Preparation and properties of spherical Ti-35.8Al-18.4Nb alloy powders by VIGA-CC method

-

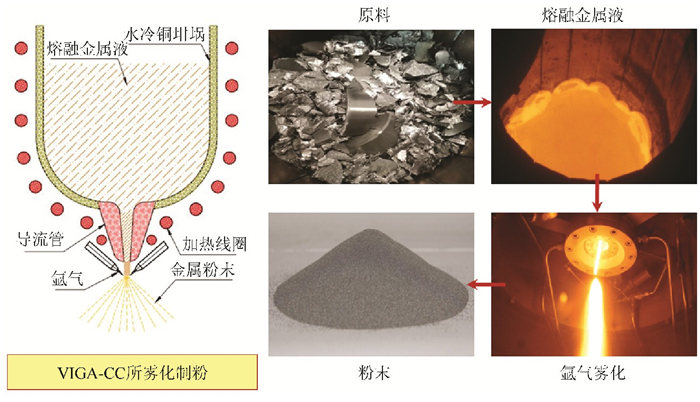

摘要: 以真空自耗电弧熔炼的Ti-35.8Al-18.4Nb(质量分数)合金铸锭为原料,采用水冷铜坩埚真空感应熔炼气雾化制粉技术(water-cooled copper crucible vacuum induction melting-gas atomizing,VIGA-CC)制备球形Ti-35.8Al-18.4Nb合金粉末,利用振动筛分法、扫描电子显微镜(scanning electron microscope,SEM)观察、X射线衍射(X-ray diffraction,XRD)分析等手段对所制备的粉末进行性能表征。结果表明,VIGA-CC技术制备的粉末粒度分布较宽,主要分布在45~150 μm之间,呈正态分布,其中粒径不高于45 μm粉末收得率为15.8%,粒径不低于150 μm粉末收得率为12%;粉末流动性为27.2[s·(50 g)-1],粉末中氧质量分数的增量小于0.01×10-6,粉末整体氧质量分数小于0.06×10-6;TiAlNb合金粉末主要以γ(TiAl)相和α2(Ti3Al)相为主,随着粉末粒径的减小,冷却速率逐渐提高,γ(TiAl)相逐渐减少,α2(Ti3Al)相逐渐增加;大颗粒粉末表面为枝状冷凝组织,小颗粒粉末为光滑表面。Abstract: Spherical Ti-35.8Al-18.4Nb (mass fraction) alloy powders were prepared by the water-cooled copper crucible vacuum induction melting-gas atomizing (VIGA-CC) technology, using the TiAlNb alloy ingots prepared by vacuum consumable arc melting as the raw material. The properties of the TiAlNb alloy powders were characterized by vibration sieving, scanning electron microscope (SEM), and X-ray diffraction (XRD). In the results, the powder size distribution exhibits a normal state in the range of 45~150 μm. The powder yield with the particle size less than 45 μm is 15.8%, and that larger than 150 μm is 12%. The powder fluidity is 27.2 [s·(50 g)-1]. The oxygen increment by mass in the powders is less than 0.01×10-6, and the total oxygen content by mass in the powders is less than 0.06×10-6. The TiAlNb alloy powders are mainly composed of γ(TiAl) phase and α2(Ti3Al) phase. With the decrease of powder size, the cooling rate increases gradually, leading to the decrease of γ(TiAl) phase and the increase of α2(Ti3Al) phase. The powder surface with large size shows the dendritic structure, and that with small size is smooth.

-

Key words:

- vacuum induction melting-gas atomizing /

- powder preparation /

- microstructure /

- properties

-

图 3 不同粒度TiAlNb粉末的表面形貌:(a)180μm;(b)100μm;(c)44μm;(d)图 3(a)局部放大;(e)图 3(b)局部放大;(f)图 3(c)的局部放大

Figure 3. Surface images of the TiAlNb powders in the different particle sizes: (a) 180μm; (b) 100μm; (c) 44μm; (d) the amplification of Fig. 3(a); (e) the amplification of Fig. 3(b); (f) the amplification of Fig. 3(c)

图 4 不同粒度TiAlNb粉末的截面形貌:(a)180μm;(b)100μm;(c)44μm;(d)图 3(a)局部放大;(e)图 3(b)局部放大;(f)图 3(c)的局部放大

Figure 4. Cross-sectional images of the TiAlNb powder in the different particle sizes: (a) 180 μm; (b) 100 μm; (c) 44 μm; (d) the amplification of Fig. 3(a); (e) the amplification of Fig. 3(b); (f) theamplification of Fig. 3(c)

表 1 VIGA-CC和PREP工艺所制TiAlNb粉末性能

Table 1. Performance of the TiAlNb powders prepared by VIGA-CC and PREP

制粉技术 松装密度/(g·cm-3) 振实密度/(g·cm-3) 流动性/[s·(50 g)-1] 球形度/% VIGA-CC 2.54 2.90 27.4 91 prep[7] 2.57 2.61 33.0 92 表 2 VIGA-CC制备TiAlNb粉末的化学成分(质量分数)

Table 2. Chemical composition of the TiAlNb powdersprepared by VIGA-CC

% C N O(粗粉)O(细粉) Al Nb Ti 0.051 0.130 0.040 0.068 35.800 18.400 余量 -

[1] Zou G S, Bai H L, Xie E H, et al. Solid diffusion bonding of Ti-22Al-25Nb O phase alloy. Chin J Nonferrous Met, 2018, 18(4): 577 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ200804001.htm邹贵生, 白海林, 谢二虎, 等. O相合金Ti-22Al-25Nb固态扩散连接. 中国有色金属学报, 2018, 18(4): 577 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ200804001.htm [2] Yang X, Xi Z P, Liu Y, et al. Characterization of TiAl powders prepared by plasma rotating electrode processing. Rare Met Mater Eng, 2010, 39(12): 2251 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201012040.htm杨鑫, 奚正平, 刘咏, 等. 等离子旋转电极法制备钛铝粉末性能表征. 稀有金属材料与工程, 2010, 39(12): 2251 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201012040.htm [3] Zhang J W, Li S Q, Liang X B, et al. Research and application of Ti3Al and Ti2AlNb based alloys. Chin J Nonferrous Met, 2010, 20(Suppl 1): 336 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ2010S1075.htm张建伟, 李世琼, 梁晓波, 等. Ti3Al和Ti2AlNb基合金的研究与应用. 中国有色金属学报, 2010, 20(增刊1): 336 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ2010S1075.htm [4] Zhang G Q, Liu Y F, Liu N, et al. Progress in powder metallurgy TiAl-based intermetallics. Aeronaut Manuf Technol, 2019, 62(22): 38 https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201922022.htm张国庆, 刘玉峰, 刘娜, 等. TiAl金属间化合物粉末冶金工艺研究进展. 航空制造技术, 2019, 62(22): 38 https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201922022.htm [5] Sun S J. TiAl alloy parts produced by additive manufacturing method will be used in turbine blade of aircraft engine, Powder Metall Ind, 2015, 25(1): 65 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201501028.htm孙世杰. 增材制造方法生产的TiAl合金零件将被应用于飞机发动机涡轮叶片. 粉末冶金工业, 2015, 25(1): 65 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201501028.htm [6] Mao W, Li X, Han F, et al. Research progress of powder metallurgy technology of high quality TiAl-Nb based alloys. Hot Working Technol, 2019, 48(8): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201908002.htm毛旺, 李轩, 韩枫, 等. 高品质TiAl-Nb基合金的粉末冶金技术研究进展. 热加工工艺, 2019, 48(8): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201908002.htm [7] He W W, Tang H P, Liu Y, et al. Preparation of high-temperature TiAI pre-alloyed powder by PREP and its densification microstructure research. Rare Met Mater Eng, 2014, 43(11): 2768 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201411042.htm贺卫卫, 汤慧萍, 刘咏, 等. PREP法制备高温TiAl预合金粉末及其致密化坯体组织研究. 稀有金属材料与工程, 2014, 43(11): 2768 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201411042.htm [8] He W W, Tang H P, Chen B K, et al. Study on process and particle size prediction on high-Nb TiAl powder produced by PREP. Titanium Ind Prog, 2019, 36(3): 26 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ201903011.htm贺卫卫, 汤慧萍, 陈斌科, 等. PREP法制备高铌TiAl粉末工艺研究及粒度预测. 钛工业进展, 2019, 36(3): 26 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ201903011.htm [9] Du Y L, Ou Y Y, Lu X X, et al. Research progress on additive manufacturing of TiAl intermetallic compound. J Xuzhou Inst Technol Nat Sci, 2016, 31(2): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-OXZG201602001.htm杜宇雷, 欧园园, 卢晓阳, 等. TiAl金属间化合物的增材制造研究进展. 徐州工程学院学报(自然科学版), 2016, 31(2): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-OXZG201602001.htm [10] Xue C. Research on the Microstructure Evolution and Mechanical Property of the Isothermally Forged Ti-22Al-25Nb Alloys[Dissertation]. Xi'an: Northwest Ploytechnic University, 2014薛晨. 等温锻造Ti-22Al-25Nb合金的显微组织演变与力学性能研究[学位论文]. 西安: 西北工业大学, 2014 [11] Zhang Z X. Research on Microstructures and Mechanical Properties of Ti-22.5Al-xNb Alloys[Dissertation]. Harbin: Harbin Institute of Technology, 2011张振兴. Ti-22.5Al-xNb合金组织与性能研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2011 [12] Zan X. Dynamic Mechanical Behavior of TiAl Intermetallic Compound at High Temperature[Dissertation]. Hefei: University of Science and Technology of China, 2008昝祥. TiAl金属间化合物高温动态力学行为[学位论文]. 合肥: 中国科学技术大学, 2008 [13] Tourret D, Reinhart G, Gandin Ch A, et al. Gas atomization of Al-Ni powders: Solidification modeling and neutron diffraction analysis. Acta Mater, 2011, 59(17): 6658 doi: 10.1016/j.actamat.2011.07.023 [14] Sun Y Q. Surface relief and the displacive transformation to the lamellar microstructure in TiAl. Philos Mag Lett, 1998, 78(4): 297 doi: 10.1080/095008398177878 [15] Jones S A, Kaufmann M J. Phase equilibria and transformations in intermediate titanium aluminum alloys. Acta Metall Mater, 1993, 41(2): 387 doi: 10.1016/0956-7151(93)90069-5 -

下载:

下载: