Effect of treatment process on the formability of Fe–Al alloy powders and the crushing strength of green compacts

-

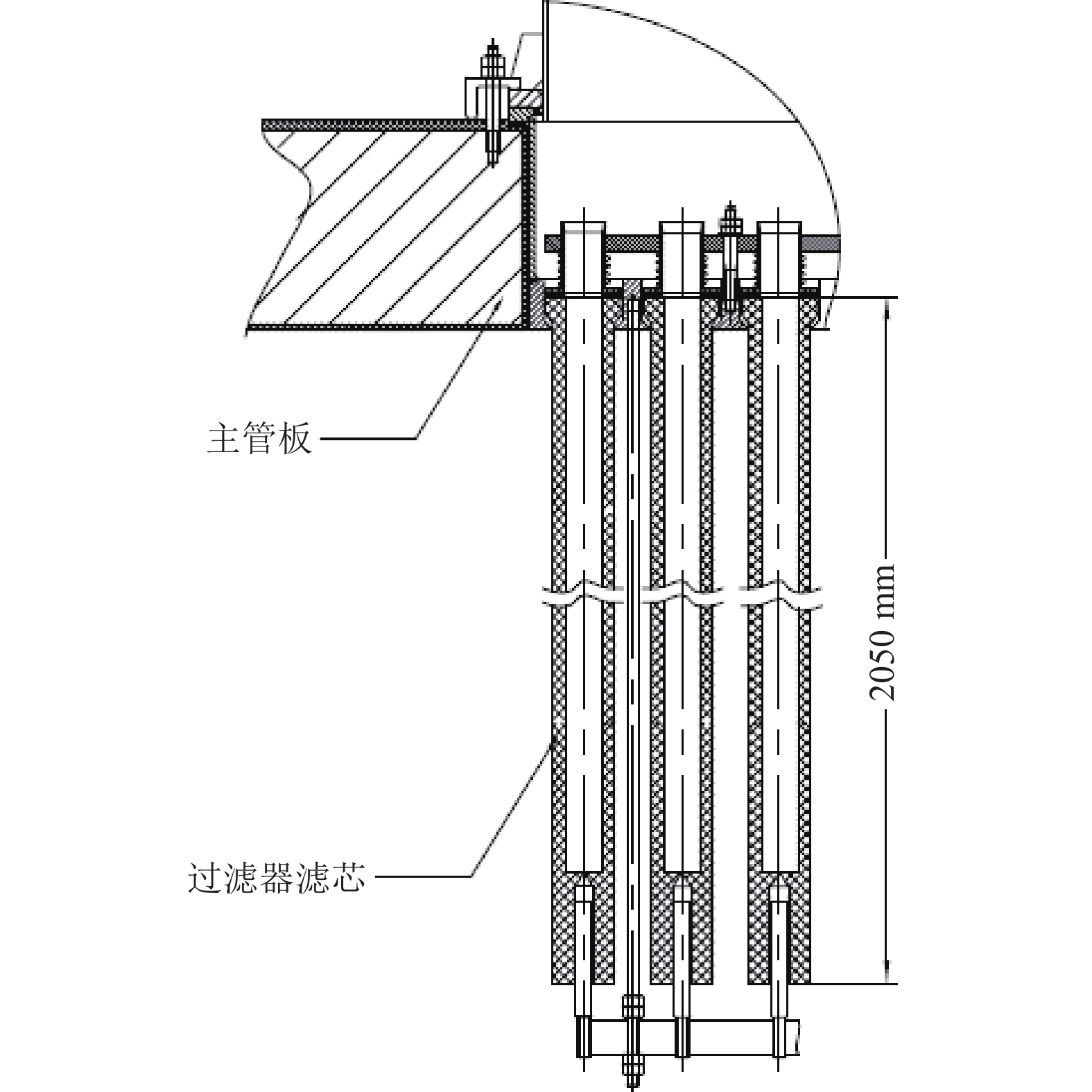

摘要: 为了提高Fe–Al合金粉末的压制成形性和生坯压溃强度,分析了氢气还原和真空退火工艺对Fe–Al合金粉末形貌和性能的影响,研究了原始粉末和经过处理后粉末所制管坯的成形率。结果发现,经氢气还原和真空退火处理后,粉末形貌变化不大,粉末性能提高,生坯压溃强度增强,成形性得到改善;尤其是经真空退火粉末的性能得到极大提高,氧的质量分数由0.5%低到0.2%,松装密度由1.82 g·cm−3降低到1.64 g·cm−3,显微硬度由HV 260降低到HV 158,压缩比由63%降低到56%,生坯压溃强度由2.0 MPa提高到2.7 MPa,粉末成形性得到极大改善。在批量化压制长管坯时,对原始粉末预先进行真空退火处理,长管生坯数量成品率由50%提高至100%,产品成本降低。Abstract: To improve the formability of Fe–Al alloy powders and the crushing strength of green compacts, the effects of hydrogen reduction and vacuum annealing on the morphology and properties of the Fe–Al alloy powders were analyzed, and the forming rate of the tube billets made from the original powders and the treated powders were studied. The results show that, after the hydrogen reduction and vacuum anneal treatment, the morphology of the original Fe–Al alloy powders has little change, the powder properties are enhanced, and the crushing strength and formability of the green compacts are improved. Especially after the vacuum anneal treatment, the powder properties are significantly enhanced, oxygen mass fraction decrease from 0.5% to 0.2%, apparent density decrease from 1.82 g·cm−3 to 1.64 g·cm−3, microhardness decrease from HV 260 to HV 158, compression ratio decrease from 63% to 56%, crushing strength of the green compact increase from 2.0 MPa to 2.7 MPa, the formability is greatly improved. In the quantity production of long tube billets, the vacuum annealing pretreatment of the original Fe–Al alloy powders can effectively increase the qualified rate of the long tube billets from 50% to 100% and reduce the product cost.

-

Key words:

- Fe–Al alloy powders /

- hydrogen reduction /

- vacuum annealing /

- porous property /

- crushing strength

-

表 1 烧结Fe–Al合金多孔材料性能

Table 1. Properties of the sintered Fe–Al alloy porous materials

试样

编号压溃强度 / MPa 透气度 / (m3·m−2·h−1·kPa−1) 最大孔径 / μm 平均孔径 / μm 1# 52 164 20 15 2# 57 158 18 13 3# 62 150 15 10 陶瓷

滤管29 135 17 11 表 2 粉末长样品管坯数量成品率

Table 2. Quantity qualified rate of the long green compacts

试样编号 生产数量 / 支 合格数量 / 支 成品率 / % 成形性 1#-C 10 5 50 管坯成形较差,管身微裂纹,法兰/管底断裂 2#-C 10 8 80 管坯成形良好,管身无裂纹,法兰/管底棱角掉粉 3#-C 10 10 100 管坯成形极好,管身无裂纹,法兰/管底棱角无掉粉 -

[1] Cui C J, Wen Y G, Yang M, et al. Research progress of Fe–Al intermetallic compound. Mater Protect, 2017, 50(9): 82崔春娟, 问亚岗, 杨猛, 等. Fe–Al金属间化合物的研究进展. 材料保护, 2017, 50(9): 82 [2] Hammel E C, Ighodaro O L R, Okoli O I. Processing and properties of advanced porous ceramics: An application based review. Ceram Int, 2014, 40(10): 15351 doi: 10.1016/j.ceramint.2014.06.095 [3] Banhart J. Manufacture, characterization and application of cellular metals and metal foams. Prog Mater Sci, 2001, 46(6): 559 doi: 10.1016/S0079-6425(00)00002-5 [4] Jiang Y, He Y H, Liu C T. Review of porous intermetallic compounds by reactive synthesis of elemental powders. Intermetallics, 2018, 93: 217 doi: 10.1016/j.intermet.2017.06.003 [5] Wang Q B, Tang H P, Xi Z P, et al. The studies progress of the metal porous material using in the gasification technology. Rare Met Mater Eng, 2006, 35(Suppl 2): 448汪强兵, 汤慧平, 奚正平, 等. 煤气化技术用金属多孔材料研究进展. 稀有金属材料与工程, 2006, 35(增刊2): 448 [6] Gao H Y, He Y H, Zou J, et al. Tortuosity factor for porous FeAl intermetallics fabricated by reactive synthesis. Trans Nonferrous Met Soc China, 2012, 22(9): 2179 doi: 10.1016/S1003-6326(11)61446-5 [7] Amaya M, Espinosa-Medina M A, Porcayo-Calderon J, et al. High temperature corrosion performance of FeAl intermetallic alloys in molten salts. Mater Sci Eng A, 2003, 349: 12 doi: 10.1016/S0921-5093(01)01940-2 [8] Wang F, Liu G Y, Yang J J, et al. Application and development of metal filter materials in high-temperature gas filtration. Powder Metall Technol, 2018, 36(3): 230王凡, 刘冠颖, 杨军军, 等. 金属过滤材料在高温除尘中的应用与发展. 粉末冶金技术, 2018, 36(3): 230 [9] Liu X S, Gu H, Ping S B, et al. Performance of Fe3Al metal filter and its application in U-gas coal gasification plant. Clean Coal Technol, 2017, 23(5): 119刘显胜, 顾虎, 平韶波, 等. Fe3Al金属滤芯特性及在U-gas煤气化装置中的应用. 洁净煤技术, 2017, 23(5): 119 [10] Sun W J. Application of metal filter in ash removal system of shell gasifier. Chem Enterpr Manag, 2013(6): 107 doi: 10.3969/j.issn.1008-4800.2013.06.089孙卫军. 金属滤芯在壳牌气化炉除灰系统中的应用. 化工管理, 2013(6): 107 doi: 10.3969/j.issn.1008-4800.2013.06.089 [11] Zhou G L. Research progress and application of filter element in fly-ash filter of coal gasification plant. Shanxi Chem Ind, 2017(5): 112周贵龙. 煤气化装置飞灰过滤器用滤芯研究进展及应用初探. 山西化工, 2017(5): 112 [12] Wang H, Yang J J, Liu G Y, et al. Application of Fe3Al filter element in fly ash filter of coal gasification device. Clean Coal Technol, 2013, 19(1): 78王浩, 杨军军, 刘冠颖, 等. Fe3Al滤芯在煤气化装置飞灰过滤器中的应用. 洁净煤技术, 2013, 19(1): 78 [13] Ma J T, Li Z, Shangguan G Q. Performance comparison of metal filter and ceramic filter in HPHT fly-ash filter of coal gasification device. Chem Enterp Manage, 2015(3): 158 doi: 10.3969/j.issn.1008-4800.2015.03.141马江涛, 李准, 上官国青. 煤气化装置高温高压飞灰过滤器金属滤芯与陶瓷滤芯性能对比. 化工管理, 2015(3): 158 doi: 10.3969/j.issn.1008-4800.2015.03.141 [14] Huang P Y. Power Metallurgy Principles. Beijing: Metallurgy Industry Press, 2006黄培云. 粉末冶金原理. 北京: 冶金工业出版社, 2006 [15] Wang H, Yang J J, Wang F, et al. Study progress and application on coal gasification device fly ash filter candle. Petro-Chem Equip, 2012, 41(3): 68 doi: 10.3969/j.issn.1000-7466.2012.03.020王浩, 杨军军, 王凡, 等. 煤气化装置飞灰过滤器用滤芯研究进展及应用. 石油化工设备, 2012, 41(3): 68 doi: 10.3969/j.issn.1000-7466.2012.03.020 -

下载:

下载: