Research progress of inhomogeneous structure cemented carbide based on surface modification

-

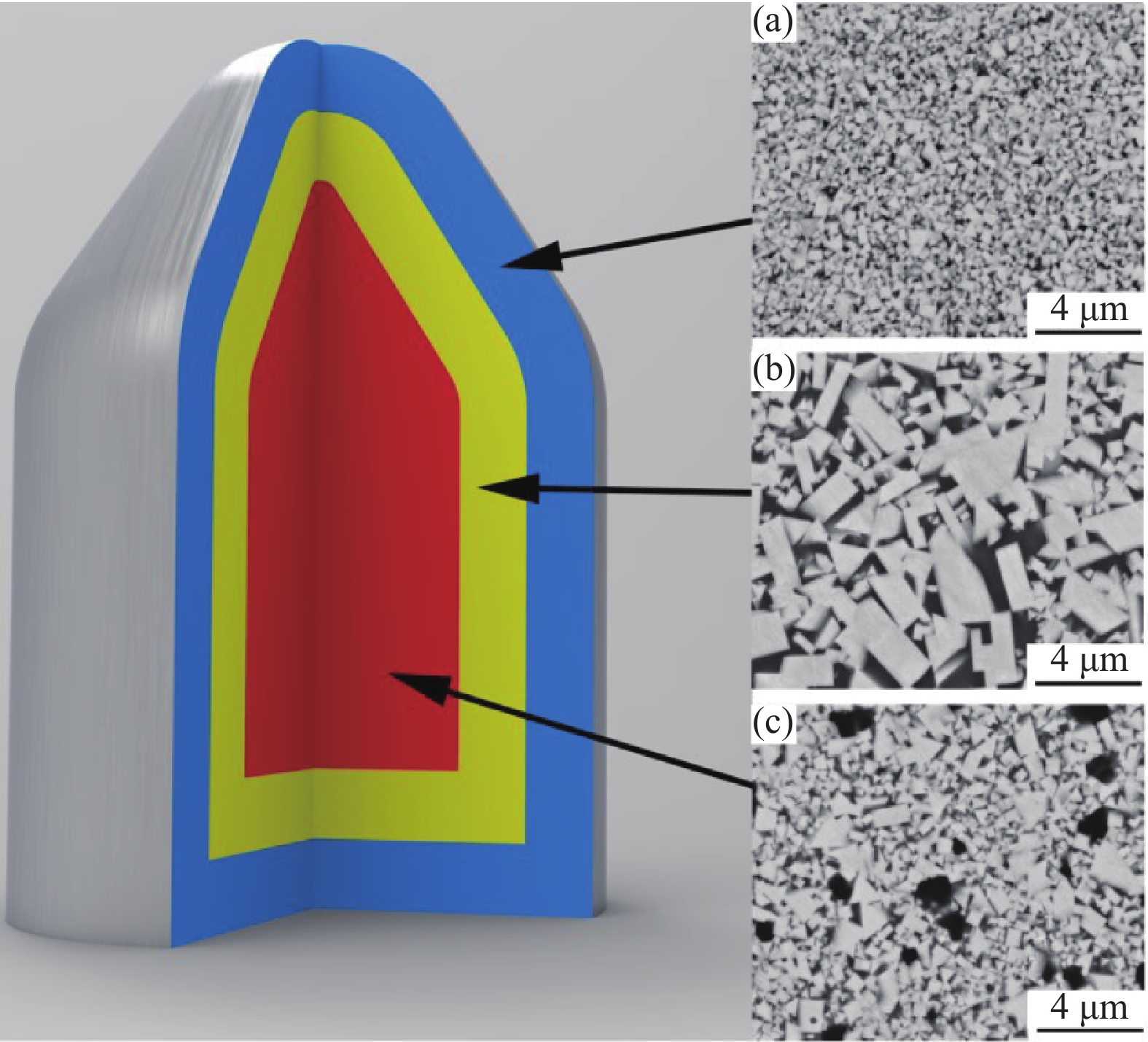

摘要: 表面改性是使材料表面获得与其基体不同微观组织的处理技术,能够有效调控材料表面的力学性能。因此,将表面改性方法应用于改善硬质合金表面的微观组织,能够有效避免均匀结构硬质合金显微结构–宏观性能的局限性,为制备高性能非均匀结构硬质合金提供技术方案。由于硬质合金表面改性研究的起步较晚且表面改性方法较多,表面改性方法的选取及其改性机理依然面临思路不清的问题。本文总结了化学表面改性梯度硬质合金的材料体系、制备机理、微观结构及力学性能,概括了物理表面改性得到的硬质合金涂层方法与功能,综述了表面改性在硬质合金领域的应用和研究进展,以期为制备高耐磨和高韧性的非均匀结构硬质合金提供参考。Abstract: Surface modification is the treatment technology that makes the tailored surface microstructure different from that of the matrix, which can efficiently control the mechanical properties of the material surface. Therefore, the surface modification can improve the microstructure of the cemented carbides, effectively avoid the limitation of the homogeneous structure cemented carbides on the microstructure and macroscopic properties, and provide the technical scheme for the preparation of the high performance inhomogeneous structure cemented carbides. Due to the late start of the surface modification research and a mass of surface modification methods, the selection of surface modification methods and the modification mechanism are still not clear. The material system, preparation mechanism, microstructure, and mechanical properties of the graded cemented carbides obtained by chemical surface modification were summarized in this paper, the methods and functions of the graded cemented carbide coatings obtained by physical surface modification were concluded. The application and research progress of the surface modification used for the cemented carbides were analyzed to provide the reference for the preparation of the cemented carbides with high wear resistance and good fracture toughness.

-

Key words:

- cemented carbides /

- surface modification /

- graded structure /

- coatings /

- research progress

-

表 1 基于化学表面改性的常见梯度硬质合金

Table 1. Graded cemented carbides based on the chemical surface modification

化学表面

改性方法材料体系特点 梯度结构特征 渗碳处理 缺碳 表层贫Co,芯部含η相 正常碳的质量分数 表层贫Co,芯部不含η相 脱碳处理 碳的质量分数偏高 表层富Co 渗氮处理 含Ti、Ta、Nb等元素 表层富含立方相 脱氮处理 含N元素 表层富Co,无立方相 -

[1] Liu X M, Zhang J L, Hou C, et al. Mechanisms of WC plastic deformation in cemented carbide. Mater Des, 2018, 150: 154 doi: 10.1016/j.matdes.2018.04.025 [2] Toller L, Jacobson S, Norgren S. Life time of cemented carbide inserts with Ni–Fe binder in steel turning. Wear, 2017, 376: 1822 [3] Furberg A, Arvidsson R, Molander S. Environmental life cycle assessment of cemented carbide (WC–Co) production. J Clean Prod, 2019, 209: 1126 doi: 10.1016/j.jclepro.2018.10.272 [4] Katiyar P K, Singh P K, Singh R, et al. Modes of failure of cemented tungsten carbide tool bits (WC/Co): A study of wear parts. Int J Refract Met Hard Mater, 2016, 54: 27 doi: 10.1016/j.ijrmhm.2015.06.018 [5] Li C W, Chang K C, Yeh A C, et al. Microstructure characterization of cemented carbide fabricated by selective laser melting process. Int J Refract Met Hard Mater, 2018, 75: 225 doi: 10.1016/j.ijrmhm.2018.05.001 [6] Bushlya V, Johansson D, Lenrick F, et al. Wear mechanisms of uncoated and coated cemented carbide tools in machining lead-free silicon brass. Wear, 2017, 376: 143 [7] Brookes K A. Half a century of hardmetals. Met Powder Rep, 1995, 50(12): 22 doi: 10.1016/0026-0657(95)80019-0 [8] Fang Z Z, Koopman M C, Wang H T. Cemented tungsten carbide hardmetal—An introduction. Compr Hard Mater, 2014, 1: 123 [9] Ortner H M, Ettmayer P, Kolaska H, et al. The history of the technological progress of hardmetals. Int J Refract Met Hard Mater, 2014, 44: 148 doi: 10.1016/j.ijrmhm.2013.07.014 [10] Ren X Y, Miao H Z, Peng Z J. A review of cemented carbides for rock drilling: An old but still tough challenge in geo-engineering. Int J Refract Met Hard Mater, 2013, 39: 61 doi: 10.1016/j.ijrmhm.2013.01.003 [11] Weidow J, Ekström E, Kritikos M, et al. Impact of crystal defects on the grain growth of cemented carbides. Int J Refract Met Hard Mater, 2018, 72: 199 doi: 10.1016/j.ijrmhm.2017.12.017 [12] Wen Y, Liao J X, Yang Q M, et al. Effect of particle size and high-energy ball milling time on microstructure and mechanical properties of WC–10Co cemented carbides with plate-like WC grains. Mater Res Express, 2019, 6(10): 106570 doi: 10.1088/2053-1591/ab3886 [13] Zhou X K, Xu Z F, Wang K, et al. One-step sinter-HIP method for preparation of functionally graded cemented carbide with ultrafine grains. Ceram Int, 2016, 42(4): 5362 doi: 10.1016/j.ceramint.2015.12.069 [14] Zhu E T, Zhang J X, Guo S D, et al. Investigation on sintering principle of ultra-fine cemented carbide prepared by WC–6Co composite powder. Mater Res Express, 2019, 6(11): 116537 doi: 10.1088/2053-1591/ab4745 [15] Zhou X K, Wang K, Xu Z F, et al. Effect of powder particle size on gradient formation and grain growth in ultrafine crystalline gradient cemented carbide. Int J Refract Met Hard Mater, 2016, 56: 63 doi: 10.1016/j.ijrmhm.2015.11.013 [16] Avdeenko E N, Zamulaeva E I, Zaitsev A A, et al. Structure and properties of coarse-grained WC–Co alloys with an especially homogeneous microstructure. Russ J Non-Ferrous Met, 2019, 60: 542 doi: 10.3103/S1067821219050055 [17] Ding Q J, Zheng Y, Ke Z, et al. Effects of fine WC particle size on the microstructure and mechanical properties of WC–8Co cemented carbides with dual-scale and dual-morphology WC grains. Int J Refract Met Hard Mater, 2020, 87: 105166 doi: 10.1016/j.ijrmhm.2019.105166 [18] Ke Z, Zheng Y, Zhang G T, et al. Microstructure and mechanical properties of dual-grain structured WC–Co cemented carbides. Ceram Int, 2019, 45(17): 21528 doi: 10.1016/j.ceramint.2019.07.146 [19] Tang S W, Li P Z, Liu D S, et al. Cutting performance of a functionally graded cemented carbide tool prepared by microwave heating and nitriding sintering. High Temp Mater Processes, 2019, 38: 582 doi: 10.1515/htmp-2019-0011 [20] Konyashin I, Ries B, Hlawatschek S. Engineered surfaces on cemented carbides obtained by tailored sintering techniques. Surf Coat Technol, 2014, 258: 300 doi: 10.1016/j.surfcoat.2014.09.009 [21] Upadhyaya A, Sarathy D, Wagner G. Advances in alloy design aspects of cemented carbides. Mater Des, 2001, 22: 511 doi: 10.1016/S0261-3069(01)00003-6 [22] Konyashin I, Farag S, Ries B, et al. WC–Co–Re cemented carbides: Structure, properties and potential applications. Int J Refract Met Hard Mater, 2019, 78: 247 doi: 10.1016/j.ijrmhm.2018.10.001 [23] Zhang W B, Du Y, Peng Y B. Effect of TaC and NbC addition on the microstructure and hardness in graded cemented carbides: Simulations and experiments. Ceram Int, 2016, 42: 428 doi: 10.1016/j.ceramint.2015.08.127 [24] Garcia J, Prat O. Experimental investigations and DICTRA simulations on formation of diffusion-controlled fcc-rich surface layers on cemented carbides. Appl Surf Sci, 2011, 257: 8894 doi: 10.1016/j.apsusc.2011.05.024 [25] Li X F, Liu Y, Liu B, et al. Effects of submicron WC addition on structures, kinetics and mechanical properties of functionally graded cemented carbides with coarse grains. Int J Refract Met Hard Mater, 2016, 56: 132 doi: 10.1016/j.ijrmhm.2016.01.003 [26] Fischer U, Waldenström M, Hartzell T. Cemented Carbide Body with Increased Wear Resistance: U. S. Patent, 5856626. 1999-1-5 [27] Fischer U K R, Hartzell E T, Akerman J G H. Cemented Carbide Body Used Preferably for Rock Drilling and Mineral Cutting: U. S. Patent, 4743515. 1988-5-10 [28] Fan P, Fang Z Z, Guo J. A review of liquid phase migration and methods for fabrication of functionally graded cemented tungsten carbide. Int J Refract Met Hard Mater, 2013, 36: 2 doi: 10.1016/j.ijrmhm.2012.02.006 [29] Ke Z, Zheng Y, Gao L, et al. Fabrication of functionally graded WC–Co cemented carbides with plate-like WC grains. Powder Metall Met Ceram, 2019, 58: 463 doi: 10.1007/s11106-019-00096-7 [30] Konyashin I, Hlawatschek S, Ries B, et al. Cobalt capping on WC–Co hardmetals. Part I: A mechanism explaining the presence or absence of cobalt layers on hardmetal articles during sintering. Int J Refract Met Hard Mater, 2014, 42: 142 [31] García J, Englund S, Haglöf F. Controlling cobalt capping in sintering process of cermets. Int J Refract Met Hard Mater, 2017, 62: 126 doi: 10.1016/j.ijrmhm.2016.06.008 [32] Emanuelli L, Molinari A, Arrighetti G, et al. Effect of the sintering parameters on the liquid Co migration in WC–Co. Int J Refract Met Hard Mater, 2018, 70: 202 doi: 10.1016/j.ijrmhm.2017.10.014 [33] Tang S W, Liu D S, Li P N, et al. Microstructure and mechanical properties of functionally gradient cemented carbides fabricated by microwave heating nitriding sintering. Int J Refract Met Hard Mater, 2016, 58: 137 doi: 10.1016/j.ijrmhm.2016.04.013 [34] Chen Q W, Deng Y, Jiang S, et al. Functionally graded cemented carbides of WC–TiC–Co with cubic rich surface. Powder Metall Technol, 2020, 38(1): 36陈巧旺, 邓莹, 姜山, 等. 表层富立方相WC–TiC–Co功能梯度硬质合金. 粉末冶金技术, 2020, 38(1): 36 [35] Shi L Y, Yang J W, Huang J H, et al. Microstructure evolution and formation mechanism of graded cemented carbide with cubic-carbide-free layer prepared with TiN or Ti(C, N) free powder mixture. Int J Refract Met Hard Mater, 2017, 66: 198 doi: 10.1016/j.ijrmhm.2017.03.017 [36] Suzuki H, Hayashi K, Taniguchi Y, et al. The β-free layer formed near the surface of vacuum-sintered WC–β–Co alloys containing nitrogen. Trans Jpn Inst Met, 1981, 22(11): 758 doi: 10.2320/matertrans1960.22.758 [37] Yang M, Guo Z X, Qi K F, et al. Surface modification of WC-based cemented carbide by one-pot non-vapor deposition method derived Al2O3 coatings. Ceram Int, 2016, 42(9): 11509 doi: 10.1016/j.ceramint.2016.04.077 [38] Fukui H. Evolutional history of coating technologies for cemented carbide inserts—chemical vapor deposition and physical vapor deposition. SEI Tech Rev, 2016, 188(1): 26 [39] Ginting A, Skein R, Cuaca D, et al. The characteristics of CVD-and PVD-coated carbide tools in hard turning of AISI 4340. Measurement, 2018, 129: 548 doi: 10.1016/j.measurement.2018.07.072 [40] Thakur A, Gangopadhyay S, Maity K P, et al. Evaluation on effectiveness of CVD and PVD coated tools during dry machining of Incoloy 825. Tribol Trans, 2016, 59(6): 1048 doi: 10.1080/10402004.2015.1131350 [41] Saketi S, Olsson M. Influence of CVD and PVD coating micro topography on the initial material transfer of 316L stainless steel in sliding contacts–A laboratory study. Wear, 2017, 388: 29 [42] Boing D, de Oliveira A J, Schroeter R B. Limiting conditions for application of PVD (TiAlN) and CVD (TiCN/Al2O3/TiN) coated cemented carbide grades in the turning of hardened steels. Wear, 2018, 416: 54 [43] Berkani S, Yallese M A, Boulanouar L, et al. Statistical analysis of AISI304 austenitic stainless steel machining using Ti(C,N) /Al2O3/TiN CVD coated carbide tool. Int J Ind Eng Comput, 2015, 6(4): 539 -

下载:

下载: