Microstructure and mechanical properties of powder metallurgy sinter hardening steels with low Cr content

-

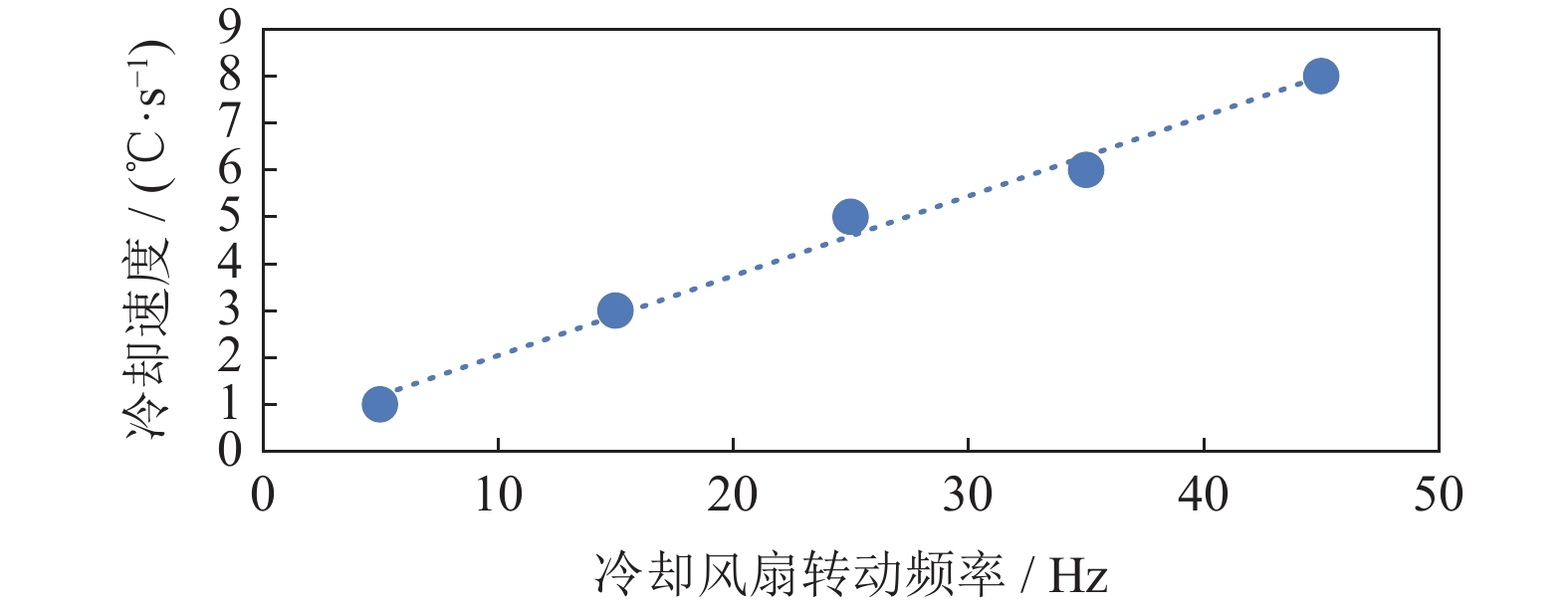

摘要: 烧结硬化作为一种经济有效的高强度粉末冶金零件生产工艺,可以通过控制烧结后冷却速度影响显微组织(马氏体含量),从而改善材料的最终性能。本文介绍了一种新开发的低Cr预合金烧结硬化材料AstaloyTM CrA,研究其在不同烧结温度和冷却速度下的力学性能和显微组织,并与常见的粉末冶金烧结硬化钢Distaloy® DH进行对比。研究表明,在压制密度为7.0 g·cm−3并添加同等含量碳的条件下,添加质量分数2%Ni的AstaloyTM CrA混粉淬透性更高,获得比其他两种材料更高的马氏体含量及表观硬度。AstaloyTM CrA在1250 ℃烧结、冷却速度为3 ℃·s−1时,硬度最高达到HRC 38;在1250 ℃烧结,冷却速度为1 ℃·s−1时,强度和韧性最佳。Abstract: Sinter hardening is an established cost-effective process to produce high strength powder metallurgy parts by controlling the cooling speed to affect the sintered microstructure (martensite content) to improve the final performance. A newly developed pre-alloy sinter hardening steels with low Cr content (AstaloyTM CrA) was introduced in this paper, the mechanical properties and microstructure under the different sintering temperature and cooling rate were investigated, and the common powder metallurgy sinter hardening material (Distaloy® DH) was referenced for the comparison. In the results, under the pressing density of 7.0 g·cm−3 at the same carbon level, the AstaloyTM CrA added with 2% nickel (mass fraction) has the highest hardenability which can obtain the highest martensite content and the macro hardness compared to the other materials. AstaloyTM CrA sintered at 1250 ℃ and followed with the cooling rate of 3 ℃·s−1 can achieve the hardness of HRC 38, which can obtain the optimum strength and toughness by sintered at the same temperature and followed with the lower cooling rate of 1 ℃·s−1.

-

Key words:

- powder metallurgy /

- sinter hardening /

- microstructure /

- mechanical properties

-

表 1 三种混粉的化学成分及粉末名称

Table 1. Chemical composition and name of the three mixture powders

混粉编号 粉末名称 成分(质量分数) / % Fe Cu Mo Ni Cr C 1 DH 余量 2** 1.5* — — 0.6 2 CrA2Ni 余量 — — 2 1.8* 0.6 3 CrA1Cu 余量 1 — — 1.8* 0.6 注:*预合金;**扩散粘结 表 2 不同烧结温度下样品烧结密度和碳氧含量

Table 2. Sintered density, carbon content, and oxygen content of specimens sintered at different temperatures

粉末名称 烧结密度 / (g·cm−3) 烧结后碳质量分数 / % 烧结后氧质量分数 / % 1120 ℃ 1250 ℃ 1120 ℃ 1250 ℃ 1120 ℃ 1250 ℃ DH 6.93 6.99 0.57 0.52 0.01 0.01 CrA2Ni 7.04 7.12 0.54 0.50 0.04 0.01 CrA1Cu 6.97 7.04 0.57 0.51 0.04 0.01 表 3 不同烧结温度和冷速下拉伸试棒的马氏体含量

Table 3. Martensite content of the tensile strength specimens at the different sintering temperatures and cooling rates

粉末名称 马氏体体积分数 / % 1120 ℃ 1250 ℃ 1 ℃·s−1 3 ℃·s−1 1 ℃·s−1 3 ℃·s−1 DH 20.0 80.0 12.5 75.0 CrA2Ni 41.5 77.5 32.0 87.0 CrA1Cu 22.5 64.0 27.5 62.5 -

[1] Akpan E, L' Esperance G, Roy L. Case histories with sinter hardening low alloy steel powder // Advances in Powder Metallurgy & Particulate Materials. Princeton, 1993: 289 [2] Höganäs A B. Internal Handbook for Sintered Component, Metallography. Sweden: Höganäs A B, 2015 [3] Engström U. Evaluation of sinter hardening of different PM materials // Advances in Powder Metallurgy & Particulate Materials. Princeton, 2000: 5 [4] Engström U. Cost effective material for sinter hardening applications // World Powder Metallurgy Meeting. Washington, 2008 [5] Günen M, Bakkaloğlu A. Influence of sinter-hardening on microstructures and mechanical properties of AstaloyTM Mo-based steels. Mater Lett, 2019, 251: 201 doi: 10.1016/j.matlet.2019.05.066 [6] Nyberg I, Schmidt M, Thorne P, et al. Effect of sintering time and cooling rate on sinterhardenable materials // Powder Metallurgy & AMP, Particulate Materials Meeting 2003. Las Vegas, 2003: part5 101 [7] Lindskog P. Controlling the hardenability of sintered steels. Powder Metall, 1970, 13(6): 280 [8] ASM International. ASM Handbook, Vol. 7: Powder Metal Technologies and Applications. Ohio: ASM International, 1998 [9] Maroli B, Berg S, Larsson M, et al. Performance of sinter-hardened P/M steels [J/OL]. ResearchGate GmbH [2020-06-22]. https://www.researchgate.net/publication/266289508 [10] Engström U. High performance materials for sinter hardening applications // World Powder Metallurgy Conference. Florence, 2010 [11] Larsson C, Engström U. High performance sinter hardening materials for synchronizing hubs // EURO Powder Metallurgy Conference. Barcelona, 2011 [12] Chasoglou D, High performance pm steels through sinter hardening // EURO Powder Metallurgy Conference. Milano, 2017 [13] Sheikhi M K, Solimanjad N. Effects of sinter hardening technology on homogeneous and heterogeneous microstructures. Powder Metall, 2013, 56(3): 245 doi: 10.1179/1743290112Y.0000000050 [14] Xin X, Han Y J, Cao H B. A competitive sinter-hardening solution for industrial manufacturing // APMA Conference. Xiamen, 2013 [15] Yang J, Wang J, Niu S, et al. Sinter-hardening PM steels with improved dimensional consistency for high performance components. Powder Metall Technol, 2015, 33(1): 22 doi: 10.19591/j.cnki.cn11-1974/tf.2015.01.006杨洁, 王军, 牛森, 等. 烧结硬化粉末冶金钢在高性能零件中的应用. 粉末冶金技术, 2015, 33(1): 22 doi: 10.19591/j.cnki.cn11-1974/tf.2015.01.006 [16] Herring D. Grain size and its influence on materials. Ind Heat, 2005, 72(8): 20 [17] Xu X, Han Y J, Niu S, et al. Sinter-hardening solutions for industrial manufacturing. Powder Metall Ind, 2016, 26(3): 78 doi: 10.13228/j.boyuan.issn1006-6543.20150053徐信, 韩云娟, 牛森, 等. 适用于工业制造的烧结硬化解决方案. 粉末冶金工业, 2016, 26(3): 78 doi: 10.13228/j.boyuan.issn1006-6543.20150053 [18] Cheng C H. Study on the parameters affecting the gear properties of sinter hardening. Powder Metall Technol, 2005, 23(3): 208 doi: 10.3321/j.issn:1001-3784.2005.03.011郑朝旭. 影响烧结硬化合金钢齿轮特性之参数探讨. 粉末冶金技术, 2005, 23(3): 208 doi: 10.3321/j.issn:1001-3784.2005.03.011 -

下载:

下载: