Microstructure and mechanical properties of annealed Ti−6Al−3Nb−2Zr−1Mo titanium alloys

-

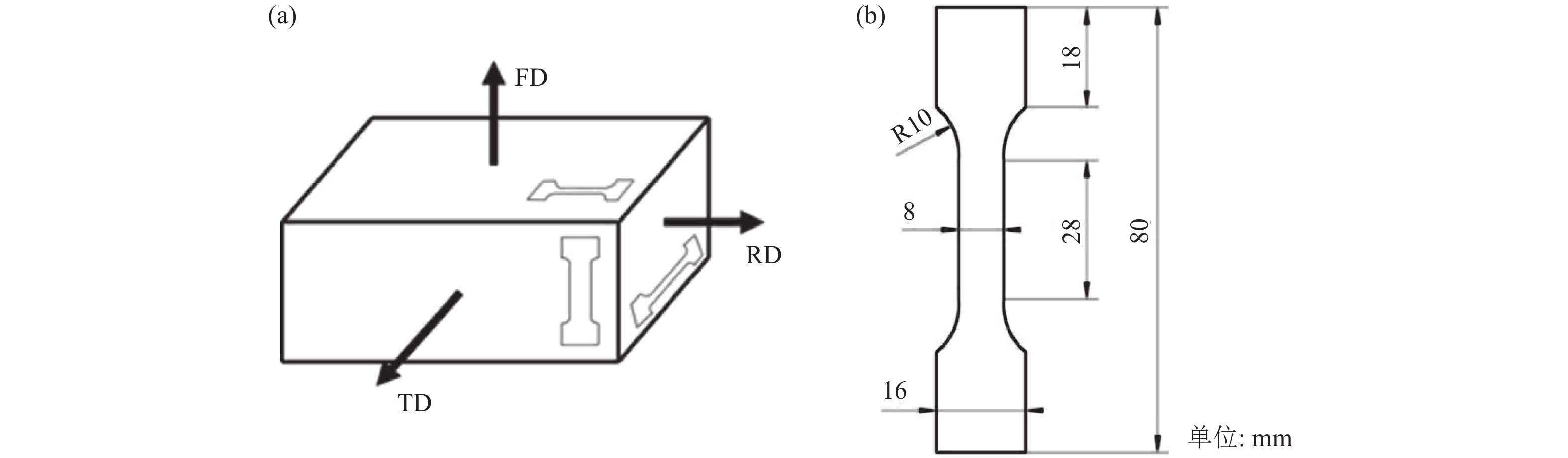

摘要: 采用模锻工艺及980 ℃退火工艺制备了Ti−6Al−3Nb−2Zr−1Mo合金,通过扫描电子显微镜(scanning electron microscope,SEM)观察和电子背向散射衍射(electron back-scattered diffraction,EBSD)分析等方法研究了退火态合金不同截面上的微观组织与力学性能。结果表明:与锻态合金比较,退火态Ti−6Al−3Nb−2Zr−1Mo合金的α相含量减少,亚稳态的β相增多。在空气冷却的过程中,合金的亚稳态β相又转化为次生α相和少量β相。退火态Ti−6Al−3Nb−2Zr−1Mo合金中α-Ti呈现出RD//[

$ \bar {1} $ 2$ \bar {1} $ 0]、FD//[0001]的织构类型(FD为锻件压缩方向(锻造方向),RD为锻件自由延伸方向)。退火态Ti−6Al−3Nb−2Zr−1Mo合金的三个方向拉伸断裂主要是韧性断裂,并且断裂方式呈现出微孔聚集断裂。沿RD方向拉伸时韧窝尺寸较大,对应的延伸率也优于其他方向。Abstract: Ti−6Al−3Nb−2Zr−1Mo alloys were prepared by forging and annealing at 980 ℃. The microstructure and mechanical properties of the annealed alloys on the different sections were studied by scanning electron microscopy (SEM) and electron back-scattered diffraction (EBSD). The results show that, compared with the forged alloys, the content of α phase in the annealed Ti−6Al−3Nb−2Zr−1Mo alloys decreases, and the content of the metastable β phase increases. During the cooling in the air, the metastable β phase is transformed into the secondary α phase and a small amount of β phase. After annealing at 980 ℃, α-Ti in Ti−6Al−3Nb−2Zr−1Mo alloys exhibits the texture types of RD//[$ \bar {1} $ 2$ \bar {1} $ 0] and FD//[0001], where RD is the forging compression direction (forging direction), and FD is the free extension direction of forging. The fracture morphology of Ti−6Al−3Nb−2Zr−1Mo alloys along the different tensile direction is mainly ductile fracture, and the fracture mode shows the micropore aggregation fracture. When the annealed alloys are stretched in RD direction, the size of the dimple is larger, and the corresponding elongation is superior to that in any other direction.-

Key words:

- titanium alloys /

- forging /

- annealing /

- mechanical properties /

- microstructure

-

图 4 退火态Ti−6Al−3Nb−2Zr−1Mo合金取向成像图(IPF-Z)和反极图(IPF):(a)侧面IPF-Z图;(b)断面IPF-Z图;(c)侧面IPF图;(d)断面IPF图

Figure 4. Orientation mapping (IPF-Z) and inverse pole figure (IPF) of the annealed Ti−6Al−3Nb−2Zr−1Mo alloys: (a) IPF-Z of broad side; (b) IPF-Z in cross section; (c) IPF of broad side; (d) IPF in cross section

表 1 试验用钛合金锻造工艺

Table 1. Forging process of the titanium alloys

锻造次数 温度 / ℃ 保温时间 / min 1 1170 60 2 1100 3 1030 4 970 5 6 960 7 表 2 退火态Ti−6Al−3Nb−2Zr−1Mo合金三个方向的拉伸力学性能

Table 2. Mechanical properties of the annealed Ti−6Al−3Nb−2Zr−1Mo alloys in the different direction

方向 弹性模量 /

GPa屈服强度 /

MPa抗拉强度 /

MPa延伸率 /

%RD 109.9 754.4 843.5 16.3 TD 122.3 771.6 869.1 12.7 FD 107.7 776.9 889.1 10.0 -

[1] Faller K, Frose F H. The use of titanium in family automobiles: Current trends. JOM, 2001, 53(4): 27 doi: 10.1007/s11837-001-0143-3 [2] Nyakana S L, Fanning J C, Boyer R R. Quick reference guide for β titanium alloys in the 00s. J Mater Eng Perform, 2005, 14(6): 799 doi: 10.1361/105994905X75646 [3] Boyer R R. Attributes, characteristics, and applications of titanium and its alloys. JOM, 2010, 62(5): 21 doi: 10.1007/s11837-010-0071-1 [4] Zhou W Z. Characteristics and application of titanium as "Marine metal". World Nonferrous Met, 2014(8): 28邹武装. “海洋金属”钛的特性及应用. 世界有色金属, 2014(8): 28 [5] Xu L J, Cheng D B. Ship Ti alloy and Ti alloy powder metallurgy technology. Dev Appl Mater, 2009, 24(2): 68 doi: 10.3969/j.issn.1003-1545.2009.02.017徐鲁杰, 程德彬. 船用钛合金及钛合金粉末冶金技术. 材料开发与应用, 2009, 24(2): 68 doi: 10.3969/j.issn.1003-1545.2009.02.017 [6] Hu Y J. Developing marine titanium alloy. Titanium Ind Prog, 1998(4): 1胡耀君. 发展中的船用钛合金. 钛工业进展, 1998(4): 1 [7] Li L, Sun J K, Meng X J. Application state and prospects for titanium alloys. Titanium Ind Prog, 2004, 21(5): 19 doi: 10.3969/j.issn.1009-9964.2004.05.005李梁, 孙健科, 孟祥军. 钛合金的应用现状及发展前景. 钛工业进展, 2004, 21(5): 19 doi: 10.3969/j.issn.1009-9964.2004.05.005 [8] Du Y Q, Wang J P, Wang S H, et al. Welding procedure research of new titanium alloy Ti−6Al−3Nb−2Zr−1Mo (Ti80). Petro-Chem Equip, 2015, 44(2): 67 doi: 10.3969/j.issn.1000-7466.2015.02.015杜永勤, 王建平, 王书华, 等. 新型Ti−6Al−3Nb−2Zr−1Mo(Ti80)合金焊接工艺研究. 石油化工设备, 2015, 44(2): 67 doi: 10.3969/j.issn.1000-7466.2015.02.015 [9] Huang Y, Tang H P, Jia W P, et al. Influence of element addition ways on the performance of Ti−6Al−3Nb−2Zr−1Mo alloy. Rare Met Mater Eng, 2011, 40(12): 2227黄瑜, 汤慧萍, 贾文鹏, 等. 元素添加方式对Ti−6Al−3Nb−2Zr−1Mo合金性能的影响. 稀有金属材料与工程, 2011, 40(12): 2227 [10] Guo K, Meng K, Miao D, et al. Effect of annealing on microstructure and tensile properties of skew hot rolled Ti–6Al–3Nb–2Zr–1Mo alloy tube. Mater Sci Eng A, 2019, 766: 138346 doi: 10.1016/j.msea.2019.138346 [11] Zhao Y, He Y H, Jiang Y, et al. Research on preparation of Ti6Al4V alloy using powder metallurgy. Powder Metall Technol, 2009, 27(2): 108赵瑶, 贺跃辉, 江垚, 等. 粉末冶金Ti6Al4V合金的研究. 粉末冶金技术, 2009, 27(2): 108 [12] Zhou D D, Zeng W D, Xu J W, et al. Evolution of equiaxed and lamellar α during hot compression in a near alpha titanium alloy with bimodal microstructure. Mater Charact, 2019, 151: 103 doi: 10.1016/j.matchar.2019.03.005 [13] Dong Y, Sun X Q. Combination mechanical properties of power forged steel with median and high carbon contents. Powder Metall Technol, 1994, 12(1): 8董颐, 孙晓强. 中高碳量粉末锻造钢的综合性能. 粉末冶金技术, 1994, 12(1): 8 [14] Joane L M. Phase Diagrams of Binary Titanium Alloys. Ohio: ASM International, 1987 [15] Zhang W F, Cao C X, Li X W, et al. Effect of β heat treatment on mechanical properties of TA15 titanium alloy. Rare Met Mater Eng, 2004, 33(7): 768张旺峰, 曹春晓, 李兴无, 等. β热处理TA15钛合金对力学性能的影响规律. 稀有金属科学与工程, 2004, 33(7): 768 [16] Chen C M. Study on Composition Optimization and Microstructures and Properties of Corrosion Resistant Ti−Al−Nb−Zr−Mo Alloy [Dissertation]. Harbin: Harbin Institute of Technology, 2018陈才敏. 耐蚀Ti−Al−Nb−Zr−Mo合金的组成优化及组织性能研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2018 -

下载:

下载: