Preparing powder raw materials of permeable bricks by ball milling using electric porcelain wastes

-

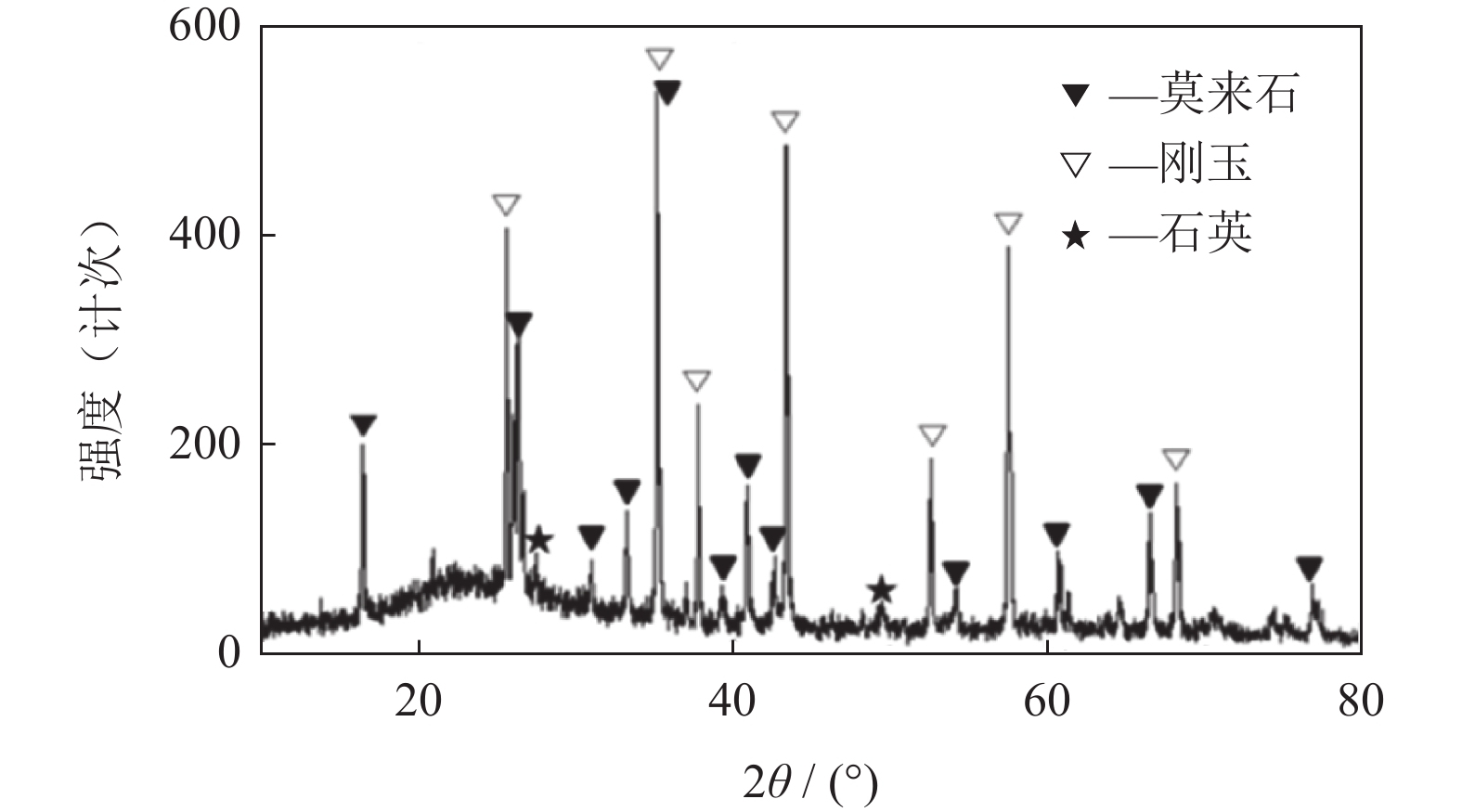

摘要: 研究了球磨工艺对电瓷废料球磨效率的影响,并以电瓷废料球磨粉体为原料制备了透水砖。结果表明:电瓷废料粉体的粒度随球磨时间的延长而逐渐减小,随着球磨转速的增加呈现先减小后增大的趋势,表明球磨效率先提高后降低。由于电瓷废料硬度高,随着大球磨球比例的增加,粉体粒度减小;当中球比例降低后,球磨粉体粒度又随大球比例的增加而增大。当装料量小于35%时,电瓷废料粉体的粒度逐渐上升,球磨效率逐渐降低;当装料量大于35%后,电瓷废料粉体的粒度上升速度加快,球磨效率迅速降低。通过优化电瓷废料球磨工艺并综合考虑透水砖性能,确定球磨时间为20 h、球磨转速为140 r·min‒1、瓷球大、中、小级配比为5:3:2、装料量为35%较为合适,球磨后电瓷废料粉体的中位径为4.1 μm,筛余量为15%。以电瓷废料球磨粉体为主要原料制备透水砖,获得了抗压强度6.1 MPa、透水系数0.028 cm·s‒1的透水砖。Abstract: The influence of ball milling process on the ball milling efficiency of electric porcelain wastes was investigated, and the permeable bricks were prepared by using the ball milled electric porcelain waste powders as the raw materials. The results show that, the particle size of electric porcelain waste powders gradually decreases with the extension of ball milling time, and firstly decreases and then increases with the increase of ball milling speed, indicating that the ball milling efficiency first increases and then decreases. Due to the high hardness of electric porcelain waste, the particle size of the powders decreases with the increase of the large ball proportion in the milling ball. After the decrease of the middle ball proportion, the particle size of the powders increases with the increase of the large ball proportion. When the charge amount is less than 35%, the particle size of the electric porcelain waste powders gradually increases, and the ball milling efficiency gradually decreases. When the charge amount is more than 35%, the increasing rate of particle size is accelerated, and the ball milling efficiency is rapidly lowered. By optimizing the ball milling process of electric porcelain wastes and considering the comprehensive performance of the permeable bricks, the suitable ball milling time is 20 h, the ball milling speed is 140 r·min‒1, the ratio of large, medium, and small stage of porcelain ball is 5:3:2, and the charge amount is 35%. The median diameter of the electric porcelain waste powders after ball milling is 4.1 μm, the sieve residue is 15%. The permeable bricks with the compressive strength of 6.1 MPa and the permeability coefficient of 0.028 cm·s‒1 are prepared by using the ball milled electric porcelain waste powders as the main raw materials.

-

表 1 电瓷废料的化学成份(质量分数)

Table 1. Chemical compositions of the electric porcelain wastes

% Al2O3 SiO2 Fe2O3 CaO K2O Na2O MgO TiO2 余量 47.62 41.36 1.67 0.96 2.66 0.58 0.80 1.98 0.36 -

[1] Gong Y X. Improvement of high temperature loading capacity of porcelain insulators by adding Zhangcun clay. Adv Ceram, 2016, 37(2): 145 doi: 10.16253/j.cnki.37-1226/tq.2016.02.006宫云霞. 章村土提高电瓷绝缘子高温荷重性能的研究. 现代技术陶瓷, 2016, 37(2): 145 doi: 10.16253/j.cnki.37-1226/tq.2016.02.006 [2] Pu Z H, Xiong Y Y, Wu T T, et al. Design and construction of a new insulator detection robot for application in 500 kV strings: Electric field analysis and field testing. Electron Power Syst Res, 2019, 173: 48 doi: 10.1016/j.jpgr.2019.03.025 [3] He J W, Ma A Q. In-situ synthesis of mullite ceramics by electroceramics waste. J Mater Sci Eng, 2016, 34(1): 123贺嘉伟, 马爱琼. 利用电瓷废料原位合成莫来石陶瓷. 材料科学与工程学报, 2016, 34(1): 123 [4] Wang Q, Du Q Y, Yao Q H, et al. Study on preparation of porous thermal insulation materials by comprehensive utilization of tile industry waste. Non-Met Mines, 2015, 38(5): 31王前, 杜庆洋, 姚奇恒, 等. 建陶厂废料综合利用制备多孔保温材料研究. 非金属矿, 2015, 38(5): 31 [5] Keshavarz Z, Mostofinejad D. Porcelain and red ceramic wastes used as replacements for coarse aggregate in concrete. Constr Build Mater, 2019, 195: 218 doi: 10.1016/j.conbuildmat.2018.11.033 [6] Yang C Y, Liu Y Z, Yu K B. Effects of ball milling time on microstructures and properties of graphene/ODS copper composite materials. Mater Sci Eng Powder Metall, 2018, 23(3): 281 doi: 10.3969/j.issn.1673-0224.2018.03.008杨长毅, 刘允中, 余开斌. 球磨时间对石墨烯/ODS铜基复合材料组织与性能的影响. 粉末冶金材料科学与工程, 2018, 23(3): 281 doi: 10.3969/j.issn.1673-0224.2018.03.008 [7] Song J G, Wang R H, Li S B, et al. Wear of ball milling media for preparing quartz sands powder in the industry. Bull Chin Ceram Soc, 2015, 34(Suppl 1): 66 doi: 10.16552/j.cnki.issn1001-1625.2015.s1.015宋杰光, 王瑞花, 李世斌, 等. 工业球磨制备石英砂粉体球磨介质的磨损研究. 硅酸盐通报, 2015, 34(增刊 1): 66 doi: 10.16552/j.cnki.issn1001-1625.2015.s1.015 [8] Matej B. Ball milling of eggshell waste as a green and sustainable approach: A review. Adv Colloid Interface Sci, 2018, 256: 256 doi: 10.1016/j.cis.2018.04.001 [9] Li H X, Li S X, Zhang H, et al. Nanostructural evolution and antifriction effect of ball-milled expanded graphite. Non-Met Mines, 2018, 41(3): 103 doi: 10.3969/j.issn.1000-8098.2018.03.034李会新, 李姝贤, 张辉, 等. 膨胀石墨在球磨期间的微观结构演化及减摩性能. 非金属矿, 2018, 41(3): 103 doi: 10.3969/j.issn.1000-8098.2018.03.034 [10] Singh Y P, Tanvar H, Gulshan K, et al. Investigation of planetary ball milling of sericite for potash recovery. Powder Technol, 2019, 351: 115 doi: 10.1016/j.powtec.2019.04.013 [11] Yang S B, Dong W, Shen D, et al. Effect of ball milling time on the microstructure and reversible storage properties of natural graphite. Bull Chin Ceram Soc, 2016, 35(4): 1080 doi: 10.16552/j.cnki.issn1001-1625.2016.04.016杨绍斌, 董伟, 沈丁, 等. 球磨时间对天然石墨微观结构和可逆储钠性能的影响. 硅酸盐通报, 2016, 35(4): 1080 doi: 10.16552/j.cnki.issn1001-1625.2016.04.016 [12] He K, Ku J G. Grinding parameters of quartz sand with shape of medium. China Powder Sci Technol, 2019, 25(5): 29 doi: 10.13732/j.issn.1008-5548.2019.05.005何逵, 库建刚. 磨矿介质形状对石英砂粉碎参数的影响. 中国粉体技术, 2019, 25(5): 29 doi: 10.13732/j.issn.1008-5548.2019.05.005 [13] Fan T, Shen X, Wang H, et al. Effects of ball milling technology on microstructure and properties of SiCp/Cu composites prepared by in situ synthesis. Powder Metall Technol, 2016, 34(4): 264范涛, 申珣, 王虎, 等. 球磨工艺对原位合成SiCp增强铜复合材料组织及性能的影响. 粉末冶金技术, 2016, 34(4): 264 [14] Xu J L, Guo Q, Kang Z, et al. Effect of milling time and milling rate on nano-Sb powders prepared by wet ball milling. Trans Mater Heat Treat, 2013, 34(6): 18 doi: 10.13289/j.issn.1009-6264.2013.06.006徐建林, 郭强, 康昭, 等. 球磨时间和转速对球磨法制备纳米锑粉的影响. 材料热处理学报, 2013, 34(6): 18 doi: 10.13289/j.issn.1009-6264.2013.06.006 [15] Song J G, Liu Y, He L, et al. Influence of ball milling process on the pinned effect of Al2O3/Al cermet composite powder. Key Eng Mater, 2018, 777: 80 doi: 10.4028/www.scientific.net/KEM.777.80 [16] Sun J Q. Application of energy saving technology for ultra-high chromium ball mill. Metall Mater, 2019, 39(2): 137 doi: 10.3969/j.issn.1674-5183.2019.02.087孙嘉权. 钢球磨煤机超高铬磨球节能技术的应用. 冶金与材料, 2019, 39(2): 137 doi: 10.3969/j.issn.1674-5183.2019.02.087 [17] Nkwanyana S, Loveday B. Addition of pebbles to a ball-mill to improve grinding efficiency. Miner Eng, 2017, 103-104: 72 doi: 10.1016/j.mineng.2016.09.004 [18] Song J G, Wang F, Wu S B, et al. Technological optimization for mechanical ball milling of superfine quartz sand powder. J Ceram, 2011, 32(2): 192 doi: 10.3969/j.issn.1000-2278.2011.02.010宋杰光, 王芳, 吴世斌, 等. 超细石英砂粉体的机械球磨工艺优化研究. 陶瓷学报, 2011, 32(2): 192 doi: 10.3969/j.issn.1000-2278.2011.02.010 [19] Wang F, Wang X Q, Yang C, et al. Influence of loading quantity on the properties of quartz sand powder via mechanical ball milling method // Proceedings of the 2nd Annual International Conference on Advanced Material Engineering (AME 2016). Wuhan, 2016: 701 [20] Yin Z X, Peng Y X, Zhu Z C, et al. Effect of mill speed and slurry filling on the charge dynamics by an instrumented ball. Adv Powder Technol, 2019, 30: 1611 doi: 10.1016/j.apt.2019.05.009 -

下载:

下载: