-

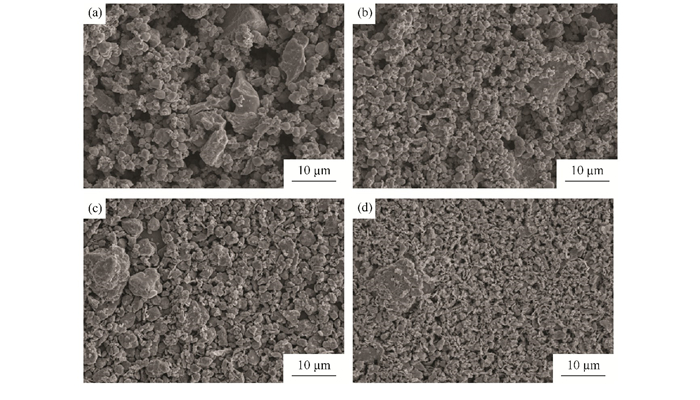

摘要: 为了研究脱氧工艺对钼铌粉末中氧含量(质量分数)的影响,将经48、72、96、120 h球磨处理的钼铌粉末压制为直径17 mm的圆棒,并进行低、中温氢气脱氧,中、高温真空脱氧及高温氢气脱氧处理,分析脱氧处理后钼铌圆棒的氧含量、微观形貌及烧结密度。结果表明:球磨不会明显增加钼铌粉末中的游离氧的含量,更不会增加氢含量;低、中温氢气脱氧处理后,钼铌圆棒试样中的氧含量整体明显升高;中温真空脱氧处理后,钼铌圆棒试样中氧含量有所降低,高温真空脱氧后效果进一步加强,且随着脱氧的进行,钼铌圆棒试样烧结密度显著提高,表明高温真空能实现脱氧;高温氢气脱氧后,钼铌合金的氧质量分数接近0.11%。Abstract: To investigate the effect of the deoxidation processes on the oxygen mass fraction in the molybdenum and niobium powders, the molybdenum and niobium powders were pressed into the round rod specimens with a diameter of 17 mm after ball-milling for 48, 72, 96, and 12h. The Mo-Nb round rod specimens were treated by the hydrogen deoxidation at low and medium temperatures, the vacuum deoxidation at medium and high temperatures, and the hydrogen deoxidation at high temperatures, respectively, to analyze the oxygen mass fraction, microstructure, and sintered density of Mo-Nb specimens after deoxidation. In the results, the mass fractions of oxygen and hydrogen are not significantly increased by ball milling. After the hydrogen deoxidation at low and medium temperatures, the oxygen content by mass of Mo-Nb round rod specimens shows an increase obviously. After the vacuum deoxidation at medium temperature, the oxygen content by mass of Mo-Nb specimens decreases, the effect of vacuum deoxidization at high temperature is further enhanced, and the sintered density of Mo-Nb specimens increases significantly after the vacuum deoxidization, indicating that the deoxidization can be achieved by high temperature vacuum. The oxygen mass fraction of Mo-Nb specimen is close to 0.11% after the hydrogen deoxidization at high temperature.

-

Key words:

- molybdenum-niobium powders /

- deoxidization /

- mass fraction /

- microstructure /

- sintered density

-

表 1 钼铌粉末粒度变化以及氢氧含量(质量分数)

Table 1. Particle size and mass fraction of the hydrogen and oxygen in the molybdenum-niobium powders

试样批号 Fsss/μm O质量分数/% H质量分数/% 20-48 2.05 0.156 0.0058 20-72 1.92 0.157 0.0062 20-96 1.90 0.163 0.0065 20-120 1.80 0.166 0.0060 表 2 氢气脱氧后的钼铌粉末氧质量分数

Table 2. Oxygen mass fraction in the molybdenum-niobium rod samples after the hydrogen deoxidation treatment%

试样批号 氧质量分数/% 脱氧前 1120 K × 2 h 1620 K × 2 h 20-48 0.156 0.478 0.923 20-72 0.157 0.465 0.954 20-96 0.163 0.523 0.916 20-120 0.166 0.515 0.934 表 3 真空脱氧后钼铌粉末氧质量分数

Table 3. Oxygen mass fraction in the molybdenum-niobiumrod samples after the vacuum deoxidation treatment

% 试样批号 氧质量分数/% 脱氧前 1620 K × 2 h 1870 K × 5 h 20-48 0.156 0.321 0.233 20-72 0.157 0.354 0.241 20-96 0.163 0.359 0.257 20-120 0.166 0.357 0.255 表 4 高温氢气脱氧后钼铌棒试样氧质量分数和烧结密度

Table 4. Oxygen mass fraction and sintering density of the molybdenum-niobium rod samples after the hydrogen deoxidation treatment at high temperature

试样批号 密度,ρ / (g∙cm-3) O质量分数/% 20-48 9.29 0.119 20-72 9.37 0.134 20-96 9.41 0.126 20-120 9.54 0.138 -

[1] Xiao L R, Yi D Q, Yin L, et al. Progress in research on high temperature protective coating of Nb and Nb-based alloys. Mater Rev, 2004, 18(1): 13 doi: 10.3321/j.issn:1005-023X.2004.01.004肖来荣, 易丹青, 殷磊, 等. 铌及铌合金高温涂层研究进展. 材料导报, 2004, 18(1): 13 doi: 10.3321/j.issn:1005-023X.2004.01.004 [2] Zhang Q, Li Z K, Zhen Y Z, et al. Development of big size molybdenum-niobium single crystal. Rare Met Mater Eng, 2005, 34(12): 1948 doi: 10.3321/j.issn:1002-185X.2005.12.025张清, 李中奎, 郑玉柱, 等. 大尺寸钼-铌合金单晶的研制. 稀有金属材料与工程, 2005, 34(12): 1948 doi: 10.3321/j.issn:1002-185X.2005.12.025 [3] Zhang W G, Li Y Y, Sun X D, et al. Analysis of market demand and supply of sputtering target in flat-panel display industry. Chin J Vac Sci Technol, 2018, 38(9): 821 https://www.cnki.com.cn/Article/CJFDTOTAL-ZKKX201809015.htm张卫刚, 李媛媛, 孙旭东, 等. 平板显示行业用金属溅射靶材的市场需求分析. 真空科学与技术学报, 2018, 38(9): 821 https://www.cnki.com.cn/Article/CJFDTOTAL-ZKKX201809015.htm [4] Sun H M, Zhao W P, Chen Y G. Preparation of Mo Nb Alloy Sputtering Target: China Patent, 201610306488. X. 2018-6-29孙虎民, 赵文普, 陈亚光. 一种钼铌合金溅射靶材的制备工艺: 中国专利, 201610306488. X. 2018-6-29 [5] Chen Y Z. Processing Technology of Mo Nb Alloy Plate Target: China Patent, 201210009053.0. 2013-10-23陈玉柱. 钼铌合金板靶材加工工艺: 中国专利, 201210009053.0. 2013-10-23 [6] An G, Sun J, Liu R Z. Study on microstructure and properties of Mo thin films sputtered by two kinds of Mo targets. Mater Sci, 2018, 8(6): 709 http://www.hanspub.org/DownLoad/Page_DownLoad.aspx?DOI=10.12677/MS.2018.86084&FileName=MS20180600000_37174912.pdf [7] Gao J. Properties of the Sputtered Films and Preparation of Molybdenum Niobium Alloy Targets[Dissertation]. Yinchuan: North Minzu University, 2017高杰. 钼铌合金靶材制备及其溅射薄膜性能研究[学位论文]. 银川: 北方民族大学, 2017 [8] Chen Y F, Xie J P, Wang A Q, et al. Research status and development trend of molybdenum and molybdenum alloy sputtering target materials. Powder Metall Technol, 2018, 36(5): 393 doi: 10.19591/j.cnki.cn11-1974/tf.2018.05.013陈艳芳, 谢敬佩, 王爱琴, 等. 钼及钼合金溅射靶材的研究现状与发展趋势. 粉末冶金技术, 2018, 36(5): 393 doi: 10.19591/j.cnki.cn11-1974/tf.2018.05.013 [9] Dang X M, An G, Li J, et al. Study on rolling process of molybdenum niobium alloy target material. Hot Working Technol, 2019, 48(11): 117 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201911031.htm党晓明, 安耿, 李晶, 等. 钼铌合金靶材轧制工艺研究. 热加工工艺, 2019, 48(11): 117 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201911031.htm [10] Dang X M, An G, Li J, et al. Effect of niobium powder granularity and sintering method on Mo-Nb alloy. Powder Metall Technol, 2016, 34(4): 272 doi: 10.3969/j.issn.1001-3784.2016.04.007党晓明, 安耿, 李晶, 等. 铌粉粒度和烧结方法对钼铌合金的影响. 粉末冶金技术, 2016, 34(4): 272 doi: 10.3969/j.issn.1001-3784.2016.04.007 [11] Guo R M. Preparation and development of high purity niobium. Rare Met Mater Eng, 1989(1): 74 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE198901023.htm郭让民. 高纯铌的制取方法及发展现状. 稀有金属材料与工程, 1989(1): 74 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE198901023.htm [12] Xia M X, Zhen X, Cai X M, et al. Effects of annealing temperature on microstructure and mechanical properties of Nb alloy thin-walled tube. Hot Working Technol, 2018, 47(16): 215 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201816056.htm夏明星, 郑欣, 蔡小梅, 等. 退火温度对铌合金薄壁管组织和力学性能的影响. 热加工工艺, 2018, 47(16): 215 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201816056.htm [13] Jiang Y F. Fixed value of oxygen and nitrogen in niobium powder. Cement Carb, 2015, 32(6): 395 https://www.cnki.com.cn/Article/CJFDTOTAL-YZHJ201506012.htm蒋亚芳. 铌粉中氧、氮定值. 硬质合金, 2015, 32(6): 395 https://www.cnki.com.cn/Article/CJFDTOTAL-YZHJ201506012.htm [14] Zhu J, Ma C H, Guo X F, et al. Synthesis of ultra-fine niobiun and tantalum powders by hydrogen reduction. Chin J Rare Met, 2007, 31(1): 53 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS200701012.htm朱骏, 马春红, 郭晓菲, 等. 气相还原制备超细微铌和钽粉末. 稀有金属, 2007, 31(1): 53 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS200701012.htm [15] Cheng Y. Preparation of Fine Particles Low-Oxygen Niobium Powders by Electron Beam Smelting Niobium with Hydrogenation-Dehydrogenation Processing[Dissertation]. Zhengzhou: Zhengzhou University, 2018程阳. 电子束熔炼铌氢化脱氢制备细颗粒低氧铌粉的研究[学位论文]. 郑州: 郑州大学, 2018 -

下载:

下载: