Process optimization and friction and wear properties of CoCrWMo alloys fabricated by selective laser melting

-

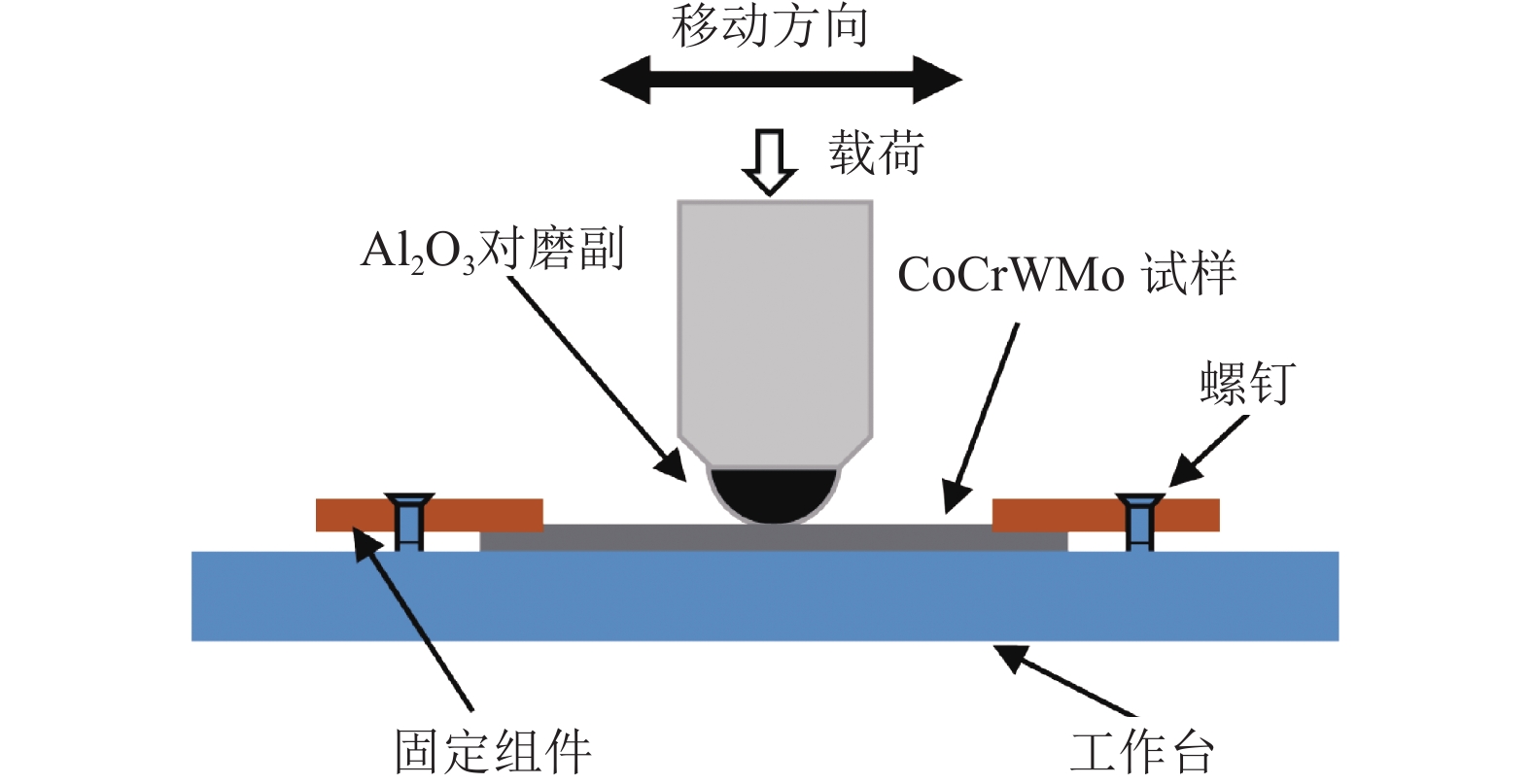

摘要: 对选择性激光熔化成形CoCrWMo合金的工艺参数进行优化,并对最佳工艺下合金试样的摩擦磨损性能进行分析。结果表明:选择性激光熔化最佳工艺参数为激光功率280 W,扫描速度800 mm·s−1,铺粉层厚0.03 mm,扫描间距0.10 mm,扫描策略为旋转扫描法(层与层之间旋转15°)。该工艺下激光体能量密度为117 J·mm−3,试样相对密度为99.4%,上表面粗糙度(Ra)为4.98 μm,显微硬度为HV 386,抗拉强度为984 MPa,屈服强度为663 MPa,断后伸长率为12.9%。在干摩擦下,CoCrWMo合金的平均摩擦系数随施加载荷的增加呈下降趋势;受磨损过程中应变诱导马氏体转变的影响,合金平均磨损率呈现先增高后降低的变化规律,主要磨损机制为磨粒磨损和粘着磨损。Abstract: Process parameters of the CoCrWMo alloys fabricated by selective laser melting (SLM) were optimized, and the friction and wear properties of the alloy samples prepared under the optimal process parameters were analyzed. The results show that, the optimal parameters of selective laser melting are as followed: the laser power is 280 W, the scanning speed is 800 mm·s−1, the layer thickness is 0.03 mm, the scanning space is 0.10 mm, and the scanning strategy is rotation method (15° rotation between adjacent layers). The laser energy density is 117 J·mm−3, the relative density of the prepared samples is 99.4%, the top surface roughness (Ra) is 4.98 μm, the microhardness is HV 386, the tensile strength is 984 MPa, the yield strength is 663 MPa, and the elongation is 12.9%. During the dry friction, the average friction coefficient of the prepared CoCrWMo alloys decreases with the increase of the applied load, while the average wear rate increases first and then decreases under the influence of the strain-induced martensite transformation during the wear process. The main wear mechanisms are abrasive wear and adhesive wear.

-

Key words:

- CoCrWMo alloys /

- selective laser melting /

- mechanical properties /

- friction /

- wear

-

图 5 不同激光体能量密度下成形试样的上表面形貌:(a)48 J·mm−3;(b)117 J·mm−3;(c)213 J·mm−3;(d)图5(a)的3D形貌;(e)图5(b)的3D形貌;(f)图5(c)的3D形貌

Figure 5. Top surface morphology of the CoCrWMo specimens prepared by SLM with different laser energy density: (a) 48 J·mm−3; (b) 117 J·mm−3; (c) 213 J·mm−3; (d) the corresponding 3D morphology of Fig.5(a); (e) the corresponding 3D morphology of Fig.5(b); (f) the corresponding 3D morphology of Fig.5(c)

表 1 CoCrWMo合金粉末化学成分(质量分数)

Table 1. Chemical composition of the CoCrWMo alloy powders

% Cr W Mo Si Co 24.12 5.45 4.95 0.92 余量 表 2 选择性激光熔化成形实验参数

Table 2. Experiment parameters of SLM manufacturing

激光功率 / W 扫描速度 / (mm·s−1) 铺粉层厚 / mm 扫描间距 / mm 旋转角度 / (°) 160、200、240、280、320 500、650、800、950、1100 0.03 0.1 15 -

[1] Toh W Q, Tan X P, Bhowmik A, et al. Tribochemical characterization and tribocorrosive behavior of CoCrMo alloys: A review. Materials, 2017, 11(1): 30 doi: 10.3390/ma11010030 [2] Liao Y F, Hoffman E, Wimmer M, et al. CoCrMo metal-on-metal hip replacements. Phys Chem Chem Phys, 2013, 15(3): 746 doi: 10.1039/C2CP42968C [3] Parkar M, Chavan C. New generation bare metal stents with hybrid cell design and thin struts are safe and effective in treatment of coronary artery stenosis: real world data analysis of Protea CoCr stent. Indian Heart J, 2018, 70(Suppl2): s69 [4] Ni X Q, Kong D C, Wen Y, et al. Influence factors and improvement methods on the porosity of 3D printing metal materials. Powder Metall Technol, 2019, 37(3): 163倪晓晴, 孔德成, 温莹, 等. 3D打印金属材料中孔隙率的影响因素和改善方法. 粉末冶金技术, 2019, 37(3): 163 [5] Harun W S W, Kamariah M S I N, Muhamad N, et al. A review of powder additive manufacturing processes for metallic biomaterials. Powder Technol, 2018, 327: 128 doi: 10.1016/j.powtec.2017.12.058 [6] Zhang G X, Liu S F, Yang X, et al. Research progress on preparation of biological implant materials by additive manufacturing. Powder Metall Technol, 2019, 37(4): 312张光曦, 刘世锋, 杨鑫, 等. 增材制造技术制备生物植入材料的研究进展. 粉末冶金技术, 2019, 37(4): 312 [7] Posada O M, Tate R J, Grant M H. Effects of CoCr metal wear debris generated from metal-on-metal hip implants and Co ions on human monocyte-like U937 cells. Toxicol in Vitro, 2015, 29(2): 271 doi: 10.1016/j.tiv.2014.11.006 [8] Wang S, Liao Z H, Feng P F, et al. Research progress on biotribocorrosion of metal material in orthopedic implants. Tribology, 2017, 37(1): 130王松, 廖振华, 冯平法, 等. 骨科植入物金属材料生物摩擦腐蚀研究进展. 摩擦学学报, 2017, 37(1): 130 [9] Radice S, Holcomb T, Pourzal R, et al. Investigation of CoCrMo material loss in a novel bio-tribometer designed to study direct cell reaction to wear and corrosion products. Biotribology, 2019, 18: 100090 doi: 10.1016/j.biotri.2019.100090 [10] Liverani E, Fortunato A, Leardini A, et al. Fabrication of Co–Cr–Mo endoprosthetic ankle devices by means of selective laser melting (SLM). Mater Des, 2016, 106: 60 doi: 10.1016/j.matdes.2016.05.083 [11] Liverani E, Balbo A, Monticelli C, et al. Corrosion resistance and mechanical characterization of ankle prostheses fabricated via selective laser melting. Procedia CIRP, 2017, 65: 25 doi: 10.1016/j.procir.2017.04.037 [12] Lin H, Yang Y Q, Zhang G Q, et al. Tribological performance of medical CoCrMo alloy fabricated by selective laser melting. Acta Opt Sin, 2016, 36(11): 1114003 doi: 10.3788/AOS201636.1114003林辉, 杨永强, 张国庆, 等. 激光选区熔化医用钴铬钼合金的摩擦性能. 光学学报, 2016, 36(11): 1114003 doi: 10.3788/AOS201636.1114003 [13] Zhang M K, Yang Y Q, Song C H, et al. An investigation into the aging behavior of CoCrMo alloys fabricated by selective laser melting. J Alloys Compd, 2018, 750: 878 doi: 10.1016/j.jallcom.2018.04.054 [14] Zhang H. Process Optimization and Microstructure Analysis of Selective Laser Melting CoCrW Alloy [Dissertation]. Taiyuan: North University of China, 2018张浩. 选区激光熔化CoCrW合金工艺优化和微观组织分析[学位论文]. 太原: 中北大学, 2018 [15] Li C Q. Study on The Microstructure and Properties of CoCrMo Alloys Fabricated by Selective Laser Melting [Dissertation]. Xi'an: Xi'an University of Technology, 2019李翠芹. 选区激光熔化成型CoCrMo合金的组织与性能研究[学位论文]. 西安: 西安理工大学, 2019 [16] Yan X C, Huang C J, Chen C Y, et al. Additive manufacturing of WC reinforced maraging steel 300 composites by cold spraying and selective laser melting. Surf Coat Technol, 2019, 371: 161 doi: 10.1016/j.surfcoat.2018.03.072 [17] Martinez-Nogues V, Nesbitt J M, Wood R J K, et al. Nano-scale wear characterization of CoCrMo biomedical alloys. Tribol Int, 2016, 93: 563 doi: 10.1016/j.triboint.2015.03.037 [18] Lashgari H R, Zangeneh S, Ketabchi M. Isothermal aging effect on the microstructure and dry sliding wear behavior of Co–28Cr–5Mo–0. 3C alloy. J Mater Sci, 2011, 46(22): 7262 [19] Salinas-Rodriguez A, Rodriguez-Galicia J L. Deformation behavior of low-carbon Co–Cr–Mo alloys for low-friction implant applications. J Biomed Mater Res, 1996, 31(3): 409 doi: 10.1002/(SICI)1097-4636(199607)31:3<409::AID-JBM16>3.0.CO;2-D [20] Zhu Z Y, Meng L, Chen L. Strain-induced martensitic transformation in biomedical Co–Cr–W–Ni alloys. Rare Met, 2020, 39(3): 241 doi: 10.1007/s12598-019-01364-6 [21] Koizumi Y, Suzuki S, Yamanaka K, et al. Strain-induced martensitic transformation near twin boundaries in a biomedical Co–Cr–Mo alloy with negative stacking fault energy. Acta Mater, 2013, 61(5): 1648 doi: 10.1016/j.actamat.2012.11.041 [22] Mori M, Yamanaka K, Matsumoto H, et al. Evolution of cold-rolled microstructures of biomedical Co–Cr–Mo alloys with and without N doping. Mater Sci Eng A, 2010, 528(2): 614 doi: 10.1016/j.msea.2010.09.002 [23] Balagna C, Spriano S, Faga M G. Characterization of Co–Cr–Mo alloys after a thermal treatment for high wear resistance. Mater Sci Eng C, 2012, 32(7): 1868 doi: 10.1016/j.msec.2012.05.003 -

下载:

下载: