun Y L, Zhang Z J, et al. Ignition and explosion characteristics of micron-scale aluminum-silicon alloy powder. J Loss Prev Process Ind, 2019, 62(3): 902 http://www.sciencedirect.com/science/article/pii/S0950423019302645 [18] EnvSafe Co., Ltd. Digital platform of dust explosion research[J/OL]. EnvSafe Co., Ltd(2017-10-12)[2020-01-12]. https://dees.envsafe.cn/沈阳因斯福环保安全科技有限公司. 粉尘爆炸研究数字化平台[J/OL]. 沈阳因斯福环保安全科技有限公司(2017-10-12)[2020-01-12]. https://dees.envsafe.cn/ [19] Wang H J, Cui Z W, Sun F, et al. Superalloy GH4169 complicated components prepared by selective laser melting forming technique. Powder Metall Technol, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009王会杰, 崔照雯, 孙峰, 等. 激光选区熔化成形技术制备高温合金GH4169复杂构件. 粉末冶金技术, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009 [20] Zhao J, Lü L X, Wang K H, et al. Effects of strain state and slip mode on the texture evolution of a near α TA15 titanium alloy during hot deformation based on crystal plasticity method. J Mater Sci Technol, 2020, 38: 125 doi: 10.1016/j.jmst.2019.07.051 [21] Wang X Q, Chou K. The effects of stress relieving heat treatment on the microstructure and residual stress of Inconel 718 fabricated by laser metal powder bed fusion additive manufacturing process. J Manuf Processes, 2019, 48: 154 doi: 10.1016/j.jmapro.2019.10.027 [22] Wang D J, Li H, Zheng W. Oxidation behaviors of TA15 titanium alloy and TiBw reinforced TA15 matrix composites prepared by spark plasma sintering. J Mater Sci Technol, 2020, 37: 46 doi: 10.1016/j.jmst.2019.07.037 [23] Wang X X, Zhan M, Gao P F, et al. Micromechanical behaviour of TA15 alloy cylindrical parts processed by multi-pass flow forming. Mater Sci Eng A, 2019, 737: 328 http://www.sciencedirect.com/science/article/pii/S0921509318312681 [24] Tong T, Yu Y, Song Z W. Study on effects of 3D printing process parameters on corrosion resistance of TC4 dental implant materials. Hot Working Technol, 2020, 49(2): 25 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY202002006.htm童彤, 于燕, 宋子威. 3D打印工艺参数对TC4牙植体材料耐蚀性能的研究. 热加工工艺, 2020, 49(2): 25 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY202002006.htm [25] Liu H J, Zhang Z M, Xu J, et al. Study on hot deformation behavior and constitutive model of SPSed TC4 titanimu alloy. J Plast Eng, 2019, 26(6): 263 doi: 10.3969/j.issn.1007-2012.2019.06.037刘海军, 张治民, 徐健, 等. 等离子烧结态TC4钛合金热变形行为及本构模型研究. 塑性工程学报, 2019, 26(6): 263 doi: 10.3969/j.issn.1007-2012.2019.06.037 [26] State Bureau of Technology Supervision. GB16428-1996 Determination of the Minimum Ignition Energy of Dust Cloud. Beijing: Standards Press of China, 1997国家技术监督局. GB16428-1996粉尘云最小着火能量测定方法. 北京: 中国标准出版社, 1997 [27] State Bureau of Technology Supervision. GB16429-1996 Determination of the Minimum Ignition Temperature of Dust Cloud. Beijing: Standards Press of China, 1997国家技术监督局. GB16429-1996粉尘云最低着火温度测定方法. 北京: 中国标准出版社, 1997 [28] Standardization Administration of the People's Republic of China. GB16430-2018 Determination of the Minimum Ignition Temperature of Dust Layer. Beijing: Standards Press of China, 2019中国国家标准化管理委员会. GB16430-2018粉尘层最低着火温度测定方法. 北京: 中国标准出版社, 2019 [29] Standardization Administration of the People's Republic of China. GB150-2011 Pressure Vessels. Beijing: Standards Press of China, 2012中国国家标准化管理委员会. GB150-2011压力容器. 北京: 中国标准出版社, 2012 -

下载:

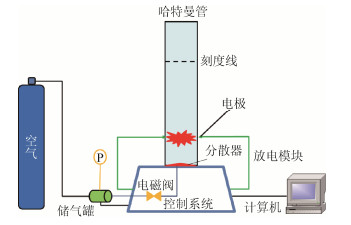

下载: