Microstructure and mechanical properties of WC-based cemented carbides with different binder phases

-

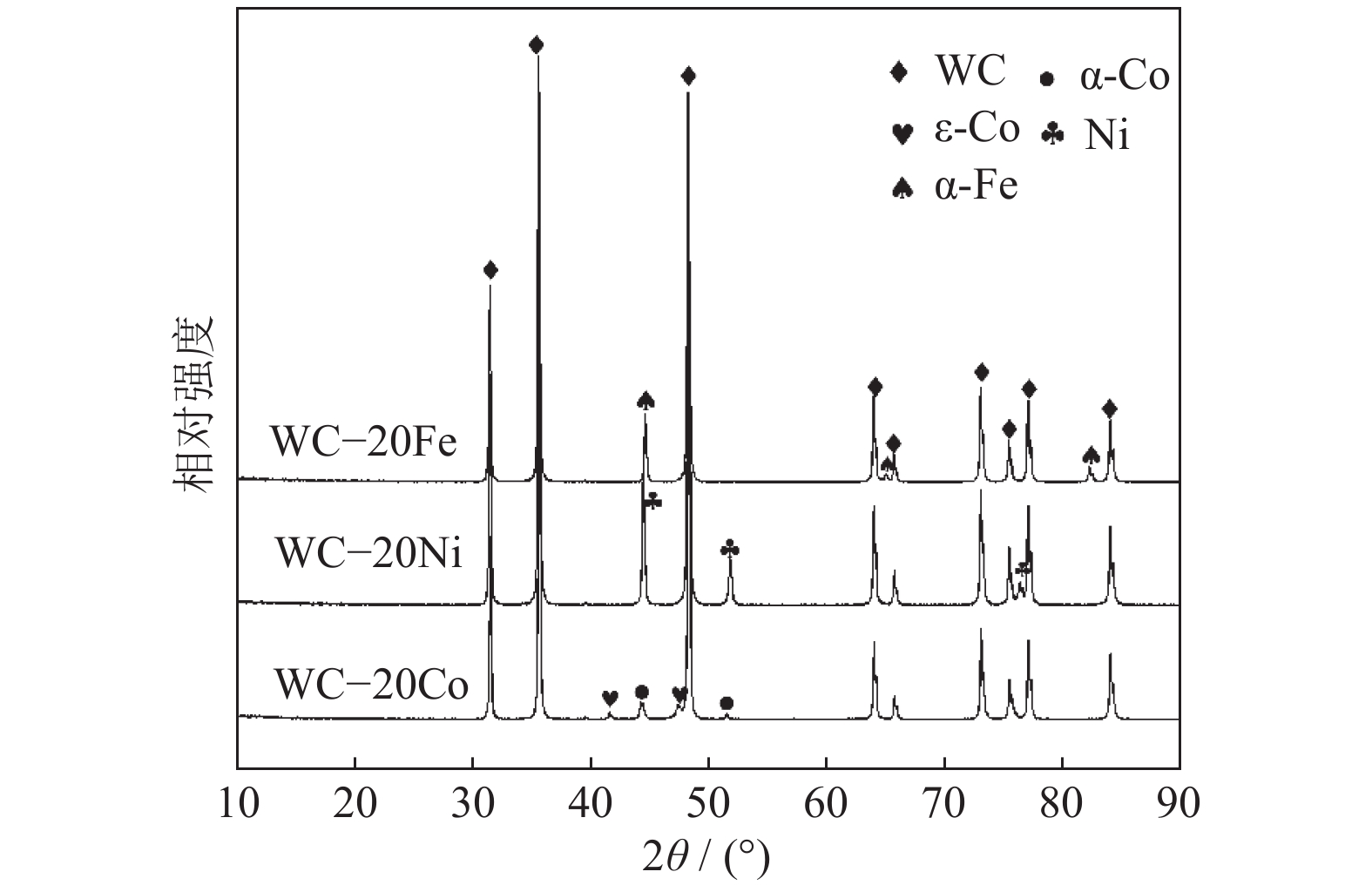

摘要: 以碳质量分数为理论含碳量的WC为硬质相,在1450 ℃下通过气压烧结制备WC‒20Fe,WC‒20Ni和WC‒20Co硬质合金,通过X射线衍射、扫描电子显微镜、电子探针和力学性能测试研究了不同金属粘结相对烧结硬质合金微观结构和力学性能的影响。结果表明:WC‒20Fe合金出现η脱碳相(Fe3W3C),W在粘结相Fe中的溶解度仅有1.915%(质量分数),WC晶粒尺寸最小。WC‒20Ni合金渗碳出现石墨相(C),W在粘结相Ni中的溶解度达到10.753%(质量分数),WC晶粒尺寸最大,合金硬度最小。WC‒20Co合金为正常两相区组织(WC+γ),具有最高抗弯强度2720 MPa和最大硬度934.41 kg∙mm‒2。所有合金断裂模式均为脆性断裂和沿晶断裂,WC‒20Co合金断口出现明显的粘结相撕裂。Abstract: The WC‒20Fe, WC‒20Ni, and WC‒20Co cemented carbides were prepared by gas pressure sintering at 1450 ℃ using the WC powders with the theoretical carbon content (mass fraction). The effects of metal binders on the microstructure and mechanical properties of the cemented carbides were investigated by X-ray diffractometer (XRD), scanning electron microscope (SEM), electron probe microanalysis (EPMA), and mechanical properties tester. The results show that, the brittle η-phase (Fe3W3C) appears in the WC‒20Fe alloys, and finer grains are observed due to the lower solubility of W (1.915% by mass) in Fe binder. However, the graphite phase (C) is detected in the WC‒20Co alloys, the solubility of W in Ni binder can reach to 10.753% by mass, resulting in the largest grain size and the lowest hardness. The WC‒20Co alloys show the two-phase region (WC+γ), which exhibit the highest bending strength and hardness of 2720 MPa and 934.41 kg∙mm‒2, respectively. The fracture mode of all the alloys can be described as the brittle fracture and intergranular fracture. Moreover, the fracture surface of the WC‒20Co alloys shows the obvious binder tearing character.

-

Key words:

- cemented carbides /

- binder /

- microstructure /

- properties

-

表 1 硬质合金晶粒尺寸和钨在粘结相中的溶解度

Table 1. Grain size of the cemented carbides and the solubility of W in the binder phases

试样 钨在粘结剂中的溶解度

(质量分数) / %WC平均晶粒

尺寸 / μmWC‒20Fe 1.915±0.294 1.29 WC‒20Ni 10.753±0.428 7.07 WC‒20Co 4.583±0.239 2.93 表 2 烧结合金物理性能

Table 2. Physical properties of the sintered alloys

试样 相对密度 /

%维氏硬度,

HV10 / (kg∙mm‒2)抗弯强度 /

MPaWC‒20Fe 97.36 886.58 1850 WC‒20Ni 99.23 650.24 1630 WC‒20Co 99.67 934.41 2720 -

[1] Sun J, Zhao J, Gong F, et al. Development and application of WC-based alloys bonded with alternative binder phase. Crit Rev Solid State, 2019, 44(3): 211 doi: 10.1080/10408436.2018.1483320 [2] Santos R F, Ferro Rocha A M, Bastos A C, et al. Microstructural characterization and corrosion resistance of WC‒Ni‒Cr‒Mo composite—The effect of Mo. Int J Refract Met Hard Mater, 2020, 86: 105090 doi: 10.1016/j.ijrmhm.2019.105090 [3] Ortner H M, Ettmayer P, Kolaska H. The history of the technological progress of hardmetals. Int J Refract Met Hard Mater, 2014, 44: 148 doi: 10.1016/j.ijrmhm.2013.07.014 [4] Pan Y F, Liu A J, Huang L. Effects of metal binder content and carbide grain size on the microstructure and properties of SPS manufactured WC‒Fe composites. J Alloys Compd, 2019, 784: 519 doi: 10.1016/j.jallcom.2019.01.057 [5] Guo Z X, Xiong J, Yang M, et al. Characterization and properties of MTCVD Ti(C, N) coated cemented carbide substrates with Fe/Ni binder. Int J Refract Met Hard Mater, 2010, 28(2): 238 doi: 10.1016/j.ijrmhm.2009.10.004 [6] Wan X H, Li W P, Su H. The study of a cemented carbide WC‒6Ni with high-strength and high hardness. Powder Metall Technol, 2015, 33(5): 323 doi: 10.3969/j.issn.1001-3784.2015.05.001万小虎, 李文鹏, 苏华. 一种高强度、高硬度WC‒6Ni硬质合金的研究. 粉末冶金技术, 2015, 33(5): 323 doi: 10.3969/j.issn.1001-3784.2015.05.001 [7] Yang J G, Tan D Q, Chen H. Cemented Carbide. Changsha: Central South University Press, 2012羊建高, 谭敦强, 陈颢. 硬质合金. 长沙: 中南大学出版社, 2012 [8] Shon I J, Jeong I K, Ko I Y, et al. Sintering behavior and mechanical properties of WC‒10Co, WC‒10Ni and WC‒10Fe hard materials produced by high-frequency induction heated sintering. Ceram Int, 2009, 35(1): 339 doi: 10.1016/j.ceramint.2007.11.003 [9] Gu L, Huang J, Xie C. Effects of carbon content on microstructure and properties of WC‒20Co cemented carbides. Int J Refract Met Hard Mater, 2014, 42: 228 doi: 10.1016/j.ijrmhm.2013.09.010 [10] Trung T B, Zuhailawati H, Ahmad Z A, et al. Sintering characteristics and properties of WC-10AISI304 (stainless steel) hardmetals with added graphite. Mater Sci Eng A, 2014, 605: 210 doi: 10.1016/j.msea.2014.03.053 [11] Borgh I, Hedström P, Borgenstam A, et al. Effect of carbon activity and powder particle size on WC grain coarsening during sintering of cemented carbides. Int J Refract Met Hard Mater, 2014, 42: 30 doi: 10.1016/j.ijrmhm.2013.10.004 [12] Borgh I, Hedström P, Persson T, et al. Microstructure, grain size distribution and grain shape in WC–Co alloys sintered at different carbon activities. Int J Refract Met Hard Mater, 2014, 43: 205 doi: 10.1016/j.ijrmhm.2013.12.007 [13] Bounhoure V, Lay S, Charlot F, et al. Effect of C content on the microstructure evolution during early solid state sintering of WC‒Co alloys. Int J Refract Met Hard Mater, 2014, 44: 27 doi: 10.1016/j.ijrmhm.2013.12.012 [14] Konyashin I, Hlawatschek S, Ries B, et al. On the mechanism of WC coarsening in WC‒Co hardmetals with various carbon contents. Int J Refract Met Hard Mater, 2009, 27(2): 234 doi: 10.1016/j.ijrmhm.2008.09.001 [15] Kim S, Han S H, Park J K, et al. Variation of WC grain shape with carbon content in the WC‒Co alloys during liquid-phase sintering. Scr Mater, 2003, 48(5): 635 doi: 10.1016/S1359-6462(02)00464-5 [16] Uhrenius B, Pastor H, Pauty E. On the composition of Fe‒Ni‒Co‒WC-based cemented carbides. Int J Refract Met Hard Mater, 1997, 15(1-3): 139 doi: 10.1016/S0263-4368(96)00023-6 [17] Fernandes C M, Senos A M R. Cemented carbide phase diagrams: A review. Int J Refract Met Hard Mater, 2011, 29(4): 405 doi: 10.1016/j.ijrmhm.2011.02.004 [18] Wittmann B, Schubert W D, Lux B. WC grain growth and grain growth inhibition in nickel and iron binder hardmetals. Int J Refract Met Hard Mater, 2002, 20(1): 51 doi: 10.1016/S0263-4368(01)00070-1 [19] Guo Y, Li Z Y, Li Y. Preparation of η phase powder and the effect of sintering process on the plate-like WC grain. Powder Metall Technol, 2017, 35(1): 39 doi: 10.3969/j.issn.1001-3784.2017.01.007郭瑜, 李志友, 李烨. η相粉末的制备及烧结工艺对板状WC晶粒的影响. 粉末冶金技术, 2017, 35(1): 39 doi: 10.3969/j.issn.1001-3784.2017.01.007 -

下载:

下载: