Effect of Cu‒Fe pre-alloyed powders on the friction and wear properties of Cu-based friction materials

-

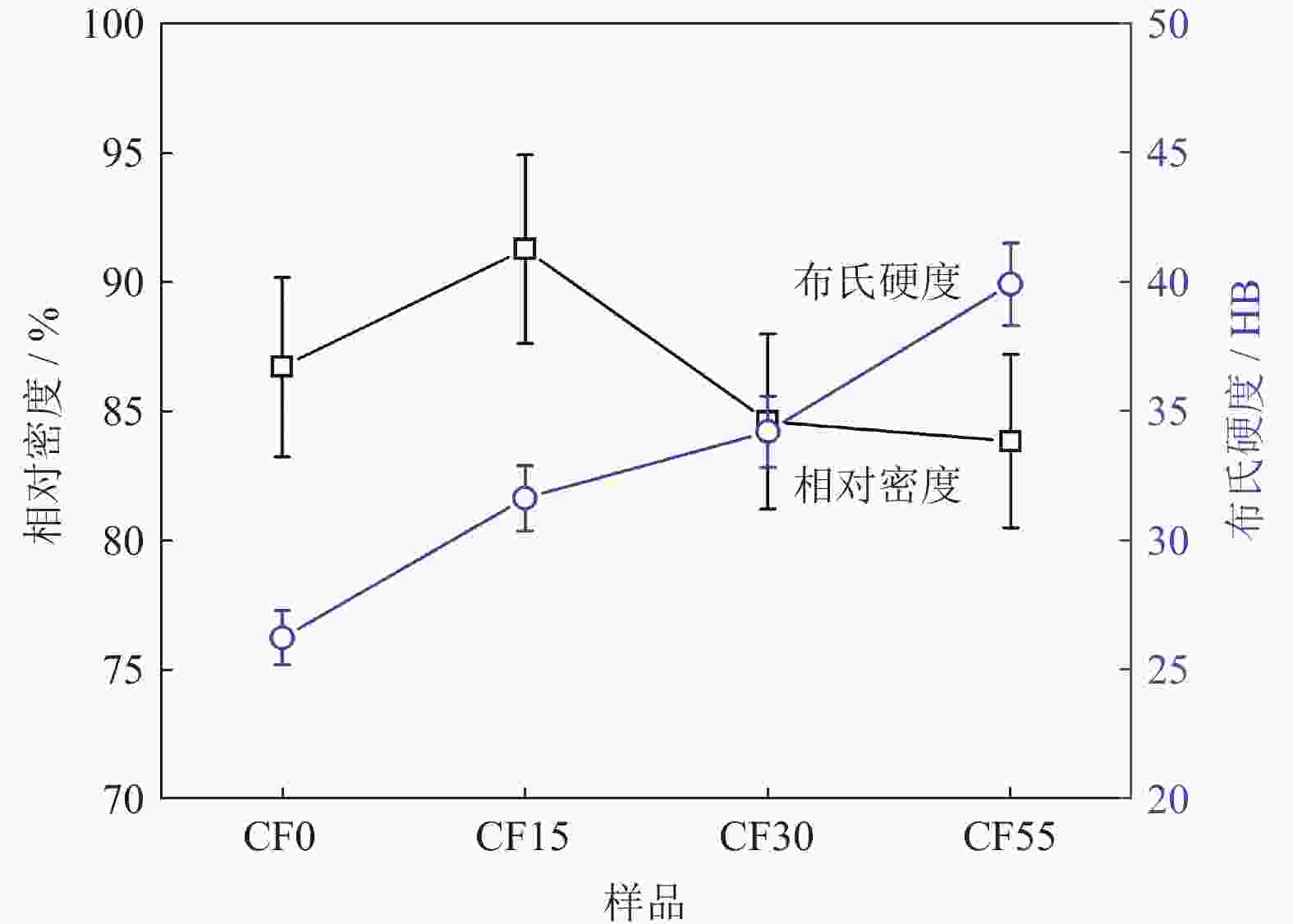

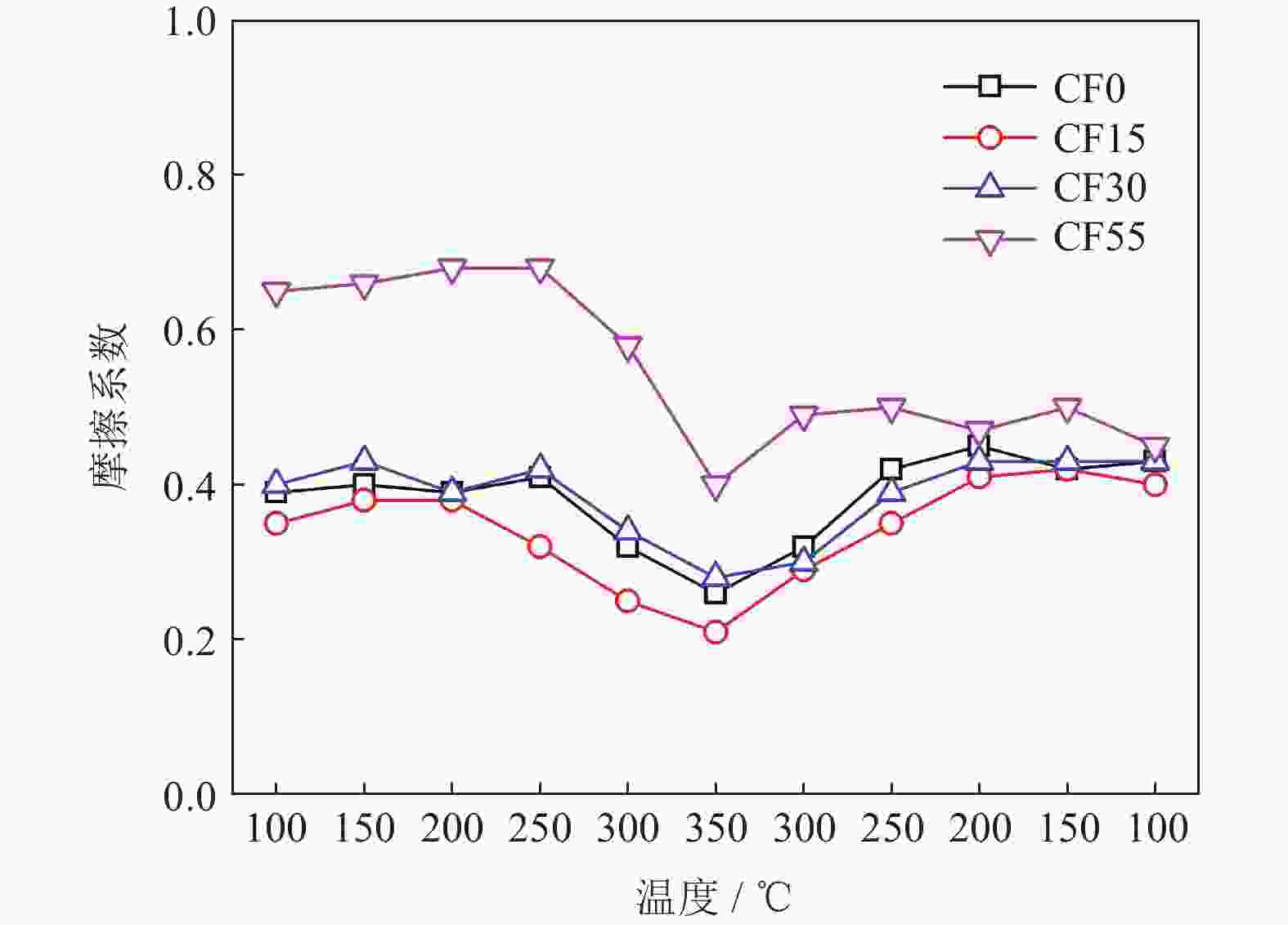

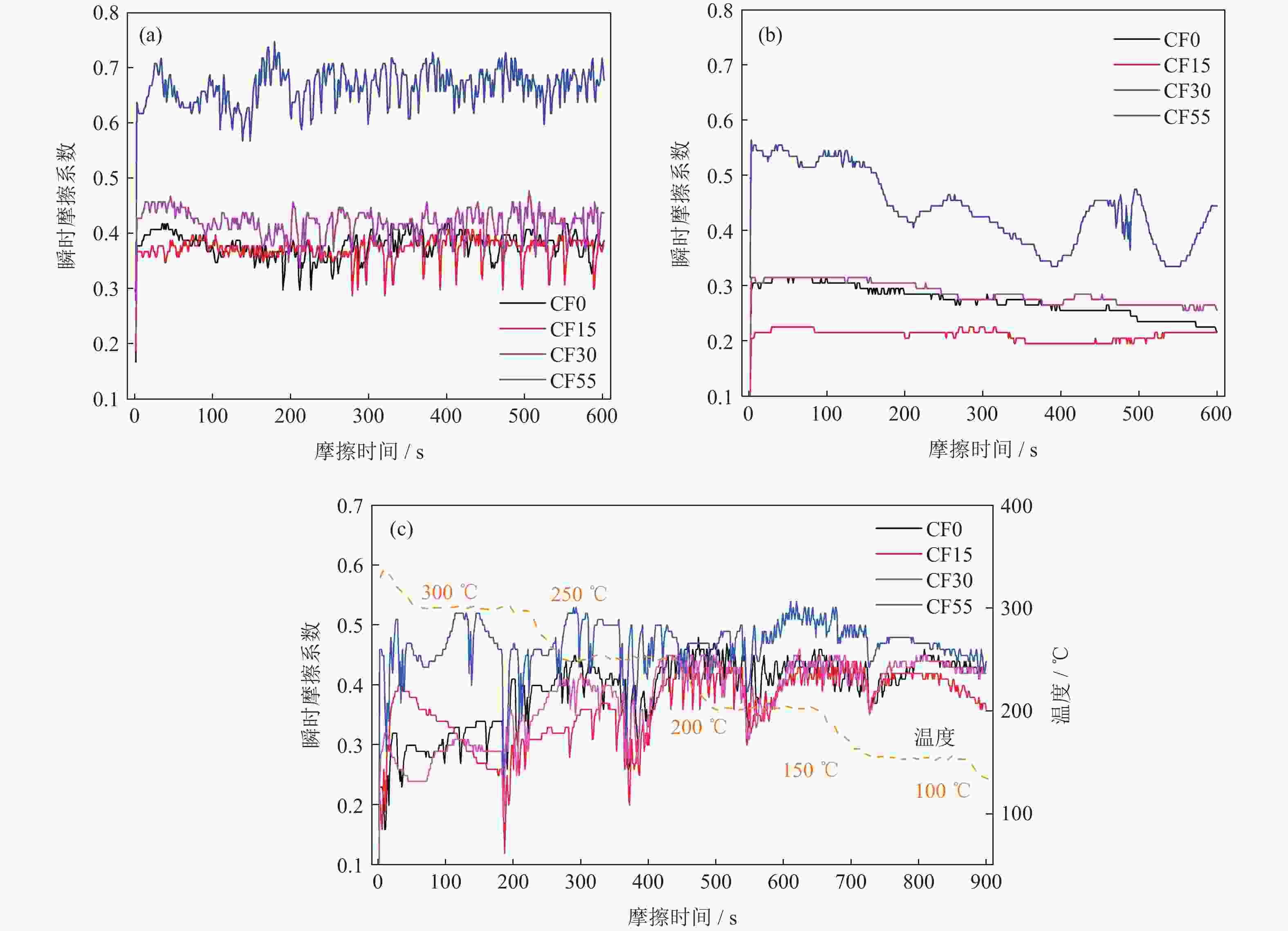

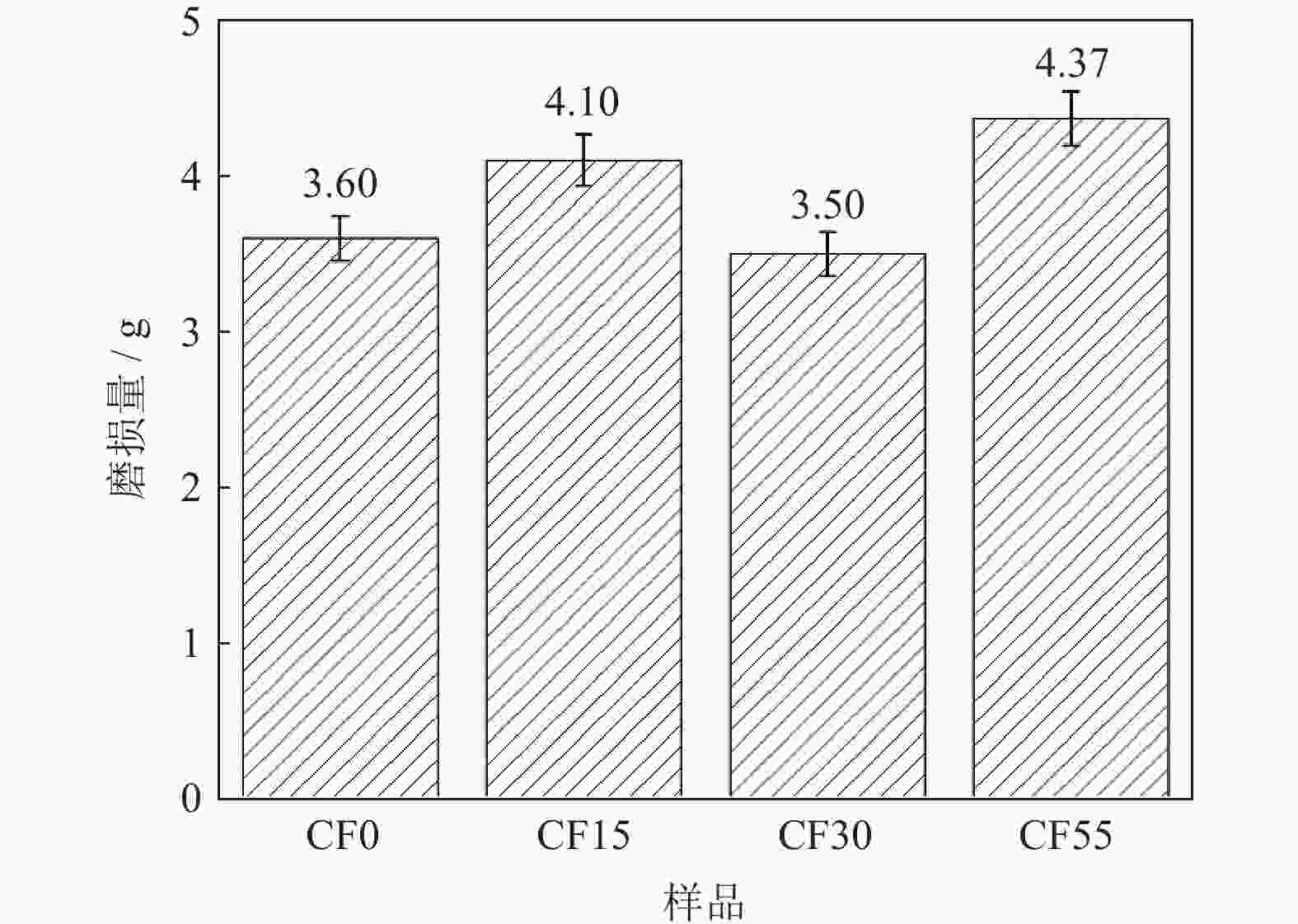

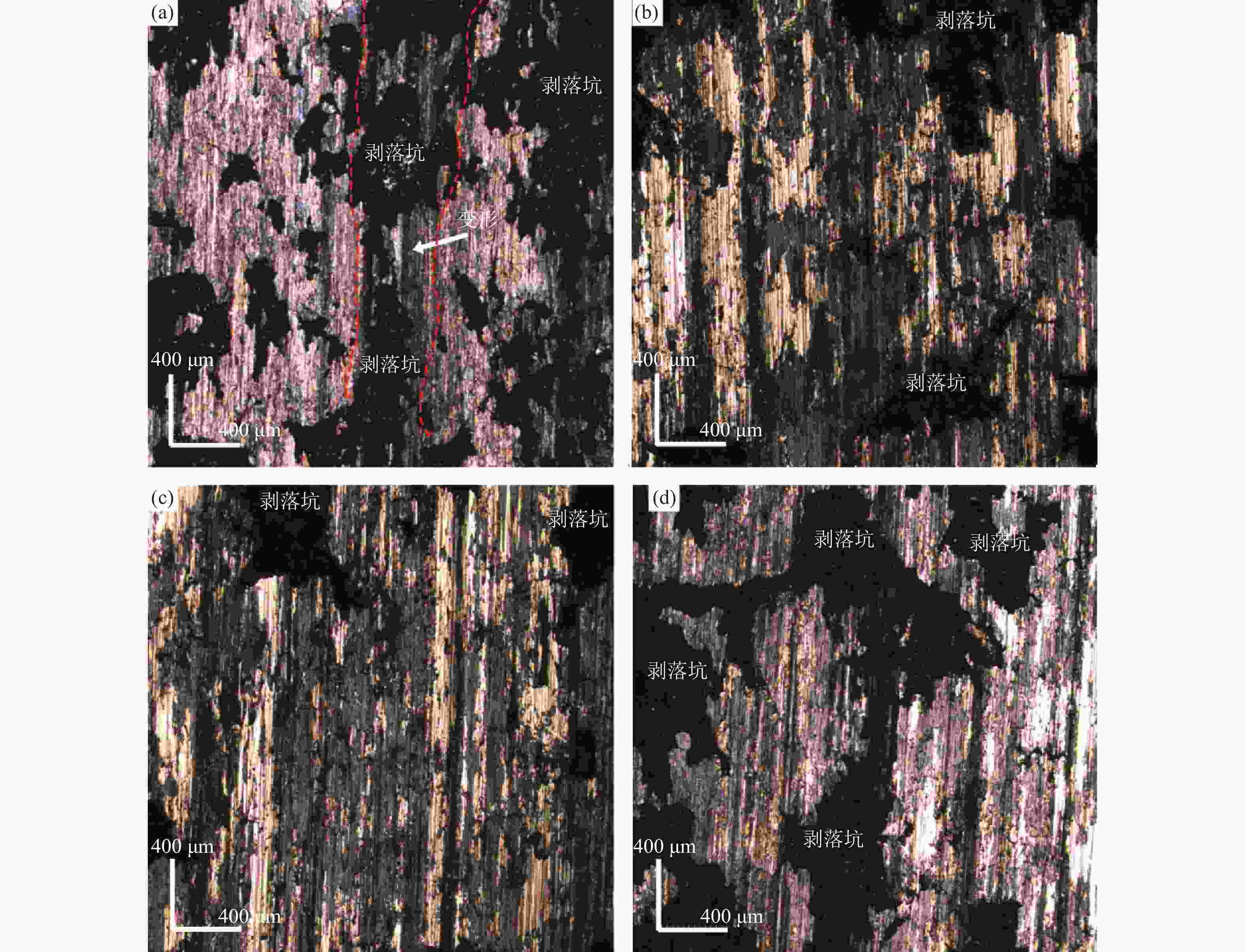

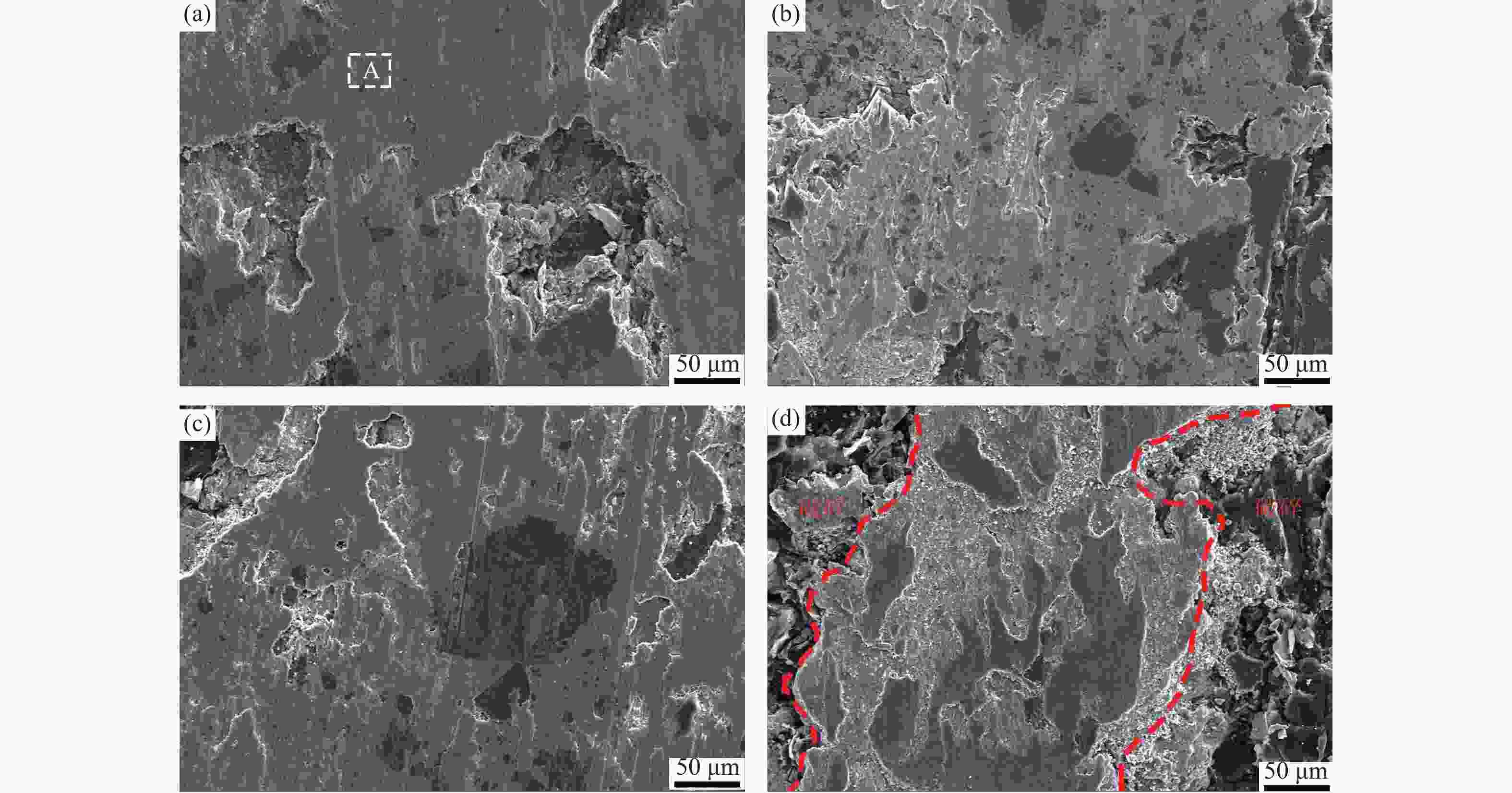

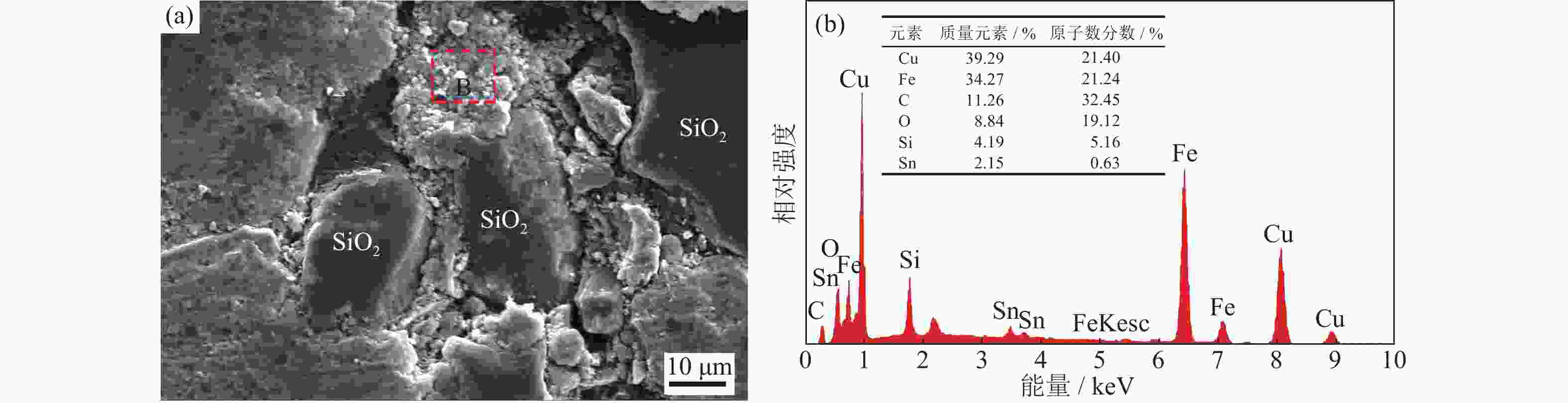

摘要: 利用粉末冶金方法制备了含不同质量分数铜铁预合金粉末的铜基摩擦材料,并在不同温度下对材料摩擦性能进行测试。结果表明:铜铁预合金粉末的引入使得铁元素在烧结后铜基体中及铜基体与其他组元界面处析出,阻碍了烧结,导致材料密度下降。存在于界面处的铁以及反应生成的珠光体成为硬质强化相,使得材料的磨损机理从纯铜基体时的黏着磨损向添加铜铁预合金粉末之后的磨粒磨损转变,导致摩擦系数先下降后上升。200~250 ℃为摩擦系数保持稳定的临界温度。当超过临界温度时,摩擦表面铜软化,其自润滑作用使得摩擦系数下降。含30%铜铁预合金粉末的铜基摩擦材料(质量分数)的摩擦磨损性能最佳,这是由于此时摩擦材料兼具铜良好的塑性以及生成的适量硬质相能够强化摩擦表面。Abstract: Copper-based friction materials containing the Cu‒Fe pre-alloyed powders in different mass fraction were prepared by powder metallurgy method, and the friction properties were tested at different temperatures. The results show that, with the introduction of the Cu‒Fe pre-alloyed powders, the iron participates in the copper matrix and the interface between copper matrix and other components, which hinders the sintering process and reduces the density. The formed pearlite and the participated iron at the interface act as the hard-strengthening phase, which changes the wear mechanism from the adhesive wear of the pure copper matrix to the abrasive wear after adding the Cu‒Fe pre-alloyed powders, resulting in the reduction of friction coefficient at first and then rising. The critical temperature is 200~250 ℃ for maintaining the stable friction coefficient. When the temperature exceeds the critical temperature, the copper on the friction surface softens and its self-lubricating effect leads to the decrease of friction coefficient. 30% Cu‒Fe pre-alloyed powders by mass is the optimum content for the copper-based friction materials, and the copper-based friction materials have the good plasticity of copper and the appropriate amount of the hard phases to strengthen the friction surface.

-

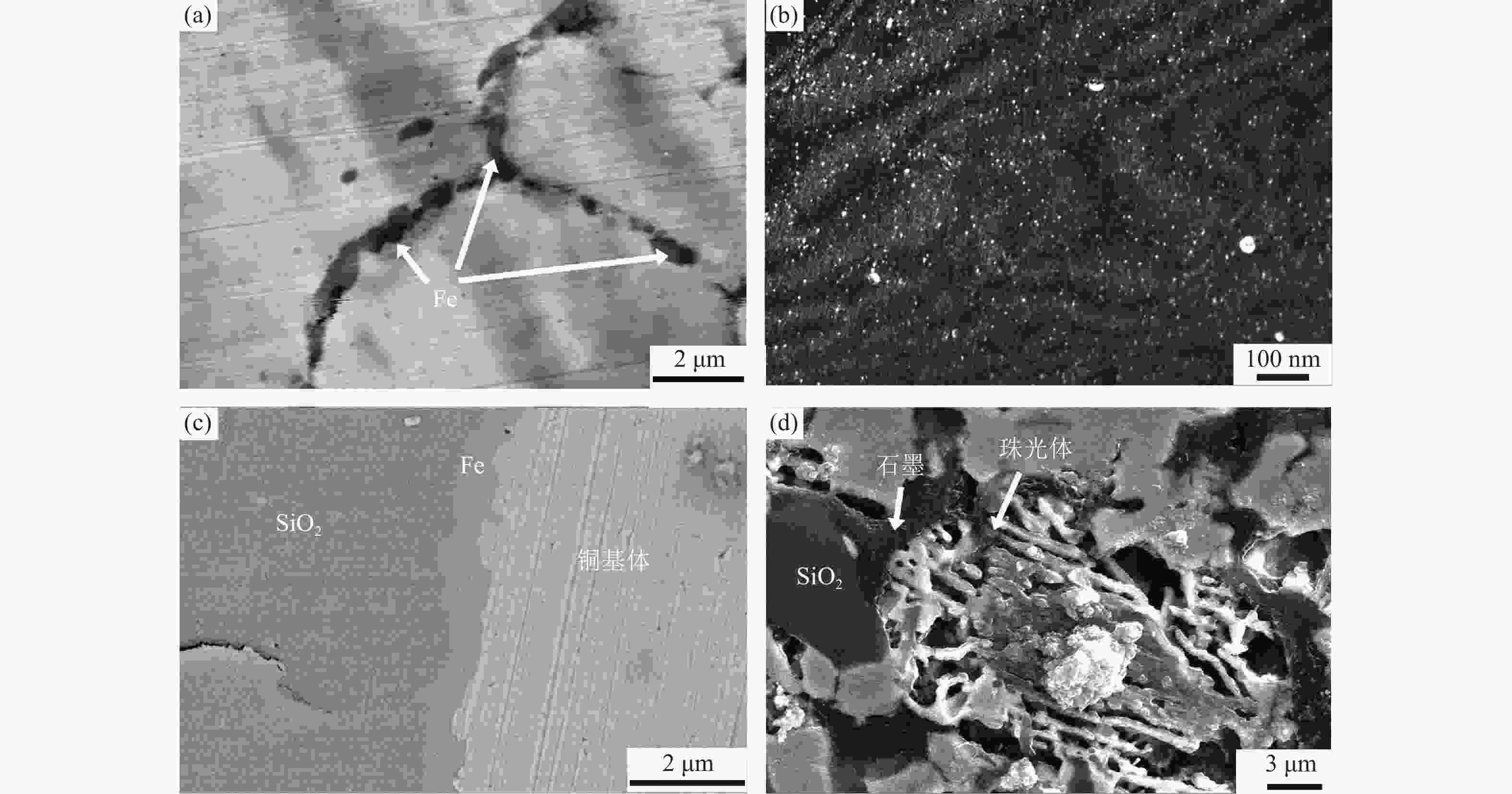

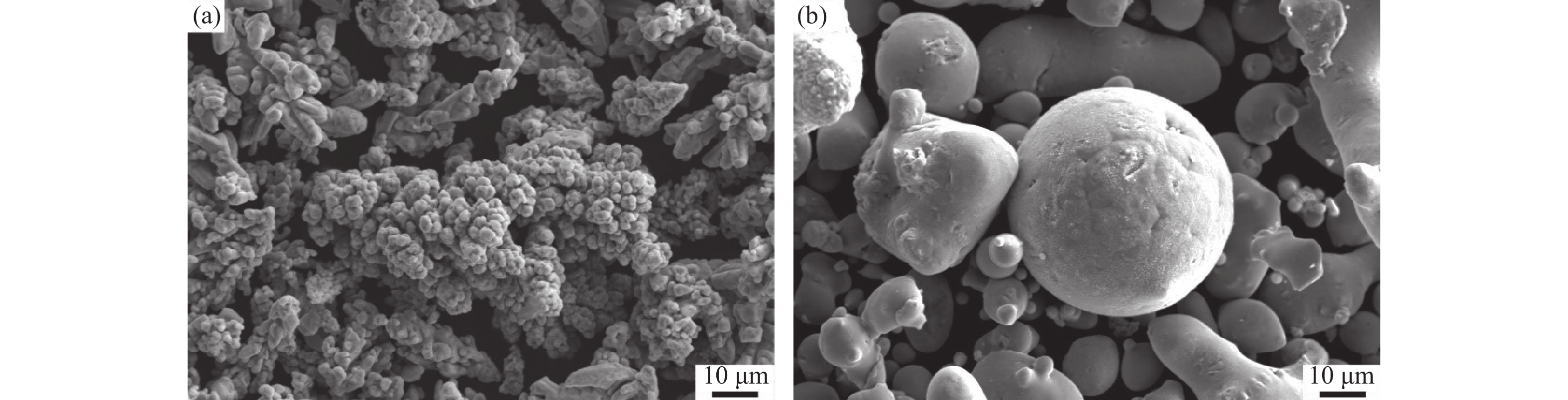

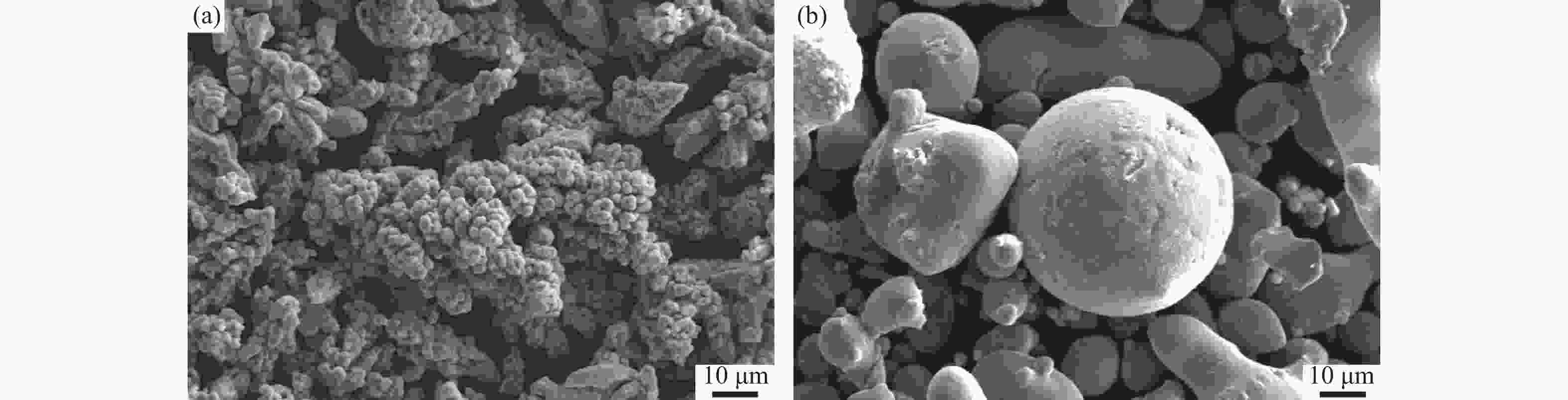

图 3 铜铁预合金粉末基体和CF55试样中铁元素的析出:(a)铜铁预合金粉末基体烧结残留界面上铁元素的析出形貌;(b)透射电镜暗场像下铜铁预合金粉末基体中弥散析出的富铁颗粒;(c)CF55试样中铁沿铜基体‒SiO2界面析出;(d)CF55试样中铁元素以珠光体的形式沿铜基体-石墨界面析出

Figure 3. Iron precipitation in the Cu‒Fe pre-alloyed powder matrix and the sample CF55: (a) precipitation image of Fe element in the residual interface of the Cu‒Fe pre-alloyed powder matrix during sintering; (b) dispersive precipitation of the iron-rich particles in Cu‒Fe pre-alloyed powder matrix in the TEM dark field image; (c) precipitation image of Fe element along the Cu‒SiO2 interface of the sample CF55; (d) precipitation image of Fe element as pearlite along the Cu‒graphite interface of the sample CF55

表 1 铜基摩擦材料化学成分(质量分数)

Table 1. Chemical composition of the prepared copper-basedfriction materials

% 试样编号 Cu Cu‒Fe Sn 石墨 SiO2 莫来石 Fe 余量 CF0 55 0 5 14 5 9 7 5 CF15 36 20 5 14 5 9 6 5 CF30 26.5 30 5 14 5 9 5.5 5 CF55 2.75 55 5 14 5 9 4.25 5 表 2 图8(a)中A区域能谱分析(原子数分数)

Table 2. Energy spectrum analysis of area A in Fig.8(a)

% O Cu Fe Al Si Sn Ni 29.34 34.14 23.94 2.68 4.69 1.61 3.59 -

[1] Xiao Y L, Zhang Z Y, Yao P P, et al. Mechanical and tribological behaviors of copper metal matrix composites for brake pads used in high-speed trains. Tribol Int, 2018, 119: 585 doi: 10.1016/j.triboint.2017.11.038 [2] Zhang X, Zhang Y, Du S, et al. Influence of braking conditions on tribological performance of copper-based powder metallurgical braking material. J Mater Eng Perform, 2018, 27(9): 4473 doi: 10.1007/s11665-018-3537-x [3] Ren S X, Chen W G, Feng T, et al. Microstructure and properties of carbon fiber reinforced Fe‒Cu based friction materials prepared by powder metallurgy. Powder Metall Technol, 2020, 38(2): 104任澍忻, 陈文革, 冯涛, 等. 粉末冶金制备碳纤维增强铁铜基摩擦材料的组织与性能. 粉末冶金技术, 2020, 38(2): 104 [4] Wang Y, Yan Q Z, Zhang X L, et al. Effect of copper powders on properties of Cu-based friction material. Chin J Mater Res, 2013, 27(1): 37王晔, 燕青芝, 张肖路, 等. 铜粉对铜基摩擦材料性能的影响. 材料研究学报, 2013, 27(1): 37 [5] Huang B Y, Li C G, Shi L K, et al. China Materials Engineering Canon. 1st Ed. Beijing: Chemical Industry Press, 2005黄伯云, 李成功, 石力开, 等. 中国材料工程大典. 1版. 北京: 化学工业出版社, 2005 [6] Han M, Du J H, Ning K Y, et al. Effect of temperature distribution on pitting damage of copper-based friction material. Powder Metall Technol, 2019, 37(1): 18韩明, 杜建华, 宁克焱, 等. 温度分布对铜基摩擦材料点蚀损伤的影响. 粉末冶金技术, 2019, 37(1): 18 [7] Li C, Feng X M, Shen Y F, et al. Preparation of Al2O3/TiO2 particle-reinforced copper through plasma spraying and friction stir processing. Mater Des, 2016, 90: 922 doi: 10.1016/j.matdes.2015.11.047 [8] Bagheri G A. The effect of reinforcement percentages on properties of copper matrix composites reinforced with TiC particles. J Alloys Compd, 2016, 676: 120 doi: 10.1016/j.jallcom.2016.03.085 [9] Zhao X, Guo L C, Zhang L, et al. Influence of nano-Al2O3-reinforced oxide-dispersion-strengthened Cu on the mechanical and tribological properties of Cu-based composites. Int J Miner Metall Mater, 2016, 23(12): 1444 doi: 10.1007/s12613-016-1368-z [10] Wang Y, Zhang L, Xiao J K, et al. The tribo-corrosion behavior of Cu-9 wt% Ni-6 wt% Sn alloy. Tribol Int, 2016, 94: 260 doi: 10.1016/j.triboint.2015.06.031 [11] Jin K J, Qiao Z H, Zhu S Y, et al. Friction and wear properties and mechanism of bronze–Cr–Ag composites under dry-sliding conditions. Tribol Int, 2016, 96: 132 doi: 10.1016/j.triboint.2015.12.031 [12] Jin K J, Qiao Z H, Zhu S Y, et al. Synthesis effects of Cr and Ag on the tribological properties of Cu–9Al–5Ni–4Fe–Mn bronze under seawater condition. Tribol Int, 2016, 101: 69 doi: 10.1016/j.triboint.2016.04.012 [13] Yao P P, Xiong X, Li S P, et al. Friction and wear behavior and mechanism of Fe and SiO2 in Cu-based P/M friction material. Tribology, 2006, 26(5): 478 doi: 10.3321/j.issn:1004-0595.2006.05.017姚萍屏, 熊翔, 李世鹏, 等. Fe及SiO2对铜基刹车材料摩擦磨损性能的影响机制. 摩擦学学报, 2006, 26(5): 478 doi: 10.3321/j.issn:1004-0595.2006.05.017 [14] Zhong Z G, Deng H J, Li M, et al. Effects of Fe content on friction and wear properties of Cu-ceramet friction materials. J Mater Eng, 2002(8): 17 doi: 10.3969/j.issn.1001-4381.2002.08.005钟志刚, 邓海金, 李明, 等. Fe含量对Cu基金属陶瓷摩擦材料摩擦磨损性能的影响. 材料工程, 2002(8): 17 doi: 10.3969/j.issn.1001-4381.2002.08.005 [15] Federici M, Gialanella S, Leonardi M, et al. A preliminary investigation on the use of the pin-on-disc test to simulate off-brake friction and wear characteristics of friction materials. Wear, 2018, 410–411: 202 [16] Xiong X, Chen J, Yao P P, et al. Friction and wear behaviors and mechanisms of Fe and SiO2 in Cu-based P/M friction materials. Wear, 2007, 262(9–10): 1182 [17] Peng T, Yan Q Z, Li G, et al. The influence of Cu/Fe ratio on the tribological behavior of brake friction materials. Tribol Lett, 2018, 66: 18 doi: 10.1007/s11249-017-0961-2 [18] Zhang P, Zhang L, Fu K X, et al. Fade behaviour of copper-based brake pad during cyclic emergency braking at high speed and overload condition. Wear, 2019, 428–429: 10 [19] Su L L, Gao F, Han X M, et al. Effect of copper powder third body on tribological property of copper-based friction materials. Tribol Int, 2015, 90: 420 doi: 10.1016/j.triboint.2015.05.003 -

下载:

下载: