Effect of WC content on the microstructure and mechanical properties of TiCN-HfN cermet tool materials

-

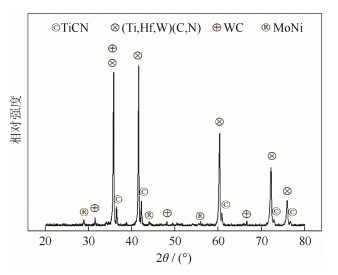

摘要: 采用热压烧结技术制备了TiCN-HfN-WC金属陶瓷刀具材料, 研究了WC含量(质量分数)对金属陶瓷刀具材料微观组织和力学性能的影响。结果表明: TiCN-HfN-32%WC金属陶瓷刀具材料由TiCN、(Ti, Hf, W)(C, N)、WC和MoNi组成, 材料中还含有极少量的(Ti, Mo, W)(C, N)固溶体, 材料内部形成了网状骨架结构。随着添加WC质量分数的增加, 材料中晶粒粒度降低, 添加WC可抑制材料中TiCN晶粒的生长, 起到细化TiCN晶粒的作用; 材料的相对密度、硬度和断裂韧度都具有先增大后减小的变化趋势, 材料的抗弯强度逐渐增大。当WC质量分数为32%时, 材料具有相对较好的综合力学性能, 其硬度为20.2GPa, 断裂韧度为7.1MPa·m1/2, 抗弯强度为1581.3MPa。Abstract: TiCN-HfN-WC cermet tool materials were fabricated by hot-pressed sintering technology, and the effect of WC mass fraction on the microstructure and mechanical properties of the cermet tool materials was investigated. The results show that, the TiCN-HfN-32%WC cermets are composed of TiCN, (Ti, Hf, W)(C, N), WC, and MoNi, which also contain a little amount of (Ti, Mo, W)(C, N), and the retiform skeleton structure forms inside the cermet material. With the increase of the WC content, TiCN grain becomes smaller, which indicates that WC can inhibit the TiCN grain growth and achieve the refinement of TiCN grain; meanwhile, the density, hardness, and fracture toughness of the TiCN-HfN-WC cermet also increase first and then decrease, however, the flexural strength increases gradually. When the WC mass fraction is 32%, the TiCN-HfN-WC cermet shows good comprehensive mechanical properties: the hardness is 20.2 GPa, the fracture toughness is 7.1 MPa·m1/2, and the flexural strength is 1581.3 MPa.

-

Key words:

- cermet /

- tool materials /

- WC /

- microstructure /

- mechanical properties

-

表 1 THW组成成分(质量分数)

Table 1. THW constituent

% 试样 TiCN WC HfN Ni Mo THW8 64 8 20 4 4 THW16 56 16 20 4 4 THW24 48 24 20 4 4 THW32 40 32 20 4 4 表 2 THW相对密度和力学性能

Table 2. Relative density and mechanical properties of THW

试样 相对密度/% 维氏硬度/GPa 断裂韧度/(MPa·m1/2) 抗弯强度/MPa TH[17] 99.6 ± 0.1 19.4 ± 0.2 8.5 ± 0.2 1235.9 ± 23.6 THW8 99.5 ± 0.2 19.2 ± 0.3 6.3 ± 0.2 1176.2 ± 31.2 THW16 99.6 ± 0.1 19.8 ± 0.2 6.7 ± 0.3 1264.5 ± 26.4 THW24 99.8 ± 0.1 20.6 ± 0.3 7.3 ± 0.2 1386.2 ± 34.9 THW32 99.7 ± 0.2 20.2 ± 0.3 7.1 ± 0.3 1581.3 ± 29.5 -

[1] Xiong J, Zhang Y K, Shen B L, et al. The preparation and performance of superfine TiCN cermet. Powder Metall Technol, 2003, 21(2): 92 doi: 10.3321/j.issn:1001-3784.2003.02.004熊继, 张亚昆, 沈保罗, 等. 超细TiCN金属陶瓷的制备及性能. 粉末冶金技术, 2003, 21(2): 92 doi: 10.3321/j.issn:1001-3784.2003.02.004 [2] Tang S W, Zhang H A, Yan J H, et al. Research on preparing ultra-fine grain TiCN matrix cermets by vacuum microwave sintering. Powder Metall Technol, 2010, 28(3): 220 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201003014.htm唐思文, 张厚安, 颜建辉, 等. 真空微波烧结制备TiCN基金属陶瓷. 粉末冶金技术, 2010, 28(3): 220 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201003014.htm [3] Li C, Li N, Liu X Q, et al. Effect of binder Co and Ni on the microstructure and mechanical properties of Ti (C0.7N0.3)-based cermets. Powder Metall Ind, 2019, 29(1): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201901011.htm李朝, 李楠, 柳学全, 等. Co和Ni对Ti (C0.7N0.3)基金属陶瓷组织和力学性能的影响. 粉末冶金工业, 2019, 29(1): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201901011.htm [4] Ye X, Chen S J, Zhong Y H, et al. Effect of Fe content on mechanical property of TiC-based cermets. Powder Metall Ind, 2019, 29(5): 31 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201905011.htm叶旋, 陈绍军, 钟燕辉, 等. Fe含量对TiC基金属陶瓷力学性能的影响. 粉末冶金工业, 2019, 29(5): 31 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201905011.htm [5] Ma D D. Influencing factors and development trend of Ti (C, N) based cermets. Ceramics, 2018(7): 20 doi: 10.3969/j.issn.1002-2872.2018.07.004马调调. Ti (C, N)基金属陶瓷性能影响因素及发展趋势. 陶瓷, 2018(7): 20 doi: 10.3969/j.issn.1002-2872.2018.07.004 [6] Xiao S Q, Liu J, Xiao B J, et al. Towards high-strength and high-toughness Ti (C, N)-based cermets: a technological review. Mater Rev, 2018, 32(7): 1129 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201807014.htm肖水清, 刘杰, 肖白军, 等. 实现Ti (C, N)基金属陶瓷强韧化的技术路径. 材料导报, 2018, 32(7): 1129 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201807014.htm [7] Yang Z X. Preparation and wear mechansim of cermet sintex for high speed cutting. Foundry Technol, 2017, 38(2): 298 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201702010.htm杨中秀. 高速切削用金属陶瓷刀具的制备及磨损机理研究. 铸造技术, 2017, 38(2): 298 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201702010.htm [8] Verma V, Kumar B V M. Processing of TiCN-WC-Ni/Co cermets via conventional and spark plasma sintering technique. Trans Indian Inst Met, 2017, 70(3): 843 doi: 10.1007/s12666-017-1069-y [9] Wu Y M, Zhou L M, Xiong J, et al. Effect of WC and Mo2C addition on microhardness of Ti (C, N)-based cermets at high temperature. Mater Mech Eng, 2017, 41(7): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201707005.htm吴悦梅, 周黎明, 熊计, 等. WC和Mo2C的添加对Ti (C, N)基金属陶瓷高温显微硬度的影响. 机械工程材料, 2017, 41(7): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201707005.htm [10] Xiong H W, Wu Y X, Li Z Y, et al. Comparison of Ti (C, N)-based cermets by vacuum and gas-pressure sintering: Microstructure and mechanical properties. Ceram Int, 2018, 44(1): 805 doi: 10.1016/j.ceramint.2017.10.003 [11] Lin N, Zhao L B, Zou J C, et al. Improvement in densification process and properties of Ti (C, N)-based cermets with vanadium carbide addition. Ceram Int, 2019, 45(2): 2692 doi: 10.1016/j.ceramint.2018.10.210 [12] Chen M, Xiao X, Zhang X F. Effect of TaC content on microstructure and properties of TiCN-based cermets. Mater Sci Eng Powder Metall, 2016, 21(2): 270 doi: 10.3969/j.issn.1673-0224.2016.02.013陈敏, 肖玄, 张雪峰. TaC含量对TiCN基金属陶瓷组织与性能的影响. 粉末冶金材料科学与工程, 2016, 21(2): 270 doi: 10.3969/j.issn.1673-0224.2016.02.013 [13] Sun W C, Zhang P, Li P, et al. Effect of short carbon fibre concentration on microstructure and mechanical properties of TiCN-based cermets. Adv Appl Ceram, 2016, 115(4): 216 doi: 10.1080/17436753.2015.1120403 [14] Zhang Y, Cheng Y, Hu H P, et al. Experimental study of Ti (C, N)/A12O3 cermet tool in dry machining of hardened steel. Tool Eng, 2017, 51(3): 19 doi: 10.3969/j.issn.1000-7008.2017.03.004张勇, 程寓, 胡瀚彭, 等. 基于微波烧结的Ti (C, N)/A12O3金属陶瓷刀具切削淬硬钢的试验研究. 工具技术, 2017, 51(3): 19 doi: 10.3969/j.issn.1000-7008.2017.03.004 [15] Lü C C, Peng Z J, Peng Y, et al. Addition effect of ZrC nano-powder on the microstructure and mechanical properties of TiCN-based cermets prepared by spark plasma sintering. Rare Met Mater Eng, 2015, 44(Suppl 1): 723 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2015S1180.htm吕长春, 彭志坚, 彭瑛, 等. 添加ZrC纳米粉对放电等离子体烧结TiCN基金属陶瓷微观结构和力学性能的影响. 稀有金属材料与工程, 2015, 44(增刊1): 723 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2015S1180.htm [16] Zhang M X, Yao H L, Wang H T, et al. In situ Ti (C, N)-based cermets by reactive hot pressing: reaction process, densification behavior and mechanical properties. Ceram Int, 2019, 45(1): 1363 doi: 10.1016/j.ceramint.2018.07.270 [17] Liu H L, Shi Q, Huang C Z, et al. In-situ fabricated TiB2 particle-whisker synergistically toughened Ti (C, N)-based ceramic cutting tool material. Chin J Mech Eng, 2015, 28(2): 338 doi: 10.3901/CJME.2015.0107.008 [18] Gao J J, Song J P, Liang G X, et al. Effects of HfC addition on microstructures and mechanical properties of TiC0.7N0.3-based and TiC0.5N0.5-based ceramic tool materials. Ceram Int, 2017, 43(17): 14945 http://www.sciencedirect.com/science/article/pii/S0272884217317029 [19] Song J P, Cao L, Gao J J, et al. Effects of HfN content and metallic additives on the microstructure and mechanical properties of TiC0.7N0.3-based ceramic tool materials. J Alloys Compd, 2018, 753: 85 doi: 10.1016/j.jallcom.2018.04.213 [20] Song J P, Xie J C, Lü M Z, et al. Microstructure and mechanical properties of TiB2-HfC ceramic tool materials. JOM, 2018, 70(11): 2544 doi: 10.1007/s11837-018-3128-1 [21] Xie J C, Song J P, Gao J J, et al. Effects of HfN content on microstructure and mechanical properties of ZrB2-HfN ceramic materials. Powder Metall Technol, 2019, 37(6): 416 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201906004.htm谢俊彩, 宋金鹏, 高姣姣, 等. HfN含量对ZrB2基陶瓷材料微观组织和力学性能的影响. 粉末冶金技术, 2019, 37(6): 416 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201906004.htm [22] Song J G, Huang C Z, Lü M, et al. Effects of TiC content and melt phase on microstructure and mechanical properties of ternary TiB2-based ceramic cutting tool materials. Mater Sci Eng A, 2014, 605: 137 doi: 10.1016/j.msea.2014.03.036 -

下载:

下载: