-

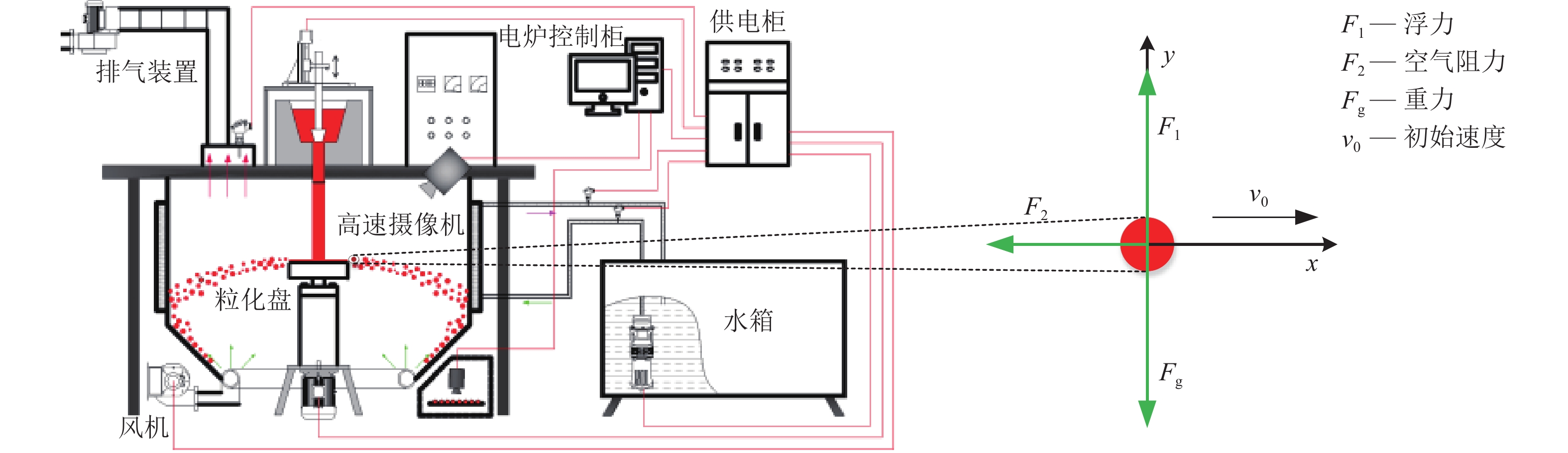

摘要: 对离心粒化后高温熔渣的飞行过程建立数学模型,通过Runge-Kutta方法对建立的数学模型进行离散求解。结果表明,熔渣液滴沿x方向飞行距离与液滴直径和初始速度成正比;由于空气绕流阻力和重力作用,熔渣液滴速度先降低后增加。对熔渣液滴撞壁后过剩反弹能进行分析,获得了熔渣液滴的临界撞击速度。结果表明,临界撞击速度为区间,存在上界和下界,且上界和下界同时随直径增加而降低。对初始速度为10、12和14 m·s‒1三种粒化工况进行实验,结果表明,由于熔渣液滴从粒化盘抛出时速度小于粒化盘边缘线速度,熔渣液滴实际下降距离大于其理论值;三种工况下熔渣液滴撞击速度在临界撞击速度区间内,均未产生粘结。Abstract: The mathematical model was established for the flight process of the molten blast furnace slag after the centrifugal graining, and the model was discretely solved by the Runge-Kutta method. The results show that, the flight distance of the slag droplets along the x direction is proportional to the diameter and the initial velocity of droplets. Due to the air flow resistance and gravity, the velocity of droplets decreases with time, and then increases slightly. Critical impact velocity of the droplets was proposed by analyzing the excess rebound energy of the slag droplets after collision with wall. The results indicate that, the critical impact velocity is an interval, and the larger the droplets, the lower the bounds. The experiments were performed with the initial droplet velocities of 10, 12, and 14 m·s‒1. The results indicate that, the actual falling distance of the slag droplets is greater than the theoretical values, because the initial velocity of the slag droplets is less than the linear velocity of the granulation plate. Meanwhile, the impact velocity of the slag droplets is between the upper and lower bound, thus no adhesion occurs.

-

Key words:

- blast furnace slag /

- flight dynamics /

- collision /

- mathematical model

-

表 1 熔渣化学成分(质量分数)

Table 1. Chemical composition of the blast slag

% SiO2 CaO Al2O3 MgO FeO MnO TiO2 S 其他 33.92 40.15 14.50 8.17 0.33 0.30 0.50 1.03 1.10 表 2 熔渣液滴直径与临界撞击速度关系

Table 2. Relationship between the slag droplet diameter and the critical impact velocity

d / mm v* / (m·s‒1) 0.5 0.45~227.32 1.5 0.33~75.75 2.5 0.27~45.44 3.5 0.24~32.45 4.5 0.22~25.23 表 3 实验工况

Table 3. Experimental condition

序号 Dm / m D / m N / (r·min‒1) v0 / (m·s‒1) 1 2 0.25 764 10 2 2 0.25 917 12 3 2 0.25 1069 14 -

[1] Wu J J, Wang H, Zhu X, et al. Centrifugal granulation performance of liquid with various viscosities for heat recovery of blast furnace slag. Appl Therm Eng, 2015, 89: 494 doi: 10.1016/j.applthermaleng.2015.06.031 [2] Worldsteel Association. Steel statistical yearbook [J/OL]. Worldsteel Association [2020-1]. Steel-Statistical-Yearbook-2019-concise-version. pdf (worldsteel. org) [3] Purwanto H, Akiyama T. Hydrogen production from biogas using hot slag. Int J Hydrogen Energy, 2006, 31(4): 491 doi: 10.1016/j.ijhydene.2005.04.021 [4] Li P, Yu Q B, Qin Q, et al. Kinetics of CO2/coal gasification in molten blast furnace slag. Ind Eng Chem Res, 2012, 51(49): 15872 doi: 10.1021/ie301678s [5] Pickering S J, Hay N, Roylance T F, et al. New process for dry granulation and heat recovery from molten blast-furnace slag. Ironmaking Steelmaking, 1985, 12(1): 14 [6] Kashiwaya Y, In-nami Y, Akiyama T. Mechanism of the formation of slag particles by the rotary cylinder atomization. ISIJ Int, 2010, 50(9): 1252 doi: 10.2355/isijinternational.50.1252 [7] Akiyama T, Toshio M, Jun-Ichiro Y, et al. Feasibility study of hydrogen generator with molten slag granulation. Steel Res Int, 2004, 75(2): 122 doi: 10.1002/srin.200405937 [8] Xie D, Washington B M, Norgate T, et al. Dry granulation of slags–turning waste into valuable products. CAMP-ISIJ, 2005, 18(4): 1088 [9] Xie D, Pan Y, Flann R, et al. Heat recovery from slag through dry granulation // 1st CSRP Annual Conference. Melbourne, 2007: 1 [10] Yu Q B, Liu J X, Dou C X, et al. Dry granulation experiment of blast furnace slag by rotary cup atomizer. J Northeast Univ Nat Sci, 2009, 30(8): 1163 doi: 10.3321/j.issn:1005-3026.2009.08.025于庆波, 刘军祥, 窦晨曦, 等. 转杯法高炉渣粒化实验研究. 东北大学学报(自然科学版), 2009, 30(8): 1163 doi: 10.3321/j.issn:1005-3026.2009.08.025 [11] Liu J X, Yu Q B, Li P, et al. Experimental study on dry-granulation of molten blast furnace slag. Iron Steel, 2010, 45(2): 95 doi: 10.13228/j.boyuan.issn0449-749x.2010.02.032刘军祥, 于庆波, 李朋, 等. 高炉渣干法粒化试验研究. 钢铁, 2010, 45(2): 95 doi: 10.13228/j.boyuan.issn0449-749x.2010.02.032 [12] Lin B, Wang H, Zhu X, et al. Crystallization properties of molten blast furnace slag at different cooling rates. Appl Therm Eng, 2016, 96: 432 doi: 10.1016/j.applthermaleng.2015.11.075 [13] Zhu X, Ding B, Wang H, et al. Phase evolution of blast furnace slags with variation in the binary basicity in a variable cooling process. Fuel, 2018, 219: 132 doi: 10.1016/j.fuel.2018.01.075 [14] Zhu X, Ding B, Wang H, et al. Numerical study on solidification behaviors of a molten slag droplet in the centrifugal granulation and heat recovery system. Appl Therm Eng, 2018, 130: 1033 doi: 10.1016/j.applthermaleng.2017.11.080 [15] Luo S Y, Fu J, Zhou Y M, et al. The production of hydrogen-rich gas by catalytic pyrolysis of biomass using waste heat from blast-furnace slag. Renew Energy, 2017, 101: 1030 doi: 10.1016/j.renene.2016.09.072 [16] Mi S, Xie K, Sun D, et al. Heat transfer and resistance characteristics between metallurgical slag particles and air. Chin J Nonferrous Met, 2015, 25(7): 1993 doi: 10.19476/j.ysxb.1004.0609.2015.07.032米沙, 谢锴, 孙岱, 等. 冶金渣颗粒与空气间的换热和阻力特性. 中国有色金属学报, 2015, 25(7): 1993 doi: 10.19476/j.ysxb.1004.0609.2015.07.032 [17] Wang C L. Investigation on the flying of powder particles Ⅰ Trajectories of flying powder particles in static atmosphere. Powder Metall Technol, 2008, 26(4): 243王崇琳. 粉末飞行之研究I粉末在静止气体场中的飞行轨迹. 粉末冶金技术, 2008, 26(4): 243 [18] Richter A, Nikrityuk P A. Drag forces and heat transfer coefficients for spherical, cuboidal and ellipsoidal particles in cross flow at sub-critical Reynolds numbers. Int J Heat Mass Trans, 2012, 55(4): 1343 doi: 10.1016/j.ijheatmasstransfer.2011.09.005 [19] Ni J J, Yu G S, Guo Q H, et al. Submodel for predicting slag deposition formation in slagging gasification systems. Energy Fuels, 2011, 25(3): 1004 doi: 10.1021/ef101696a [20] Liu J X, Yu Q B, Duan W J, et al. Experimental investigation on ligament formation for molten slag granulation. Appl Therm Eng, 2014, 73(1): 888 doi: 10.1016/j.applthermaleng.2014.08.042 [21] Sun Y Q, Shen H W, Wang H, et al. Experimental investigation and modeling of cooling processes of high temperature slags. Energy, 2014, 76: 761 doi: 10.1016/j.energy.2014.08.073 [22] Ding B, Wang H, Zhu X, et al. Crystallization behaviors of blast furnace (BF) slag in a phase-change cooling process. Energy Fuels, 2016, 30(4): 3331 doi: 10.1021/acs.energyfuels.5b03000 [23] Han C, Chen M, Zhang W D, et al. Viscosity model for iron blast furnace slags in SiO2–Al2O3–CaO–MgO system. Steel Res Int, 2015, 86(6): 678 doi: 10.1002/srin.201400340 [24] Wang L M, Yuan Y L, Shao Y M, et al. Chatter analysis about roll grinder of twenty-high rolling mill in grinding process with grinding wheel dynamic imbalance fault. Chin J Eng, 2015, 37(Suppl1): 78王利明, 袁意林, 邵毅敏, 等. 二十辊轧机轧辊磨床砂轮动不平衡对磨削颤振的影响. 工程科学学报, 2015, 37(suppl1): 78 [25] Dhirhi R, Prasad K, Shukla A, et al. Experimental study of rotating dry slag granulation unit: Operating regimes, particle size analysis and scale up. Appl Therm Eng, 2016, 107: 898 doi: 10.1016/j.applthermaleng.2016.07.049 [26] Wang L Y, Sun W Q, Li X L, et al. Flight dynamics and sensible heat recovery of granulated blast furnace slag. Open Fuels Energy Sci J, 2015, 8: 356 doi: 10.2174/1876973X01508010356 -

下载:

下载: