Preparation and properties of TiB2/AlSi10Mg composite powders used for selective laser melting

-

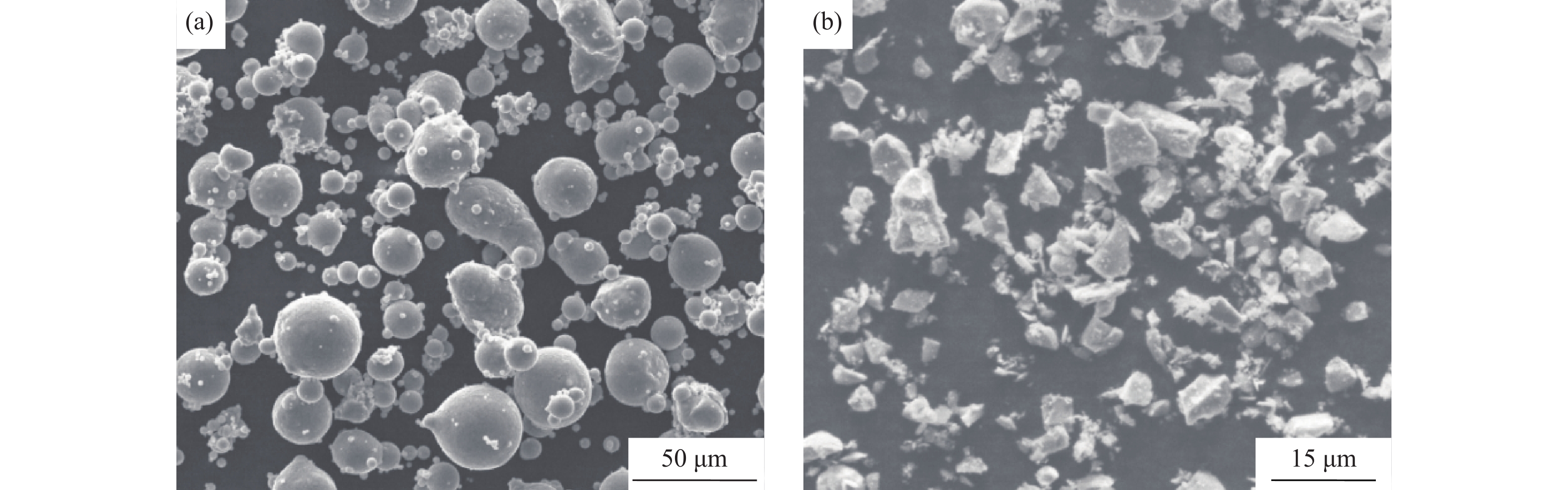

摘要: 以气雾化AlSi10Mg粉和高纯TiB2粉为原料,采用高能球磨和等离子球化技术制备选区激光熔化用TiB2/AlSi10Mg复合粉体,使用X射线衍射仪、扫描电子显微镜、透射电子显微镜、激光粒度仪和紫外可见光分光光度计等对等离子球化前后TiB2/AlSi10Mg复合粉体组织结构和性能进行表征。结果表明:经等离子球化后的TiB2/AlSi10Mg复合粉体具有优异的球形度,粒径分布均匀。此外,部分TiB2与Al之间发生了化学反应生成Al3Ti相,获得冶金结合界面,提高了界面结合强度。该复合粉体具有近似于TiB2包覆AlSi10Mg的核壳结构,改善了铝合金粉末的激光吸收率,由23.2%(AlSi10Mg)增加至42.1%(TiB2/AlSi10Mg)。Abstract: TiB2/AlSi10Mg composite powders used for selective laser melting were prepared by high-energy ball milling and plasma spheroidization, using the AlSi10Mg powders and high purity TiB2 powders as the raw materials prepared by gas atomization. The microstructure and properties of TiB2/AlSi10Mg composite powders before and after plasma spheroidization were characterized by X-ray diffraction (XRD), scanning electron microscope (SEM), transmission electron microscope (TEM), laser particle size analyzer, and UV-visible spectrophotometer. The results show that the plasma spheroidization TiB2/AlSi10Mg composite powders have the excellent sphericity and the uniform particle size distribution. Moreover, the chemical reactions between TiB2 and Al may form the Al3Ti phases, which can obtain the metallurgical bonding interface and improve the bonding strength. The core-shell structure of the composite powders is similar to that of TiB2 coated with AlSi10Mg. The laser absorption rate of the powders is improved from 23.2% (AlSi10Mg) to 42.1% (TiB2/AlSi10Mg).

-

Key words:

- TiB2 /

- AlSi10Mg /

- composite powders /

- plasma spheroidization /

- selective laser melting

-

表 1 等离子体球化工艺参数

Table 1. Process parameters of the plasma spheroidization

功率 / kW 送粉器转速 / (r·min−1) 粉体流速 / (g·min−1) 鞘气(Ar/H2)/ (L·min−1) 中心气Ar / (L·min−1) 载气Ar / (L·min−1) 30 15 20 55/15 15 3 -

[1] Pandey U, Purohit R, Agarwal P, et al. Effect of TiC particles on the mechanical properties of aluminium alloy metal matrix composites (MMCs). Mater Today, 2017, 4: 5452 doi: 10.1016/j.matpr.2017.05.057 [2] Wang Y H, Hu Q, Zhang J H, et al. Influencing factors on the tensile properties of selective laser melting 3D printing AlSi10Mg. Powder Metall Technol, 2022, 40(2): 152王永慧, 胡强, 张金辉, 等. 激光选区熔化3D打印AlSi10Mg拉伸性能影响因素. 粉末冶金技术, 2022, 40(2): 152 [3] Balcı Ö, Ağaoğulları D, Gökçe H, et al. Influence of TiB2 particle size on the microstructure and properties of Al matrix composites prepared via mechanical alloying and pressureless sintering. J Alloys Compd, 2014, 586: S78 doi: 10.1016/j.jallcom.2013.03.007 [4] Wei K W, Wang Z M, Zeng X Y. Preliminary investigation on selective laser melting of Ti–5Al–2.5Sn α-Ti alloy: From single tracks to bulk 3D components. J Mater Process Technol, 2017, 244: 73 [5] Li H, Ramezani M, Chen Z, et al. Effects of process parameters on temperature and stress distributions during selective laser melting of Ti–6Al–4V. Trans Indian Inst Met, 2019, 72: 3201 doi: 10.1007/s12666-019-01785-y [6] Sun Y, Bailey R, Moroz A. Surface finish and properties enhancement of selective laser melted 316L stainless steel by surface mechanical attrition treatment. Surface Coat Technol, 2019, 378: 124993 doi: 10.1016/j.surfcoat.2019.124993 [7] Huang M J, Zhang Z X, Chen P. Effect of selective laser melting process parameters on microstructure and mechanical properties of 316L stainless steel helical micro-diameter spring. Int J Adv Manuf Technol, 2019, 104: 2117 doi: 10.1007/s00170-019-03928-3 [8] Salman O O, Brenne F, Niendorf T, et al. Impact of the scanning strategy on the mechanical behavior of 316L steel synthesized by selective laser melting. J Manuf Proc, 2019, 45: 255 doi: 10.1016/j.jmapro.2019.07.010 [9] Wu L Z, Wen Y J, Zhang B C, et al. Research status of selective laser melting aluminum alloys. Powder Metall Technology, 2021, 39(6): 549 doi: 10.19591/j.cnki.cn11-1974/tf.2020040004吴灵芝, 温耀杰, 张百成, 等. 选区激光熔化铝合金制备研究现状. 粉末冶金技术, 2021, 39(6): 549 doi: 10.19591/j.cnki.cn11-1974/tf.2020040004 [10] Sun S Y, Liu P, Hu J Y, et al. Effect of solid solution plus double aging on microstructural characterization of 7075 Al alloys fabricated by selective laser melting (SLM). Opt Laser Technol, 2019, 114: 158 doi: 10.1016/j.optlastec.2019.02.006 [11] Dai D H, Gu D D, Xia M J, et al. Melt spreading behavior, microstructure evolution and wear resistance of selective laser melting additive manufactured AlN/AlSi10Mg nanocomposite. Surf Coat Technol, 2018, 349: 279 doi: 10.1016/j.surfcoat.2018.05.072 [12] Xiong Z H, Liu S L, Li S F, et al. Role of melt pool boundary condition in determining the mechanical properties of selective laser melting AlSi10Mg alloy. Mater Sci Eng:A, 2019, 740-741: 148 doi: 10.1016/j.msea.2018.10.083 [13] Gu X H, Zhang J X, Fan X L, et al. Abnormal corrosion behavior of selective laser melted AlSi10Mg alloy induced by heat treatment at 300 ℃. J Alloys Compd, 2019, 803: 314 doi: 10.1016/j.jallcom.2019.06.274 [14] Yu T Y, Hyer H, Sohn Y, et al. Structure-property relationship in high strength and lightweight AlSi10Mg microlattices fabricated by selective laser melting. Mater Des, 2019, 182: 108062 doi: 10.1016/j.matdes.2019.108062 [15] Teng X, Zhang G X, Zhao Y G, et al. Study on magnetic abrasive finishing of AlSi10Mg alloy prepared by selective laser melting. Int J Adv Manuf Technol, 2019, 105: 2513 doi: 10.1007/s00170-019-04485-5 [16] Zhang J L, Song B, Wei Q S, et al. A review of selective laser melting of aluminum alloys: processing, microstructure, property and developing trends. J Mater Sci Technol, 2019, 35: 270 doi: 10.1016/j.jmst.2018.09.004 [17] Aboulkhair N T, Maskery I, Tuck C, et al. On the formation of AlSi10Mg single tracks and layers in selective laser melting: microstructure and nano-mechanical properties. J Mater Process Technol, 2016, 230: 88 doi: 10.1016/j.jmatprotec.2015.11.016 [18] Prashanth K G, Scudino S, Klauss H J, et al. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: effect of heat treatment. Mater Sci Eng: A, 2014, 590: 153 doi: 10.1016/j.msea.2013.10.023 [19] Yuan P P, Gu D D. Molten pool behaviour and its physical mechanism during selective laser melting of TiC/AlSi10Mg nanocomposites: simulation and experiments. J Phys D: Appl Phys, 2015, 48: 0353033 [20] Wang X J, Wang X C, Yi X B, et al. Impact of powder characteristics on formation properties of selective laser melted Al–Si alloy. Shandong Sci, 2016, 29(2): 30 doi: 10.3976/j.issn.1002-4026.2016.02.007王小军, 王修春, 伊希斌, 等. 粉体特征对选区激光熔化Al–Si合金成型性能的影响. 山东科学, 2016, 29(2): 30 doi: 10.3976/j.issn.1002-4026.2016.02.007 [21] Liang J M, Wang L M, He W, et al. Effect of milling time on microstructures and hardness of nanocrystalline Al–7Si–0.3Mg alloy powders. Powder Metall Technol, 2019, 37(5): 373梁加淼, 王利民, 何卫, 等. 球磨时间对纳米晶Al–7Si–0.3Mg合金粉末微观组织及硬度的影响. 粉末冶金技术, 2019, 37(5): 373 [22] Zou K, Deng C M, Liu M, et al. Research spray granulation and plasma spraying deposition mechanism of TiB2–TiC powders. Rare Met Mater Eng, 2019, 48(1): 213邹柯, 邓春明, 刘敏, 等. TiB2–SiC粉末喷雾造粒及其等离子喷涂沉积机理研究. 稀有金属材料与工程, 2019, 48(1): 213 [23] Zou Y M, Wu Y S, Wang J Z, et al. Preparation, mechanical properties and cyclic oxidation behavior of the nanostructured NiCrCoAlY–TiB2 coating. Ceram Int, 2018, 44(16): 19362 doi: 10.1016/j.ceramint.2018.07.165 [24] Li X P, Ji G, Chen Z, et al. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater, 2017, 129: 183 doi: 10.1016/j.actamat.2017.02.062 [25] Kumar N, Gautam G, Gautam R K, et al. Synthesis and characterization of TiB2 reinforced aluminium matrix composites: a review. J Inst Eng (India): Series D, 2016, 97: 233 doi: 10.1007/s40033-015-0091-7 [26] Alfaify A Y, Hughes J, Ridgway K. Critical evaluation of the pulsed selective laser melting process when fabricating Ti64 parts using a range of particle size distributions. Add Manuf, 2018, 19: 197 [27] Rohit T, Kurian A, Senthilkumaran K, et al. Studies on absorptivity and marangoni flow during laser sintering. Adv Mater Res, 2012, 622-623: 531 doi: 10.4028/www.scientific.net/AMR.622-623.531 -

下载:

下载: