| [1] |

Tang H P. Metal Materials for 3D Printing. Beijing: Chemical Industry Press, 2020汤慧萍. 3D打印金属材料. 北京: 化学工业出版社, 2020

|

| [2] |

U. S. Department of Energy. The quadrennial technology review [J/OL]. U. S. Department of Energy (2015-12-13)[2020-05-19].https://www.energy.gov/quadrennial-technology-review-0

|

| [3] |

Royal Academy of Engineering. Additive manufacturing: opportunities and constraints [J/OL]. Royal Academy of Engineering (2017-05-23)[2020-05-19].https://www.raeng.org.uk/policy/policy-themes/engineering-in-society

|

| [4] |

Olakanmi E O. Effect of mixing time on the bed density, and microstructure of selective laser sintered aluminium powders. Mater Res, 2012, 15(2): 167 doi: 10.1590/S1516-14392012005000031

|

| [5] |

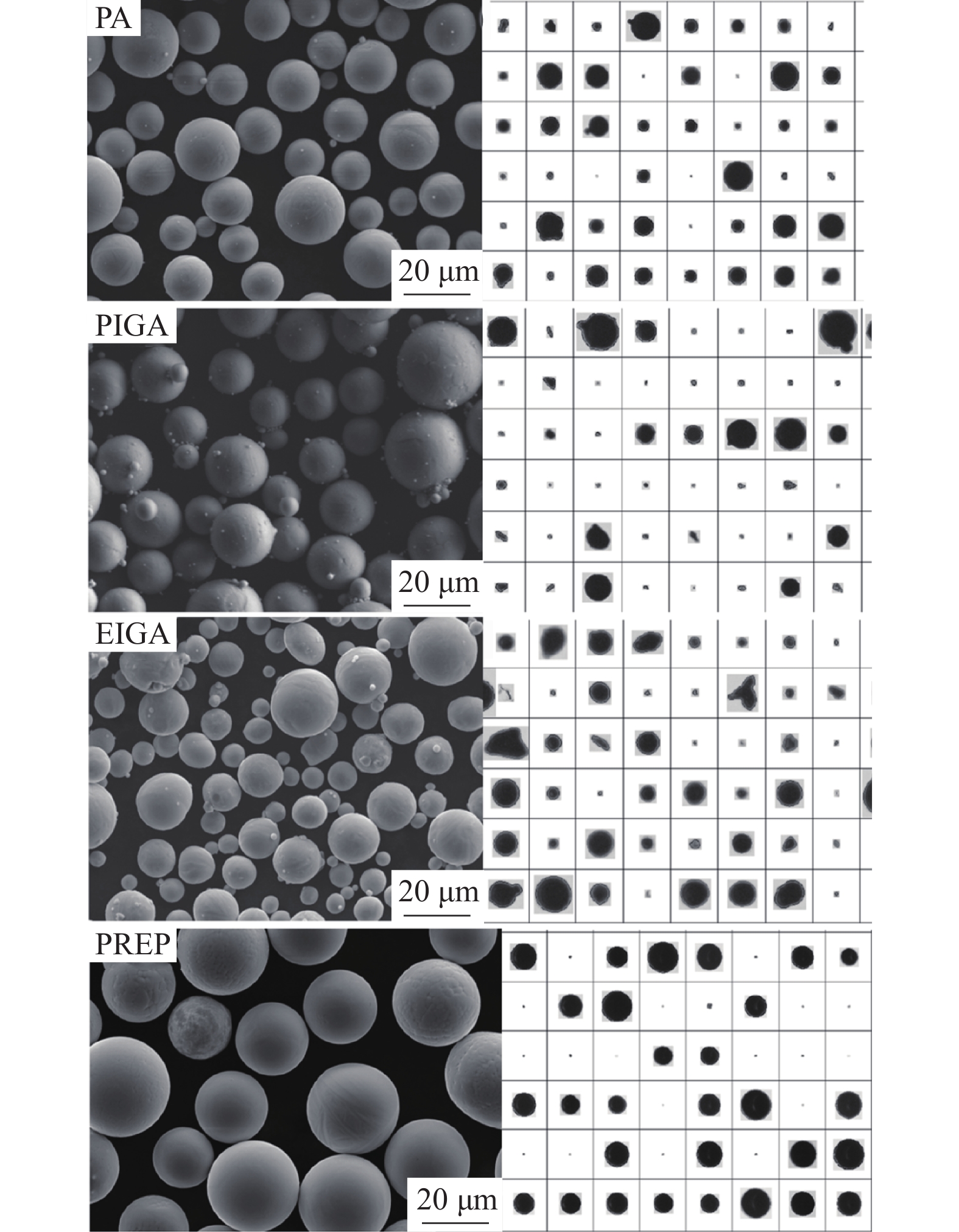

Zou L M, Mao X H, Hu K, et al. Quantitative analysis for the shape indicator of spherical Ti‒6Al‒4V powder by image analysis method. Rare Met Mater Eng, 2020, 49(3): 950邹黎明, 毛新华, 胡可, 等. 采用图像分析技术对球形Ti‒6Al‒4V粉末粒形的定量分析. 稀有金属材料与工程, 2020, 49(3): 950

|

| [6] |

Li R, Shi Y, Wang Z, et al. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl Surf Sci, 2010, 256(13): 4350 doi: 10.1016/j.apsusc.2010.02.030

|

| [7] |

Irrinki H, Dexter M, Barmore B, et al, Effects of powder attributes and laser powder bed fusion (L-PBF) process conditions on the densification and mechanical properties of 17-4 PH stainless steel. JOM, 2016, 68: 860

|

| [8] |

Ahsan M N, Pinkerton A J, Moat R J, et al. A comparative study of laser direct metal deposition characteristics using gas and plasma-atomized Ti–6Al–4V powders. Mater Sci Eng A, 2011, 528(25-26): 7648 doi: 10.1016/j.msea.2011.06.074

|

| [9] |

Strondl A, Lyckfeldt O, Brodin H, et al. Characterization and control of powder properties for additive manufacturing. JOM, 2015, 67(3): 549 doi: 10.1007/s11837-015-1304-0

|

| [10] |

Sun Y Y, Gulizia S, Oh C H, et al. Manipulation and characterization of a novel titanium powder precursor for additive manufacturing applications. JOM, 2015, 67(3): 564 doi: 10.1007/s11837-015-1301-3

|

| [11] |

Nguyen Q B, Nai M L S, Zhu Z, et al. Characteristics of inconel powders for powder-bed additive manufacturing. Engineering, 2017, 3(5): 695 doi: 10.1016/J.ENG.2017.05.012

|

| [12] |

Attar H, Prashanth K G, Zhang L C, et al. Effect of powder particle shape on the properties of in situ Ti–TiB2composite materials produced by selective laser melting. J Mater Sci Technol, 2015, 31(10): 1001 doi: 10.1016/j.jmst.2015.08.007

|

| [13] |

Tapia G, Elwany A H, Sang H. Prediction of porosity in metal-based additive manufacturing using spatial Gaussian process models. Addit Manuf, 2016, 12: 282

|

| [14] |

Liu B C, Wildman R, Tuck C, et al. Investigation the effect of particle size distribution on processing parameters optimisation in selective laser melting process // Proceedings of Solid Freeform Fabrication. Austin, 2011: 227

|

| [15] |

Gu H F, Gong H J, Dilipet J J S, et al. Effects of powder variation on the microstructure and tensile strength of Ti6Al4V parts fabricated by selective laser melting // Proceedings of Solid Freeform Fabrication. Austin, 2014: 470

|

| [16] |

Khairallah S A, Anderson A T, Rubenchik A, et al. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater, 2016, 108: 36 doi: 10.1016/j.actamat.2016.02.014

|

| [17] |

Lee Y S, Zhang W. Mesoscopic simulation of heat transfer and fluid flow in laser powder bed additive manufacturing // Proceedings of Solid Freeform Fabrication. Austin, 2015, 1154

|

| [18] |

Spierings A B, Levy G. Comparison of density of stainless steel 316L parts produced with selective laser melting using different powder grades // Proceedings of Solid Freeform Fabrication. Austin, 2015, 342

|

| [19] |

Averyanova M, Bertrand P, Verquin B. Effect of initial powder properties on final microstructure and mechanical properties of parts manufactured by selective laser melting // Proceedings of the 21st International DAAAM Symposium. Vienna, 2010: 15312

|

| [20] |

Olakanmi E O, Cochrane R F, Dalgarno K W. Spheroidisation and oxide disruption phenomena in direct selective laser melting (SLM) of pre-alloyed Al‒Mg and Al‒Si powders // TMS 2009-138th Annual Meeting and Exhibition. San Francisco, 2009: 371

|

| [21] |

Li K F, Mao X H, Khanlari K, et al. Effects of powder size distribution on the microstructural and mechanical properties of a Co‒Cr‒W‒Si alloy fabricated by selective laser melting. J Alloys Compd, 2020, 825: 153973 doi: 10.1016/j.jallcom.2020.153973

|

| [22] |

Spierings A B, Herres N, Levy G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp J, 2011, 17(3): 195 doi: 10.1108/13552541111124770

|

| [23] |

Spierings A B, Voegtlin M, Bauer T, et al. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog Addit Manuf, 2016, 1(1-2): 9 doi: 10.1007/s40964-015-0001-4

|

| [24] |

Hausner H H. Friction condition in a mass of metal powder. Int J Powder Metall, 1967, 3(4): 7

|

| [25] |

Wong A C Y. Characterisation of the flowability of glass beads by bulk densities ratio. Chem Eng Sci, 2000, 55(18): 3855 doi: 10.1016/S0009-2509(00)00048-8

|

| [26] |

Dave W, Ethan P. Moisture analysis in metal powders using Karl Fischer Titration with oven desorption [J/OL]. NSL Analytical (2021-11-12)[2022-07-06].https://www.nslanalytical.com/wp-content/uploads/2021/11/IMAT-2021-Karl-Fischer-Moisture-Presentation.pdf

|

| [27] |

Vluttert N. The Absorption of Moisture by Metal Powder in a Humid Environment and the Effects on its Composition [Dissertation]. Enschede: University of Twente, 2016

|

| [28] |

Starr T, Rafi K, Stucker B, et al. Controlling phase composition in selective laser melted stainless steels // Proceedings of Solid Freeform Fabrication. Austin, 2012: 439

|

| [29] |

Simchi A. The role of particle size on the laser sintering of iron powder. Metall Mater Trans B, 2004, 35(5): 937 doi: 10.1007/s11663-004-0088-3

|

| [30] |

Tang H P, Qian M, Liu N, et al. Effect of powder reuse times on additive manufacturing of Ti‒6Al‒4V by selective electron beam melting. JOM, 2015, 67(3): 555 doi: 10.1007/s11837-015-1300-4

|

| [31] |

Yan M, Xu W, Dargusch M S, et al. Review of effect of oxygen on room temperature ductility of titanium and titanium alloys. Powder Metall, 2014, 57: 251 doi: 10.1179/1743290114Y.0000000108

|

| [32] |

Kruth J P, Froyen L, Vaerenbergh J V, et al. Selective laser melting of iron-based powder. J Mater Process Technol, 2004, 149(1-3): 616 doi: 10.1016/j.jmatprotec.2003.11.051

|

| [33] |

Otto A, Schmidt M. Towards a universal numerical simulation model for laser material processing. Physics Procedia, 2010, 5: 35 doi: 10.1016/j.phpro.2010.08.120

|

| [34] |

Boley C D, Khairallah S A, Rubenchik A M. Calculation of laser absorption by metal powders in additive manufacturing. Appl Opt, 2015, 54(9): 2477 doi: 10.1364/AO.54.002477

|

| [35] |

Gusarov A V, Laoui T, Froyen L, et al. Contact thermal conductivity of a powder bed in selective laser sintering. Int J Heat Mass Transfer, 2003, 46(6): 1103 doi: 10.1016/S0017-9310(02)00370-8

|

| [36] |

Leung C L A, Marussi S, Atwood R C, et al. In situ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. Nat Commun, 2018, 9(1): 1355 doi: 10.1038/s41467-018-03734-7

|

下载:

下载: