Preparation and properties research of Cu-based electrical contact composites containing Cr and NbSe2

-

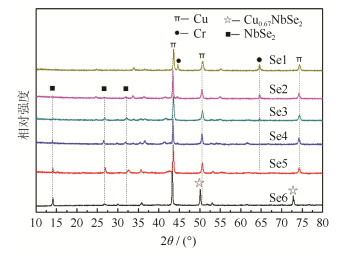

摘要: 采用复压复烧工艺制备了含不同质量分数Cr和NbSe2的铜基电接触复合材料,利用光学电子显微镜、X射线衍射仪、硬度计、扫描电子显微镜等设备研究了铜基复合材料力学、电学和电摩擦学性能。结果表明,铜基复合材料的密度随着NbSe2含量的增多而增高,硬度和断裂强度随着Cr含量的增多而提高;Cr含量高的铜基复合材料磨痕表面极易生成CuO纳米片,改善了材料的摩擦性能,但降低了电学性能;含适当比例Cr和NbSe2的铜基复合材料有着较好力学、电学性能,且因NbSe2润滑膜和CuO纳米球的协同作用,改善了材料的摩擦性能。Abstract: The Cu-based electrical contact composite materials containing Cr and NbSe2 in the different mass fractions were prepared by repressing and reburning method in this study, and the mechanical, electrical, and tribological properties of copper-based electrical contact composites were investigated by optical electron microscope, X-ray diffractometer, hardness tester, and scanning electron microscope. The results show that, the density of the copper-based composites increases with the increase of NbSe2 content, while the hardness and fracture strength increase with the increase of Cr content. The copper-based composites with the higher Cr content can easily generate the CuO nanoplates on the wear scar surface, which improves the tribological properties but reduces the electrical properties of the copper-based composite materials. Consequently, the copper-based composites containing Cr and NbSe2 in the appropriate mass fraction show the better mechanical and electrical properties. Moreover, the tribological properties of the copper-based composites are also improved due to the synergistic effect of the NbSe2 lubricating film and CuO nanospheres.

-

表 1 铜基复合材料试样组成成分及物理性能

Table 1. Composition and physical properties of the copper-based composite samples

试样编号 成分质量分数/% 密度, ρ/(kg·m-3) 相对密度,ρr/% 表面粗糙度,Ra/μm Cu NbSe2 Cr Sel 65 0 35 6.96×103 84.9 0.217 Se2 65 10 25 7.13×103 88.1 0.202 Se3 65 15 20 7.24×103 90.2 0.214 Se4 65 20 15 7.39×103 92.7 0.186 Se5 65 25 10 7.42×103 94.0 0.175 Se6 65 35 0 7.26×103 93.3 0.193 表 2 金属及其金属氧化物的电阻率

Table 2. Electrical resistivity of the metals and metal oxides

材料 Nb NbO Cr Cr2O3 Cu CuO Cu20 NbSe2 电阻率/(Ω·m) 12.5 × 10-8 10-7 12.9 × 10-8 — 1.534 × 10-8 10~50 10~50 5.35 × 10-6 -

[1] Miura H, Nishiyama N, Togashi N, et al. Structure, conductivity and mechanical properties of non-equilibrium copper-based crystalline alloy nano-composites. Intermetallics, 2010, 18(10): 1860 doi: 10.1016/j.intermet.2010.02.033 [2] Asgharzadeh H, Eslami S. Effect of reduced graphene oxide nanoplatelets content on the mechanical and electrical properties of copper matrix composite. J Alloys Compd, 2019, 806: 553 doi: 10.1016/j.jallcom.2019.07.183 [3] Khobragade N, Sikdar K, Kumar B, et al. Mechanical and electrical properties of copper-graphene nanocomposite fabricated by high pressure torsion. J Alloys Compd, 2019, 776: 123 doi: 10.1016/j.jallcom.2018.10.139 [4] Zhao X W, Zang C G, Ma Q K, et al. Thermal and electrical properties of composites based on (3-mercaptopropyl) trimethoxysilane-and Cu-coated carbon fiber and silicone rubber. J Mater Sci, 2016, 51(8): 4088 doi: 10.1007/s10853-016-9730-0 [5] Cai A H, Xiong X, Liu Y, et al. Electrical, thermal, and mechanical properties of Cu50Zr40Ti10 bulk amorphous composite. Mater Sci Eng A, 2012, 535: 92 doi: 10.1016/j.msea.2011.12.046 [6] Zhang Z W, Ji Z, Jia C C, et al. Preparation and properties of copper matrix composites reinforced by CNTs and Al2O3. Powder Metall Technol, 2016, 34(5): 356 doi: 10.3969/j.issn.1001-3784.2016.05.007张政委, 纪箴, 贾成厂, 等. 碳纳米管和氧化铝颗粒协同增强铜基复合材料的制备与性能研究. 粉末冶金技术, 2016, 34(5): 356 doi: 10.3969/j.issn.1001-3784.2016.05.007 [7] Wu Q, Jia C C, Nie J H. Friction and wear properties of magnesium matrix composites reinforced by tungsten-coated carbon nanotubes. Powder Metall Technol, 2018, 36(6): 423 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201806004.htm吴琼, 贾成厂, 聂俊辉. 镀钨碳纳米管增强镁基复合材料的摩擦磨损性能研究. 粉末冶金技术, 2018, 36(6): 423 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201806004.htm [8] Huang S Y, Feng Y, Liu H J, et al. Electrical sliding friction and wear properties of Cu-MoS2-graphite-WS2, nanotubes composites in air and vacuum conditions. Mater Sci Eng A, 2013, 560(2): 685 http://www.sciencedirect.com/science/article/pii/S0921509312014499 [9] Liu Q Y, Wang H J, Zhou C Y, et al. Preparation and high temperature properties of new self-lubricating die materials. Powder Metall Technol, 2020, 38(1): 51 doi: 10.19591/j.cnki.cn11-1974/tf.2020.01.008刘清阳, 王华君, 周春杨, 等. 新型自润滑模具材料的制备和高温性能研究. 粉末冶金技术, 2020, 38(1): 51 doi: 10.19591/j.cnki.cn11-1974/tf.2020.01.008 [10] Tang H, Cao K S, Wu Q, et al. Synthesis and tribological properties of copper matrix solid self-lubricant composites reinforced with NbSe2 nanoparticles. Cryst Res Technol, 2011, 46(2): 195 doi: 10.1002/crat.201000499 [11] Tian B H, Chen X L, Zhang Y, et al. Electrical contact characteristics of Cu-Mo-WC composites prepared by spark plasma sintering process. Rare Met Mater Eng, 2018, 47(3): 943 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201803037.htm田保红, 程新乐, 张毅, 等. 放电等离子烧结Cu-Mo-WC复合材料电接触特性. 稀有金属材料与工程, 2018, 47(3): 943 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201803037.htm [12] Watanabe Y. High-speed sliding characteristics of Cu-Sn-based composite materials containing lamellar solid lubricants by contact resistance studies. Wear, 2008, 264(7): 624 http://www.sciencedirect.com/science/article/pii/S0043164807005650 [13] Mao S C. Linear dependence of resistivity-temperature and holon-phonon scattering in Cu-O planes. J Shenyang Univ Nat Sci, 2016, 28(1): 1 doi: 10.3969/j.issn.2095-5456.2016.01.001毛善成. 铜氧面电阻率-温度线性依赖与空穴-声子散射. 沈阳大学学报(自然科学版), 2016, 28(1): 1 doi: 10.3969/j.issn.2095-5456.2016.01.001 [14] Wood J T, Griffin Jr A J, Embury J D, et al. The influence of microstructural scale on the combination of strength and electrical resistivity in copper based composites. J Mech Phys Solids, 1995, 44(5): 737 http://www.sciencedirect.com/science/article/pii/0022509696000105 [15] Change S Y, Guo Z C. Recent advance in technology of anti-oxidation copper powder. Powder Metall Ind, 2007, 17(1): 49 doi: 10.3969/j.issn.1006-6543.2007.01.010常仕英, 郭忠诚. 铜粉抗氧化性处理技术的进展. 粉末冶金工业, 2007, 17(1): 49 doi: 10.3969/j.issn.1006-6543.2007.01.010 [16] Huang S Y. Influence of current density on electrical friction property of Cu-based self-lubricating materials. Ordn Mater Sci Eng, 2020, 43(2): 77 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG202002019.htm黄仕银. 电流密度对铜基自润滑材料电摩擦性能的影响. 兵器材料科学与工程, 2020, 43(2): 77 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG202002019.htm [17] Han M, Du J H, Ning K Y, et al. Effect of temperature distribution on pitting damage of copper-based friction material. Powder Metall Technol, 2019, 37(1): 18 doi: 10.19591/j.cnki.cn11-1974/tf.2019.01.003韩明, 杜建华, 宁克焱, 等. 温度分布对铜基摩擦材料点蚀损伤的影响. 粉末冶金技术, 2019, 37(1): 18 doi: 10.19591/j.cnki.cn11-1974/tf.2019.01.003 [18] Liu H C. Study on Copper Based Electrical Contact Composites Modified by Multi Component[Dissertation]. Jinan: University of Jinan, 2018刘焕超. 多组元改性铜基电接触复合材料的研究[学位论文]. 济南: 济南大学, 2018 [19] Shi Q. Research on Electrical Contact Composites Containing Transition Metal Selenides[Dissertation]. Zhenjiang: Jiangsu University, 2017施琴. 过渡族金属硒化物电接触复合材料的研究[学位论文]. 镇江: 江苏大学, 2017 [20] Liu N. Study of Cu Matrix Graphite Friction Composite by Powder Metallurgy[Dissertation]. Harbin: Harbin University of Science and Technology, 2014刘宁. 粉末冶金法制备Cu/C复合材料的性能研究[学位论文]. 哈尔滨: 哈尔滨理工大学, 2014 [21] Li G J, Yang T Y, Ma Y Y, et al. Mechanical characteristics of the Ag/SnO2 electrical contact materials with Cu2O and CuO additives. J Alloys Compd, 2020, 817: 152710 doi: 10.1016/j.jallcom.2019.152710 [22] Li J F, Shi Q, Zhu H J, et al. Tribological and electrical behavior of Cu-based composites with addition of Ti-doped NbSe2 nanoplatelets. Ind Lubr Tribol, 2018, 70(3): 560 doi: 10.1108/ILT-10-2016-0259 [23] Wang L, Zhang X Y, Lei Y Y, et al. Study on high-temperature oxidation properties of new copper-based electrical contact materials. Nonferrous Met Extr Metall, 2016(4): 55 https://www.cnki.com.cn/Article/CJFDTOTAL-METE201604015.htm王丽, 张晓燕, 雷源源, 等. 新型铜基电接触材料的高温氧化性能研究. 有色金属(冶炼部分), 2016(4): 55 https://www.cnki.com.cn/Article/CJFDTOTAL-METE201604015.htm [24] Valladares L De Los S, Salinas D H, Dominguez A B, et al. Crystallization and electrical resistivity of Cu2O and CuO obtained by thermal oxidation of Cu thin films on SiO2/Si substrates. Thin Solid Films, 2012, 520(20): 6368 doi: 10.1016/j.tsf.2012.06.043 [25] Koshy C P, Rajendrakumar P K, Thottackkad M V. Experimental evaluation of the tribological properties of CuO nano-lubricants at elevated temperatures//Proceedings of International Conference on Advances in Tribology and Engineering Systems. New Delhi, 2014: 391 http://www.researchgate.net/publication/278326951_Experimental_Evaluation_of_the_Tribological_Properties_of_CuO_Nano-Lubricants_at_Elevated_Temperatures [26] Bahadur S, Polineni V K. Tribological studies of glass fabric-reinforced polyamide composites filled with CuO and PTFE. Wear, 1996, 200(1-2): 95 doi: 10.1016/S0043-1648(96)07327-9 [27] Wang Q H, Zhang X R, Pei X Q. A synergistic effect of graphite and nano-CuO on the tribological behavior of polyimide composites. J Macromol Sci Part B Phys, 2010, 50(2): 213 doi: 10.1080/00222341003641156 -

下载:

下载: