-

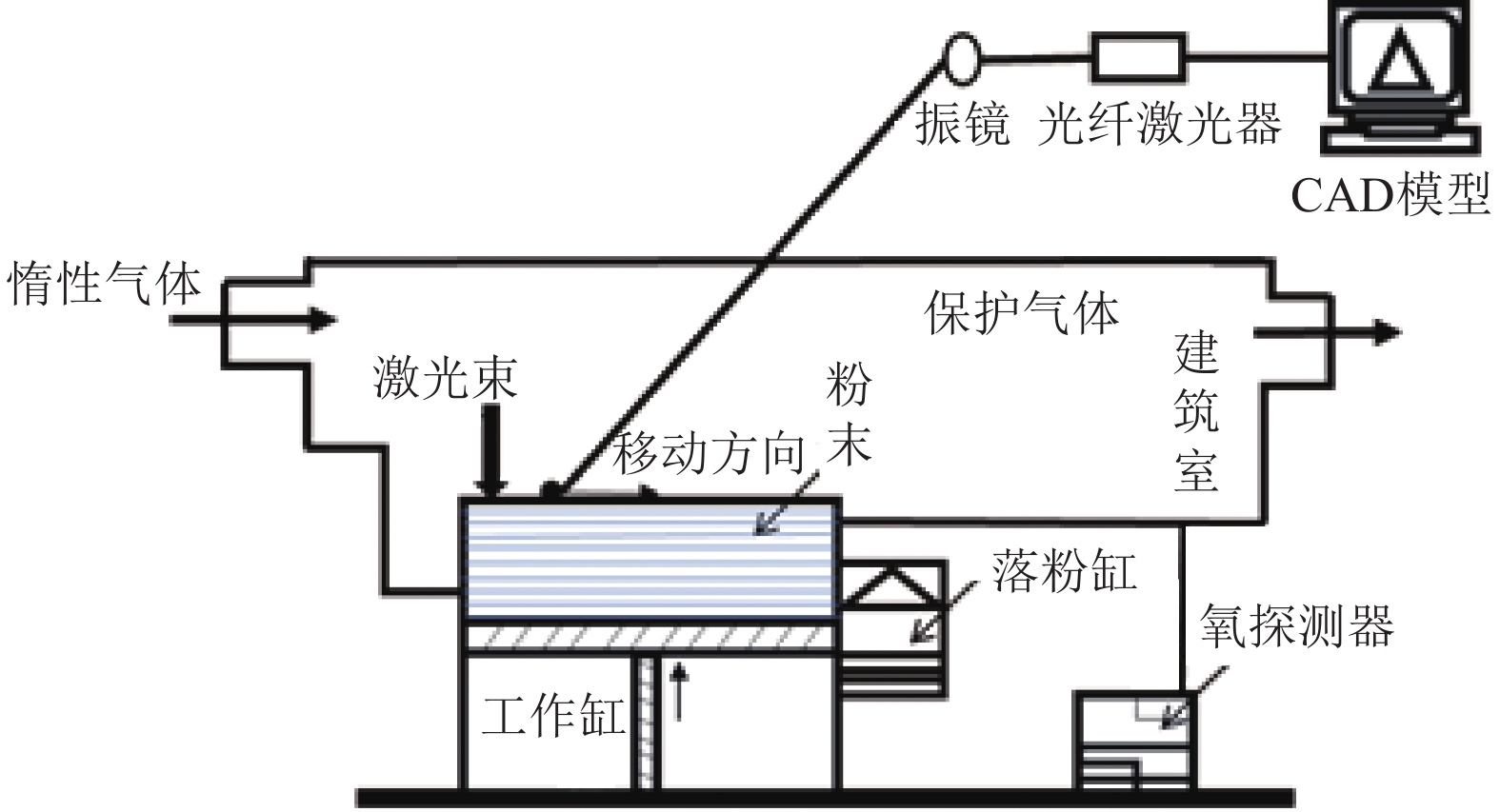

摘要: 选区激光熔化(selective laser melting,SLM)技术因具有可定制化、加工周期短及精度高等特点,在工业生产中得到广泛应用。本文对选区激光熔化技术及其在铝合金及铝基复合材料制备的研究现状进行了综合性论述。通过论述选区激光熔化特性引出选区激光熔化打印铝合金的优势。介绍了适用于选区激光熔化技术的铸造Al‒Si系合金,结合扫描策略和工艺参数优化,探究了选区激光熔化铝硅合金的微观结构、相组成和力学性能变化规律。讨论了选区激光熔化微/纳米陶瓷强化铝基复合材料的研究现状,分析与总结了添加强化颗粒对组织结构、相对密度、润湿性及相应力学性能的强化机理。总结了工业界与学术界关注的新型高强度铝合金材料的开发及其选区激光熔化的制备,重点论述了新型铝合金的固溶强化和析出相强化机理,并分析了对相对密度和力学性能的影响因素。最后对选区激光熔化铝合金发展趋势及现阶段存在的问题进行了展望。Abstract: Selective laser melting (SLM) technology has been widely applied in the industry due to its customization, short manufacturing cycle, and high precision. The research progress of aluminum alloys and composites prepared by SLM was systematically reviewed. The advantage of SLM aluminum alloys was introduced though the SLM characterization. The research of SLM casting Al‒Si series alloys was discussed, and the microstructure, phase composition, and mechanical properties was revolved, combining with the scanning strategy and laser parameter optimization. Meanwhile, the investigation of SLM nano/micro reinforced aluminum alloys was also present, the particle reinforcement mechanism on the microstructure, relative density, wettability, and mechanical properties was analyzed. On the other hand, the research progress of new high strength aluminum alloys prepared by SLM was also discussed, the strengthening mechanism, relative density, and mechanical properties were emphasized. Finally, the development trend of SLM aluminum alloys and the current problems were prospected.

-

Key words:

- additive manufacturing /

- selective laser melting /

- aluminum alloys /

- composite materials

-

图 3 SLM-AlSi10Mg微观结构[18]:(a)熔池内三个微观结构区域(细晶粒、粗晶粒和热影响区);(b)垂直于熔池边界处的粗晶粒平面上的等轴晶粒;(c)平行于构建方向的熔池核心和熔池边界处的较粗细长晶粒

Figure 3. Microstructure of the SLM-AlSi10Mg[18]: (a) microstructure in the molten pool (fine grains, coarse grains, and heat affected zones); (b) the equiaxed grains observed on the coarse grains perpendicular to the molten pool boundary; (c) the thick slender grains at the centre and boundary of the molten pool parallel to the building direction

图 12 TiB2/AlSi10Mg复合材料横截面显微形貌和维氏硬度[45]:(a)不添加TiB2,移动速度 = 420 mm·min‒1;(b)添加质量分数2%TiB2,移动速度= 420 mm·min‒1;(c)放大图像和能谱分析;(d)维氏硬度

Figure 12. Cross-section SEM images and Vickers hardness of TiB2/AlSi10Mg composites[45]: (a) without TiB2, translational speed 420 mm·min‒1; (b) with 2% TiB2 by mass, translational speed 420 mm·min‒1; (c) magnification image and EDS result of the particles; (d) Vickers hardness

图 13 Al7075和Zr+Al7075原料粉末显微形貌及其对应的枝晶生长方式[32]:(a)Al7075粉末形貌;(b)Zr+Al7075粉末显微组织;(c)Al7075柱状晶生长方式;(d)Zr+Al7075等轴晶生长方式

Figure 13. Microstructure of Al7075 and Zr+Al7075 powders and the corresponding dendrite growth[32]: (a) microstructure of Al7075 powders; (b) microstructure of Zr+Al7075 powders; (c) columnar crystal growth of Al7075; (d) equiaxed crystal growth of Zr+Al7075

-

[1] Dai S L, Zhang K, Yang S J, et al. Advanced Aviation Aluminum Alloy Materials and Applications. 1st Ed. Beijing: National Defense Industry Press, 2012.戴圣龙, 张坤, 杨守杰, 等. 先进航空铝合金材料与应用. 1版. 北京: 国防工业出版社, 2012. [2] Gao Q W, Zhao J, Shu F Y, et al. Research progress in aluminum alloy additive manufacturing. J Mater Eng, 2019, 47(11): 32 doi: 10.11868/j.issn.1001-4381.2019.000084郜庆伟, 赵健, 舒凤远, 等. 铝合金增材制造技术研究进展. 材料工程, 2019, 47(11): 32 doi: 10.11868/j.issn.1001-4381.2019.000084 [3] Yang S J, Dai S L. A glimpse at the development and application of aluminum alloys in aviation industry. Mater Rev, 2005(2): 76 doi: 10.3321/j.issn:1005-023X.2005.02.023杨守杰, 戴圣龙. 航空铝合金的发展回顾与展望. 材料导报, 2005(2): 76 doi: 10.3321/j.issn:1005-023X.2005.02.023 [4] Li L, Dai Y. Laser selective melt additive manufacturing spherical powder preparation technology status and comparison. Adv Mater Ind, 2017(8): 54 doi: 10.3969/j.issn.1008-892X.2017.08.014李礼, 戴煜. 激光选区熔化增材制造专用球形金属粉末制备技术现状及对比. 新材料产业, 2017(8): 54 doi: 10.3969/j.issn.1008-892X.2017.08.014 [5] Zhu H H, Liao H L. Research status of selective laser melting of high strength aluminum alloy. Laser Optoelectron Prog, 2018, 55(1): 22朱海红, 廖海龙. 高强铝合金的激光选区熔化成形研究现状. 激光与光电子学进展, 2018, 55(1): 22 [6] Li L Q, Qu J Y, Wang X. Formability and mechanical property of laser metal deposited AlSi10Mg alloy. Surf Technol, 2019, 48(6): 332李俐群, 曲劲宇, 王宪. 激光熔化沉积AlSi10Mg成形特性及力学性能. 表面技术, 2019, 48(6): 332 [7] Huang W X, Wang T, Yuan J, et al. Microstructure and properties of graphene/AlSi12 composites prepared by powder zone melting method. Heat Treat Met, 2019, 44(12): 38黄卫星, 汪涛, 袁揭, 等. 粉末区熔法制备石墨烯/AlSi12复合材料的组织和性能. 金属热处理, 2019, 44(12): 38 [8] Yan H, Zhang H, Yang Z G. Study on microstructure and mechanical properties of cast AlSi7MgLa aluminum alloy. New Technol Process, 2016(9): 61 doi: 10.3969/j.issn.1003-5311.2016.09.019闫洪, 张辉, 杨祖贵. 铸造AlSi7MgLa铝合金的金相组织和力学性能研究. 新技术新工艺, 2016(9): 61 doi: 10.3969/j.issn.1003-5311.2016.09.019 [9] Wang M, Zhao Y T, Tao R, et al. Effect of Sr on microstructure and mechanical properties of AlSi9Cu3 alloy. Foundry Technol, 2018, 39(6): 1153汪闵, 赵玉涛, 陶然, 等. Sr对AlSi9Cu3合金组织与力学性能的影响. 铸造技术, 2018, 39(6): 1153 [10] Awd M, Tenkamp J, Hirtler M, et al. Comparison of microstructure and mechanical properties of scalmalloy® produced by selective laser melting and laser metal deposition. Materials, 2017, 11(1): 17 doi: 10.3390/ma11010017 [11] Zhang G X, Liu S F, Yang X, et al. Research progress on preparation of biological implant materials by additive manufacturing. Powder Metall Technol, 2019, 37(4): 312张光曦, 刘世锋, 杨鑫, 等. 增材制造技术制备生物植入材料的研究进展. 粉末冶金技术, 2019, 37(4): 312 [12] Guan J, Yang S X, Guan Y, et al. Research progress of 3D printing technology in medical domain. China Med Devices, 2014, 29(4): 71 doi: 10.3969/j.issn.1674-1633.2014.04.024管吉, 杨树欣, 管叶, 等. 3D打印技术在医疗领域的研究进展. 中国医疗设备, 2014, 29(4): 71 doi: 10.3969/j.issn.1674-1633.2014.04.024 [13] Mertens A, Delahaye J, Dedry O, et al. Microstructure and properties of SLM AlSi10Mg: Understanding the influence of the local thermal history. Procedia Manuf, 2020, 47: 1089 doi: 10.1016/j.promfg.2020.04.121 [14] Mcdonald S D, Nogita K, Dahle A K. Eutectic nucleation in Al‒Si alloys. Acta Mater, 2004, 52(14): 4273 doi: 10.1016/j.actamat.2004.05.043 [15] Gremaud M, Allen D R, Rappaz M, et al. The development of nucleation controlled microstructures during laser treatment of Al single bond Si alloys. Acta Mater, 1996, 44(7): 2669 doi: 10.1016/1359-6454(95)00393-2 [16] Pei Y T, Hosson J Th M D. Functionally graded materials produced by laser cladding. Acta Mater, 2000, 48(10): 2617 doi: 10.1016/S1359-6454(00)00065-3 [17] Feufel H, Gödecke T, Lukas H L, et al. Investigation of the Al‒Mg‒Si system by experiments and thermodynamic caculations. J Alloys Compd, 1997, 247(1-2): 31 doi: 10.1016/S0925-8388(96)02655-2 [18] Maskery I, Aboulkhair N T, Corfield M R, et al. Quantification and characterization of porosity in selectively laser melted Al‒Si10‒Mg using X-ray computed tomography. Mater Charact, 2016, 111: 193 doi: 10.1016/j.matchar.2015.12.001 [19] Read N, Wang W, Essa K, et al. Selective laser melting of AlSi10Mg alloy: Process optimization and mechanical properties development. Mater Des, 2015, 65: 417 doi: 10.1016/j.matdes.2014.09.044 [20] Dong Z C, Liu Y B, Zhang Q, et al. Microstructural heterogeneity of AlSi10Mg alloy lattice structures fabricated by selective laser melting: Phenomena and mechanism. J Alloys Compd, 2020, 833: 155071 doi: 10.1016/j.jallcom.2020.155071 [21] Suryawanshi J, Prashanth K G, Scudino S, et al. Simultaneous enhancements of strength and toughness in an Al−12Si alloy synthesized using selective laser melting. Acta Mater, 2016, 115: 285 doi: 10.1016/j.actamat.2016.06.009 [22] Chen B, Moon S K, Yao X, et al. Strength and strain hardening of a selective laser melted AlSi10Mg alloy. Scr Mater, 2017, 141: 45 doi: 10.1016/j.scriptamat.2017.07.025 [23] Lam L P, Zhang D Q, Liu Z H, et al. Phase analysis and microstructure characterisation of AlSi10Mg parts produced by selective laser melting. Virtual Phys Prototyp, 2015, 10(4): 207 doi: 10.1080/17452759.2015.1110868 [24] Prashanth K G, Scudino S, Klauss H J, et al. Microstructure and mechanical properties of Al‒12Si produced by selective laser melting: Effect of heat treatment. Mater Sci Eng A, 2014, 590: 153 doi: 10.1016/j.msea.2013.10.023 [25] Qian D Y, Chen C J, Zhang M, et al. Study on microstructure and micro-mechanical properties of porous aluminum alloy fabricated by selective laser melting. Chin J Lasers, 2016, 43(4): 66钱德宇, 陈长军, 张敏, 等. 选区激光熔化成形多孔铝合金的显微组织及微观力学性能研究. 中国激光, 2016, 43(4): 66 [26] Kimura T, Nakamoto T. Microstructures and mechanical properties of A356(AlSi7Mg0.3) aluminum alloy fabricated by selective laser melting. Mater Des, 2016, 89: 1294 doi: 10.1016/j.matdes.2015.10.065 [27] Zhao X M, Qi Y H, Yu Q C, et al. Study on microstructure and mechanical properties of AlSi10Mg alloy produced by 3D printing. Foundry Technol, 2016, 37(11): 2402赵晓明, 齐元昊, 于全成, 等. AlSi10Mg铝合金3D打印组织与性能研究. 铸造技术, 2016, 37(11): 2402 [28] Buchbinder D, Schleifenbaum H, Heidrich S, et al. High power selective laser melting (HPSLM) of aluminium parts // Physics Procedia of the Sixth International WLT Conference on Lasers in Manufacturing. Munich, 2012: 271. [29] Rahman Rashida R A, Mallavarapu J, Palanisamy S, et al. A comparative study of flexural properties of additively manufactured aluminium latice structures. Mater Today Proc, 2017, 4(8): 8597 doi: 10.1016/j.matpr.2017.07.207 [30] Montero-Sistiaga M L, Mertens R, Vrancken B, et al. Changing the alloy composition of Al7075 for better processability by selective laser melting. J Mater Process Technol, 2016, 238: 437 doi: 10.1016/j.jmatprotec.2016.08.003 [31] Singh A, Ramakrishnan A, Baker D, et al. Laser metal deposition of nickel coated Al 7050 alloy. J Alloys Compd, 2017, 719: 151 doi: 10.1016/j.jallcom.2017.05.171 [32] Martin J H, Yahata B D, Hundley J M, et al. 3D printing of high-strength aluminium alloys. Nature, 2017, 549(7672): 365 doi: 10.1038/nature23894 [33] Karg M C H, Ahuja B, Wiesenmayer S, et al. Effects of process conditions on the mechanical behavior of aluminium wrought alloy EN AW-2219(AlCu6Mn) additively manufactured by laser beam melting in powder bed. Micromachines, 2017, 8(1): 23 doi: 10.3390/mi8010023 [34] Zhang H, Nie X J, Zhu H H, et al. Study on high strength Al‒Cu‒Mg alloy fabricated by selective laser melting. Chin J Lasers, 2016, 43(5): 84张虎, 聂小佳, 朱海红, 等. 激光选区熔化成形高强Al‒Cu‒Mg合金研究. 中国激光, 2016, 43(5): 84 [35] Nie X J, Zhang H, Zhu H H, et al. On the role of Zr content into Portevin-Le Chatelier (PLC) effect of selective laser melted high strength Al‒Cu‒Mg‒Mn alloy. Mater Lett, 2019, 248: 5 doi: 10.1016/j.matlet.2019.03.112 [36] Ahuja B, Karg M, Nagulin K Y, et al. Fabrication and characterization of high strength Al‒Cu alloys processed using laser beam melting in metal powder bed. Phys Procedia, 2014, 56: 135 doi: 10.1016/j.phpro.2014.08.156 [37] Zhang H, Zhu H H, Qi T, et al. Selective laser melting of high strength Al–Cu–Mg alloys: Processing, microstructure and mechanical properties. Mater Sci Eng A, 2016, 656: 47 doi: 10.1016/j.msea.2015.12.101 [38] Wei J J, Mi G F, Xu L, et al. Research progress on laser additive manufacturing aluminum alloy and its composites. Hot Working Technol, 2019, 48(8): 27魏娟娟, 米国发, 许磊, 等. 激光增材制造铝合金及其复合材料研究进展. 热加工工艺, 2019, 48(8): 27 [39] Simchi A, Godlinski D. Effect of SiC particles on the laser sintering of Al‒7Si‒0.3Mg alloy. Scr Mater, 2008, 59(2): 199 doi: 10.1016/j.scriptamat.2008.03.007 [40] Chen R, Shi Y F, Xu Q Y, et al. Effect of cooling rate on solidification parameters and microstructure of Al‒7Si‒0.3Mg‒0.15Fe alloy. Trans Nonferrous Met Soc China, 2014, 24(6): 1645 doi: 10.1016/S1003-6326(14)63236-2 [41] Luo D Z, Sun Z F. Recent developments on researches of military usage Al alloys via addictive manufacturing. J Ordn Equip Eng, 2019, 40(8): 212 doi: 10.11809/bqzbgcxb2019.08.042骆冬智, 孙智富. 铝合金增材制造技术在军工领域的研究进展. 兵器装备工程学报, 2019, 40(8): 212 doi: 10.11809/bqzbgcxb2019.08.042 [42] Ye H, Zhang J Q, Huang J Q, et al. Microstructure and fatigue properties of selected laser-melted WC/AlSi10Mg composites. Mater Rev, 2019, 33(22): 3789 doi: 10.11896/cldb.18090274叶寒, 张坚强, 黄俊强, 等. 选区激光熔化WC/AlSi10Mg复合材料的微观组织和疲劳性能. 材料导报, 2019, 33(22): 3789 doi: 10.11896/cldb.18090274 [43] Zhang T C, Zhang M, Qi J F, et al. Mechanical properties and structure analysis of SLM forming of 3%SiC/AlSi10Mg composite material. New Technol New Process, 2018(7): 1张天驰, 张明, 祁俊峰, 等. 3%SiC/AlSi10Mg复合材料SLM成形力学性能与组织分析. 新技术新工艺, 2018(7): 1 [44] Han Q, Setchi R, Evans S L. Synthesis and characterisation of advanced ball-milled Al‒Al2O3 nanocomposites for selective laser melting. Powder Technol, 2016, 297: 183 doi: 10.1016/j.powtec.2016.04.015 [45] Tan H, Hao D, Al-Hamdani K, et al. Direct metal deposition of TiB2/AlSi10Mg composites using satellited powders. Mater Lett, 2018, 214: 123 doi: 10.1016/j.matlet.2017.11.121 [46] Gu D, Wang H, Dai D, et al. Rapid fabrication of Al-based bulk-form nanocomposites with novel reinforcement and enhanced performance by selective laser melting. Scr Mater, 2015, 96: 25 doi: 10.1016/j.scriptamat.2014.10.011 [47] Gu D, Yuan P. Thermal evolution behavior and fluid dynamics during laser additive manufacturing of Al-based nanocomposites: Underlying role of reinforcement weight fraction. J Appl Phys, 2015, 118(23): 233 [48] Rao X W, Gu D D, Xi L X. Forming mechanism and mechanical properties of carbon nanotube reinforced aluminum matrix composites by selective laser melting. J Mech Eng, 2019, 55(15): 1 doi: 10.3901/JME.2019.15.001饶项炜, 顾冬冬, 席丽霞. 选区激光熔化成形碳纳米管增强铝基复合材料成形机制及力学性能研究. 机械工程学报, 2019, 55(15): 1 doi: 10.3901/JME.2019.15.001 [49] Ke L D, Xue G, Zhu H H, et al. Research on fabrication and properties of SiCp/AlSi10Mg composites by selective laser melting. Aerosp Shanghai, 2019, 36(2): 118柯林达, 薛刚, 朱海红, 等. 激光选区熔化成形SiCP/AlSi10Mg复合材料工艺及性能研究. 上海航天, 2019, 36(2): 118 [50] Lu B, Zhu J F, Fang Y, et al. Effect of SiC on the microstructure and mechanical properties of aluminum matrix composites by in-situ synthesis. Powder Metall Technol, 2020, 38(1): 42卢博, 朱建锋, 方媛, 等. 原位合成SiC对铝基复合材料微观组织和力学性能的影响. 粉末冶金技术, 2020, 38(1): 42 [51] Schmidtke K, Palm F, Hawkins A, et al. Process and mechanical properties: Applicability of a scandium modified Al-alloy for laser additive manufacturing. Phys Procedia, 2011, 12(Part A): 369 [52] Schmidtke K, Palm F. Exceptional grain refinement in directly built up Sc-modified AlMg-alloys is promising a quantum leap in ultimate light weight design // 9th International Conference on Trends in Welding Research American Society for Metal. Chicago, 2012. [53] Zhang H, Zhu H, Nie X, et al. Fabrication and heat treatment of high strength Al‒Cu‒Mg alloy processed using selective laser melting // Spie Lase. San Francisco, 2016. [54] Wang P, Deng L, Prashanth K G, et al. Microstructure and mechanical properties of Al‒Cu alloys fabricated by selective laser melting of powder mixtures. J Alloys Compd, 2017, 735: 2263 -

下载:

下载: