-

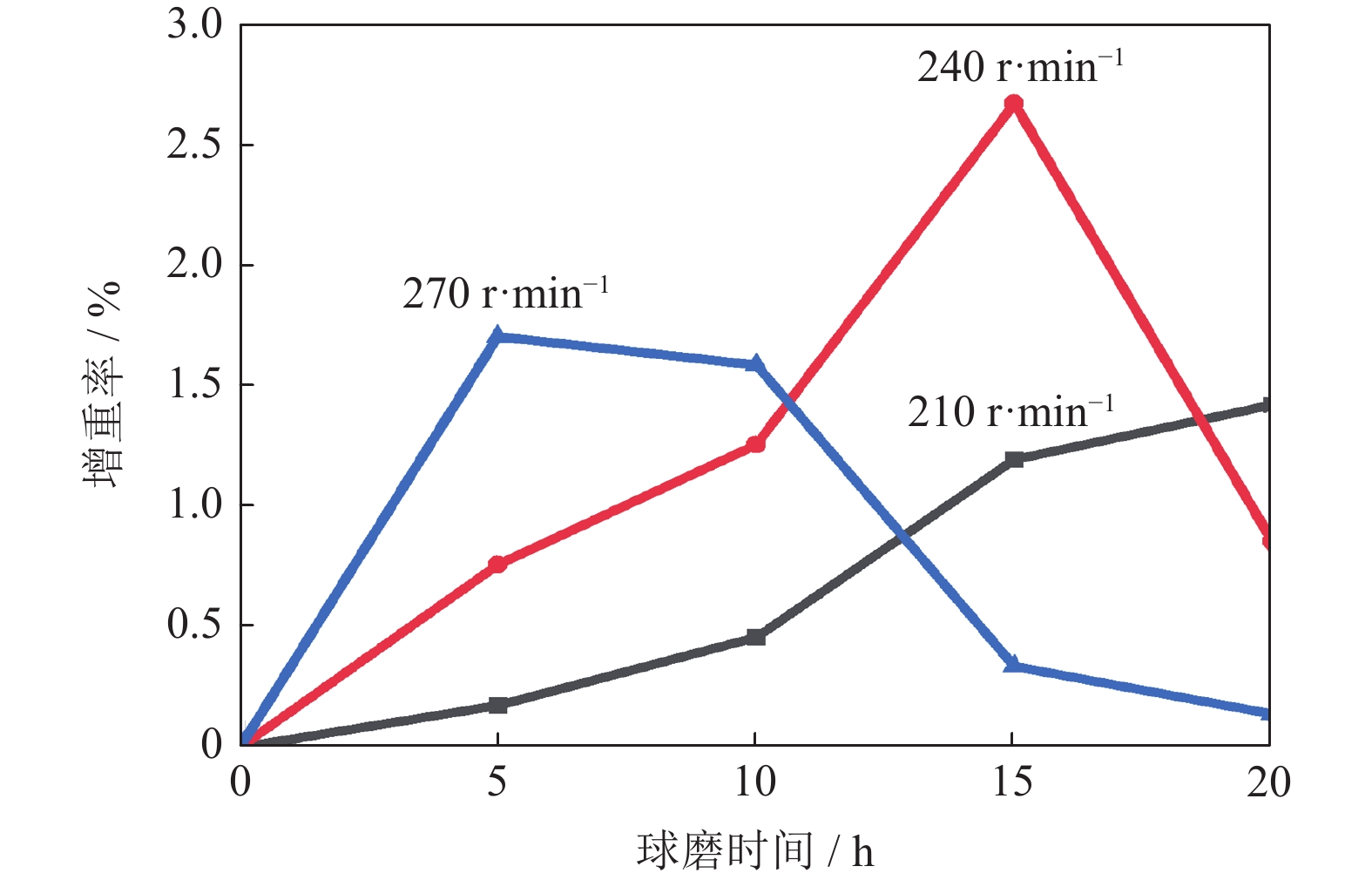

摘要: 为了研究转速和时间对机械涂覆法制备Ni涂层的影响,以金属Ni粉为涂覆原料、氧化锆(ZrO2)陶瓷球为涂覆基底制备Ni涂层。通过涂覆后陶瓷球的增重量来表征涂层的厚度,采用扫描电子显微镜和X射线衍射分析表征涂层的结构和成份。结果表明,随着转速提高,球磨初期涂层的厚度逐渐增加,持续球磨,涂层厚度反而开始降低。转速240 r∙min‒1、球磨15 h的涂覆效果最佳,涂层平均厚度约为20 μm。Ni涂层厚度经历了增厚和减薄两个阶段,转速会影响二者出现的进度,适当提高转速利于涂层加厚,提高工艺效率,但过高的转速不利涂层形成。Abstract: To investigate the influence of rotation speed and milling time on the formation of nickel (Ni) coatings prepared by mechanical coating technique (MCT), the Ni metal powders and the zirconia (ZrO2) ceramic balls were used as the coating materials and the substrates to fabricate the Ni coatings. The thickness of the coatings was characterized by the weight increase of the ZrO2 balls after the coating operation, and the microstructure and composition of the coatings were analyzed by scanning electron microscope (SEM) and X-ray diffraction (XRD). In the results, with the increase of rotational speed, the coatings thickness increases at the initial stage of ball milling and decreases at the later stage. The coatings thickness reaches the maximum (20 μm) when the rotation speed is 240 r∙min‒1 for 15 h. The formation of Ni coatings consists of two stages as thickening and thinning, which is affected by the rotation speed. The higher rotation speed is favor of the coatings formation and improves the processing efficiency, while the excessively speed will accelerate the coatings to peel off from the substrate, which is unfavorable to the formation of the coatings.

-

Key words:

- mechanical coating /

- milling speed /

- cold welding /

- photocatalysis /

- coatings

-

图 3 球磨ZrO2球表面和断面形貌: (a)转速210 r·min‒1,20 h表面形貌;(b)转速210 r·min‒1,20 h断面形貌;(c)转速240 r·min‒1,15 h表面形貌;(d)转速240 r·min‒1,15 h断面形貌;(e)转速270 r·min‒1,5 h表面形貌;(f)转速270 r·min‒1,5 h断面形貌

Figure 3. Surface and cross section SEM images of the ZrO2 balls after milling: (a) surface image at 210 r·min‒1 for 20 h; (b) cross section image at 210 r·min‒1 for 20 h; (c) surface image at 240 r·min‒1 for 15 h; (d) cross section image at 240 r·min‒1 for 15 h; (e) surface image at 270 r·min‒1 for 5 h; (f) cross section image at 270 r·min‒1 for 5 h

表 1 实验原料及参数

Table 1. Raw materials and parameters in experimental

材料 粒度 密度 / (g·cm‒3) 纯度 / % ZrO2球 ϕ1 mm 6.0 >95.0 Ni粉 200目 8.9 >99.5 -

[1] Farahbakhsh I, Zakeri A, Manikandan P, et al. Effect of mechanical alloying parameters on the formation of Ni–Cu solid solution coating on the Ni balls. Jpn J Appl Phys, 2011, 50(1S2): 01BE06 doi: 10.1143/JJAP.50.01BJ06 [2] Chen L J, Zha W S, Wu K X, et al. Application of mechanical milling in fabrication of surface coatings. Powder Metall Technol, 2014, 32(1): 64 doi: 10.3969/j.issn.1001-3784.2014.01.012陈立甲, 查五生, 吴开霞, 等. 机械球磨方法在表面薄膜涂层制备中的应用. 粉末冶金技术, 2014, 32(1): 64 doi: 10.3969/j.issn.1001-3784.2014.01.012 [3] Zhang G Y, Zha W S, Chen X L, et al. Application of mechanical ball-milling technology in material preparation. Powder Metall Technol, 2018, 36(4): 315 doi: 10.19591/j.cnki.cn11-1974/tf.2018.04.013张桂银, 查五生, 陈秀丽, 等. 机械球磨技术在材料制备中的应用. 粉末冶金技术, 2018, 36(4): 315 doi: 10.19591/j.cnki.cn11-1974/tf.2018.04.013 [4] Qi B S, Wang Z, Xu Y, et al. The Cr‒Al alloy coating on grinding balls surface by mechanical alloying. Heat Treat Met, 2005, 30(4): 59 doi: 10.3969/j.issn.0254-6051.2005.04.018齐宝森, 王志, 徐英, 等. 机械合金化制备磨球表面铬铝合金涂层. 金属热处理, 2005, 30(4): 59 doi: 10.3969/j.issn.0254-6051.2005.04.018 [5] Farahbakhsh I, Zakeri A, Manikandan P, et al. Evaluation of nanostructured coating layers formed on Ni balls during mechanical alloying of Cu powder. Appl Surf Sci, 2011, 257(7): 2830 doi: 10.1016/j.apsusc.2010.10.071 [6] Duan C Y. Investigation on Preparation of High Nitrogen Stainless Steels and High Stainless Steel Coatings by Mechanical Alloying [Dissertation]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016段翠媛. 机械合金化制备高氮不锈钢及高氮不锈钢涂层的研究[学位论文]. 南京: 南京航空航天大学, 2016 [7] Yoshida H, Lu Y, Nakayama H, et al. Fabrication of TiO2 film by mechanical coating technique and its photocatalytic activity. J Alloys Compd, 2009, 475(1): 383 [8] Lu Y, Hao L, Toh K, et al. Fabrication of TiO2/Cu composite photocatalyst thin film by 2-step mechanical coating technique and its photocatalytic activity. Adv Mater Res, 2012, 415: 1942 [9] Lu Y, Guan S J, Hao L, et al. Review on the photocatalyst coatings of TiO2: Fabrication by mechanical coating technique and its application. Coatings, 2015, 5(3): 425 doi: 10.3390/coatings5030425 [10] Hao L, Lu Y, Asanuma H, et al. The influence of the processing parameters on the formation of iron thin films on alumina balls by mechanical coating technique. J Mater Process Technol, 2012, 212(5): 1169 doi: 10.1016/j.jmatprotec.2012.01.001 [11] Hao L, Lu Y, Sato H, et al. Fabrication of zinc coatings on alumina balls from zinc powder by mechanical coating technique and the process analysis. Powder Technol, 2012, 228: 377 doi: 10.1016/j.powtec.2012.05.056 [12] Liu Y H, Ye J F, Zhang H X, et al. Research progress on photocatalytic performance of TiO2 modified by nickel. China Resour Compr Util, 2012, 30(10): 40 doi: 10.3969/j.issn.1008-9500.2012.10.022刘艳花, 叶姣凤, 张红霞, 等. Ni改性TiO2光催化性能研究进展. 中国资源综合利用, 2012, 30(10): 40 doi: 10.3969/j.issn.1008-9500.2012.10.022 [13] Li D Y, Zhang W T, Zhang C. Research progress in improving the photocatalytic properties of TiO2 materials by doping with different metals. Mater Rep, 2019, 33(23): 3900 doi: 10.11896/cldb.19020021李大玉, 张文韬, 张超. 不同种类金属掺杂改性TiO2材料光催化性能的研究进展. 材料导报, 2019, 33(23): 3900 doi: 10.11896/cldb.19020021 [14] Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci, 2001, 46(1): 1 [15] Hao L, Lu Y, Sato H, et al. Influence of metal properties on the formation and evolution of metal coatings during mechanical coating. Metall Mater Trans A, 2013, 44A(6): 2717 [16] Wu K X, Zha W S, Tang X X, et al. Study on the preparation process of Ti coatings on ZrO2 balls by mechanical milling coating technology. Powder Metall Technol, 2019, 37(6): 444 doi: 10.19591/j.cnki.cn11-1974/tf.2019.06.007吴开霞, 查五生, 唐鑫鑫, 等. 氧化锆球体表面机械球磨涂覆钛涂层工艺研究. 粉末冶金技术, 2019, 37(6): 444 doi: 10.19591/j.cnki.cn11-1974/tf.2019.06.007 [17] Wang L, Hou L F, Wei Y H, et al. Investigation on Al alloy layer formation of pure copper surface subjected to surface mechanical attrition treatment. Hot Working Technol, 2013, 42(24): 161王磊, 侯利锋, 卫英慧, 等. 纯铜在表面机械研磨辅助下形成铝合金层的研究. 热加工工艺, 2013, 42(24): 161 -

下载:

下载: